– 8 –

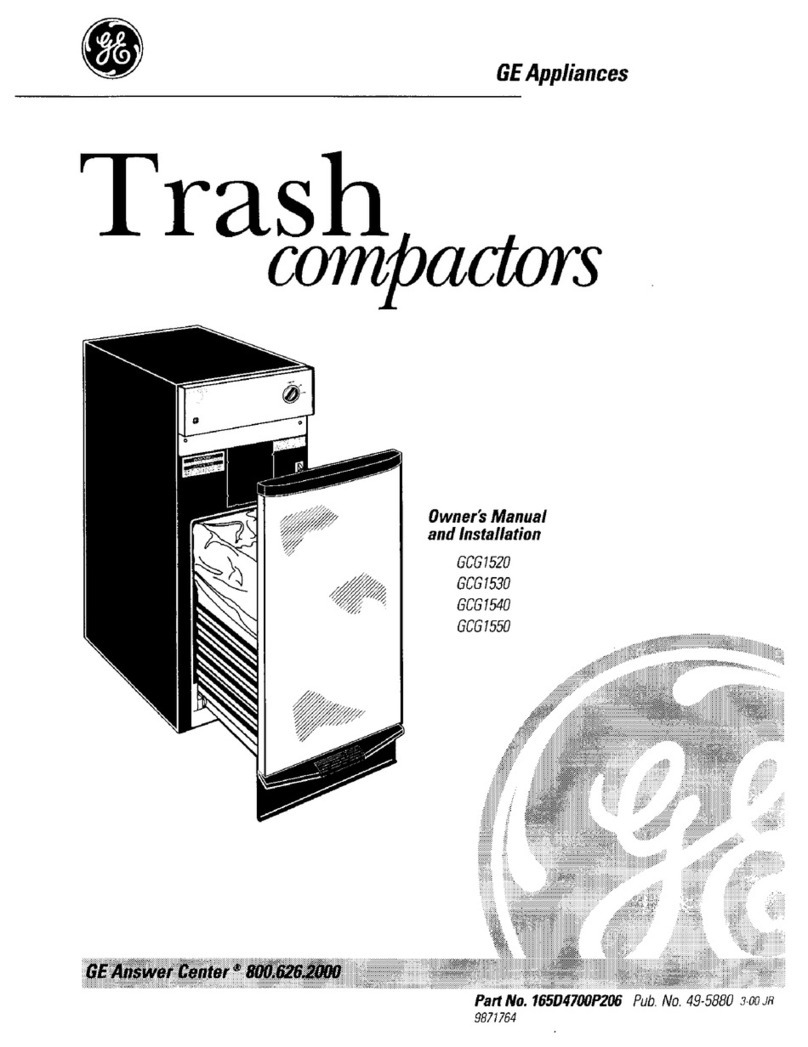

What It Does and How It Works

Your compactor reduces household trash to as little

as one-fourth of its original volume.

It compacts most refuse, including paper, cans,

bottles, jars, plastic containers, wrappings,

sweepings and some food wastes.

Drop trash into the disposable bag (designed for

compactor use) that lines the compactor trash

drawer and close the drawer. When you start the

compactor, an electrically-operated ram moves

down into the drawer, compacts trash, moves

back up again―and the compactor shuts off

automatically.

Note: The trash drawer must be at least 1/2 full

before you will notice compaction because the ram

does not travel all the way down into the drawer. By

adding trash, compaction is transferred to earlier

discarded items until all trash is compacted.

ON-OFF Knob

The removable knob is provided for your protection

as a safety measure. When the knob switch is in the

OFF position, the compactor will not operate.

Child Lockout Instructions:

Lock the compactor when it is not in use, by

removing the knob. This will keep children from

operating the compactor and prevent anyone from

tampering with it.

Drawer Safety Switch

The compactor has two safety switches to ensure

that the drawer is in its fully closed position before

operation. The compactor will not cycle without the

drawer being fully closed.

Trash Bag Installation

Before installing a new bag, be sure that:

1. The drawer side is securely locked.

2. The container is clean and free of sharp debris

that may puncture the bag.

Reinforced plastic bags came with your compactor

and are ready to be installed.

You must use the specially designed heavy-duty

trash bags included with your compactor. These

bags are available from your dealer or Factory

Service Center. Ask for catalog number WC60X5017.

If you prefer, you can order by mail. A handy

order form is provided with your compactor and is

included in every replacement bag package.

To install a new bag:

1. Place the bag in the drawer. Open the bag and

pull the top edges over the drawer top.

2. Lock the bag in place

by pulling the four

prepunched holes over

the bag retainer buttons.

Holes will expand over

the buttons without

harming the bag.

3. Press inside of bag

against the drawer

bottom, sides and

corners for a smooth fit.

Loading

Slightly lift and pull the

compactor door handle or

press the foot pedal and pull

the drawer out.

Remember:

To help keep the ram clean

when compacting messy food waste, place a

couple of folded sheets of newspaper on top of

the load to be compacted.

An item that is too bulky to go into the drawer

can be folded to fit. If an item cannot be folded

to fit into the drawer, do not force it in.

Folded newspaper is also helpful when

compacting a large glass bottle, or several

bottles or jars, or any other item that might

shatter.

Although it is not necessary to compact until

the drawer is full or nearly full, we suggest that,

for maximum compaction, start the compactor

each time a significant amount of trash is

added.

Using the Built-In Compactor

(Continued next page)