DitoGear Trinity User manual

1

Welcome

Thank you very much for purchasing DitoGear™ motion

control equipment. We hope that the devices will meet

your expectations bringing a great value to your productions.

We really strive for delivering the best unboxing and

equipment usage experience. If we (or someone else)

failed at some point, just let us know and we’ll do our

best to fix it promptly.

Here’s where to get started.

» ditogear.com/welcome

More resources

Latest user manuals are available at

» ditogear.com/user-manuals

For advanced connection diagrams check

» ditogear.com/charts

In case you need further assistance contact us at

» ditogear.com/support

2

Quick Start Guide

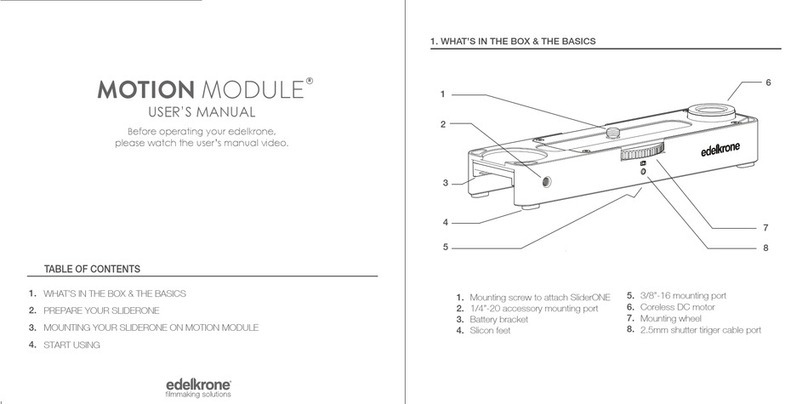

1. Getting to know the TRINITY

1 Base (A)

2 Rotating arm (B)

3 Product plate (C)

4 Slide plate (D)

5 Angle plate (E)+ Side arm (F),

TRINITY

c

d

e+f

b

a

Quick Start Guide

4

3

5

6

2

1

TRINITY

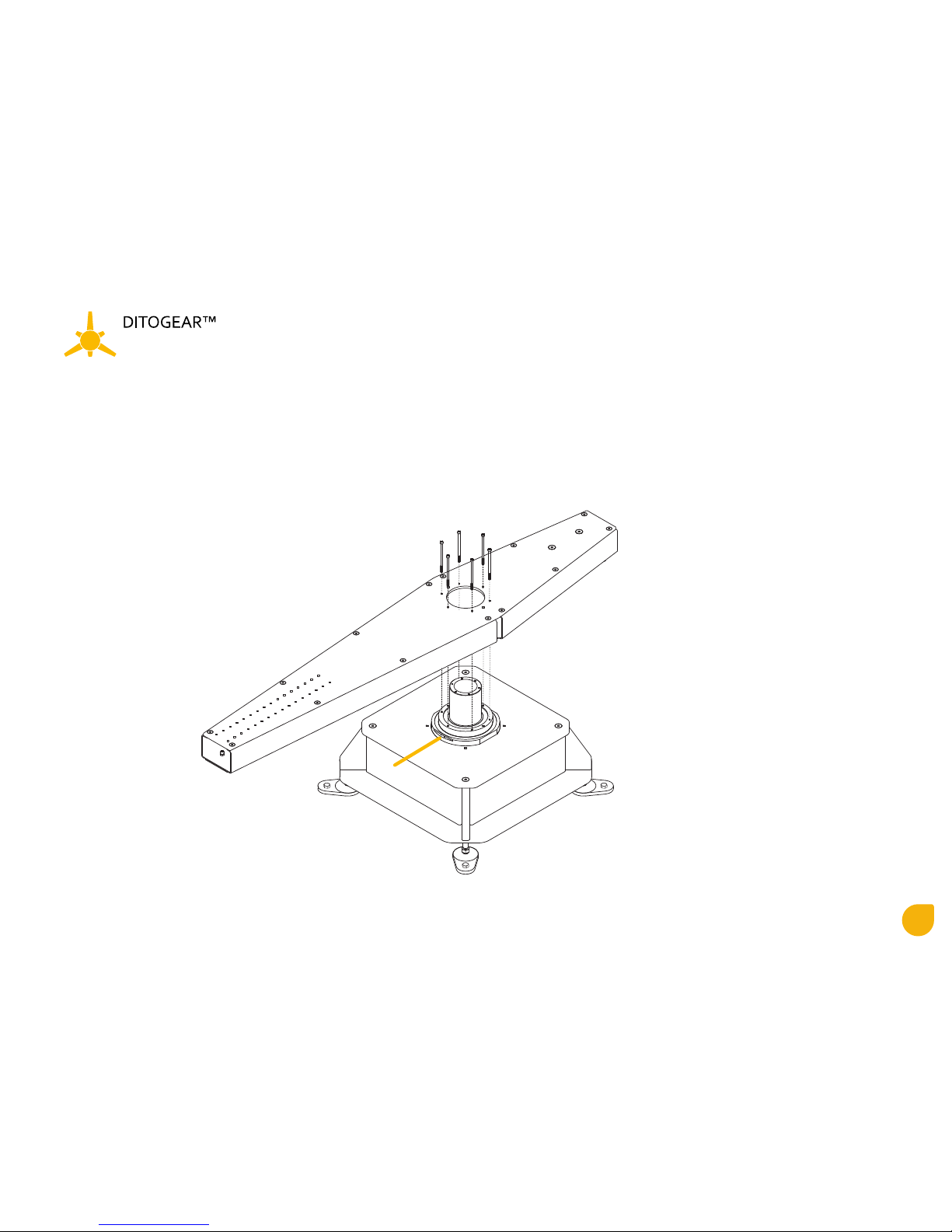

2. Assembly order

1 Base

2 Rotating arm

3 Product plate

4 Slide plate

5 Side arm

6 Angle plate

2. Preparing the work area

1 Make sure that you have at least 175cm diameter

safe work area with a solid concrete floor

2 Prepare 4 holes for M12 screws

Ø

175c

m

61.2cm

3

4

Quick Start Guide

TRINITY

3. Attaching the Base to the floor

1 Put the Base on a firm and concrete floor

2 Use four M12 screws (included) to attach

the Base to the floor

3 Level the Base using four nuts

0° 0°

3

5

Quick Start Guide

TRINITY

4. Attaching the Rotating Arm to the Base

1 Attach Rotating Arm to the Base.

Point A is a 0° starting point of the Rotating Arm

2 Use six M6 (included) screws and a included

thread glue to screw the Rotating Arm to the Base

a

6

Quick Start Guide

TRINITY

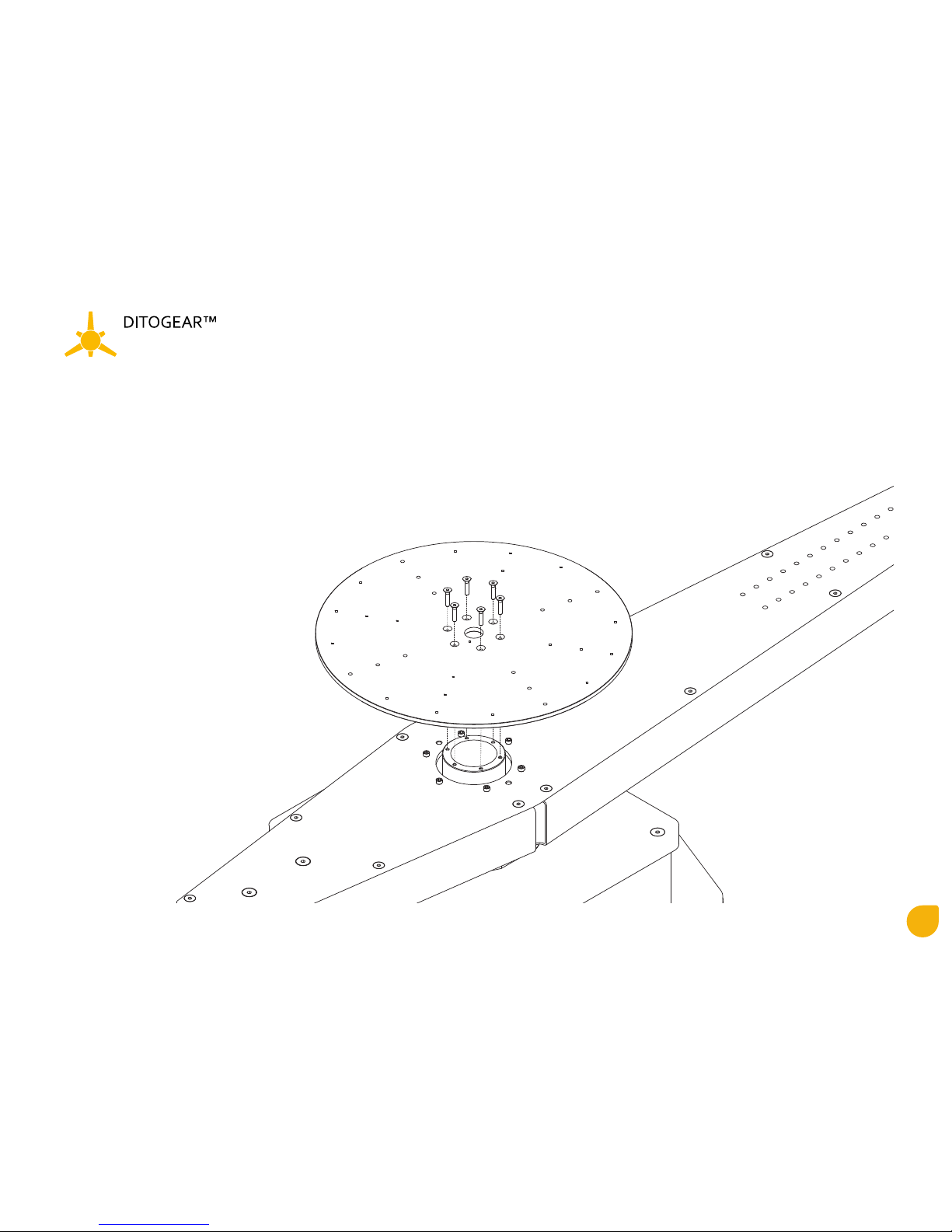

4. Mounting the Product plate

1 Attach Product plate to the Base

2 Use six M6 (included) screws and a included

thread glue to screw the Product plate

to the Base

2

3

1

7

Quick Start Guide

TRINITY

5. Mounting the Slide plate

1 Slide the Slide plate to desire position on the

Rotating Arm

2 Use six M6 (included) screws and a included

thread glue to screw the Slide plate

to the Rotating Arm

3 Tighten the clamping levers

6. Mounting the Side arm

1 Attach the Side arm to the Slide plate on the

desire height

2 Use six M6 (included) screws and a included

thread glue to screw the Side arm to the Slide

plate

8

Quick Start Guide

TRINITY

7. Mounting the Angle plate

1 Attach the Angle plate to the Side arm

2 Use two clamping levers to screw the Angle plate

to the Side arm

8. Using the Angle plate

1 Use lower clamping levers to rotate plate horizontaly

2 Use two side clamping levers to change the angle of the plate,

always use two M6 screws to sustain the angle of the plate.

3 Attach the Camera to the Angle plate using at least two

Camera mounting screws (not included)

1

2

9

Quick Start Guide

TRINITY

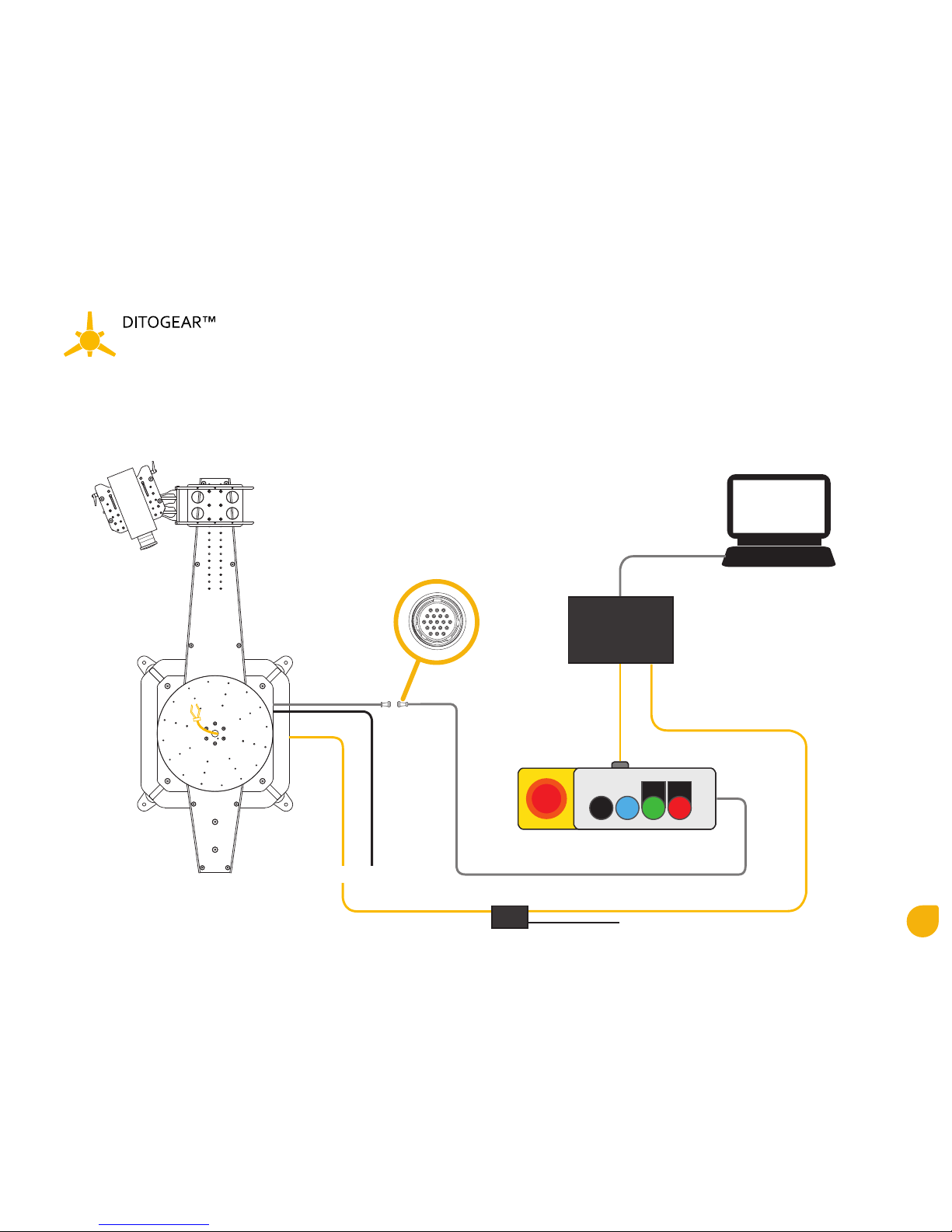

9. Cabling schematic

A - Optional trigger

B - Power input (220v)

C - 19pin data connector

D - Control panel

E - RJ45 cable

F - Speedfire

G - USB cable

H- Laptop/desktop PC

I - Trigger Box

J - Trigger Box

Power input (12v)

A B

C

d

e

F

G

h

i

j

10

Quick Start Guide

TRINITY

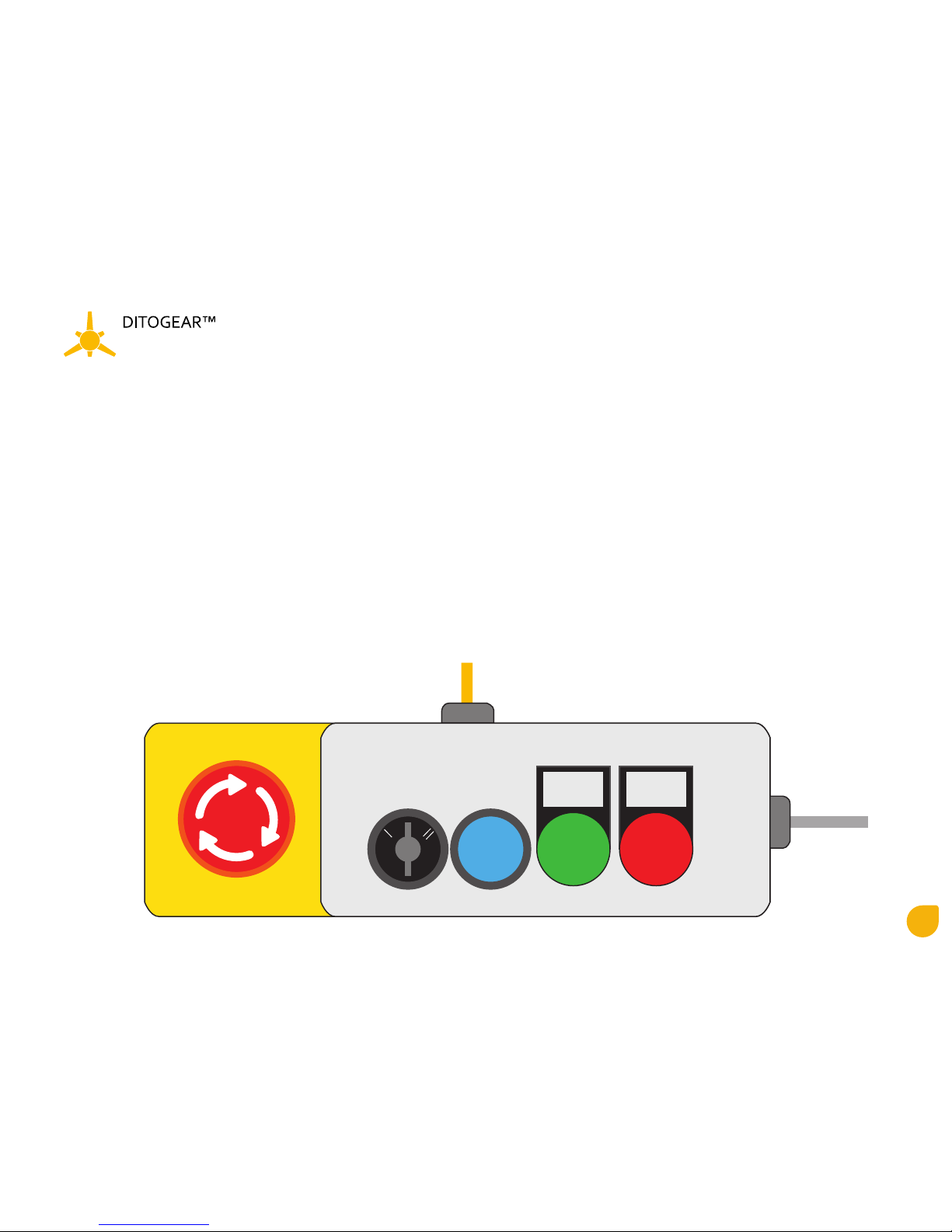

9. Control panel

A - Safety button

- lit up - unit is in operating mode

- in case of an emergency - push the button to cut the power o

(to return to the operating mode, turn the button clockwise)

B - Working mode switch

I - Turned on

0 - Turned o

II - Emergency brake release - to turn the Rotating Arm to the desire position

C - Reset button - to reset the unit after overload

D - Power indicator

E - Alarm indicator (possible overload or other error)

F - 19pin data connector

G - Speedfire cable

R

POWER

0

ALARM

A b c d e

f

g

11

Quick Start Guide

TRINITY

10. Speedfire connectors

Side A

Highspeed RJ45 connectors

AX1 - Trinity

AX2-AX4 - other hispeed units

Triggers RJ45 connectors

AX5 - first group of triggers (contains maximus 3 triggers in series connection)

AX6 - second group of triggers (contains maximus 3 triggers in series connection)

Side B

1 - 12v power input

2 - USB connection to the laptop/desktop PC

A

A

b

b

1

2

12

Quick Start Guide

TRINITY

11. Connecting triggers to the Speedfire via Trigger Box

1. Connect 12v power to power input A. You will hear a beep sound indicating the channel of

this particular unit (1 beep = channel 1, 2 beeps = 2 channel, 3 beeps = channel 3).

To change the channel of the unit, press and hold MODE button F for more than 3 seconds.

Unit have a memory and will remember the channel after plugging the power out.

2. Connect RJ45 cable from SPEEDFIRE unit to (AX5 or AX6) the SIGNAL/BRIDGE connectors

(both sockets are IN/OUT sockets).

3. Connect the trigger to the OUT (mini jack 3.5mm) socket.

4. Now you can adjust the gripper/throttle servo trigger postion with ADJ potentiometer.

Press the MODE button once (1 beep) and adjust the first position of the trigger, confirm

the position by pressing the button again. Now adjust the second position of the trigger

by pressing the button again.

5. Valve triggers don`t have to be adjusted because they are binary (open or closed).

6. If needed connect next trigger box to the SIGNAL/BRIDGE socket with RJ45 cable in serial

connection. One power source (A) works with up to 8 trigger boxes connected to the AX5 or AX6.

A b c

d fe

f

e

d

c

b

A

12345678

A

13

Quick Start Guide

TRINITY

12. SAFETY RULES

1. Prepare a obstacle free working area

at least 1.75m diameter ”safe work area” with any objects and a 6x6m “no entry” area during the operation

2. Always disconnect the power source via Control Panel when you are in safe work area

3. Double check all the screws and loose elements.

4. Be aware that the Rotating Arm is rotating at extreme speeds

and needs a few seconds to stop.

5. Always use safety cables to secure possible elements that can

detach during movement of the Rotating Arm.

6. Ditogear is not liable if and to the extent that

the damage resulted from the misuse of the Ditogear Trinity.

Ø

175c

m

600cm

14

Quick Start Guide

TRINITY

13. Using SPEEDFIRE software on Windows PC

ab

d

c

e

g h i j k l

m n o p r s t u v w x y

f

15

Quick Start Guide

TRINITY

14. Installing SPEEDFIRE software on Windows PC

1. Download latest version of SPEEDFIRE software from Ditogear.com website.

2. There is no need to install the software - it`s a portable, ready to use software.

15. General options - see image at the paragraph 13

A - File

Export to XML - saves parameters and keyframes to the XML file

Import to XML - loads parameters and keyframes from the XML File

B - Tabs

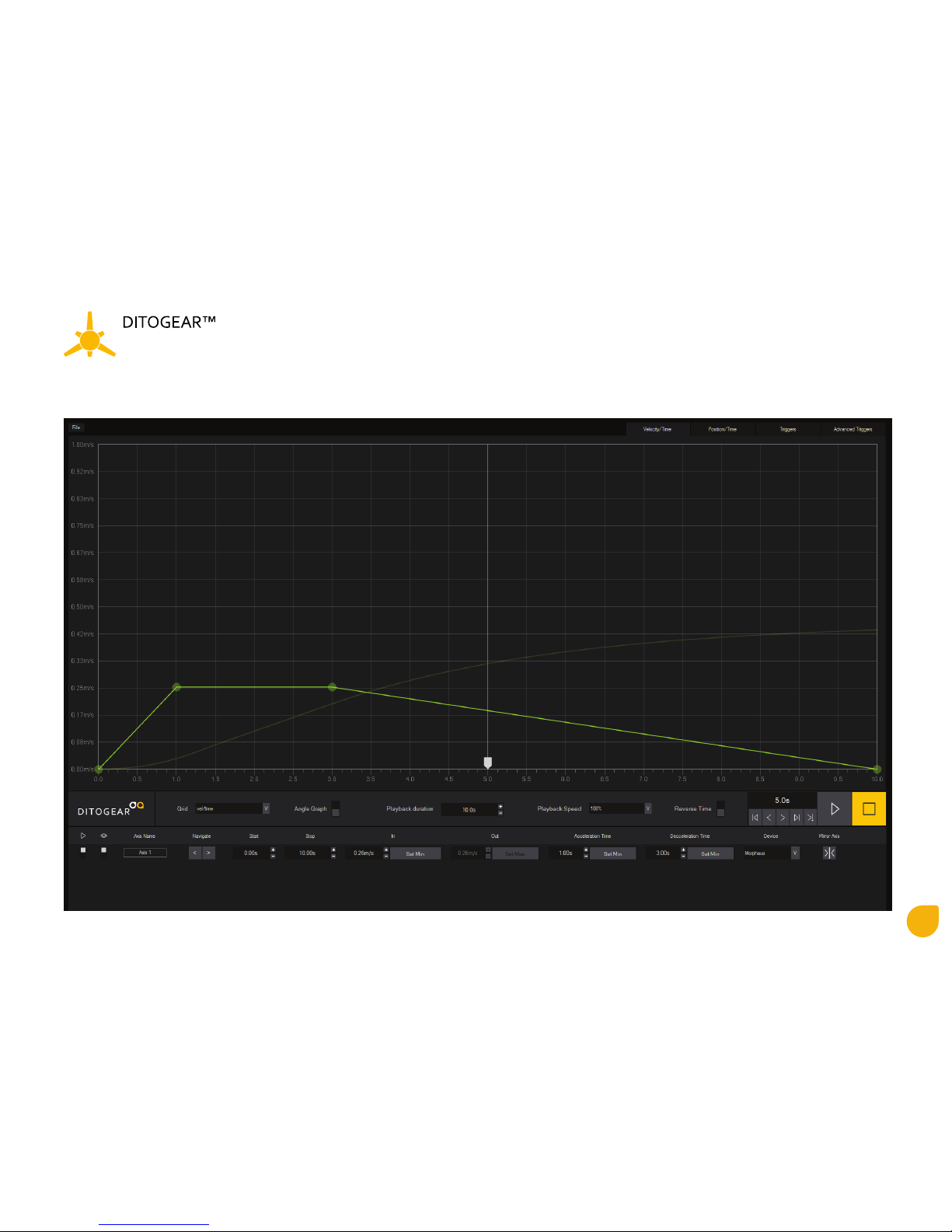

Velocity/Time - Graph with visual representation of the Rotating Arm velocity during Playback time.

Move the keyframes with a mouse or change parameters in P, R, S, U, V, X

Position/Time - Graph with during Playback time.

Triggers - Activates Triggers panel. Change keyframes of maximum 6 channels of triggers.

Advanced Triggers - Activates Tadvanced triggers panel

C - Graph

Visual representation of the Rotating Arm velocity and position during playback time.

Toggle between vel/time // position/time in F.

16

Quick Start Guide

TRINITY

D - Velocity/Time graph.

Each dot represents the keyframe. Vertical graph axis shows the speed of the arm.

Horizontal graph axis shows time.

1 - First keyframe - time when the Arm starts acceleration

2 - Second keyframe - moment when the Rotating Arm reaches operational speed (shown in S)

3 - Line representing Top speed of the rotation - move it up/down to increase/decrease operational speed of the Arm

4 - Third keyframe - time when the Arm starts deceleration

5 - Fourth keyframe - moment whem the Arm stops

1

2 3 4

5

17

Quick Start Guide

TRINITY

E - Position/Time graph.

The line represents change of the Arm position during time. It`s dependent on the keyframes in Velocity/Time changed

in Velocity/Time graph. Vertical axis shows position of the Arm, Horizontal shows time. You can highlight the line in Position/Time tab at

the top right section of the screen (Paragraph 13.B)

In example below playhead (1) is at 2.1s and at this moment tha Arm will be at 90°. To precisely check the angle at the given time

turn on the Angle Graph (Paragraph 13.H)

1

2 3 4

5

1

18

Quick Start Guide

TRINITY

F - Playhead

It indicates the velocity and position of the Arm during playback. Move the Playhead manualy to get precise info about Position and Time using

Angle Graph (Paragraph 13.H).

G - Grid

Changes the Graph axes fromt vel/time to pos/time

H - Angle Graph

Shows the Angle Graph when user is in Velocity/Time // Position/Time tabs.

1 - visual representation of the position of the Arm at given Time

2 - position of the Arm at given Time . “X” is the number of the full 360° turns of the Arm.

3 - visual representation of the number of the full 360° turns of the Arm.

Each ring represents 360°.

4 - Start/End - range of the movement

I - Playback duration

Duration of the timeline. Maximum time where the keyframes can be adjusted.

J - Playback Speed

Changes speed of the movement and all the keyframes. It don`t aect the graph units.

100% - full speed

75% - 1/3 times slower

50% - 2 times slower

25% - 4 times slower

10% - 10 times slower

5% - 20 times slower

1

2

3

4

h

19

Quick Start Guide

TRINITY

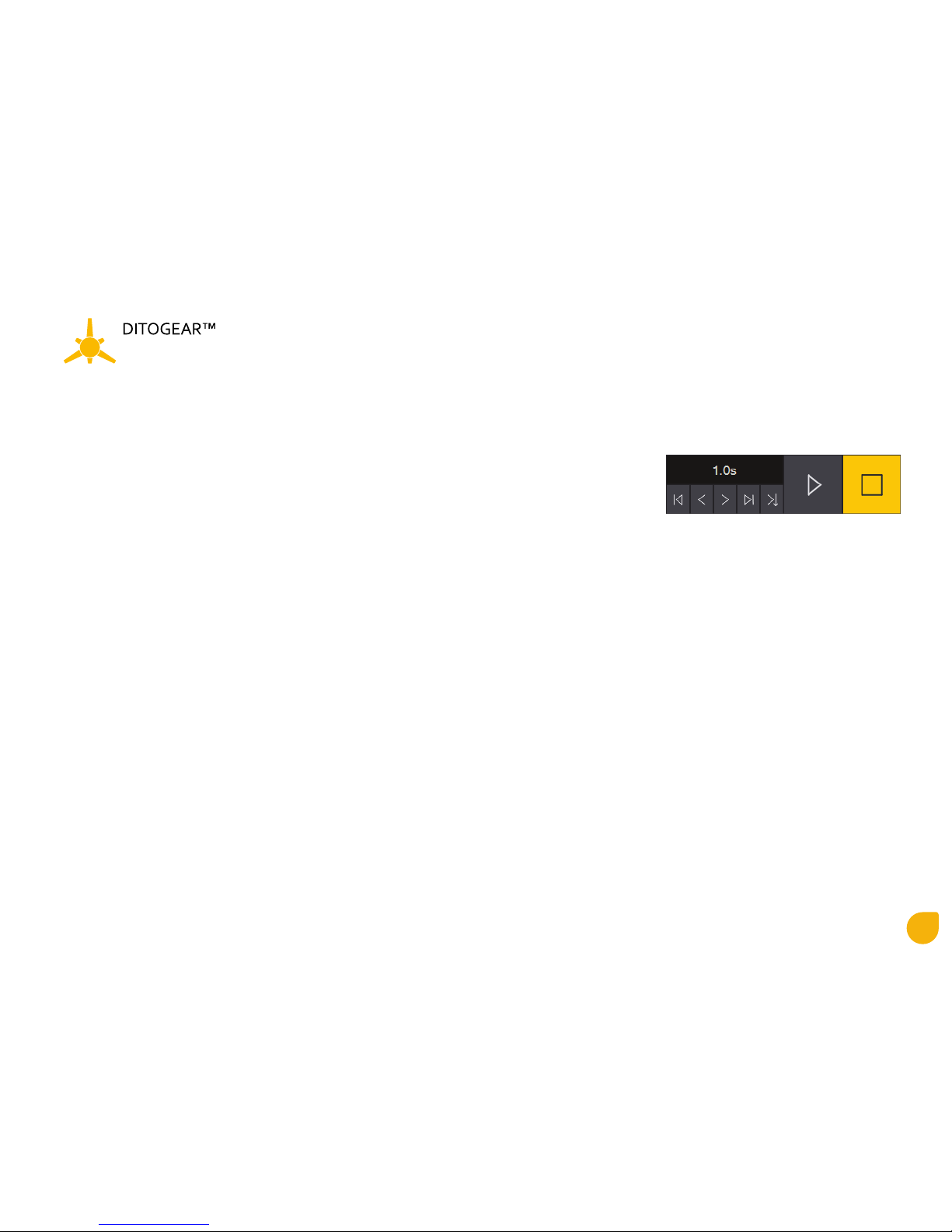

K - Reverse Time

Mirrors the horizontal axis, all keyframes/triggers are played backwards.

L - Control Panel

1 - time indicator / Playhead position

2 - Start playback

3 - Stop playback

4 - Go to Start

5 - Move Playhead 1s backward

6 - Move Playhead 1s forward

7 - Go to End

8 - Move the Rotation Arm to the Playhead position

M - Active/Inactive Axis

N - Show/Hide Axis (even if it is hide position it still works)

O - Axis name (change by clicking on the name)

P - Function in development (inactive)

R - Position of the first keyframe. Start of the acceleration.

T - Position of the top speed line (D). Change the operation speed of the Rotating Arm.

U - Function in development (inactive)

1 2 3

4 5 6 7 8

20

Quick Start Guide

TRINITY

V - Acceleration Time

Ratio between the first and the second frame. Time of the acceleration.

W - Deceleration Time

Position of the third frame. Moment when the Arm start decelerating.

X - Type of device connected to the Speedfire

Morpheus/Trinity

Y - Mirror Axis

Changes the direction of the rotation from the clockwise to counterclockwise

16. Position/Time Tab (Paragraph 15.B)

Highlights the Position/Time line on the graph.

Table of contents