Distek Premiere 5100 User manual

Operation

Manual

Premiere 5100

Dissolution Test System

About This Manual

Operation Manual: Model 5100 i

Distek Premiere 5100 Dissolution Test System

Operation Manual

Document # 3851-0020

Distek, Inc.

121 North Center Dr. • North Brunswick, NJ 08902

Phone 732.422.7585 • Fax 732.422.7310

http://www.distekinc.com

About This Manual

Operation Manual: Model 5100 ii

Notice

This document contains proprietary information. All rights are

reserved. No part of this document may be photocopied,

reproduced or translated without the prior written consent of

DISTEK Incorporated.

DISTEK, INC.

121 North Center Drive

North Brunswick, NJ 08902-4905

Tel. (732) 422-7585

Fax. (732) 422-7310

Website: http://www.distekinc.com

“Dow Corning” is a registered trademark of Dow Corning Corporation, USA.

IBM and IBM PC are registered trademarks of IBM Corp.

CenterChek, HeightChek, RPMChek, ShaftChek, and TempChek are trademarks

of DISTEK, Inc.

The DISTEK logo is a registered trademark of DISTEK, Inc.

All other company and product names are trademarks or registered trademarks

of their respective holders.

Document Revision History

Rev Date Document Notes

A September 1996 3851-0020

B March 1997 3851-0020

C December 1997 3851-0020

D June 2002 3851-0020

E August 2003 3851-0020 See Distek Change Notice 0381

About This Manual

Operation Manual: Model 5100 iii

Contents

About this Manual .............................................................................vi

Purpose ......................................................................................... vii

Audience........................................................................................ vii

Contents ........................................................................................ vii

Prerequisites .................................................................................. viii

Documentation ............................................................................... viii

Conventions ................................................................................... viii

1Introduction...........................................................................1-1

Specification .................................................................................. 1-2

Overview....................................................................................... 1-3

2Installation ............................................................................2-1

Unpacking ..................................................................................... 2-2

To remove packing....................................................................... 2-2

Leveling: Model 5100 ........................................................................ 2-3

To level unit on bench .................................................................. 2-3

Positioning the Vessels ...................................................................... 2-6

To install vessels in vessel plate....................................................... 2-6

Paddles and Baskets ......................................................................... 2-6

To install paddle blades................................................................. 2-6

To install baskets ........................................................................ 2-6

Checking paddles, baskets and shafts for straightness ............................ 2-8

Checking shaft centering ............................................................... 2-8

Installing the Calibration Probe............................................................ 2-8

To install calibration probe ............................................................ 2-8

About This Manual

Operation Manual: Model 5100 iv

Adjusting the Paddle (or Basket) Height ................................................. 2-9

To set height of paddle or basket ................................................... 2-11

Installation Checkout ...................................................................... 2-12

RPM Control ............................................................................. 2-12

Test Duration ........................................................................... 2-12

Temperature Control .................................................................. 2-12

Time and Date .......................................................................... 2-13

3Operation.............................................................................. 3-1

To Run a Pre-programmed Automatic Test .......................................... 3-5

Control Keypad ............................................................................... 3-7

Stir Key .................................................................................... 3-7

Arrow Keys ................................................................................ 3-7

Enter Keys ................................................................................. 3-7

Clear Key .................................................................................. 3-7

START Key ................................................................................. 3-7

Sleep Key (System Standby) ............................................................ 3-8

Display and Control Screens ................................................................ 3-8

Display Screens ........................................................................... 3-9

For Method History Information ..................................................... 3-12

Automatic Testing Methods............................................................... 3-13

Select Method .......................................................................... 3-13

Edit Test Method ....................................................................... 3-14

Pre-Test Initialization ................................................................. 3-18

START Test Using Paddles ............................................................ 3-19

Program New Auto Test ............................................................... 3-23

Delete Test Method .................................................................... 3-24

Basket Testing .......................................................................... 3-24

Manual Operation .......................................................................... 3-25

Set RPM .................................................................................. 3-26

Controlling Vessel Individually ....................................................... 3-26

Controlling All Vessels Together ..................................................... 3-27

System Setup and Calibration ............................................................ 3-29

Introduction............................................................................. 3-29

Calibrate Using 5100 Calibration Probe ............................................ 3-30

Calibrating Using TempChek Digital Thermometer ............................... 3-36

Calibrating Using NIST Traceable Reference Thermometer..................... 3-44

Advanced Setup Options .............................................................. 3-53

Printouts ..................................................................................... 3-54

Serial Port Control of 5100 ............................................................... 3-57

RS-232 Port.............................................................................. 3-57

Serial RS-485 Address and Beep Mode .................................................. 3-61

4Maintenance ..........................................................................4-1

General Care and Maintenance of Model 5100 .......................................... 4-2

About This Manual

Operation Manual: Model 5100 v

5Troubleshooting & Service.......................................................... 5-1

Troubleshooting Chart....................................................................... 5-3

Model 5100 System Initialize Procedure ................................................ 5-19

Clearing the Dallas Chip................................................................... 5-21

Replacing Chip Number U13 .............................................................. 5-21

Function Check and Initialize Instrument .............................................. 5-22

Initialize Unit ............................................................................... 5-22

Service ....................................................................................... 5-24

Appendix A: Spare Parts and Accessories ................................................A-1

Appendix B: Preventive Maintenance Checklist .........................................B-1

Appendix C: Pre-Installation Considerations: Electrical Power Supply ..............C-1

Appendix D: CE Declaration of Conformity ..............................................D-1

Appendix E: Certificate of Compliance ................................................... E-1

Appendix F: Sample Printouts from Parallel Printer.................................... F-1

About This Manual

Operation Manual: Model 5100 vi

About this Manual

About This Manual includes information about what is contained in this manual

and the conventions used.

Purpose ......................................................................................... vii

Audience........................................................................................ vii

Contents ........................................................................................ vii

Prerequisites .................................................................................. viii

Documentation ............................................................................... viii

Conventions ................................................................................... viii

About This Manual

Operation Manual: Model 5100 vii

Purpose

This manual covers the installation, routine operation, maintenance and repair

of your Model 5100 Dissolution Test System. It contains information regarding

the commands, menus, indicators and controls. Chapter 1 provides an overview

of the 5100. Chapter 2 covers unpacking, installation, and qualification of the

system. Chapter 3 contains operation and programming information. Chapters

4 and 5 cover maintenance and troubleshooting. Please read Chapters 1, 2

and 3 before proceeding.

Audience

This manual is written for any person responsible for maintaining, operating or

troubleshooting the Distek Premiere 5100 Dissolution Test System.

Contents

This manual is divided into chapters. The pages of the manual are numbered

providing easy navigation to assist in finding information quickly.

The following list describes the material covered in each chapter:

Table 1: Chapter Descriptions

Chapter 1 - Introduction Provided a general overview and

warnings about the instrument.

Chapter 2 - Installation Describes how to unpack and properly

install the unit.

Chapter 3 - Operation Describes how the functionalities of

the system and how to run the unit.

Chapter 4 - Maintenance Explains the steps necessary to

maintain the unit.

Chapter 5 – Troubleshooting & Service Provides and troubleshooting chart

and description of error messages to

assist the user is a problem should

arise.

Appendix A – Spare Parts and

Accessories

Provides a table of recommended and

optional spare parts.

Appendix B - Preventive Maintenance

Checklist

Provides a checklist of preventive

maintenance actions.

Appendix C - Pre-Installation Recommendation information

About This Manual

Operation Manual: Model 5100 viii

Considerations: Electrical Power

Supply

pertaining to electrical power supply.

Appendix D - CE Declaration of

Conformity

CE Declaration of Conformity

certificate.

Appendix E - Certificate of Compliance Certificate of Compliance

Appendix F - Sample Printouts from

Parallel Printer

Sample printouts for a parallel printer.

Prerequisites

This manual assumes that you understand the principles of dissolution testing.

Documentation

This manual contains important information regarding the safe operation,

maintenance and repair of your Distek Premiere 5100 Dissolution Test System.

We urge you to read Sections 1, 2, and 3 before proceeding.

Conventions

The following table lists conventions and terms used throughout this manual:

Table 2: Conventions

“WARNING” statements are used in this manual to prevent

injury to personnel.

\“CAUTION” statements are used to prevent damage to

equipment.

“NOTES” contain helpful information.

REQUIRED

ACTION

Used where necessary to distinguish the action needed from

the Warnings, Cautions and Notes.

Chapter 1: Introduction

Operation Manual: Model 5100 1-1

1Introduction

The Distek Premiere 5100 Dissolution Test System is a state of the art instrument.

This chapter will introduce the user to the unit.

Specification .................................................................................. 1-2

Warnings and Notes .......................................................................... 1-3

Chapter 1: Introduction

Operation Manual: Model 5100 1-2

Specification

The Distek Premiere 5100 dissolution system utilizes state of the art electronics, solid

state components, and advanced materials to provide the fastest, cleanest, and most

cost effective dissolution testing solution available today. The 5100 has intelligent

programming features that allow individual vessel control of heating profile, remote

programming and control, and comprehensive method reporting, documentation, and

validation.

Table 3: System Specifications

Dissolution Vessels: 7 built-in vessel positions

Volume: 500mL to 1000mL, programmable

Heating Time (20-37ºC) Approximately 15-20 minutes, 0.3º C

maximum overshoot

RPM Control Range: 25-300 RPM, digitally controlled, closed loop

Resolution: 0.1 RPM

Accuracy: +/- 0.2 RPM from 50-150 RPM

Display: 0.75” (19mm) high output four-digit LED

Motor: High Torque, Permanent Magnet

Vessel Temperature

Control:

Each individual vessel is continuously

monitored and controlled.

Display Resolution: 0.01º C

Accuracy: +/- 0.25º C

Calibration: Built-in Calibration Probe

Shaft Wobble: Less than 0.010” (0.254mm) TIR

Program Modes: Manual (individual vessel control)

Automatic (30 pre-programmed methods)

External (ProduKey memory device)

Interface Ports: RS-232 (1), RS-485 (2), Parallel Printer

Construction Materials: Cast Aluminum, Stainless Steel, Acid

resistant solid state heating elements,

Engineered Plastics

Dimensions: 27”(W) x 37”(H) x 19”(D) (68.6 x 94.0 x

48.3cm Deep)

Weight: 150 lb. (68kg)

Electrical Power: 115V 50/60Hz 15A or 220V 50/60Hz 8A

(Operating voltage pre-set at factory)

Chapter 1: Introduction

Operation Manual: Model 5100 1-3

Warnings and Notes

Improper servicing or adjustment practice can cause

equipment failure or serious physical injury. This

equipment must be adjusted and serviced by qualified

electrical maintenance personnel who are familiar with

the construction and operation of the equipment and

the hazards involved. Take diligent care during

adjustment. All exposed points on the control circuit

boards are electrically hot with respect to earth ground.

HIGH VOLTAGE IS EXPOSED WHEN THE LOWER REAR

PANEL IS OPENED ON THE 5100. Dangerous voltages

exist on the circuit boards when powered.

Disconnect AC power from the 5100 while

troubleshooting. Be alert. High voltage can cause

serious or fatal injury.

The Model 5100 is supplied with proper heaters and

settings for the specified operating voltage (see label

for information). Do not attempt to convert unit to

another power supply without contacting the factory

first!

Take care when removing or replacing vessel

heaters. Turn off unit and disconnect power from

5100. Do not use metal tools or sharp objects to

mount heater. Heater failure and/or injury could

result.

Heater surfaces may be HOT. Do not touch vessel

heater assemblies, when 5100 is in operation. Injury

may result.

Take proper precautions when handling dissolution

media. Liquid in vessel may be HOT. Wear

protection from splash to avoid exposure to

scalding, acidic, caustic, or pharmaceutical hazards.

Bacteria have been shown to thrive in certain

media, especially at test temperatures.

Improper remote PC control of 5100 may lead to

unexpected motor and/or heater operation. Make

sure personnel are clear before issuing PC

commands.

Chapter 1: Introduction

Operation Manual: Model 5100 1-4

\

To avoid damaging the instrument:

•Do not operate heaters with less than 500ml liquid

in each vessel.

•The stirring element (paddle or basket) must be

immersed into the liquid and rotating when heaters

are operating.

•Use only glass vessels supplied for the model 5100

by Distek.

•Connect this unit to the specified AC supply.

Observe proper grounding.

•Failure to observe these precautions may

damage the heater assemblies and/or vessels.

\

To avoid glass breakage and injury:

♦Do not heat vessels empty.

♦Do not clean with materials that scratch.

♦Do not bump.

♦Discard vessels if cracked, scratched, or heated

empty.

All Distek 5100 heaters have thermostatic protection.

In the event of a malfunction (or if no liquid in vessel),

the heater will cut off at approximately 150ºC.

Thermostat automatically resets after cooling down.

The 5100 incorporates a height sensor to stop rotation

and heating whenever the drive unit is raised well

above operating position. This feature helps to

prevent overheating and addresses safety issues. To

resume rotation and heating, return drive unit to

operating position and press START key.

External cables (excluding power cable) are limited to less

than 3 meters length in order to maintain electromagnetic

compliance.

Some forms of electromagnetic interference may cause

unexpected operation. If this occurs, the unit will return

to normal operation once the interference is removed.

Chapter 2: Installation

Operation Manual: Model 5100 2-1

2Installation

This chapter describes the steps necessary to properly unpack and install the

instrument.

Unpacking ..................................................................................... 2-2

To remove packing....................................................................... 2-2

Leveling: Model 5100 ........................................................................ 2-3

To level unit on bench .................................................................. 2-3

Positioning the Vessels ...................................................................... 2-6

To install vessels in vessel plate....................................................... 2-6

Paddles and Baskets ......................................................................... 2-6

To install paddle blades................................................................. 2-6

To install baskets ........................................................................ 2-6

Checking paddles, baskets and shafts for straightness ............................ 2-8

Checking shaft centering ............................................................... 2-8

Installing the Calibration Probe............................................................ 2-8

To install calibration probe ............................................................ 2-8

Quick Change Height Adjustment Knob................................................... 2-9

To set height of paddle or basket ..................................................... 2-9

Adjusting the Paddle (or Basket) Height ............................................... 2-11

To set height of paddle or basket ................................................... 2-11

Installation Checkout ...................................................................... 2-12

RPM Control ............................................................................. 2-12

Test Duration ........................................................................... 2-12

Temperature Control .................................................................. 2-12

Time and Date .......................................................................... 2-13

Chapter 2: Installation

Operation Manual: Model 5100 2-2

Unpacking

To avoid injury, two people should remove 5100 from carton.

\Do not bump or disturb built-in paddle shafts as this may affect shaft

runout.

\The drive unit is locked in place during shipping.

Please take a few moments when unpacking unit to check for all

items indicated on packing list. Notify DISTEK or your shipper

immediately of any discrepancies or damage to cartons or contents in

transit.

Packing must be removed before operating this instrument.

To remove packing

1. Cut through tape at top of carton. Open four top flaps.

2. Carefully remove packing inserts and lift instrument from shipping carton.

See warning and cautions above.

3. If drive unit is locked in place, tie-wraps are visible from the front of the

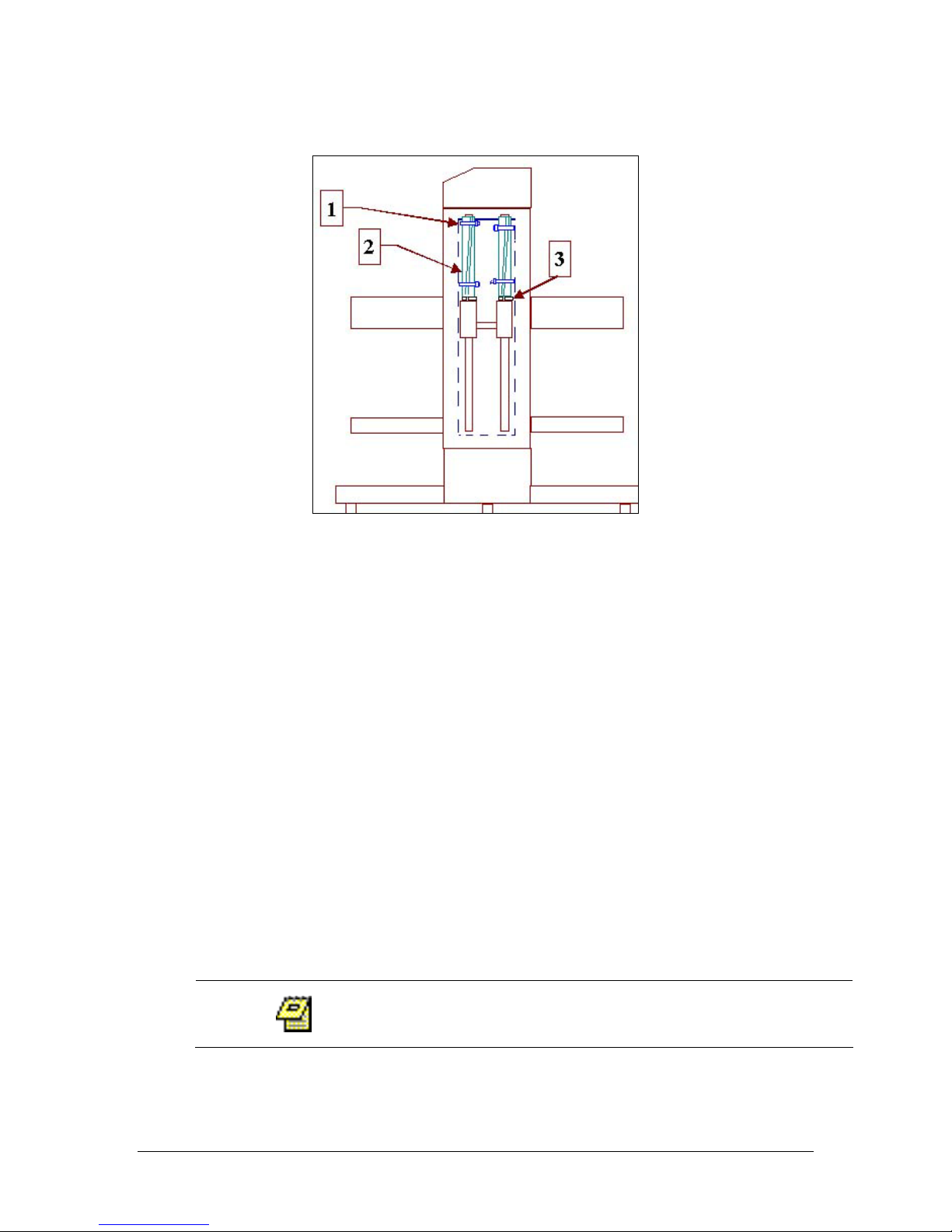

unit, above the bearings (see item 1 below).

4. Identify & cut the tie-wraps on the guide rods above the bearings and

remove split tubing (see item 2 below).

5. Remove split washer (item 3) from top of each bearing.

6. Press brake release key (see Figure 2-3) and gently raise or lower drive unit.

7. Let go of brake release key to set drive unit at desired height.

Chapter 2: Installation

Operation Manual: Model 5100 2-3

Figure 2-1: Rear View – Inside

The power cord is shipped in a separate carton from the main unit. Connect

power cord supplied to 5100 below power switch (see Figure 2-3). Locate

proper outlet for 5100. See Appendix C for electrical power requirements.

Leveling: Model 5100

To level unit on bench

1. Trained personnel should lift unit onto bench and slide it into position.

2. Make certain the two stabilizers under rear of base are not touching bench.

3. Loosen locking nuts on front leveling feet, using the appropriate (1/2”)

wrench.

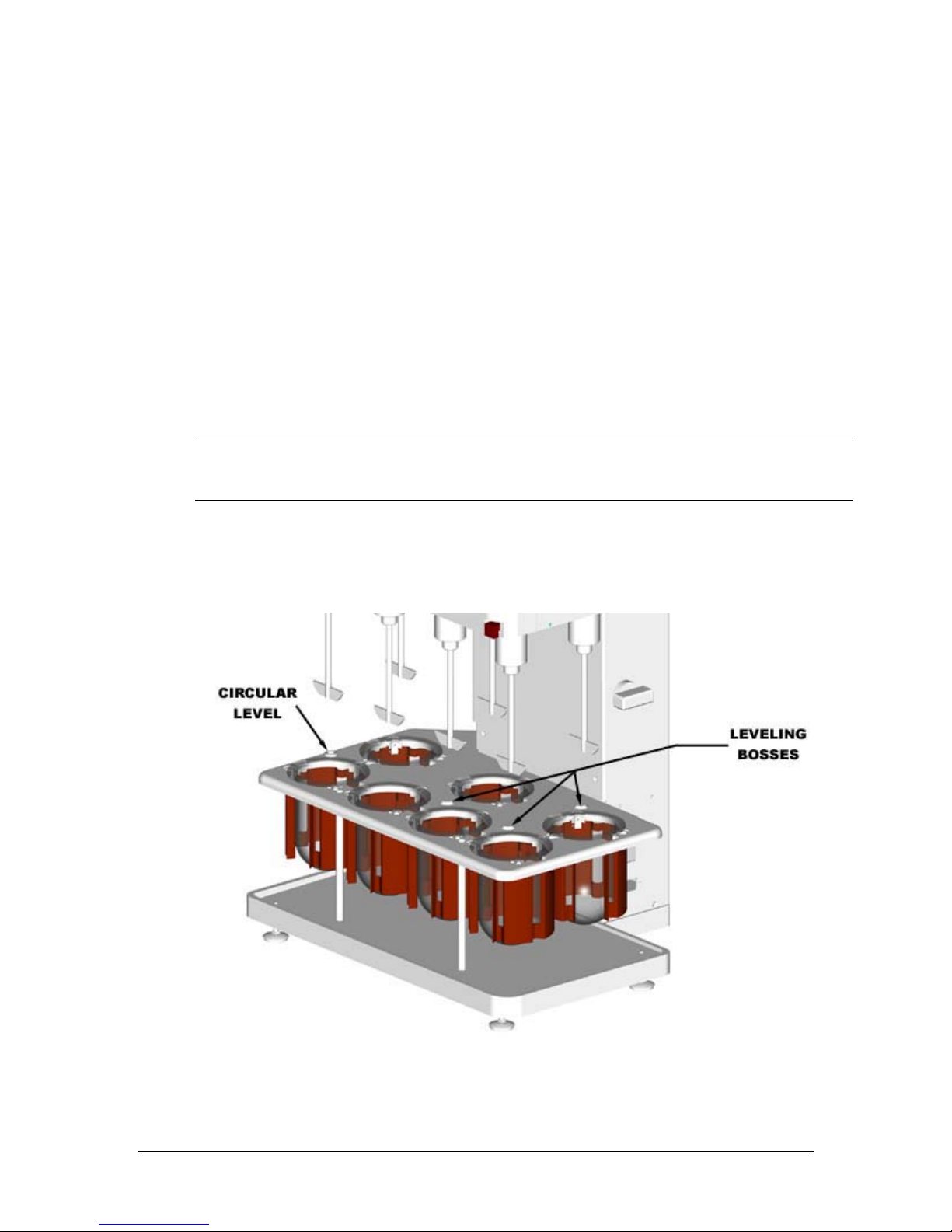

4. Observe permanently mounted circular level on vessel support plate.

5. Level unit from front to back and side to side by adjusting front two leveling

feet under instrument base (see Figure 2-3).

Do not loosen rear leveling foot. Level unit by adjusting front

leveling feet.

Chapter 2: Installation

Operation Manual: Model 5100 2-4

6. Required Action: Tighten locking nut on each foot at this time.

7. After leveling, adjust two stabilizers under rear of instrument base so that

they just touch bench.

8. Mark location of leveling feet on bench, to prevent changes in level due to

moving unit.

9. Check the level after completing installation, or after moving the Model

5100 to a new location. Verify accuracy of built-in circular level by placing

6-9” carpenter’s level on vessel plate leveling bosses (see Figure 2-2).

Check from front to back and side to side.

\

Connect this unit to the specified ac supply. Observe proper

grounding.

10.Plug Model 5100 into proper electrical outlet provided.

Figure 2-2: Leveling Model 5100

Chapter 2: Installation

Operation Manual: Model 5100 2-5

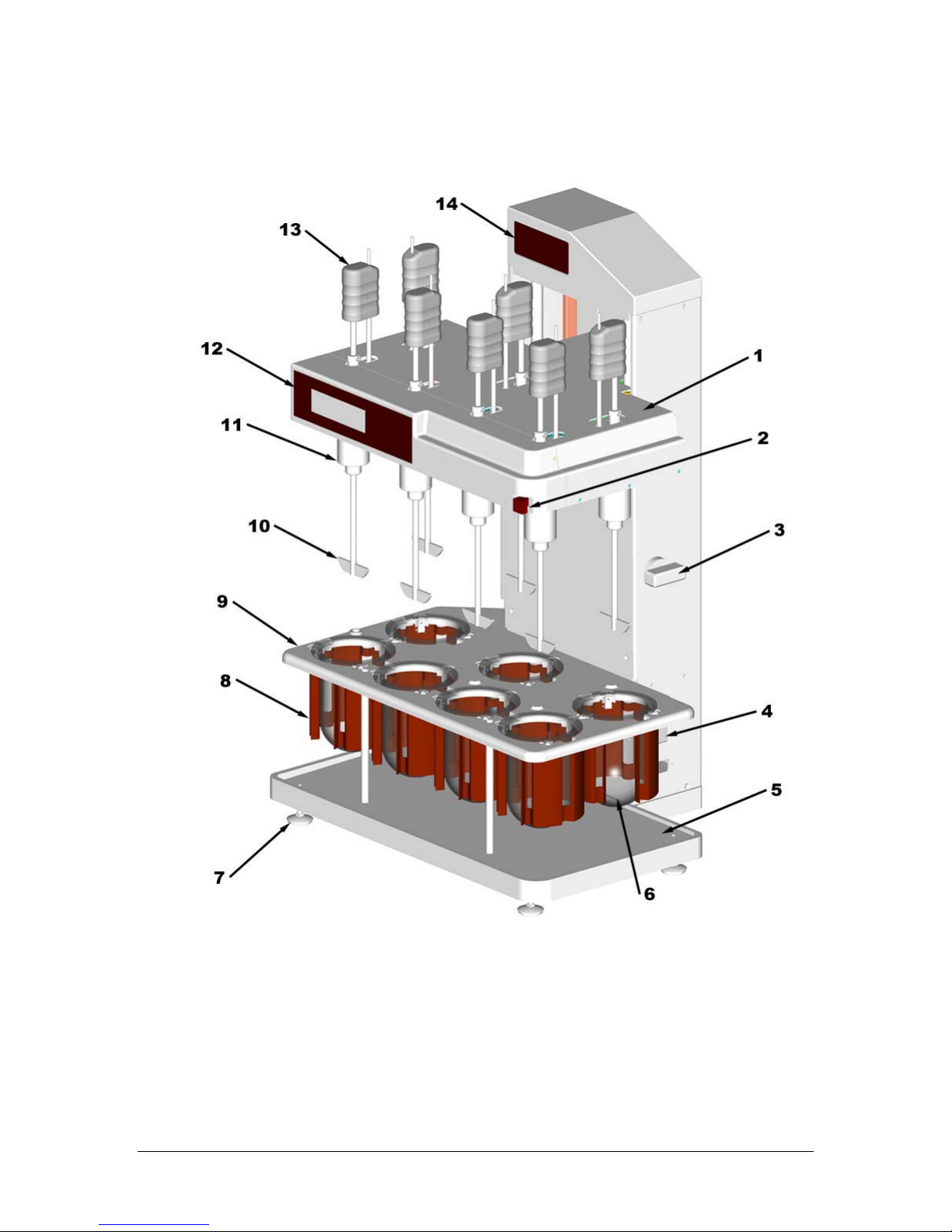

1. Drive Unit 6. Glass Vessel 11. Spindle Assembly

2. Brake Release 7. Leveling Feet 12. Front LCD Display

3. Height Adjustment Knob 8. Heater Assembly 13. Shaft Handle

4. Power Switch 9. Vessel Support Plate 14. Top LED Display

5. Base Plate 10. Paddle Blade

Figure 2-3: Model 5100 Installation

Chapter 2: Installation

Operation Manual: Model 5100 2-6

Positioning the Vessels

To install vessels in vessel plate

1. Raise drive unit.

2. Insert a vessel in each position on vessel plate.

3. Slide vessel through vessel clips until it can go no further.

Top of at least one vessel clip should contact bottom of vessel

flange.

\

DISTEK supplies highly uniform vessels that fit properly into

the 5100 heater assemblies. Use of vessels other than those

supplied by DISTEK for the 5100 may result in unsatisfactory

operation or heater damage and void the warranty.

Paddles and Baskets

To install paddle blades

Carefully screw a paddle blade onto bottom of each shaft. Assemble finger-

tight.

\

Do not grasp basket by mesh screen when installing or

removing. ALWAYS GRASP BASKETS BY KNURLED UPPER RIM.

Proper handling will prevent basket distortion and RESULTING

wobble.

To install baskets

1. Carefully screw a basket adapter onto bottom of each shaft. Assemble

finger-tight (see Figure 2-4).

2. Vessel pre-heat to be performed at 250 RPM with basket adapter only.

Baskets are not installed during pre-heat.

Chapter 2: Installation

Operation Manual: Model 5100 2-7

3. Always place tablet or capsule into a dry, empty basket before test.

4. When vessel stabilizes at test temperature, lift shaft out of vessel.

5. Place basket, open end up, in palm with thumb and fingers grasping knurled

grip (see Caution above.)

6. Raise basket until inside of knurled ring just contacts the O-ring shown in

Figure 2-4.

7. Twist and push basket onto adapter.

8. When removing basket, grasp only on the knurled grip. Pull down and twist.

Upon completion of each test, rinse baskets and shafts

thoroughly with distilled water. DO NOT ALLOW ACIDS

OR BUFFERS TO DRY ON THE METAL SURFACES.

Figure 2-4: Installing Basket on Shaft

\

Handle paddle blades and optional baskets carefully to avoid

bending or damage. Store carefully in original container to

prevent damage.

Table of contents

Other Distek Test Equipment manuals