djm direct DJMSS406 User manual

Scroll Saw

Item No.:DJMSS406

SCROLL SAW

Original Operating Manual

1

1.Introduction

MANUFACTURER:

DJM Direct.com

Unit 43 Churchill Way,

Lomeshaye Industrial Estate,

Nelson, Lancashire BB9 6RT UK

DEAR CUSTOMER

We hope your new tool brings you much enjoyment

and success.

NOTE:

According to the applicable product liability laws, the

manufacturer of the device does not assume liability

for damages to the product or damages caused by the

product that occurs due to:

●Improper handling,

●Non-compliance of the operating instructions,

●Repairs by third parties, not by authorized service

technicians,

●Installation and replacement of non-original spare

parts, .

●Application other than specified,

WE RECOMMEND:

Read through the complete text in the operating

instructions before installing and commissioning the

device. The operating instructions are intended to help

the user to become familiar with the machine and take

advantage of its application possibilities in accordance

with the recommendations. The operating instructions

contain important information on how to operate the

machine safely, professionally and economically, how

to avoid danger, costly repairs, reduce downtimes

and how to increase reliability and service life of the

machine.

In addition to the safety regulations in the operating

instructions, you have to meet the applicable

regulations that apply for the operation of the machine

in your country. Keep the operating instructions

package with the machine at all times and store it in a

plastic cover to protect it from dirt and moisture. Read

the instruction manual each time before operating

the machine and carefully follow its information. The

machine can only be operated by persons who are

instructed concerning the operation of the machine

and who are informed about the associated dangers.

The minimum age requirement must be complied

with. In addition to the safety requirements in these

operating instructions and your country’s applicable

regulations, you should observe the generally

recognized technical rules concerning the operation of

woodworking machines.

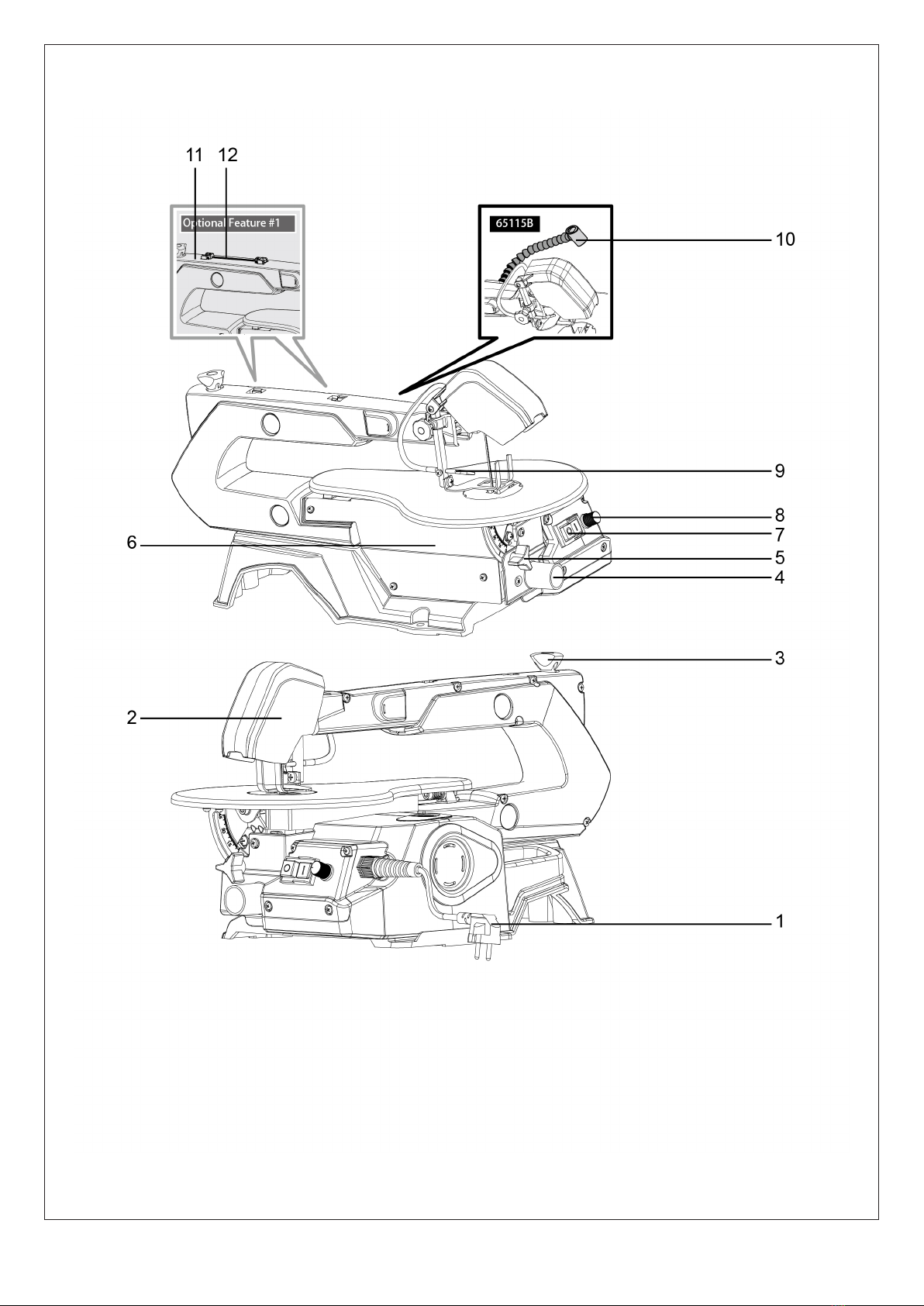

2.Device Description

1. Power Cord & Plug

2. Blade Guard

3. Clamping Screw

4. Suction Adapter

5. Star Button

6. Angle scale

7. ON/OFF switch

8. Speed Switch

9. Air Nozzle

10. Adjustable Hose Lamp

11. Saw-blade Adapter (Optional Feature #1)

12. Flat Saw-blade (Optional Feature #1)

2

3

3. Unpacking

●Open the packaging and remove the device carefully.

●Remove the packaging material as well as the

packaging and transport bracing (if available).

●Check if the delivery is complete.

●Check the device and accessory parts for transport

damage.

●If possible, store the packaging until the warranty

period has expired.

ATTENTION

The device and packaging materials are not toys!

Children must not be allowed to play with plastic

bags, film and small parts! There is a risk of

swallowing and suffocation!

4. Safety

a) General Safety Rules

Understand your Machine

Read this manual and labels affixed to the machine to

understand its limitations and potential hazards.

Be thoroughly familiar with the controls and their

proper operation. Know how to stop the machine and

disengage the controls quickly.

Do not attempt to operate the machine until you fully

understand how to properly operate and maintain

the engine and how to avoid accidental injuries and/or

property damage.

If the unit is to be used by someone other than original

purchaser or loaned, rented, or sold, always provide

this manual and any needed safety training before

operation. The user can prevent and is responsible for

accidents or injuries that may occur to themselves,

other people, and property.

Do not force the machine. Use the correct machine for

your application. The correct machine will do the job

more efficiently and safer at the rate it was designed.

Personal Safety

Do not permit children to operate this machine at any

time.

Keep children, pets, and other people not using the

unit away from the work area. Be alert and shut off

unit if anyone enters work area. Keep children under

the watchful care of a responsible adult.

Do not operate the machine while under the influence

of drugs, alcohol, or any medication that could affect

your ability to use it properly.

Dress properly. Wear heavy long pants, boots, and

gloves. Do not wear loose clothing, short pants, or

jewelry of any kind. Secure long hair so it is above

shoulder level. Keep your hair, clothing, and gloves

away from moving parts. Loose clothes, jewelry, or

long hair can be caught in moving parts.

safety glasses with side shields when operating.

Protect eyes, face, and head from objects that may be

thrown from the unit. Always wear safety goggles or

safety glasses with side shields when operating.

Wear appropriate hearing protection. Wear respiratory

protection to avoid the risk of inhaling harmful dust.

Always keep hands and feet away from all moving

parts during operation. Moving parts can cut or crush

body parts.

Always keep hands and feet away from all pinch

points.

Do not touch parts that might be hot from operation.

Allow parts to cool before attempting to maintain,

adjust, or service.

Stay alert, watch what you are doing, and use common

sense when operating the machine.

Do not overreach. Do not operate the machine

while barefoot or when wearing sandals or similar

lightweight footwear. Wear protective footwear that

will protect your feet and improve your footing on

slippery surfaces. Keep proper footing and balance at

all times. This enables better control of the machine in

unexpected situations.

Inspect your Machine

Check your machine before starting it. Keep guards in

place and in working order. Make sure all nuts, bolts,

etc., are securely tightened.

Never operate the machine when it is in need of

repair or is in poor mechanical condition. Replace

damaged, missing, or failed parts before using it.

Keep the machine in safe working condition. Regularly

check to see that keys and adjusting wrenches are

removed from the machine area before starting it. A

wrench or a key that is left attached to a rotating part

of the machine may result in personal injury. Avoid

accidental starting. Be sure the motor switch is off

before transporting the machine or performing any

maintenance or service on the unit.

Transporting or performing maintenance or service on

a machine with its switch on invites accidents. If the

machine should start to vibrate abnormally, stop the

motor and check immediately for the cause. Vibration

is generally a warning sign of trouble.

Electric Safety

Protect yourself from electric shock. Do not plug or

unplug the motor while standing in or around damp

or wet ground. Do not use the unit in wet or damp

areas or expose it to rain. Prevent body contact with

grounded surfaces: pipes, radiators, ranges, and

refrigerator enclosures. Make sure your fingers do

not touch the plug’s metal prongs when plugging or

unplugging the unit.

Avoid inadvertent starting. Make sure that the switch

is switched off when plugging the plug into an outlet.

Only use approved and appropriately identified

extension cables for use outdoors. Only use cable reels

in the unrolled state.

4

Do not use the cable for purposes for which it is not

intended. Do not use the cable to pull the plug out of

the outlet. Protect the cable from heat, oil and sharp

edges.

Have your electric tool repaired by a qualified

electrician. This electric tool conforms to the

applicable safety regulations. Repairs may only be

performed by an electrician using original spare parts.

Otherwise accidents can occur.

Work Area & Store Area

Keep the work area orderly. Disorder in the work area

can lead to accidents.

Take environmental influences into account. Do not

expose electric tools to rain. Do not use electric tools

in a damp or wet environment. Make sure that the

work area is well-illuminated. Do not use electric tools

where there is a risk of fire or explosion.

Securely store unused electric tools. Unused electric

tools should be stored in a dry, elevated or closed

location out of the reach of children.

b) Specific Safety Rules

Intended Use

The contents of the instructions must cover not only

the intended use of the machinery but also take into

account any reasonably foreseeable misuse thereof.

Safety Precautions

Connect the dust extraction device. If connections for

dust extraction and a collecting device are present,

make sure that they are connected and used properly.

Operation in enclosed areas is only permitted with a

suitable extraction system.

Additional Safety Rules for Scroll Saws

• This scroll saw is intended for use in dry conditions,

and for indoor use only.

• Do not cut pieces of material too small to hold by

hand outside the blade guard.

• Avoid awkward hand positions where a sudden slip

could cause a hand to move into the blade.

• Always use the blade guard to avoid possible injury

due to blade breakage.

• Never leave the scroll saw work area with the

power, or before the machine has come to a complete

stop.

• Do not perform layout, assembly or set up work on

the table while the cutting tool is in operation.

• Never turn your scroll saw on before clearing the

table of all objects: (tools, scraps of wood, etc) except

for the workpiece and related feed or support devices

for the operation planned.

• Take care of your tools. Keep cutting tools sharp

and clean in order to be able to work better and more

safely. Follow the instructions for lubrication and

for tool replacement. Check the connection cable of

the electric tool regularly and have it replaced by a

recognized specialist when damaged. Check extension

cables regularly and replace them when damaged.

Keep the handle dry, clean and free of oil and grease.

Residual Risks

Despite proper use, additional residual risks cannot

be completely ruled out. The following risks may arise

due to the nature of the Scroll Saw:

Mechanical hazards related to:

Machine parts or workpieces:

• Shape

• Relative location

• Mass and velocity (kinetic energy of elements in

controlled or uncontrolled motion)

• Mechanical strength

• Crushing hazard

• Cutting or severing hazard

• Entanglement hazard

• Drawing-in or trapping hazard

Electrical hazards due to:

• Contact of persons with live parts (direct contact)

• Contact of persons with parts which have become

live under faulty conditions (indirect contact)

• Electrostatic phenomena

Hazards generated by noise, resulting in:

• Hearing loss (deafness), other physiological

disorders (loss of balance, loss of awareness)

• Interference with speech communication, acoustic

signals.

Hazards generated by materials and substances (and

their constituent elements)

processed or used by the machinery

• Hazards from contact with or inhalation of harmful

fluids and dusts

• Fire hazard

Hazards generated by neglecting ergonomic principles

in machinery design related to:

• Unhealthy postures or excessive effort

• Hand-arm or foot-leg anatomy

• Local lighting

• Mental overload and underload, stress

• Human error, human behaviour

• Design, location or identifiation of manual controls

Combination of hazards

Unexpected start up, unexpected overrun/ overspeed

(or any similar malfunction) from:

• Failure/disorder of the control system

• External influences on electrical equipment

• Errors made by the operator (due to mismatch of

machinery with human

characteristics and abilities)

5

• Impossibility of stopping the machine in the best

possible conditions

• Variations in the rotational speed of tools

• Failure of the power supply

• Failure of the control circuit

• Errors of fitting

• Break-up during operation

• Falling or ejected objects or fluids

• Loss of stability / overturning of machinery

5. Technical Data

Technical Data

Specifications:

Mains Voltage : 240V/50Hz

Power : 120W

Throat Capacity : 406 mm

Max. Cutting Height : 50 mm @ 90°

20 mm @ 45°

Stroke : 19 mm

Stroke Speed : 400-1650 rpm

Blade Length : 127 mm

Table Size : 255×415mm

Table Tilt : 0° - 45°

6. Contents Supplied

The scroll saw comes partially assembled and is

shipped in carefully packed carton. After all the

parts have been removed from the carton, you

should have:

1. Main Machine

2. Blade guard

3. Saw-blade Adapter (Optional Feature #1)

4. Allen Wrench (Optional Feature #1)

5. Flat Saw-blade (Optional Feature #1)

6. Operator’s Manual

7. Hardware Bag

Blade Guard Assembly

Install the blade guard to the holder. Secure the

screw with a nut and two washers.

6

9. Machine Use and Care

-Do not use low-output electric tools for heavy work.

Do not use the electric tool for purposes for which it

is not intended. For example, do not use hand-held

circular saws for the cutting of branches or logs. Do

not use the electric tool to cut firewood.

-When the saw blade is blocked due to abnormal

feed force during cutting, turn the machine off and

disconnect it from power supply. Remove the work

piece and ensure that the saw blade runs free. Turn

the machine on and start new cutting operation with

reduced feed force.

-Do not remove any cutting residues or other parts of

workpieces from the cutting zone while the machine is

running and the saw unit is not at rest.

Never remove loose splinters, chips or jammed pieces

of wood while the saw blade is running.Switch off the

machine to troubleshoot or remove jammed pieces of

wood.

-Refitting, including adjusting and measuring works,

and cleaning must be carried out only when the motor

is switched off. - Disconnect the main power plug -

Before switching on again, ensure that keys and

adjustment tools have been removed.

-Take care of your tools. Keep cutting tools sharp and

clean in order to be able to work better and more

safely. Follow the instructions for lubrication and for

tool replacement.

-Check the connection cable of the electric tool

regularly and have it replaced by a recognized

specialist when damaged. Check extension cables

regularly and replace them when damaged. Keep the

handle dry, clean and free of oil and grease.

-Check the electric tool for potential damage.

Protective devices and other parts must be carefully

inspected to ensure that they are faultfree and

function as intended prior to continued use of

the electric tool. Check wether the moving parts

function faultlessly and do not jam or whether

parts are damaged. alll parts must be correctly

mounted and all conditions must be fulfilled to

ensure faultfreeoperation of the electric tool. The

moving protective hood may not be fixed in the open

position. Damaged protective devices and parts must

be properly repaired or replaced by a recognised

workshop, insofar as nothing different is specified

in the operating manual. Damaged switches must

be replaced at a customer service workshop. Do not

use any faulty or damaged connection cables. Do not

use any electric tool on which the switch can not be

switched on and off.

7. Introduction

Your new Scroll saw will more than satisfy your

expectations. It has been manufactured under

stringent quality standards to meet superior

performance criteria. You will find it easy and safe to

operate, and with proper care, it will give you many

years of dependable service.

High performance and powerful variable speed

scroll saw. Suitable for precise or intricate cuts in

wood, plastic, metal, plexiglass and plaster.

8. Application Conditions

This scroll saw is designed for operating under

ambient temperatures between +5°C and 40°C

and for installation at altitudes no more than

1000m above M.S.L. The surrounding humidity

should less than 50% at 40°C. It

* S2, Short-time duty. After continuous operation

of 10 minutes the drill stops until the device tem-

perature deviates by less than 2 K (2°C) from the

room temperature.

* The noise was measured according to clause

13.2 of EN 61029-1:2009+A11

Carefully read through this entire

operator’s manual before using your

new Scroll saw. Take special care to

heed the cautions and warnings.

Sound pressure

level (LPA)

Sound power level

(LwA)

78.1 db(A)* k=3 db(A)

88.6 db(A)* k=3 db(A)

7

10. Operation

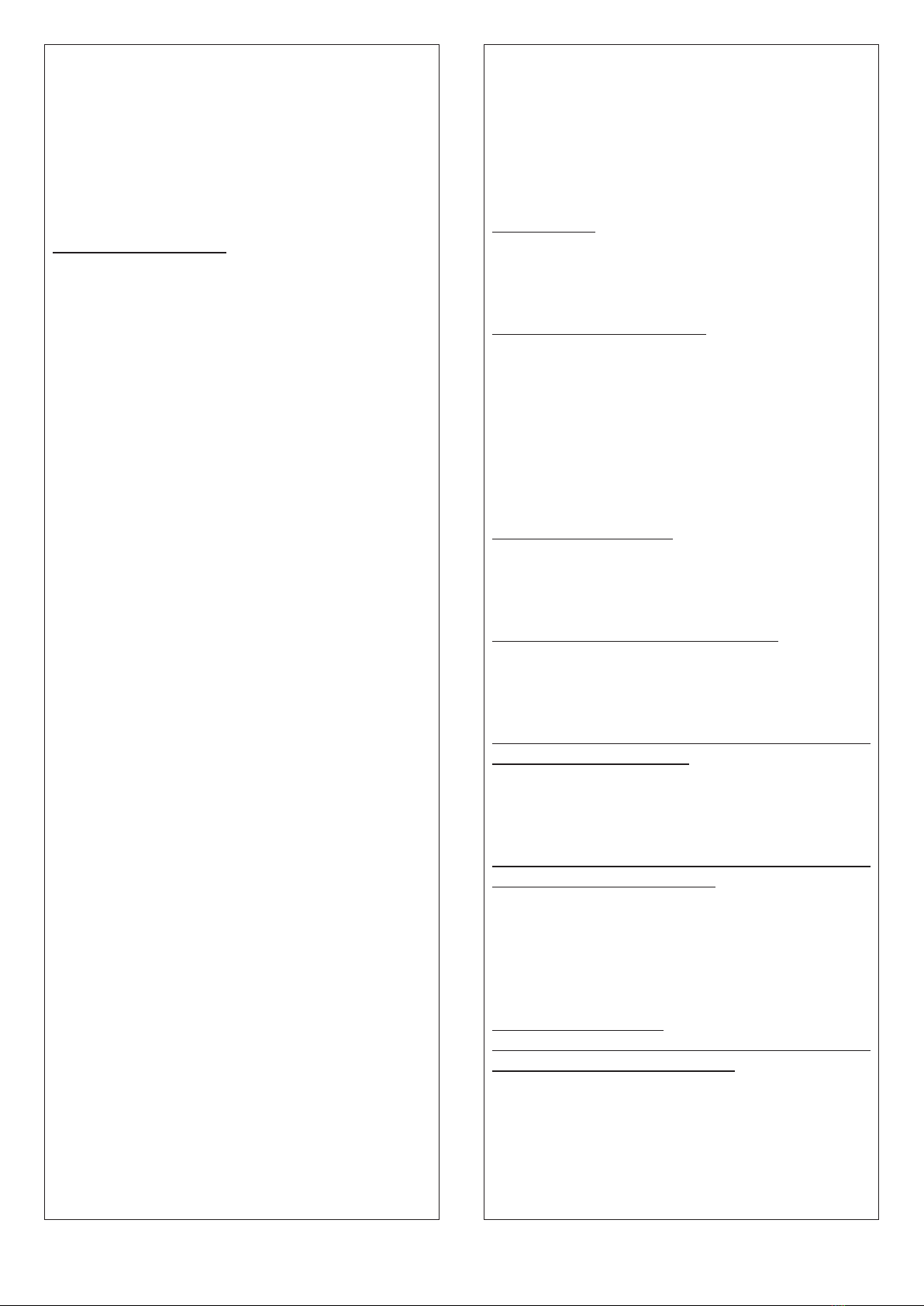

Mounting the machine on a work bench

A workbench made from solid wood is better than

one made of plywood, as interfering vibrations

and noise are more noticeable with plywood.

The necessary tools and small parts for assembling

the saw on a workbench are not supplied with

the saw. However, use equipment of at least the

following:

1. Machine

2. Bolt M8 (×3)

3. Flat Washer Ø8 (×3)

4. Rubber Pad

5. Work Table

6. Big Flat Washer Ø8 (×3)

7. Lock Washer Ø8 (×3)

8. Nut M8 (×3)

First of all, drill holes into the seating surface

and then Insert the screws.

A foam rubber base for reduction of noise is

not supplied with the saw either. However, we

expressly recommend that you use such a base to

keep vibration and noise to a minimum. Ideal size

400 × 240 mm.

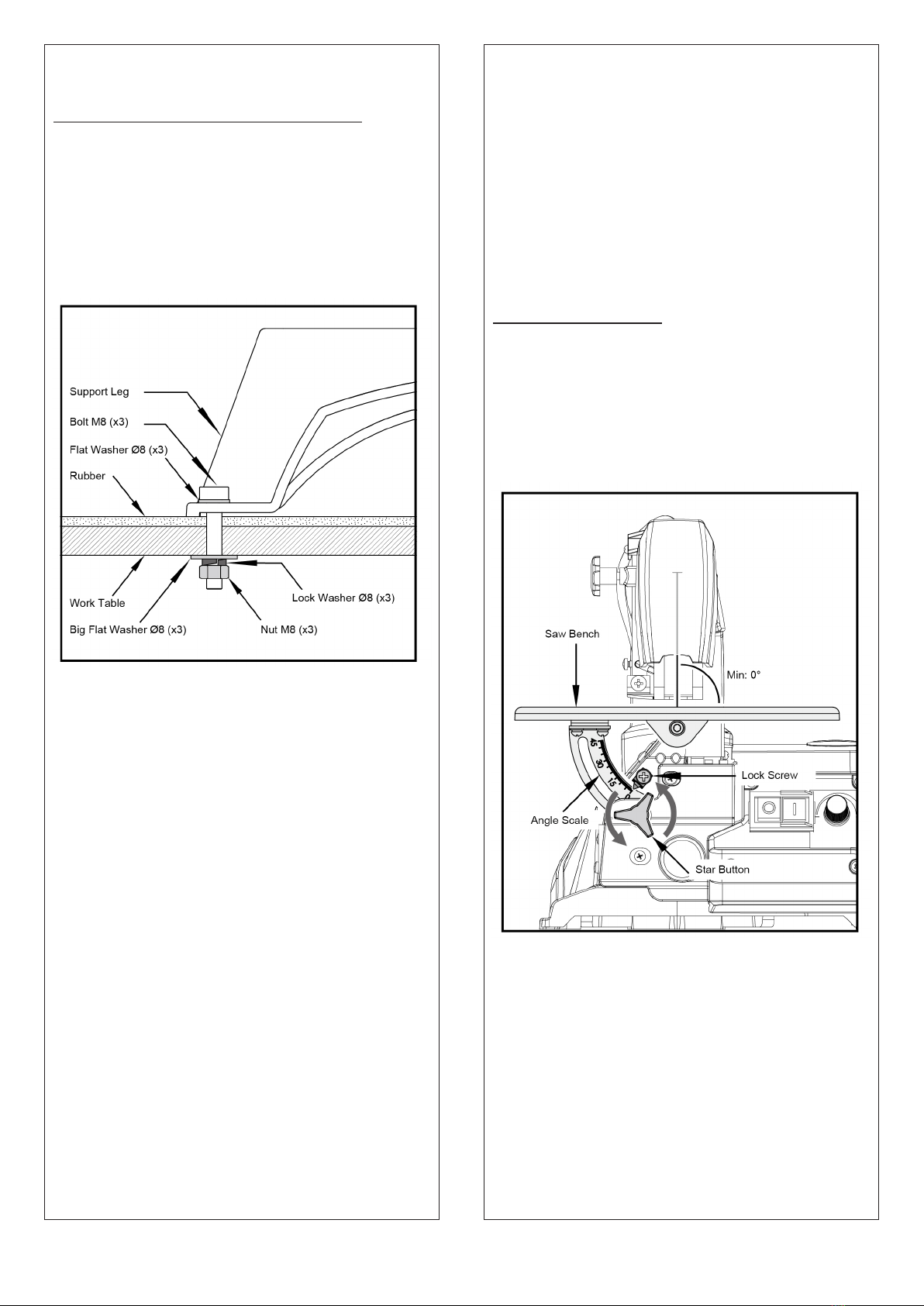

11. Setting the Saw Bench

• Release the star button and bring the saw

bench to a right angle in relation to the saw blade.

Use a 90° angle L-square measure the right angle

between the blade and the bench. The saw blade

be at 90° to the angle.

• Close the star button when the distance

between the blade and the 90° angle is at a

minimum. The bench should then be at 90° to the

saw blade.

Setting the angle scale

• Release the lock screw and bring the indicator

to the zero position. Fasten the screw.

Please note: the angle scale is a useful piece of

supplementary equipment, but should not be

used for precision work. Use scrap wood for saw

tests, adjust the bench if necessary.

Horizontal Saw Bench and Diagonal Cuts

The saw bench can be positioned into a 45°

diagonal position or be left in the horizontal

position.

You can read off the approximate slope angle

by using the angle scale located under the work

bench. For more exact adjustment, use scrap

wood for some saw tests; adjust the bench if

necessary.

8

A scroll saw is fundamentally a “curve cutting

tool“ but which can also carry out straight and

angled edge cuts. Familiarise yourself with the

following important points prior to commissioning

the saw.

• The saw does not automatically cut wood.

You must feed the wood against the saw blade

manually.

• The cutting process occurs only while the blade

is moving downwards.

• Feed the wood slowly against the saw blade as

the saw blade teeth are small and cut only while

moving downwards.

• All persons carrying out work with the saw

require training. The saw blade may break easily

during this training time while the operator is still

unfamiliar with the saw.

• The saw is best suited for sheets of wood less

than 2.5 cm thick.

• Feed the wood especially slowly against the

blade and avoid abrupt curves to prevent the

saw blade from breaking, if you wish to cut wood

sheets thicker than 2.5 cm.

• Saw blade teeth becomes blunt over time, saw

blades must be replaced. The saw blades are

sufficient for 1/2 to 2 operating time depending

upon the type of wood.

• Try and make sure that the saw blade follows

the grain of the wood in order to obtain a clean

cut.

• The saw speed must be reduced to minimum

when cutting precious and non-terrous metals.

12. Inside Cuts

This saw is suited also to inside cuts cut not

starting at the edge of the work piece. Proceed

as follows:

• Drill a 6 mm hole in the work piece.

• Loosen the clamping screw (blade tensioner)

and release the tension in the blade.

• Place the bore hole over the saw blade slot in

the work bench.

• Install the saw blade through the hole in the

work piece and through the work blade slot, and

fasten the blade to the holders.

• When you have completed the inside cut,

remove the saw blade and then remove the work

piece from the bench.

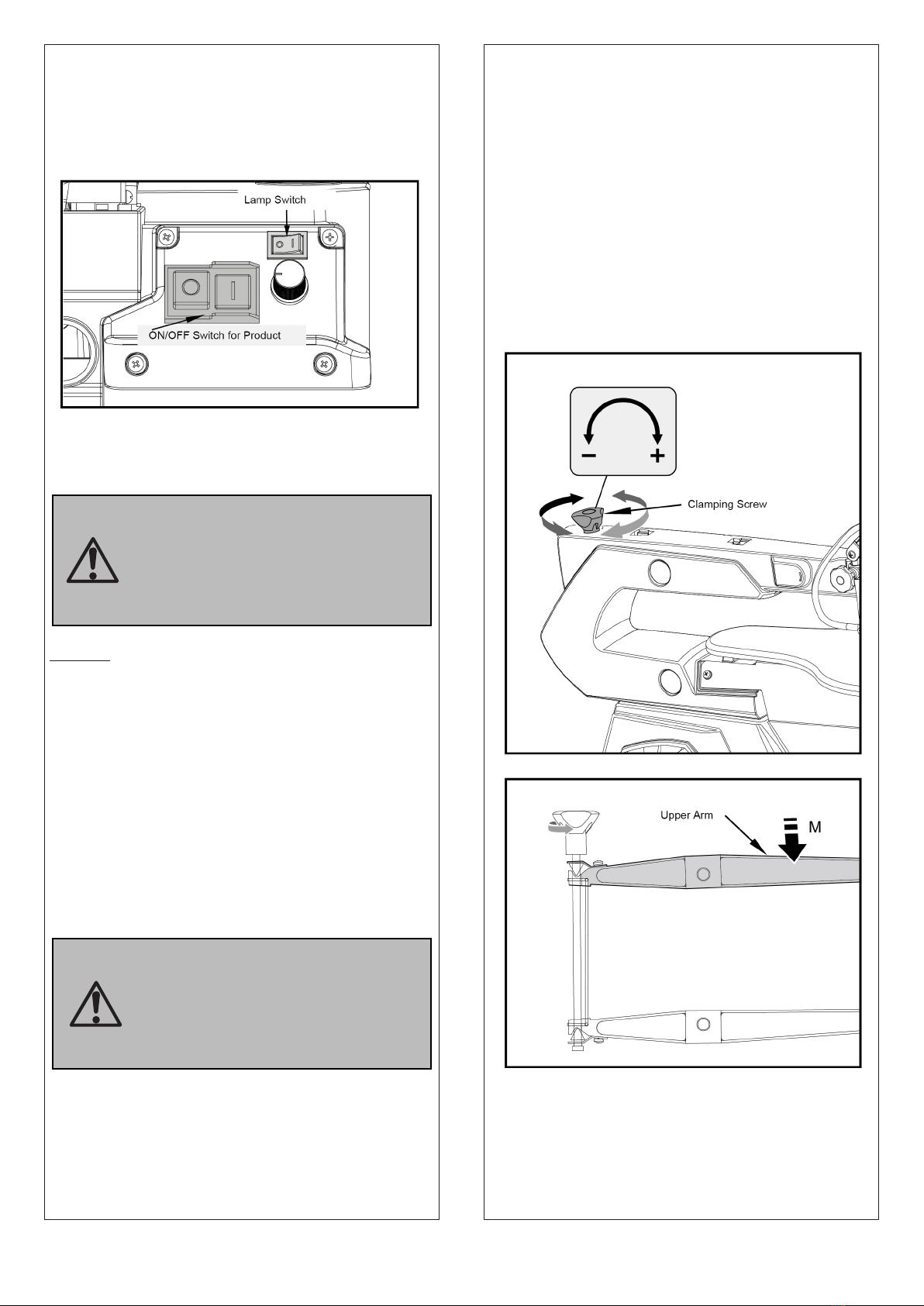

Continuous Operation

It is possible to switch the saw on by pressing the

green "I" button for continuous operation.

In order to switch the saw off, it is necessary to

press the red "0" button.

With the continuously variable electronic speed

control, the cutting speed can be increased by

turning to the right or reduced by turning to the

left.

Warning: Switch off the saw andremove

the mains supply plug before doing

inside cuts in order to avoid injuries

caused by unintentional activation of

the saw.

Lighting System (For #65115B)

Press "I" to turn on the lamp.

Press "O" to turn off the lamp

This light switch can only work when the ON/

OFF switch for the product is turned on

13. Maintenance

General

Wipe chips and dust off the machine from time to

time using a cloth.

Re-application of the wax coating on the

workbench makes feeding the workpiece to the

blade easier.

The mains cable should be replaced immediately

if pulled out, cut or damaged in any other way.

Do not lubricate the motor bearings or internal

parts!

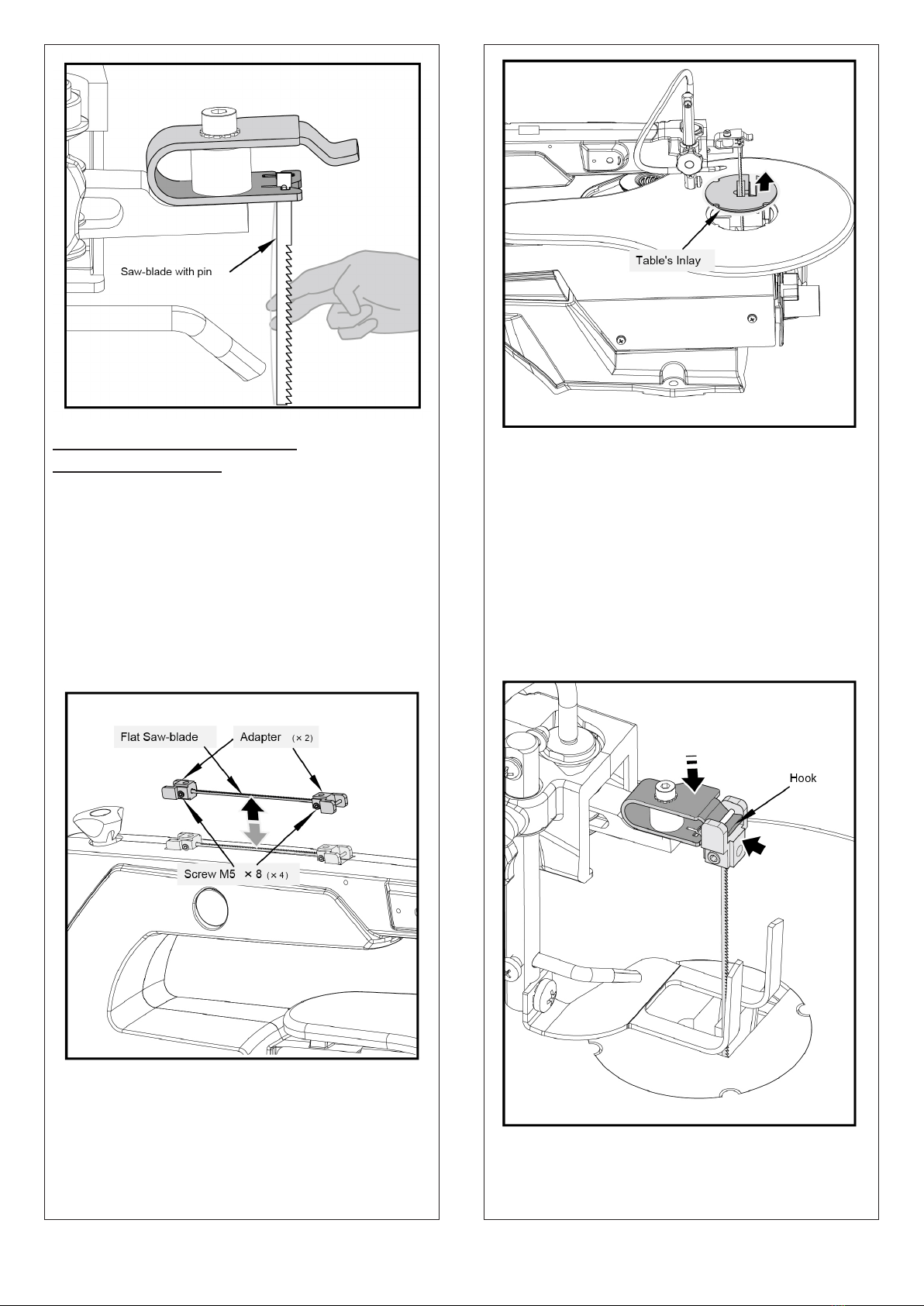

Changing the Saw Blade with pins

1. Saw blade removal. Extract the saw-blade by

unscrewing the Clamping screw. Remove the saw-

blade from the upper and lower support by slightly

pressing the upper arm down.

2. Inserting the new saw-blade. Lead one end of the

saw-blade through the perforation in the table and

insert the saw-blade pins into the notch. Repeat this

procedure at the upper blade support. Before hooking

it in. Slightly press the upper arm down. Check the

position of the blade pins at the supports. Tighten

the blade by means of the Clamping screw. Check the

blade's tightness. Keep on rotating clockwise in order

to tighten the blade even more.

9

Warning! In the interests of

operational safety, always switch off

the saw and remove the mains plug

before carrying out maintenance

work.

Switch off the saw and remove the

mains supply plug before installing

saw blades in order to avoid injuries

caused by unintentional activation of

the saw.

10

Changing the flat saw-blade

(Optional Feature #1)

1. Take out the adapter. Fix the saw-blade with

allen screws using allen wrench.

2. Extract the saw-blade by sliding the table's inlay

up, then unscrew the clamping screw.

3. Slightly press the upper arm down.

4. Then remove the saw-blade by pulling it

forward out of the supports and through the

access perforation in the table

5. Put the saw-blade with the two adapter into

the lower support, the other end into the upper

support.

6. Slight press the upper arm down before

hooking it in.

7. Tighten the blade with the tightening screw

by rotating it clockwise. Check the tightness of

the blade. Keep on rotating clockwise in order to

tighten the blade even more.

11

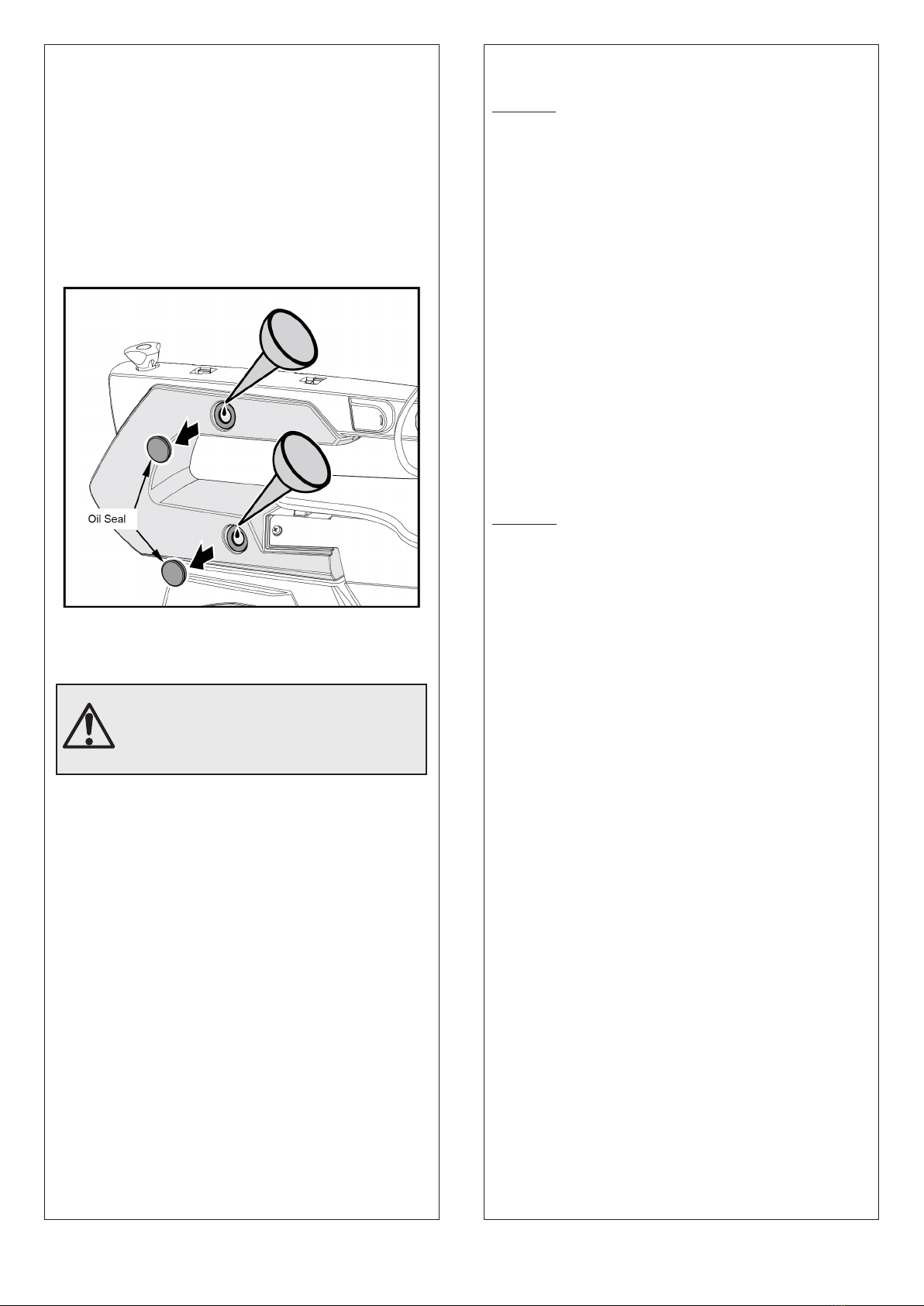

14. Lubrication

Lubricate the saw arm bearings every 50 hours.

Proceed as above figure shown.

Turn the saw to the side.

Apply a generous amount of SAE 20 oil to the

shaft end and bronze bearings.

Let the lubricant oil work in overnight.

Repeat the procedure the next day on the other

side of the saw.

Carbon Brushes Inspection

In case of excessive sparking, have the carbon

brushes checked only by a qualified electrician.

15. Transport

1. Be sure turn off the power and pull out the plug

after use.

2. Pull down the transparent blade guard to

prevent hand cutting during transportation.

3. Disconnect the vacuum cleaner and the other

connecting devices, and remove the connection

bolts between the machine and the work table.

4. Hold the upper end of the U-shaped arm with

one hand while moving; If the saw-blade adapter

& allen wrench (Optional Feature #1) is on the top

of the U-shaped arm, you can move it with both

hands.

5. Raw materials or precision-cut semi-finished

products are recommended to be removed from

the worktable before moving, which may damage

the saw blade and its fixing device.

16. Maintenance

Servicing

Pull the mains plug before any adjustments,

maintenance or repair.

Have any work on the device that is not described in

this instruction guide performed by a professional.

Only use original parts. Allow the device to cool off

before any maintenance or cleaning is undertaken.

There is a risk of burning!

Always check the device before using it for obvious

defects such as loose, worn or damaged parts, correct

the positioning of screws or other parts. Exchange the

damaged parts.

The ball bearings in the spindle and the V-belt pulley

assembly are greased and permanently sealed. Pull the

spindle down and oil the spindle sleeve moderately

every three months.

Lubricate the table bracket and locking knobs if they

become difficult to use.

Cleaning

Do not use any cleaning agents or solvents. Chemical

substances can etch the plastic parts of the device.

Never clean the device under running water.

• Thoroughly clean the device after every use.

• Clean the ventilation openings and the surface of

the device with a soft brush or cloth.

• Remove chips, dust and dirt with a vacuum cleaner

if necessary.

• Lubricate moving parts regularly.

• Vacuum sawdust or metal shavings that accumulate

in and on the motor, pulley housing, table, and work

surface.

• Apply a light coat of paste wax to the column and

table to help keep these surfaces clean and rust-free.

• Do not allow lubricants to come into contact with

switches, V-belts, pulleys and drill lifting arms.

Danger! The carbon brushes should

not be replaced by anyone but a

qualified electrician.

12

17. Storage

Store the device and its accessories in a dark, dry and

frost-proof place that is inaccessible to children. The

optimum storage temperature is between 5 and 30˚C.

Store the electrical tool in its original packaging.

Cover the electrical tool in order to protect it from

dust and moisture.

Store the operating manual with the electrical tool.

Danger! Store the Scroll Saw a way

it cannot be started by unauthorised

persons and that nobody can be injured.

Caution! Do not store the Scroll Saw

unprotected outdoors or in a moist

environment.

Problem Cause Remedy

Saw blades break

Tension incorrectly set Set the correct tension

Load to great Feed the workpiece more slowly

Incorrect saw blade variety Use the correct saw blades

Workpiece not fed straight Avoid exerting pressure from the side

Motor does not

function

Mains Gable faulty Change faulty parts

Motor faulty Call customer service. Do not attempt to

repair the motor yourself as

this should be carried out by trained

personnel.

Vibration

(NOTE: The saw

vibrates slightly

when the motor is

running in normal

opera- tion.)

Saw incorrectely installed Set the correct tension

Unsuitable underlay Feed the workpiece more slowly

The work bench is not screwed

down or is on the motor

Use the correct saw blades

The motor is not secured Avoid exerting pressure from the side

Saw blade swings

out., holders not

aligned straight

Holders not aligned Losen the screws with which the holders

are fastenedto the arm. Align the

holders so that they are perpendicular

to each other and retighten the screws

Trouble Shooting

In the interests of operational safety, always switch off the saw and remove the mains plug

before carrying out maintenance work.

13

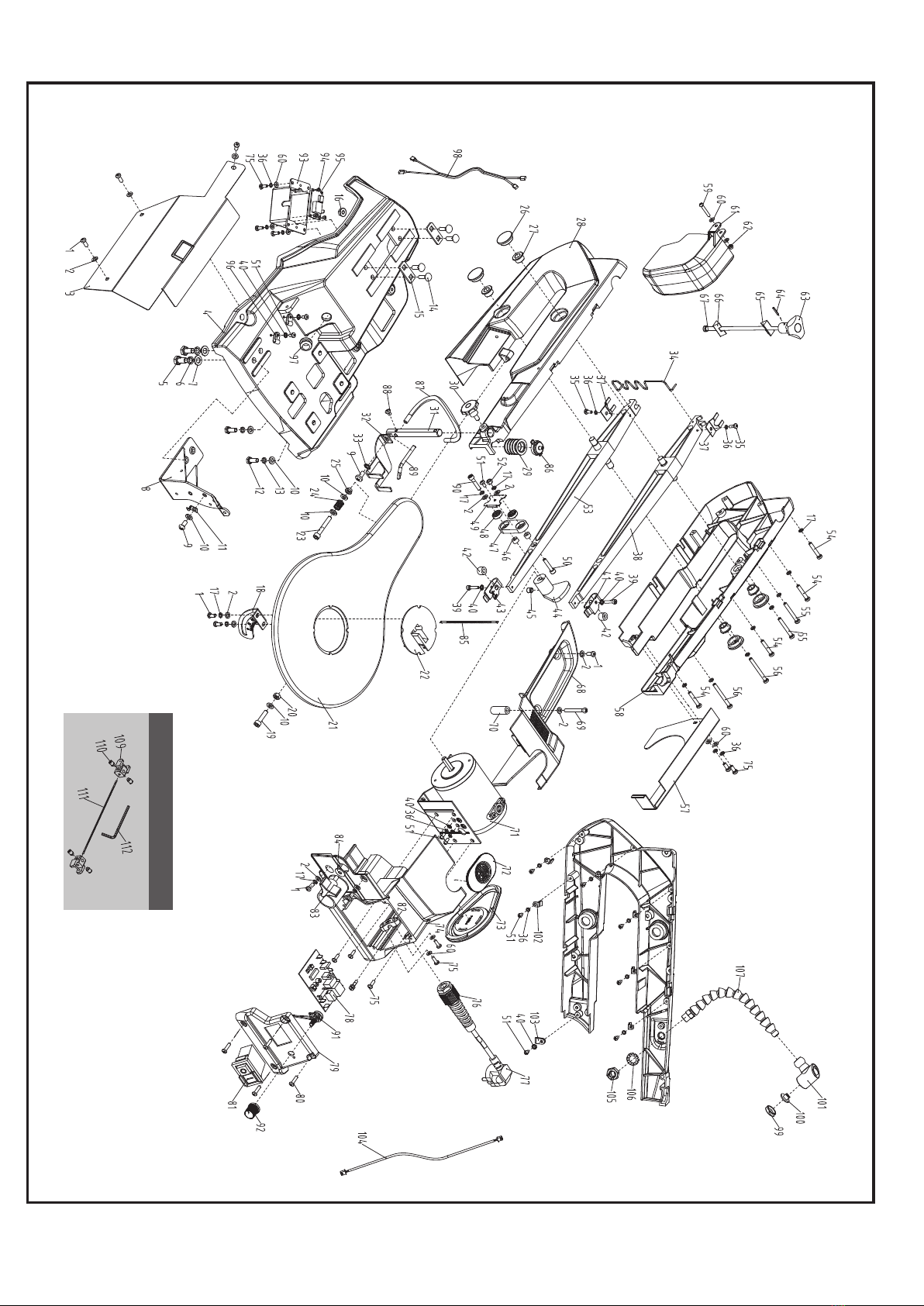

16" SCROLL SAWS

22

GB

OPTIONAL FEATURE #1 OPTIONAL FEATURE #2

65115B

14

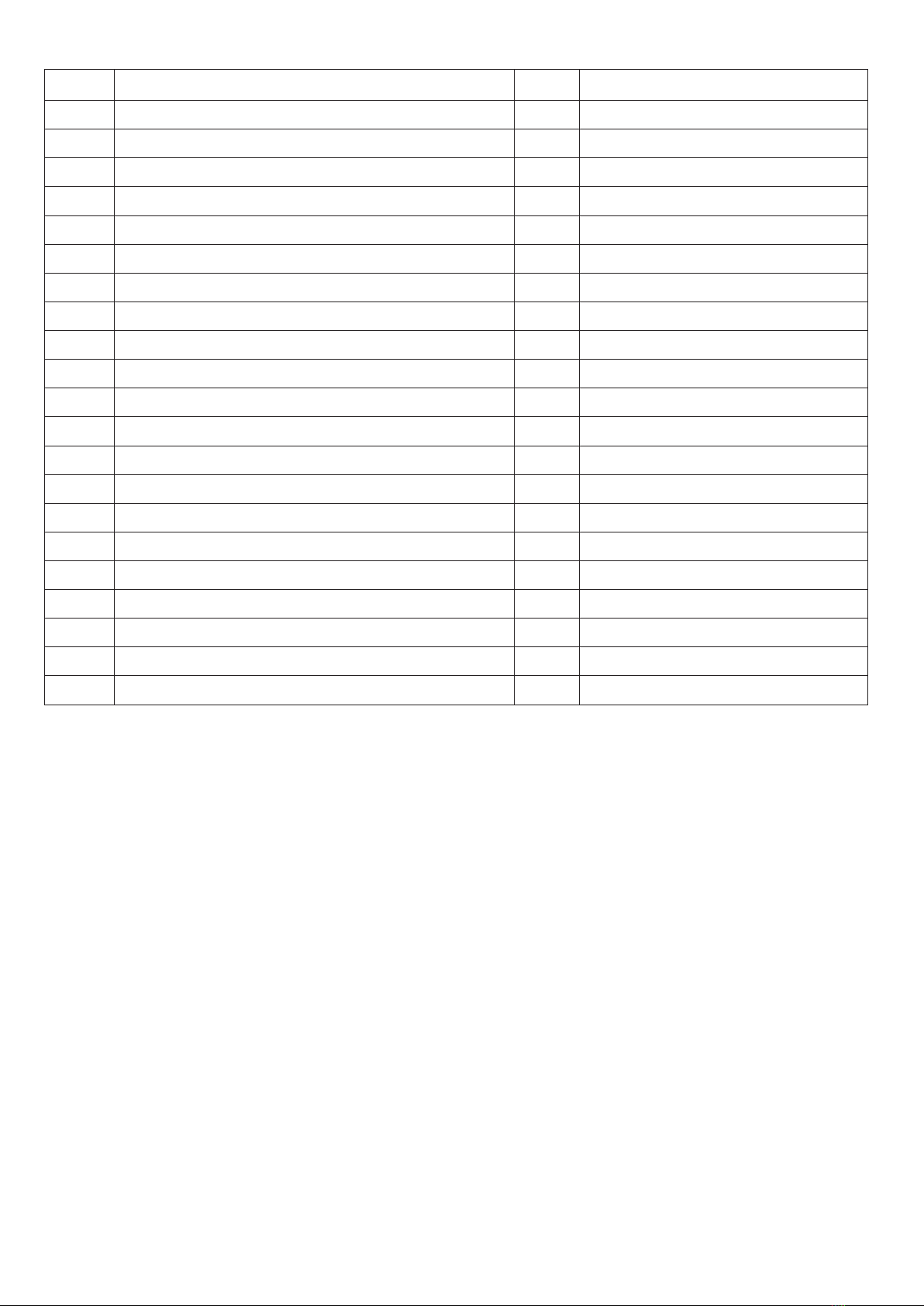

No. Description No. Description

1 Screw M5×12 39 Screw M4×20

2 Flat Washer Ø5 40 Lock Washer Ø4

3 Body Outside Cover 41 Upper Clip

4 Base 42 Bushing

5 Bolt M8×20 43 Lower Clip

6 Spring Washer Ø8 44 Eccentric Bushing

7 Flat Washer Ø8 45 Screw M8×8

8 Support Bracket 46 Small Shaft Sleeve

9 Screw M6×12 47 Plastic Bearing Seat

10 Flat Washer Ø6 48 Bearing 625-2Z

11 Indicator 49 Bearing Cover

12 Bolt M6×16 50 Screw M5×25

13 Spring Washer Ø6 51 Screw M4×8

14 Bolt M6×20 52 Nut M5

15 Press Plate 53 Lower Arm

16 Flange Nut M6 54 Bolt M5×30

17 Spring Washer Ø5 55 Screw M5×40

18 Angle Scale 56 Screw M5×50

19 Screw M6×25 57 Welded Cover

20 Nut M6 58 Main Frame-Left

21 Work Table 59 Screw M4×25

22 Table Inlay 60 Flat Washer Ø4

23 Screw M6×40 61 Blade Guard

24 Spring 62 Locknut M4

25 Locknut M6 63 Clamping Screw

26 Rubber Plug 64 Pin 2.5×16

27 Shaft Sleeve 65 Adjusting Block 1

28 Main Frame-Right 66 Adjusting Block 2

29 Air Bag 67 Adjusting Rod

30 Star Handle Screw 68 Rear Cover

31 Blade Guard Holder 69 Screw M5×45

32 Protective Bracket 70 Rear Cover Busing

33 Lock Washer Ø6 71 Motor

34 Connected Net 72 Rubber Cap

35 Screw M4×10 73 Middle Cover

36 Spring Washer Ø4 74 Front Cover

37 Limit Plate 75 Screw M4×12

38 Upper Arm 76 Cable Gland Strain Relief

Connector

15

No. Description No. Description

77 Power Cord & Plug 96 Cable Clamp R-5.3

78 Circuit Board 97 Rubber Sleeve

79 Switch Board 98 Double Core Cable

80 Screw ST4.2×16 99 Lamp Cover

81 ON/OFF Switch 100 Led Lamp

82 Cable Holder 101 Lamp Holder

83 Star Button M6x13 102 Pipe Clamp 1

84 Big Flat Washer Ø6 103 Cable Clamp U-3.3

85 Blade 104 Lamp Cable 1

86 Air Bag Seat 105 Lock Nut

87 Plastic Air Pipe 106 Lock Washer

88 Screw M5×6 107 Light Tube

89 Air Nozzle 108 Mode Switch

90 Screw M5×20 109 Adapter

91 Potentiometer 110 Screw M5x8

92 Speed control knob 111 Flat Saw-blade

93 Circuit Board Housing 112 Allen Wrench 2.5

94 Screw ST2.9x6.5

95 Led Lamp Circuit Board B

16

Date:05/17/2021

EN ISO 12100:2010

EN 55014-1:2017

EN 55014-2:2015

EN 61000-3-2:2014

EN 61000-3-3:2013

Scroll Saw - Part. No. DJMSS406

2006/42/EC Machinery Directive

2014/30/EU EMC Directive

17

12

Table of contents

Other djm direct Saw manuals