disperator 500A-GKF User manual

GLASS CHRUSHER

550A-GKF EXCELLENT SERIES

Product Descripon Installaon Safety Operaon Service

USER MANUAL

User Manual in Original

Dok. ref: 550A_GKF_am_en_230306

DISPERATOR AB Tel: 08-724 0160 E-mail: info@disperator.se

Mälarvägen 9, 141 71 Segeltorp Web page: www.disperator.se

User Manual in Original

Dok. ref: 550A_GKF_am_sv_230306

DISPERATOR AB Tel: 08-724 0160 E-mail: info@disperator.se

Mälarvägen 9, 141 71 Segeltorp Web page: www.disperator.se

User Manual in Original

Dok. ref: 550A_GKF_am_sv_230306

DISPERATOR AB Tel: 08-724 0160 E-mail: info@disperator.se

Mälarvägen 9, 141 71 Segeltorp Web page: www.disperator.se

Table of Content

1. Safety Precauons _______________________________________________________ 6

1.1. Safety Signs __________________________________________________________ 6

1.2. Personnel Qualicaons and Training______________________________________ 7

2. Company Prole _________________________________________________________ 8

3. Product Descripon and Technical Specicaon _______________________________ 8

3.1. Glass Crusher Model 550A-GKF __________________________________________ 8

3.2. Technical Specicaon _________________________________________________ 9

4. Storage and Displacement _________________________________________________ 10

4.1. Storage of the Machine_________________________________________________ 10

4.2. Displacement of the Machine____________________________________________ 10

5. Included in Delivery ______________________________________________________ 11

5.1. Documentaon _______________________________________________________ 11

5.2. Food Waste Disposer___________________________________________________ 11

6. Installaon Descripon for the Machine _____________________________________ 13

6.1. Assembly of the Machine _______________________________________________ 13

6.2. Electrical Connecon___________________________________________________ 13

6.1.1. Deployment of the Machine ___________________________________________ 13

6.2.1. Supply Voltage_____________________________________________________ 13

6.2.2. Mains Fuses _______________________________________________________ 13

6.2.3. Wall/Bulkhead Mounted Electrical Security Breaker _______________________ 13

6.2.4. Cable Dimension ___________________________________________________ 13

6.2.5. Cable Protecon ___________________________________________________ 13

6.2.6. Earth Wire ________________________________________________________ 13

6.2.7. Direcon of Rotaon for the Disposer __________________________________ 13

6.2.8. Check of the funcon of the Safety Interlock Switch _______________________ 14

6.3. Start Up and Final Tesng _______________________________________________ 14

6.3.1. Check before Start Up _______________________________________________ 14

6.3.2. Checks during Start-up ______________________________________________ 14

6.3.3. Final Measures ____________________________________________________ 14

7. Safety Instrucons _______________________________________________________ 15

8. Driinstrukoner ________________________________________________________ 16

8.1. Start and Stop ________________________________________________________ 16

8.2. Daily Cleaning ________________________________________________________ 16

8.3. Trouble Shoong _____________________________________________________ 17

8.3.1. The Machine Reduces Speed, Stops or does not Start ______________________ 17

8.3.2. The Machine does not Start and makes no Sound _________________________ 17

User Manual in Original

Dok. ref: 550A_GKF_am_sv_230306

DISPERATOR AB Tel: 08-724 0160 E-mail: info@disperator.se

Mälarvägen 9, 141 71 Segeltorp Web page: www.disperator.se

5 / 35

9. Service Instrucons ______________________________________________________ 18

9.1. Authorizaon_________________________________________________________ 18

9.2. Exploded Views and Spare Parts List for the Disposer _________________________ 18

9.3. Overhaul of the Machine _______________________________________________ 21

9.3.1. Funcon Checks of the Interlock Switch (3/28 och 6/1)_____________________ 21

9.3.2. Check of the Automac Funcon for Collecon of Glass Dust________________ 21

9.3.3. Other Checks ______________________________________________________ 21

9.4. Dismantling of the Machine _____________________________________________ 22

9.5. Assembly of the Machine _______________________________________________ 26

9.6. Intervals for Overhaul and Maintenance ___________________________________ 30

9.7. Spare Parts___________________________________________________________ 31

9.7.1. Service Packages ___________________________________________________ 31

9.7.2. Spare Parts and Accessories not included in Service Package ________________ 32

9.7.3. Idencaon Guide for 550A-GKF EXCELLENT-Series Spare Parts _____________ 33

User Manual in Original

Dok. ref: 550A_GKF_am_sv_230306

DISPERATOR AB Tel: 08-724 0160 E-mail: info@disperator.se

Mälarvägen 9, 141 71 Segeltorp Web page: www.disperator.se

6 / 35

This manual contains instrucons for installaon, operaon and maintenance of the food waste disposer

(below also called the machine). It is therefore essenal for the installer, union representaves and

users of the machine to read the manual thoroughly prior to installaon, commissioning, operaon and

overhaul & maintenance.

This manual must always be at hand where the machine is being used.

It is not only the general safety instrucons in this secon that need to be considered, but also the other

special safety instrucons given in this manual.

1. Safety Precautions

1.1. Safety Signs

The following safety signs are used in this manual and on the machine. Failure to comply with the safety

regulaons contained in this manual as well as on the machine may cause personal injury or damage the

machine.

Read this User Manual before use

Use protecve goggles

Use ear protecon

Warning for electric voltage

General personal danger

Warning for mechanically caused damage (rotang parts)

Warning plates located on or close to the machine must always be observed and kept legible.

User Manual in Original

Dok. ref: 550A_GKF_am_sv_230306

DISPERATOR AB Tel: 08-724 0160 E-mail: info@disperator.se

Mälarvägen 9, 141 71 Segeltorp Web page: www.disperator.se

7 / 35

6 / 35

1.2. Personnel Qualications and Training

All personnel managing the below tasks for the machine as described in this manual, must have the

necessary qualicaons to carry out this work. Areas of responsibility, scope of authority and sta

supervision must be carefully dened by the machine owner. If the personnel do not have the necessary

qualicaons for this, they must receive training and instrucons. Such training can be provided by the

manufacturer / supplier. Moreover, it is the responsibility of the machine owner to make sure that all

users read and understand the content of this User Manual.

Moving the Machine

Sta responsible for moving the machine must have knowledge about the handling of the liing gear

and stopping devices and have knowledge of applicable safety regulaons for these. If they lack this

knowledge, they must receive the required training.

Installaon

Personnel responsible for the installaon of the machine must have knowledge equivalent to educaon

in industrial mechanics/technician. The electric connecon must be performed by trained and cered

electrician.

Commissioning and Maintenance

Personnel responsible for commissioning, overhaul and maintenance of the machine must be familiar

with all funcons, and how to operate these funcons. Furthermore, they must know of all safety

precauons in this manual, and which in other respects also are valid where the machine is used.

Operaon

All persons who operate and maintain the machine must be aware of the risks that may occur with its use

and as described in this manual.

Service and Repair

Responsible personnel for service and repair of the machine must have knowledge equivalent to

educaon in industrial and design mechanics, and also know and understand the technical data of the

machine described in this manual. Assisng personnel for these jobs must be trained and performed

repair work must be checked by the machine owner.

User Manual in Original

Dok. ref: 550A_GKF_am_sv_230306

DISPERATOR AB Tel: 08-724 0160 E-mail: info@disperator.se

Mälarvägen 9, 141 71 Segeltorp Web page: www.disperator.se

8 / 35

3. Product Description and Technical Specication

3.1. Glass Crusher Model 550A-GKF

A Disperator glass crusher makes the work of handling empty boles, jars and other glass containers

easier by grinding them into small parcles of gravel size. Most kitchens, galleys and bars have problems

with the volume of glass containers, which also gets sharp if it breaks uncontrollably.

Collecng and transporng glass waste is me consuming due to the large volume. Floor space that could

be used beer is occupied by a mountain of empty boles. These problems diminish when a Disperator

glass crusher is used.

Model 550A-GKF is easy to install in a kitchen, galley or waste room. Alternavely, the glass crusher can

be installed on a lower oor near the waste collecon area, and fed with empty boles through a tube

from bar or kitchen on the oor above.

Disperator glass crusher 550A-GKF is designed to provide long service life in environments where

reliability and eciency are essenal.

2. Company Prole

Disperator’s business idea is to provide innovave and adapve equipment for kitchens on land as well

as galleys at sea, and for the food processing industry, which enables ecient collecon of communited

food leovers for anaerobic digeson or composng in subsequent stages, which is of benet to society.

With over 70 years of experience in the development and producon of such equipment, our devoon

to this has resulted in the unique operaonal reliability required for the extreme condions prevailing in

the marine industry. Furthermore, our innovaveness has provided commercial kitchens on land with an

alternave approach to handle food waste separaon at source, complying with modern demands and

being economically aordable.

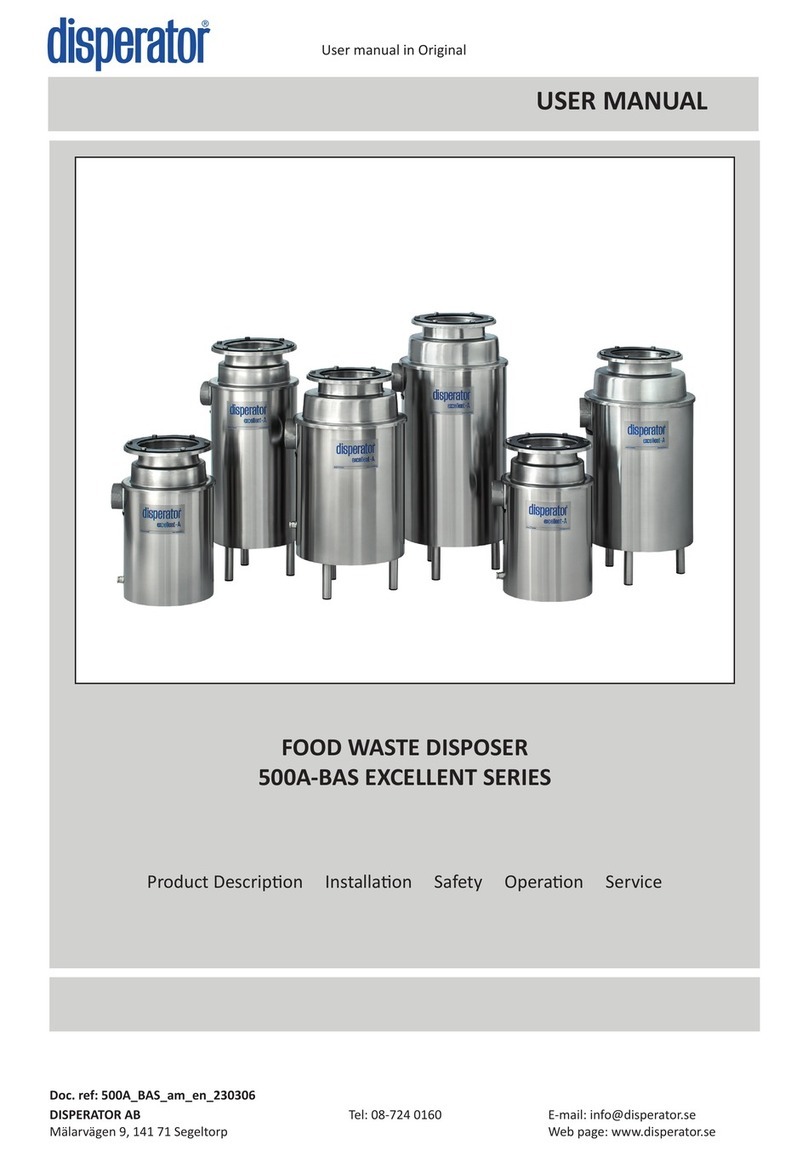

Our product assortment is unique! Disperator can as the only manufacturer of such equipment oer

all types of installaon possibilies needed in a kitchen. Our basic range of ve dierent series of

water-based food waste disposers, consisng of three to six dierent sizes in each serie, which may be

combined with as many as 13 dierent mounng assemblies. Furthermore, the advantage of the basic

model’s design is that the waste disposers may easily be integrated into other kitchen manufacturer’s

mounng assembly or furniture. Thereby, each workplace in a kithen or galley can be designed to its

specic requirements regarding funcon, ergonomics and economy. To all this there is also the dierent

series of water-saving processor technology for collecon and storage of grinded food waste in a tank, as

well as disposers that grinds food waste without any ushing water at all.

User Manual in Original

Dok. ref: 550A_GKF_am_sv_230306

DISPERATOR AB Tel: 08-724 0160 E-mail: info@disperator.se

Mälarvägen 9, 141 71 Segeltorp Web page: www.disperator.se

9 / 35

8 / 35

3.2. Technical Specication

616

82

1166

1318

848

365

365

145

455

295

89

35

1347

295

User Manual in Original

Dok. ref: 550A_GKF_am_sv_230306

DISPERATOR AB Tel: 08-724 0160 E-mail: info@disperator.se

Mälarvägen 9, 141 71 Segeltorp Web page: www.disperator.se

10 / 35

4. Storage and Displacement

4.1. Storage of the Machine

If the machine will be stocked before installaon and use the following applies:

• The machine should be stored in a dry and clean room where the relave humidity may not

exceed 60%.

• Recommended storage temperature of -20 °C to + 60 °C.

4.2. Displacement of the Machine

For land use the glass crusher is delivered with two wheels which are mounted at the back of the

boom plate. Upon delivery, the glass cross can be moved by gently liing its inlet feeding tube so

that the front of the machine is lied from the oor, whereupon the machine can be rolled to its nal

installaon site.

For marine installaon of the glass crusher, foot xtures or vibraon insulators are available (as

alternave to the wheels) to x the machine in the oorboard. Please see secon 3.2, Technical

Specicaon above. In this case, the machine should not be lied or moved by hand. During

installaon, we recommend using a pallet jack or forkli, and during service a liing trolley for

component parts (like the crusher placed inside the cabinet).

User Manual in Original

Dok. ref: 550A_GKF_am_sv_230306

DISPERATOR AB Tel: 08-724 0160 E-mail: info@disperator.se

Mälarvägen 9, 141 71 Segeltorp Web page: www.disperator.se

11 / 35

10 / 35

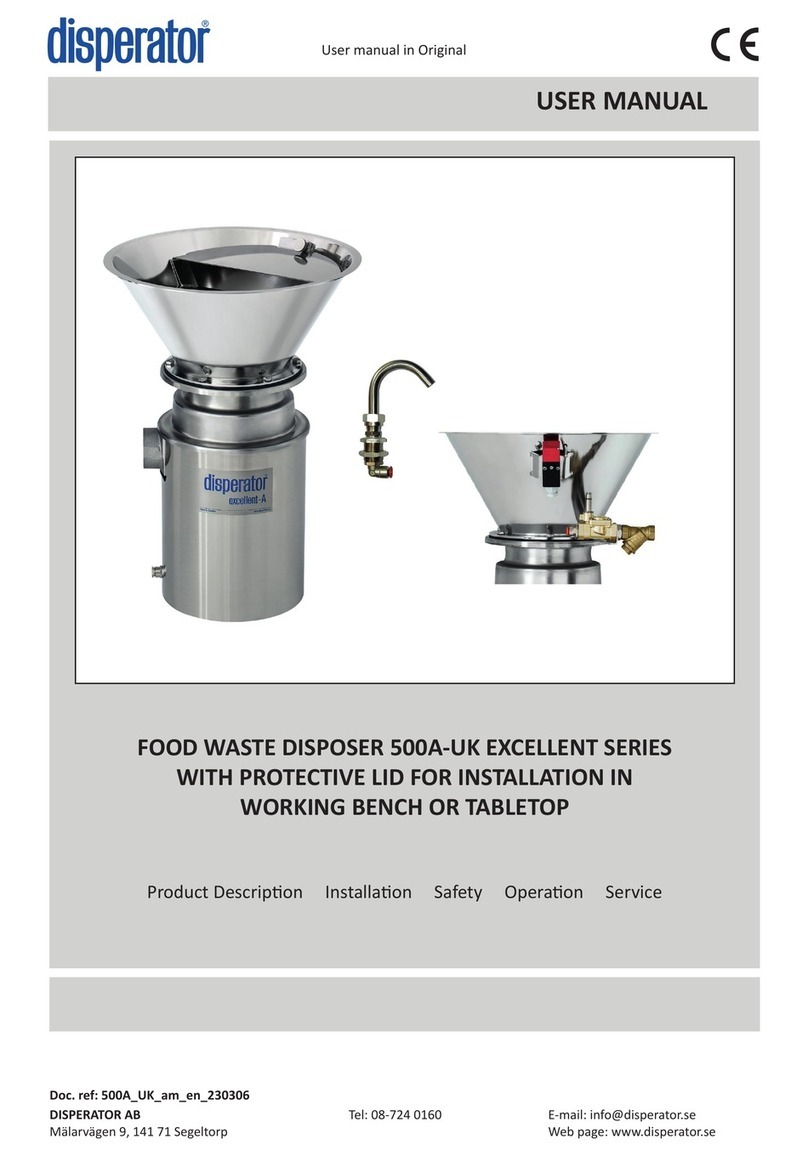

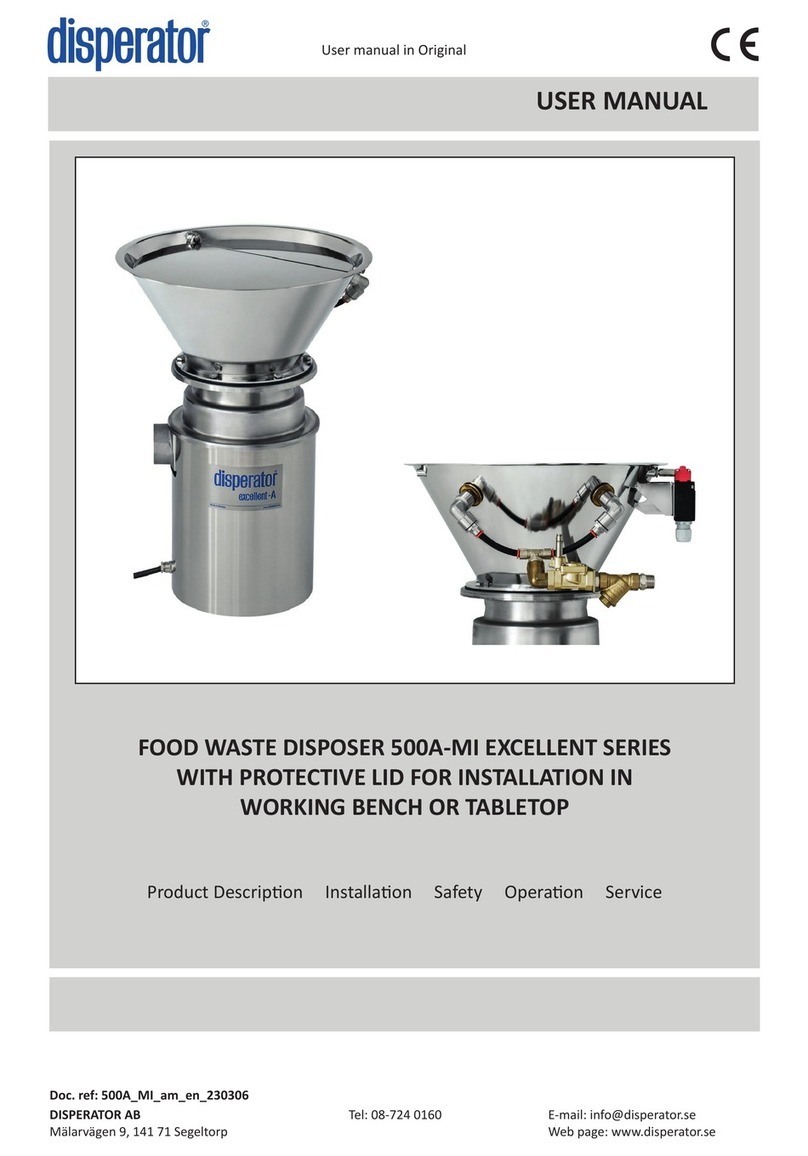

Glass crusher for connecon voltage

according to the supplied delivery note. For a

detailed descripon of the machine, see also

secon 3.2 on page 8 of this manual.

Complete control system according to the

aached electrical wiring diagram and

component layout diagram. Start/stop unit

including contactor with zero voltage release,

reseable motor overload protector, and

control coil.

Including interlock switch that closes the

control circuit if the inlet feeding tube for

glass waste is in place.

Jam release wrench for release of glass

crusher grinding unit, if a non-grindable

object by mistake happens to fall therein.

Bag, 1 pc. for the container of the automac

glass dust collector.

5. Included in Delivery

5.1. Documentation

• This User Manual

• Safety Instrucon (laminated),

• Operang Instrucon (laminated),

• Electric documentaon (connecon & wiring diagram and component layout diagram)

5.2. Food Waste Disposer

User Manual in Original

Dok. ref: 550A_GKF_am_sv_230306

DISPERATOR AB Tel: 08-724 0160 E-mail: info@disperator.se

Mälarvägen 9, 141 71 Segeltorp Web page: www.disperator.se

12 / 35

Reinforced plasc bag (start package of 10

pcs.) for connecon to the machine’s outlet

for collecon of crushed glass.

User Manual in Original

Dok. ref: 550A_GKF_am_sv_230306

DISPERATOR AB Tel: 08-724 0160 E-mail: info@disperator.se

Mälarvägen 9, 141 71 Segeltorp Web page: www.disperator.se

13 / 35

12 / 35

Move the machine to its installaon place as described in secon 4.2. above.

6. Installation Description for the Machine

6.1.1. Deployment of the Machine

6.1. Assembly of the Machine

6.2. Electrical Connection

The electrical connecon of the delivered machine must be done by an authorized

electrician and in accordance to valid local regulaons.

The wiring made at the factory, and the electrical connecons to be done during

installaon, are shown in the electrical wiring diagram aached to this manual. The

machine’s specic electrical data are given in this manual, secon 3.2 above, as well

as on its serial number plate located on its outer cover (in cabinet assemblies there

is also an addional plate inside the cabinet).

6.2.1. Supply Voltage

Check that the supply voltage to be connected corresponds to the specied voltage on the

machine’s serial number plate.

6.2.2. Mains Fuses

Check that the supply voltage for the delivered machine is fused and protected as specied in

secon 3.2 of this manual.

6.2.3. Wall/Bulkhead Mounted Electrical Security Breaker

A separate wall / bulkhead mounted main electrical security breaker (circuit breaker) must be

connected in the incoming power line to the machine. The electrical security breaker is not

included in standard delivery but is available as an opon from Disperator.

6.2.4. Cable Dimension

Use connecon cable having 1.5 mm² wires for machines having a rated current up to 14A. For

machines having a rated current above 14A, use 2.5 mm² wires. The rated voltage and current is

specied on the machine’s serial number plate.

6.2.5. Cable Protection

All electrical cables must be protected against damage by being securely

fastened, for example to kitchen furniture or wall/bulkhead. If there is a risk

that the cables can be damaged, for example by passing trolleys, then the cables

must be protected by a exible sleeve or conduit. The cables must never be kept

on the oor/oor plate.

6.2.6. Earth Wire

a) The earth wire must be longer than the main voltage wires, when connecng to the cable

terminal block. This gives earth protecon in case the voltage wires become unxed in the

cable nipple, allowing them to be pulled from their terminals.

b) The machine must not be connected via residual current device, RCD (also

called earth leakage circuit breaker). The reason is that the currents in all

3-phase motors during start-up are out of balance unl the motor comes

up to speed, why the RCD without intended reason will trip. Note also that

when the machine’s electrical connecon is permanently installed through

a wall / bulkhead mounted electrical security breaker (see item 6.4.3.

above), usually under current rules in most countries no RCD is required.

6.2.7. Direction of Rotation for the Disposer

The disposer operates correctly irrespecve of the motor’s rotaonal direcon. It is therefore

irrelevant in which sequence the electrical phases are connected to the disposer motor.

User Manual in Original

Dok. ref: 550A_GKF_am_sv_230306

DISPERATOR AB Tel: 08-724 0160 E-mail: info@disperator.se

Mälarvägen 9, 141 71 Segeltorp Web page: www.disperator.se

14 / 35

6.3. Start Up and Final Testing

6.3.1. Check before Start Up

Loosen the knob and li o the inlet feeding tube from the front panel of the machine.

Check that the rotary shredder in the inlet opening of the machine turns freely in both direcons

by hand, and make sure that no foreign object has been dropped into the grinding unit during

installaon.

Ret the inlet feeding tube.

6.3.2. Checks during Start-up

6.3.3. Final Measures

1. Aach a collecon bag to the glass crusher outlet using the pre-mounted elasc cord (see

photo in secon 5.2. above). Make sure the bag closes ghtly against the O-rings on the

outlet.

2. Start the glass crusher to determine that the rotary shredder is spinning.

3. While the glass crusher is running, check its automac funcon for collecng glass dust by

placing a thin at paper over the enre opening of the inlet feeding tube. The paper should

then remain on the tube by the created under-pressure in the crusher. If the paper drops

from the tube, it leaks somewhere along the O-ring between the inlet feeding tube and the

crushing unit. Then check:

a) that this O-ring is correctly mounted on the tube,

b) that this O-ring is undamaged,

c) that this O-ring´s sealing funcon is not disturbed by foreign objects.

4. Make sure that the safety interlock switch works properly according to secon 6.2.8 above.

If the machine fails to operate, see secon 8.3. ”Trouble shoong” in this manual.

Before the documentaon and the jam release wrench for the crushing

unit are handed over to the personnel responsible for the machine, instruct

this personnel about the operaon and daily maintenance of the machine,

especially about what is said under secon 7 and 8 of this manual.

6.2.8. Check of the function of the Safety Interlock Switch

The inlet feeding tube is xed with a knob against the front panel of the glass crusher.

a) Check the funcon of the safety interlock switch (the key switch) by loosening the knob so

that the inlet feeding tube is released. The electrical connecon must be broken when there

are a number of threads turns le on the knob, i.e. before the inlet feeding tube is released.

Check that the machine idle run stops before the inlet feeding tube can be released and

removed.

b) If necessary, ne-tune the posioning of this switch and make sure it is properly xed.

c) Ensure that the key mounted on the inlet feeding tube can easily move in and out of this

switch.

d) Also make sure that the important O-ring on the inlet feeding tube, that will seal against the

crushing unit and protect the switch from crushed glass, is in place and in good condion.

Fasten the laminated operang and safety instrucons (included in delivery)

in a place on the wall / bulkhead where they are easily seen by the operator

before the start of the machine.

User Manual in Original

Dok. ref: 550A_GKF_am_sv_230306

DISPERATOR AB Tel: 08-724 0160 E-mail: info@disperator.se

Mälarvägen 9, 141 71 Segeltorp Web page: www.disperator.se

15 / 35

14 / 35

7. Safety Instructions

1. There is a rotating disc under inlet feeding

tube. Do not insert hands into the tube when

glass crusher is running.

2. Even if there in the inlet feeding tube are a

number of protective covers with sluices that

protect against glass splinters, do not hold

your face in front of the tube opening.

3. Immediately press the red stop button if e.g.

metal caps or other non-crushable materials

accidentally are dropped into the crusher, or if

unfamiliar noises are heard. See section 8.3.

“Trouble shooting” in this manual.

4. If the glass crusher is running even though

the inlet feeding tube above the crusher is

removed, press the red stop button, switch-off

and lock the main electrical safety switch and

call for service.

5. The main electrical safety switch on the wall/

bulkhead must be locked in the OFF-position,

with a padlock during all maintenance and

service work.

6. The glass crusher emits noise of more than

70 dB (A). Therefore, the operator must have

hearing protection when using the machine.

Read these safety instructions

before using the machine!

User Manual in Original

Dok. ref: 550A_GKF_am_sv_230306

DISPERATOR AB Tel: 08-724 0160 E-mail: info@disperator.se

Mälarvägen 9, 141 71 Segeltorp Web page: www.disperator.se

16 / 35

8. Driftinstruktioner

The machine is only intended for crushing pure glass!

8.2. Daily Cleaning

DISPERATOR AB

Mälarvägen 9, 141 71 Segeltorp

Tel: 08-724 0160

info@disperator.se, www.disperator.se

Doc. ref:

Opera� ng Instruc� on

550A-GKF_di_sv+en_210409

OPERATING INSTRUCTION

FOR GLASS CRUSHER

Disposer Control Panel Daily Cleaning of Disposer

1. Attach a collection bag of strong

plastics to the machine outlet.

Use the pre-mounted elastic cord,

and make sure the bag ts tightly

against the seals on the outlet.

2. Press the green button (1) - the

glass crusher starts.

3. Depending on size, feed the

bottles one by one into the inlet

tube at every 5 - 10 sec.

4. When the crushing is completed

only the machine’s idle sound is

heard.

5. Press the red button (0) - the

glass crusher stops within 5 sec.

1. Use protective gloves.

2. Remove the bag with crushed

glass, and instead place a bucket

under the machine outlet.

3. Start glass crusher with green

button (1).

4. Insert a hose in the inlet tube

opening, and rinse with warm

water to remove beverage

residue and prevent bad odors.

5. If needed, empty the bucket and

repeat item 4 above.

6. Press the red button (0) - the

glass crusher stops within 5 sec.

7. Use the main electrical safety

breaker (placed on the wall/

bulkhead) to disconnect

electrical supply. Lock the

breaker with a padlock if you

need to leave the machine

temporarily before item 11 below

is completed.

8. Loosen the knob and lift off the

inlet tube from the machine

front panel. Make sure that the

area around the O-ring seal

on the tube, and also the area

around the front panel opening

to the interlock switch, is clean

and free from crushed glass.

9. Remove any foreign objects

(e.g. bottle caps, plastics etc.)

that may remain in the glass

crushing unit of the machine.

10. When the inlet tube is reted

and xed with the knob on the

front panel, also check that the

O-ring seal is intact and that the

key on the tube easily slides into

the interlock switch.

11. See section 9.3.2 of the user

manual, and check that the

machine´s automatic function for

collecting glass dust works.

12. Use the main electrical safety

breaker to connect the electrical

supply

The glass crusher is intended for crushing pure glass only

• What can be crushed: wine, beer, champagne bottles, jars and containers of glass

• What cannot be crushed: materials that can cause explosion, spread infection or

chemical pollution (e.g. lamps containing mercury)

• Non-crushable materials: metal, stone, wood, plastic, rubber, strings and the like

• What can be crushed: wine, beer, champagne bottles, jars and containers of

glass

• What cannot be crushed: materials that can cause explosion, spread infection or

chemical pollution (e.g. lamps containing mercury)

• Non-crushable materials: metal, stone, wood, plastic, rubber, strings and the like

8.1. Start and Stop

User Manual in Original

Dok. ref: 550A_GKF_am_sv_230306

DISPERATOR AB Tel: 08-724 0160 E-mail: info@disperator.se

Mälarvägen 9, 141 71 Segeltorp Web page: www.disperator.se

17 / 35

16 / 35

8.3. Trouble Shooting

8.3.1. The Machine Reduces Speed, Stops or does not Start

A humming sound might be heard from the motor of the machine.

1. Press the red stop buon (0).

2. Use main electrical safety switch on wall/bulkhead to disconnect electrical supply. Lock the

switch with a padlock if you temporarily leave the machine before the measure of this error

has been completed as per item 14 below.

3. Use protecve gloves.

4. Loosen the knob and li o the inlet feeding tube from the front panel of the machine.

5. Check if any foreign object blocks the crushing unit so that the rotary shredder cannot be

turned by hand. If something is jammed, place the jam release wrench on the center washer.

See picture below.

6. Release by rotang the wrench backwards and forwards unl the shredder

rotates freely a whole lap in both direcons. If needed, extend the bar on

the wrench and hit the bar with a hammer.

7. Remove the jam release wrench.

8. Remove any non grindable objects from the crushing unit, e.g. metal caps.

9. Make sure that the area around the O-ring on the inlet feeding tube, and

also the area around the front panel opening to the safety interlock switch is clean and free

from crushed glass.

10. Ret the inlet feeding tube and x it by turning the knob. At the same me ensure that the

key mounted on the tube can easily slide into the safety interlock switch in the front panel

and connect.

11. Check wall fuses/automac breakers. Change/reset these if needed.

12. Reset motor protector by pressing in the red buon on the start & stop unit.

13. Connect the electrical supply on the main electrical safety switch on the wall/bulkhead.

14. Press the green buon (1) to start and empty the machine.

Grinder and jam release

wrench from above

8.3.2. The Machine does not Start and makes no Sound

1. Is the inlet feeding tube correctly mounted and xed with the knob so that the interlock

switch is closed?

2. Check that the main electrical safety switch on the wall/bulkhead is in ON-posion.

3. Make sure the wall fuses/automac breakers are funconing and switched on.

4. Check that the motor protector is reset by pressing the red stop buon.

If the fault cannot be remedied please contact authorized service personnel

or Disperator AB / local representave. Always provide the machine’s serial

number when contacng Disperator.

User Manual in Original

Dok. ref: 550A_GKF_am_sv_230306

DISPERATOR AB Tel: 08-724 0160 E-mail: info@disperator.se

Mälarvägen 9, 141 71 Segeltorp Web page: www.disperator.se

18 / 35

Picture 1

9. Service Instructions

9.1. Authorization

9.2. Exploded Views and Spare Parts List for the Disposer

Disconnecon and reconnecon of the machine to incoming water & sewer service

and electricity may only be carried out by authorized personnel and in accordance

with valid local regulaons.

Upon delivery of the machine, its electrical documentaon is aached to this user

manual.

User Manual in Original

Dok. ref: 550A_GKF_am_sv_230306

DISPERATOR AB Tel: 08-724 0160 E-mail: info@disperator.se

Mälarvägen 9, 141 71 Segeltorp Web page: www.disperator.se

19 / 35

18 / 35

Picture 2

When ordering spare

parts always state the

machine serial number.

NOTE! All screws and

nuts must have the

correct quality and

strength. Disperator

cannot guarantee the

safety if other screws

and nuts are used than

those supplied by us.

-01 Staonary shredder

-02 Rotary shredder

-03/00 Washer for V-ring seal

-03/01 V-ring seal

-03/02 Axle seal, 2 pcs. with stainless spring

-03/03 Locking ring, SgH

-06 Axle washer

-07 Axle screw

-10 Key for carrier

-13G End shield

-14 Motor with drained upper ange

-14/01 Axle seal, 1 pc. motor drive end, 1 pc.

motor non-drive end

-14/02 Bearing, 1 pc. motor drive end,1 pc.motor

non-drive end

-14/03 Key for motor axle

-18 Carrier

-23 Screw for mounng end shield, 4 pcs.

Not depicted parts (instead see photos on page 31 below):

-04 Special grease for seals and carrier

-09 Rubber sealing mass

User Manual in Original

Dok. ref: 550A_GKF_am_sv_230306

DISPERATOR AB Tel: 08-724 0160 E-mail: info@disperator.se

Mälarvägen 9, 141 71 Segeltorp Web page: www.disperator.se

20 / 35

1. Top cover

2. Seal for staonary shredder, spare part No. -05

3. Screw M8x35 and washer (4pcs.), s.p. No. -25

4. Spacer (4pcs.) spare part No. -25

5. Screw M8x16 (4pcs.), spare part No. -25

6. Cover for inlet feeding tube

7. Gasket for cover for inlet feeding tube

8. Lower protecve cover

9. Upper protecve cover

10. Rubber protecve cover

11. Inlet feeding tube

12. O-ring seal for inlet feeding tube

13. Outlet connecon

14. O-ring seal for outlet/outlet connecon

15. Outlet

16. Screw M5x10 (4pcs.) for outlet

17. Seal rings (2pcs.) for outlet

18. Elasc cord for aachment of collecon bag

19. Cover for dust collecng bag

20. Dust collecng bag

21. Inlet pipe for dust collecng bag

22. Dust hose

23. Toeboard rubber

24. Wheel (2pcs.), spare part No. -240/12

25. Power supply cable and cable gland in boom

plate

26. Vibraon damper (4pcs.)

27. Start/stop-unit incl. contactor and motor

protector, spare part No. -38

28. Safety interlock switch (key switch), s.p. No. -39

29. Key for safety interlock switch

Picture 3

This manual suits for next models

1

Table of contents

Other disperator Commercial Food Equipment manuals

disperator

disperator 500A-BAS EXCELLENT Series User manual

disperator

disperator 500A-DRR-K EXCELLENT Series User manual

disperator

disperator 500A-HK User manual

disperator

disperator EXCELLENT Series User manual

disperator

disperator 500A-UK User manual

disperator

disperator 500A-MI EXCELLENT Series User manual