Distek Evolution 6300 User manual

Operation

Manual

Evolution

Dissolution Test

System

6100

6300

Evolution Dissolution Test System

Operation Manual

Document # 3861-0001

Distek, Inc.

121 Nort Center Dr. • Nort Brunswick, NJ 08902

P one 732.422.7585 • Fax 732.422.7310

ttp://www.distekinc.com

Notice

This document contains proprietary information. All ri hts are

reserved. No part of this document may be photocopied,

reproduced or translated without the prior written consent of

Distek, Inc.

Distek, Inc.

121 North Center Drive

North Brunswick, NJ 08902-4905

Tel. (732) 422-7585

Fax. (732) 422-7310

Website: http://www.distekinc.com

“Dow Corning” is a registered trademark of Dow Corning Corporation, USA.

CenterC ek, Heig tC ek, RPMC ek, S aftC ek and TempC ek are trademarks of Distek,

Inc.

T e Distek logo is a registered trademark of Distek, Inc.

All ot er company and product names are trademarks or registered trademarks of t eir

respective olders.

Document Revision History

Rev Date Notes

A June 2003 Initial Release

B December 2003 See Distek C ange Notice 0405

C October 2004 Updated for Firmware Rev. 2.13. See Distek C ange Notice

0456.

D June 2005 Updated Appendix A: Spare Parts & Accessories. See Distek

C ange Notice 0508.

E September 2005

Removed Certificate of Compliance from Manual. Certificate

is a separate file on manual CD. See C ange Notice 0516.

Page B-1: Step # 5.3 – c ange “0.3V” to “2.0 V” and “0.5 V”

to “3.0 V”

Page D-2 and D-3 – add note to bottom of page - “Asterisk (*)

in Temperature Profiles denotes out of USP specification”

F May 2007 See Distek C ange Notice 0580. Updated for FW Rev. 2.15.

Operation Manual: Evolution Series

Contents

About this Manual......................................................................... i

Purpose .................................................................................. ii

Audience ................................................................................ ii

Contents................................................................................. ii

Prerequisites............................................................................iii

Documentation .........................................................................iii

Conventions.............................................................................iii

1Introduction ..................................................................... 1-1

Overview .............................................................................. 1-2

Specification.......................................................................... 1-2

P ysical Site Considerations........................................................ 1-4

Environmental Considerations ..................................................... 1-5

Distek & t e WEEE Directive (Waste Electrical & Electronic Equipment) 1-5

Ambient Laboratory Temperatures ............................................. 1-5

Ambient Laboratory Humidity ................................................... 1-6

Air Quality Considerations ....................................................... 1-7

Operation Warnings and Notes..................................................... 1-8

General Instrument Overview .....................................................1-11

2Installation....................................................................... 2-1

Unpacking ............................................................................. 2-2

Leveling t e Evolution System ..................................................... 2-3

Installing t e T ermocirculator (Evolution 6300 Only) ......................... 2-6

Placement and Connections ..................................................... 2-7

Filling t e Water Bat ............................................................ 2-8

Priming t e Pump ................................................................. 2-8

Operation Manual: Evolution Series

Positioning t e Vessels .............................................................2-10

Paddle and Basket Installation ....................................................2-11

Paddle Blade Installation........................................................2-11

Basket Installation ...............................................................2-11

C ecking Paddles, Baskets and S afts for Straig tness.....................2-12

C ecking S aft Centering .......................................................2-12

Paddles and Basket Heig t Adjustment..........................................2-12

Initial Heig t Setting for Paddles and Baskets: ..............................2-13

Quick C ange Heig t Adjustment Knob (Paddles or Baskets)..............2-14

Installing t e Calibration Probe...................................................2-14

Installation C eckout...............................................................2-15

RPM Control .......................................................................2-15

Test Duration .....................................................................2-15

Temperature Control ............................................................2-16

Time and Date ....................................................................2-16

3Operation ........................................................................ 3-1

Control Keypad ....................................................................... 3-4

ESC/DEL Button.................................................................... 3-4

RUN/STOP Button ................................................................. 3-4

Arrow Keys ......................................................................... 3-4

ENTER Button ...................................................................... 3-4

+ Button ............................................................................ 3-5

- Button............................................................................. 3-5

Stir LED ............................................................................. 3-5

Heat LED............................................................................ 3-5

Sleep LED........................................................................... 3-5

produKEY ........................................................................... 3-5

Startup Screens....................................................................... 3-5

System Administration .............................................................. 3-6

System Setup....................................................................... 3-7

Advanced Options .............................................................. 3-8

Unit Address ..................................................................... 3-8

TCS Address (Evolution 6300 Only)........................................... 3-9

Pre eat (Evolution 6300 Only) ................................................ 3-9

Temperature Control (Evolution 6300 Only)............................... 3-10

Beep Mode ...................................................................... 3-10

Heig t Switc Setting ......................................................... 3-10

Printer S aring Configuration (Evolution 6100 Only) ..................... 3-11

About Window.................................................................. 3-12

User Configuration ...............................................................3-12

Login Procedures .............................................................. 3-13

Creating a New Account ...................................................... 3-14

C anging t e Privileges of an Existing Account ........................... 3-15

C anging a Password .......................................................... 3-15

Deleting an Account........................................................... 3-16

Temperature Calibration........................................................3-16

Operation Manual: Evolution Series

Calibrate Using Evolution Calibration Probe............................... 3-18

Calibrate Using TempC ek Digital T ermometer ......................... 3-19

Calibrate Using NIST-Traceable Reference T ermometer ............... 3-19

Calibrate calPROBE Using TempC ek Digital T ermometer ............. 3-20

Calibrate calPROBE Using NIST-Traceable Reference T ermometer... 3-21

Display Screens ......................................................................3-21

Temperature Screen .............................................................3-21

Temperature and RPM Screen ..................................................3-22

Current Met od...................................................................3-23

Report History ....................................................................3-23

Printing a Saved Report .........................................................3-24

Working wit Met ods (Automatic Mode) .......................................3-24

Selecting a Met od to Run ......................................................3-24

Sorting t e Met od List..........................................................3-25

Programming a New Met od....................................................3-25

Running a Simultaneous Drop wit Paddles ..................................3-27

Running a Simultaneous Drop wit Baskets...................................3-28

Running a Staggered Drop wit Paddles ......................................3-28

Running a Staggered Drop wit Baskets.......................................3-28

Open/View an Existing Met od.................................................3-29

Modify a Saved Met od ..........................................................3-30

Deleting a Met od................................................................3-30

Copy a Saved Met od to a New Name.........................................3-30

Printing Met od Parameters....................................................3-31

Working in Manual Mode ...........................................................3-31

Controlling Vessels Individually (Evolution 6100 Only) .....................3-32

Controlling All Vessels ...........................................................3-33

TCS Activation (Evolution 6300 Only) .........................................3-35

Running a Manual Mode Test ...................................................3-35

Using t e produKEY.................................................................3-36

Saving a Met od to t e produKEY..............................................3-36

Viewing Met ods on t e produKEY.............................................3-37

Saving a Met od from t e produKEY to t e Instrument ....................3-37

Running a Met od from t e produKEY ........................................3-37

Deleting Met ods from t e produKEY .........................................3-38

Printing a Met od from t e produKEY.........................................3-38

Using a Premiere 5100 produKEY ..............................................3-38

Using t e calKEY ....................................................................3-38

Storing Calibration Data.........................................................3-39

Restoring Calibration Data ......................................................3-39

Printouts..............................................................................3-40

Serial Port Control ..................................................................3-40

4Maintenance..................................................................... 4-1

General Information ................................................................. 4-2

Emptying t e Water Bat & TCS (Evolution 6300 Only) ........................ 4-3

Removing t e Water Bat (Evolution 6300 Only)................................ 4-4

Operation Manual: Evolution Series

Re-installing t e Water Bat (Evolution 6300 Only) ............................ 4-5

Replacing t e Water Bat and TCS Tubing (Evolution 6300 Only) ............ 4-5

5Troubles ooting................................................................. 5-1

Troubles ooting ...................................................................... 5-2

Error Messages.......................................................................5-15

Warning Messages...................................................................5-17

General Messages ...................................................................5-18

Service................................................................................5-19

Appendix A : Spare Parts and Accessories ...................................... A-1

Appendix B : Pre-Installation Considerations: Electrical Power SupplyB-1

Appendix C : CE Declaration of Conformity .................................... C-1

Appendix D : Sample Printouts from Parallel Printer ......................... D-1

About T is Manual

Operation Manual: Evolution Series

i

About this Manual

About T is Manual includes information about w at is contained in t is manual and

t e conventions used.

Purpose .................................................................................. ii

Audience ................................................................................ ii

Contents................................................................................. ii

Prerequisites............................................................................iii

Documentation .........................................................................iii

Conventions.............................................................................iii

About T is Manual

Operation Manual: Evolution Series

ii

Purpose

T is manual covers t e installation, routine operation, maintenance and repair of

your Evolution Dissolution Test System. It as information regarding t e

commands, menus, indicators and controls. C apter 1 provides an overview of t e

system. C apter 2 covers unpacking, installation, and qualification of t e system.

C apter 3 as operation and programming information. C apters 4 and 5 cover

maintenance and troubles ooting. Please read C apters 1, 2 and 3 before

proceeding.

Audience

T is manual is written for any person responsible for maintaining, operating or

troubles ooting t e Distek Evolution Dissolution Test System.

Contents

T is manual is divided into c apters. T e pages of t e manual are numbered

providing easy navigation to assist in finding information quickly.

T e following list describes t e material covered in eac c apter:

C apter 1 - Introduction Provides a general overview and

warnings about t e instrument.

C apter 2 - Installation Describes ow to unpack and properly

install t e unit.

C apter 3 - Operation Describes t e functionalities of t e

system and ow to run t e unit.

C apter 4 - Maintenance Explains t e steps necessary to

maintain t e unit.

C apter 5 - Troubles ooting Provides a troubles ooting c art and

description of error messages to assist

t e user if a problem arises.

Appendix A – Spare Parts and

Accessories

Provides a table of recommended and

optional spare parts.

Appendix B - Pre-Installation

Considerations: Electrical Power

Supply

Recommendation information

pertaining to electrical power supply.

Appendix C - CE Declaration of

Conformity

CE Declaration of Conformity

certificate.

Appendix D - Certificate of

Compliance

Certificate of Compliance

Appendix E - Sample Printouts from

Parallel Printer

Sample printouts for a parallel printer.

About T is Manual

Operation Manual: Evolution Series

iii

Prerequisites

T is manual assumes t at you understand t e principles of dissolution testing.

Documentation

T is manual contains important information regarding t e safe operation,

maintenance and repair of your Distek Evolution Dissolution Test System.

Conventions

T e following table contains Warnings, Cautions and Notes t at are used

t roug out t e document for your protection. Please read t is section before

using t e Evolution Dissolution Testing System.

“WARNING” statements are used in t is manual to prevent

injury to personnel.

"CAUTION: Risk of Electric Shock" statements are used to

prevent injury w en ig voltage is present.

“CAUTION” statements are used to prevent damage to

equipment.

“NOTES” contain elpful information.

REQUIRED

ACTION

“REQUIRED ACTION” is used w ere necessary to distinguis

t e action needed from Warnings, Cautions and Notes.

C apter 1: Introduction

Operation Manual: Evolution Series

1

-

1

1

11

1 Introduction

T e Distek Evolution Dissolution Test System is a state of t e art instrument. T is

c apter will provide an overview of t e unit and system specific specifications.

Overview .............................................................................. 1-2

Specification.......................................................................... 1-2

P ysical Site Considerations........................................................ 1-4

Environmental Considerations ..................................................... 1-5

Distek & t e WEEE Directive (Waste Electrical & Electronic Equipment) 1-5

Ambient Laboratory Temperatures ............................................. 1-5

Ambient Laboratory Humidity ................................................... 1-6

Air Quality Considerations ....................................................... 1-7

Operation Warnings and Notes..................................................... 1-8

General Instrument Overview .....................................................1-11

C apter 1: Introduction

Operation Manual: Evolution Series

1

-

2

Overview

Distek is once again setting t e standard by w ic all dissolution systems will be

measured. T e new Evolution Series is taking dissolution testing to t e next level

by advancing t e state of t e art design of its predecessor, t e ig ly successful

Premiere Model 5100.

T e Evolution Series is designed to meet today's demanding standards for accurate

temperature control and test result reporting. T e en anced user interface offers

a ric array of features and functionality, greatly improving t e dissolution

c emist's productivity and control over t e dissolution test. T e Evolution as

menu driven navigation for ease of setup, manager and user log-in levels, 100

sorted met ods and up to 40 test report storage.

Specification

Table 1-1: Evolution Specifications

Evolution 6100

Bathless

Evolution 6300

Water Bath

Dissolution Vessels Six Standard/

Up to Seven Vessels

Six Standard/

Up to Seven Vessels

Volume 500mL - 1000mL

programmable

500mL - 1000mL

programmable

Vessel Heating Rate Approx. 1.5°C per minute Approx. 0.3°C per minute

RPM Control Ran e 25-300 RPM, digitally

controlled, closed loop

25-300 RPM, digitally

controlled, closed loop

Resolution 0.1 RPM 0.1 RPM

Accuracy ±0.2 RPM ±0.2 RPM

Display LED's, .75” (19mm) ig LED's, .75” (19mm) ig

Motor Hig Torque, Permanent

Magnet

Hig Torque, Permanent

Magnet

Vessel Temperature

Control

Independently controlled

two-zone eater jackets

TCS T ermocirculator

Display Resolution 0.01 °C 0.01 °C

Accuracy ±0.25 °C* ±0.25 °C at 37.0 °C

Calibration Built-in Calibration Probe Built-in Calibration Probe

C apter 1: Introduction

Operation Manual: Evolution Series

1

-

3

Evolution 6100

Bathless

Evolution 6300

Water Bath

Shaft Wobble Less t an 0.010” (0.254mm)

Total Indicator Runout

Less t an 0.010” (0.254mm)

Total Indicator Runout

Pro ram Modes Manual

(Individual Vessel Control)

Manual

(Individual Vessel Control)

Automatic

(Up to 100 Pre-Programmed

Met ods)

Automatic

(Up to 100 Pre-Programmed

Met ods)

External

(produKEY™ Memory Device)

External

(produKEY™ Memory Device)

Interface Ports RS-232 (2), RS-485 (1),

Parallel Printer (1)

RS-232 (2), RS-485 (1),

Parallel Printer (1)

Construction

Materials

Cast Aluminum, Stainless

Steel, Acid resistant solid

state eating elements,

Engineered Plastics

Cast Aluminum, Stainless

Steel, 316 Stainless Steel

eating elements,

Engineered Plastics

Dimensions 26”(W) x 39”(H) x 20”(D)

(66cm x 99cm x 51cm)

26”(W) x 39”(H) x 20”(D)

(66cm x 99cm x 51cm)

TCS: 7" w x 16" x 7" d

(18cm x 41 cm x 18 cm)

Wei ht 150 lb. (67.5 kg) 150 lb. (67.5 kg)

(Empty Water Bat )

TCS: 16 lb. (7.3 kg)

Electrical Power 115V ± 15V 50/60Hz 15A

or

230V ± 15V 50/60Hz 9A

(Operating voltage pre-set at

factory)

115V ± 15V 50/60Hz 3A

or

230V ± 15V 50/60Hz 3A

(Operating voltage pre-set at

factory)

TCS:

115V ± 15V 50/60Hz 8A

or

230V ± 15V 50/60Hz 5A

* Test Setting: Paddles, 900 mls, 50 RPM

C apter 1: Introduction

Operation Manual: Evolution Series

1

-

4

Physical Site Considerations

T e dimensional requirements specified below are adequate for t e installation of

t e Evolution Dissolution System:

1. T e minimum benc dept (front edge of benc to t e back splas or wall)

needed is 22” (0.56m). However, t e minimum recommended benc dept is

23” (0.59m). For manual sampling, 29” (0.74m) is recommended to allow room

in front for t e receiving flasks or tubes into w ic t e measured volumes of

sample are to be collected.

2. T e minimum linear benc space requirement is 33” (0.84m). Distek

recommends t at at least 39” (1.0m) be allocated w enever manual operations

are required to be performed adjacent to t e system.

3. T ere must be no obstruction (cabinet, s elf, or outlet) t at intrudes into t e

minimum footprint of t e unit up to a eig t of 40” (1.02m) above t e benc

surface w ere t e unit is to be installed.

4. T e benc must be capable of sustaining t e weig t of t e unit and all of its

accessory parts wit out significant bending. Because t e entire mass of t e

unit is transferred to t e benc surface t roug t ree (3) circular padded,

adjustable leveling feet, t e benc surface s ould be strong enoug to

wit stand a load of 60 pounds per square inc (4 kilograms per square

centimeter).

5. Because of t e limitation in travel of t e leveling feet, t e benc slope s ould

be less t an 0.75” (1.9cm) from front to back or from side to side over t e

unit’s foot print.

C apter 1: Introduction

Operation Manual: Evolution Series

1

-

5

Environmental Considerations

Distek & the WEEE Directive (Waste Electrical & Electronic Equipment)

Distek, Inc. is committed to protecting t e environment and

understands t e importance of proper recycling. T e “crossed

out w eelie bin” symbol on t e product or on its packaging

indicates t at t is product must not be disposed of wit domestic

ouse old waste. Instead, it is t e user’s responsibility to dispose

of t eir waste equipment by anding it over to a designated

collection point for t e recycling of electrical and electronic

equipment waste. T e separate collection and recycling of your

waste equipment at t e time of disposal will elp to conserve

natural resources and ensure t at it is recycled in a manner t at

protects uman ealt and t e environment.

For more information about w ere you can drop off your waste equipment for

recycling, please contact your local city office, your local distributor or Distek,

Inc.

Ambient Laboratory Temperatures

Distek recommends t at t e laboratory

temperature control system fans be kept on at all

times. T is s ould improve set point control, and

minimize s ort-term excursion range.

Maximum Conditions:

1. To ac ieve t e full range of controlled operation (30 to 45°C) wit in

specified tolerances t e Evolution Dissolution System is designed to be

installed and operated in laboratories w ere t e maximum operating

temperature does not exceed 25°C.

2. T e maximum allowable ambient operation temperature is 30°C.

Operating environments above 25°C limit t e range

for satisfactory operation of system to between 35

and 45°C.

C apter 1: Introduction

Operation Manual: Evolution Series

1

-

6

Minimum Conditions:

To assure controlled operation wit in specified tolerances, t e Evolution

System is designed to be operated in laboratories w ere minimum operating

temperatures do not drop below 15°C.

Variability or S ort Term Fluctuations:

To assure controlled operation wit in specified tolerances, t e system used

to control t e temperature of t e laboratory w ere t e Evolution System is

installed must be able to maintain t e ambient air temperature wit in ±2.5°C

of set point (worst case).

T ermal Loading:

For laboratories w ere temperature control is critical,

installation of several dissolution units may require t at

t e system be re-balanced. T ermostats may need to

be relocated to maintain temperature uniformity in t e

lab.

1. Eac unit contributes an average t ermal load of about 0.6 kW w en

operating. T e lab’s cooling systems must ave sufficient excess cooling

capacity to andle t e aggregate t ermal load for all systems installed.

2. T e eating system must also be able to respond to t e increased loading

from t e units by appropriately t rottling back.

Ambient Laboratory Humidity

Distek recommends t at t e laboratory umidity control

system fans be kept on at all times if possible. T is

s ould result in better set point control and reduce t e

s ort term excursion range.

Maximum:

T e Evolution System may add to t e umidity of t e laboratory during

operation. T e bat less design (6100 only) reduces umidity compared to

ot er models, but any vessels filled and left uncovered can raise umidity

levels. Water vapor and/or ydrogen c loride vapor, from dissolution media,

can cause serious effects w en condensed on electrical components and

contacts. T e lab’s environmental controls s ould maintain t e umidity

level below t e dew point, to minimize t e risk of condensation.

Minimum:

C apter 1: Introduction

Operation Manual: Evolution Series

1

-

7

T e Evolution System utilizes solid-state semiconductor devices. It is

important t at t e umidity level be kept at or above 30% relative umidity,

to minimize t e risk of damage to control circuits caused by static disc arge.

Air Quality Considerations

Distek dissolution systems are designed to be operated in a lab environment t at

as no visible dust problem, and wit organic solvent vapor levels as low as

possible. Operation is not recommended in dusty lab environments, or in labs wit

significant c lorinated or reactive solvent vapor levels. T ese dust or vapor levels

may ave serious effects on system components. Absorption of vapors into

dissolution media may bias test results. Some dissolution tests may require

dissolution and drug release media prepared from USP quality water. Absorbed

vapors may cause difficulty in complying wit USP requirements.

C apter 1: Introduction

Operation Manual: Evolution Series

1

-

8

Operation Warnin s and Notes

For your safety, the information in this

manual must be followed to minimize the risk

of fire or explosion, electrical shock, or to

prevent property dama e, personal injury or

loss of life.

Use this equipment only for its intended

purpose as described in this Operation Manual.

Never attempt to operate this instrument if it

is dama ed, malfunctionin , partially

disassembled, or has missin or broken parts,

includin a dama ed cord or plu .

Improper servicin or adjustment practice can

cause equipment failure or serious physical

injury. This equipment must be adjusted and

serviced by qualified electrical maintenance

personnel who are familiar with the

construction and operation of the equipment

and the hazards involved. Take dili ent care

durin adjustment. All exposed points on the

control circuit boards are electrically hot with

respect to earth round.

HIGH VOLTAGE IS EXPOSED WHEN THE

LOWER REAR PANEL IS OPENED ON THE

DISSOLUTION SYSTEM. Dan erous volta es

exist on the circuit boards when powered.

Disconnect AC power from the system while

troubleshootin . Be alert. Hi h volta e can

cause serious or fatal injury.

All Distek Evolution 6100 eaters ave

t ermostatic protection. In t e event of a

malfunction (or if no liquid in vessel), t e

eater will cut off at approximately 150ºC.

T ermostat automatically resets after cooling

down.

Take proper precautions when handlin

dissolution media. Liquid in vessel may be

HOT. Wear splash protection to avoid

exposure to scaldin , acidic, caustic, or

pharmaceutical hazards. Bacteria have been

shown to thrive in certain media, especially at

test temperatures.

C apter 1: Introduction

Operation Manual: Evolution Series

1

-

9

The heatin of a ressive media can cause

explosion, implosion, release of toxic or

flammable ases. Appropriate cautions should

be taken.

T e Evolution Dissolution System is capable of

utilizing all of t e commonly used dissolution

media suc as 0.1 HCL, p osp ate buffers and

sodium lauryl sulp ate.

In the event of a hazardous material spill on

the external surface of the instrument, the

unit can be cleaned with a disposable cloth or

paper wipe, then rinsed and dried with water.

The same approached can be used for internal

spill but the power must be disconnected first!

Before usin any cleanin or decontamination

method recommended by the manufacturer,

users should check with the manufacturer that

the purpose method will not dama e the

equipment.

Heater surfaces may be HOT. Do not touch

vessel heater assemblies when 6100 is in

operation. Injury may result.

Improper remote PC control of the Evolution

system may lead to unexpected motor and/or

heater operation.

To avoid lass breaka e and injury:

•Do not heat vessel empty.

•Do not clean with materials that scratch.

•Do not bump.

Discard vessels if cracked, scratched or

excessively heated empty.

T e Evolution system incorporates a eig t sensor to

stop rotation and adjust eating w enever t e drive

unit is raised well above operating position. T is

feature elps to prevent over eating and addresses

safety issues.

Operation Manual user interface screen s ots may

vary from actual instrument interface screens.

C apter 1: Introduction

Operation Manual: Evolution Series

1

-

10

CAUTION: TO AVOID DAMAGING THE INSTRUMENT

•DO NOT OPERATE 6100 HEATERS WITH LESS THAN 500mL

LIQUID IN EACH VESSEL.

•THE STIRRING ELEMENT (Paddle or Basket) MUST BE

IMMERSED INTO THE LIQUID AND ROTATING WHEN

HEATERS ARE OPERATING.

•USE ONLY GLASS VESSELS SUPPLIED FOR THE EVOLUTION

SYSTEM BY Distek.

•CONNECT THIS UNIT TO THE SPECIFIED AC SUPPLY.

OBSERVE PROPER GROUNDING.

♦FAILURE TO OBSERVE THESE PRECAUTIONS MAY DAMAGE

THE HEATER ASSEMBLIES AND/OR VESSELS.

The Evolution System is supplied with proper heaters

and settin s for the specified operatin volta e (see

label for information). Do not attempt to convert

unit to another mains supply without contactin

Distek's factory first!

Take care when removin or replacin vessel heaters.

Turn off unit and disconnect power from 6100. Do

not use metal tools or sharp objects to mount heater.

Heater failure and/or injury could result.

External cables (excluding power cable) are limited to less

t an 3 meters lengt in order to maintain electromagnetic

compliance.

Some forms of electromagnetic interference may cause

unexpected operation. If t is occurs, t e unit will return to

normal operation once t e interference is removed.

This manual suits for next models

1

Table of contents

Other Distek Test Equipment manuals

Popular Test Equipment manuals by other brands

AVO

AVO 160A OPERATING INSTRUCTIONS AND MAINTENANCE MANUAL

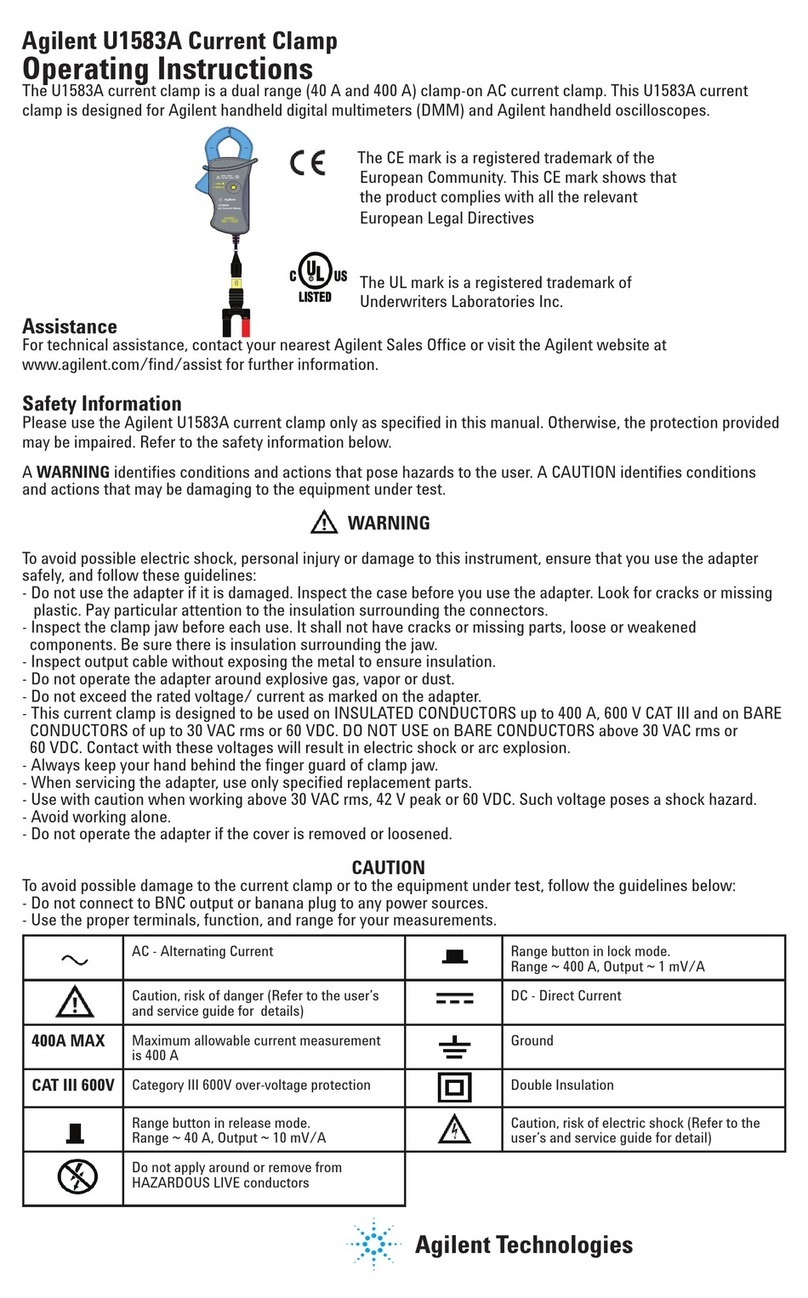

Agilent Technologies

Agilent Technologies U1583A operating instructions

Elma Instruments

Elma Instruments Elma 1500B user manual

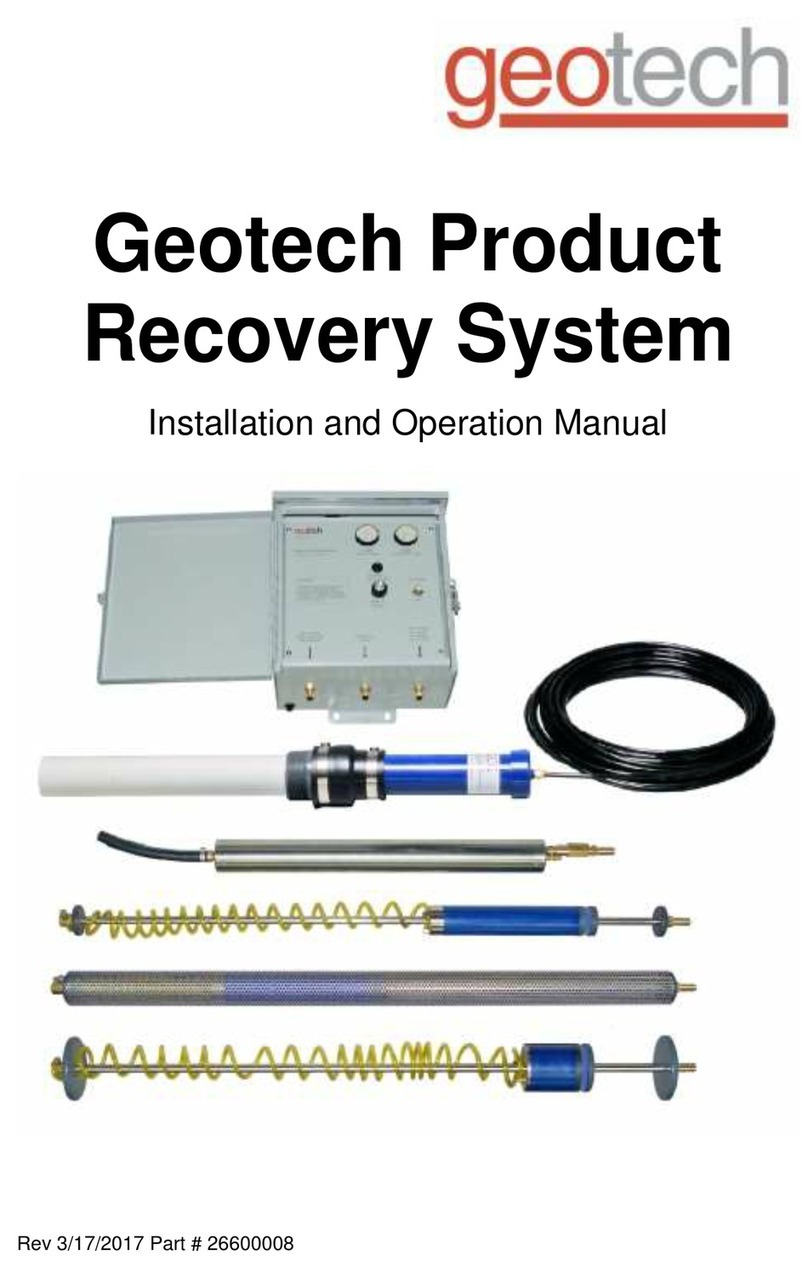

Geotech

Geotech PRS Installation and operation manual

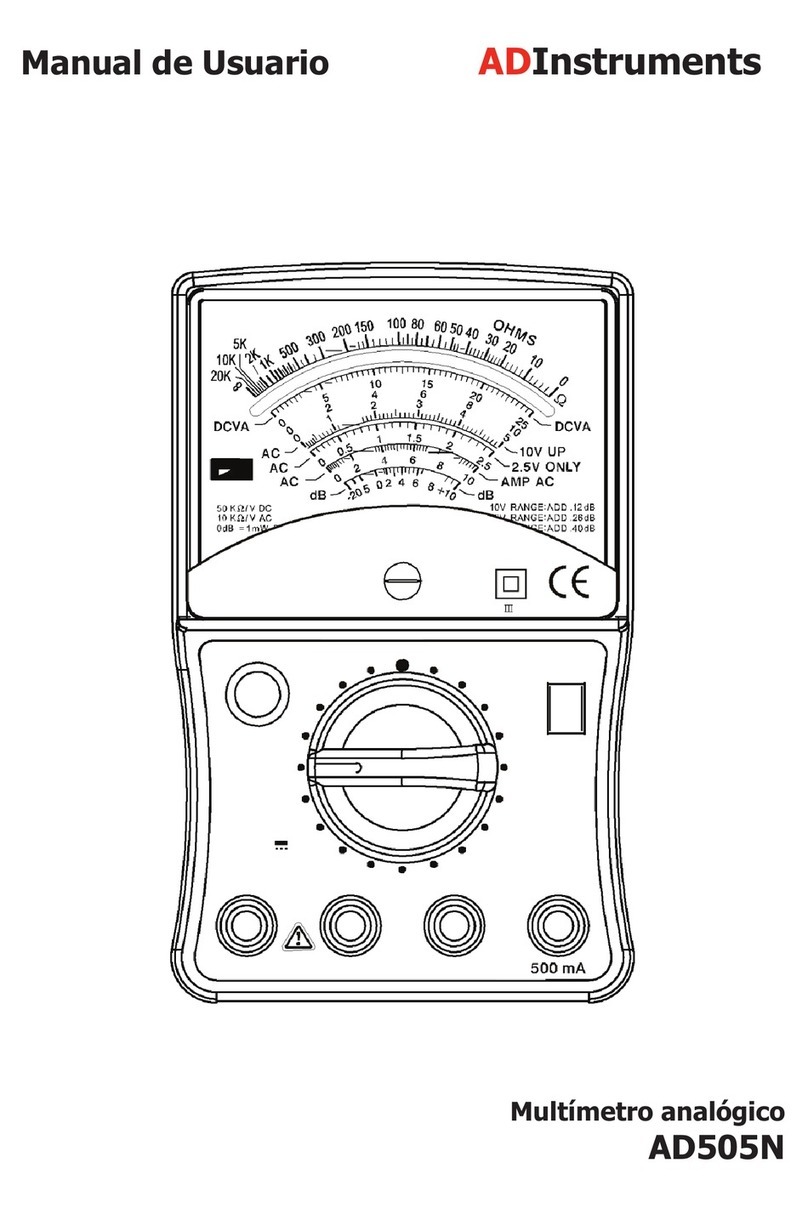

ADInstruments

ADInstruments AD505N Instrument manual

PCE Instruments

PCE Instruments PCE-900-ICA user manual