4

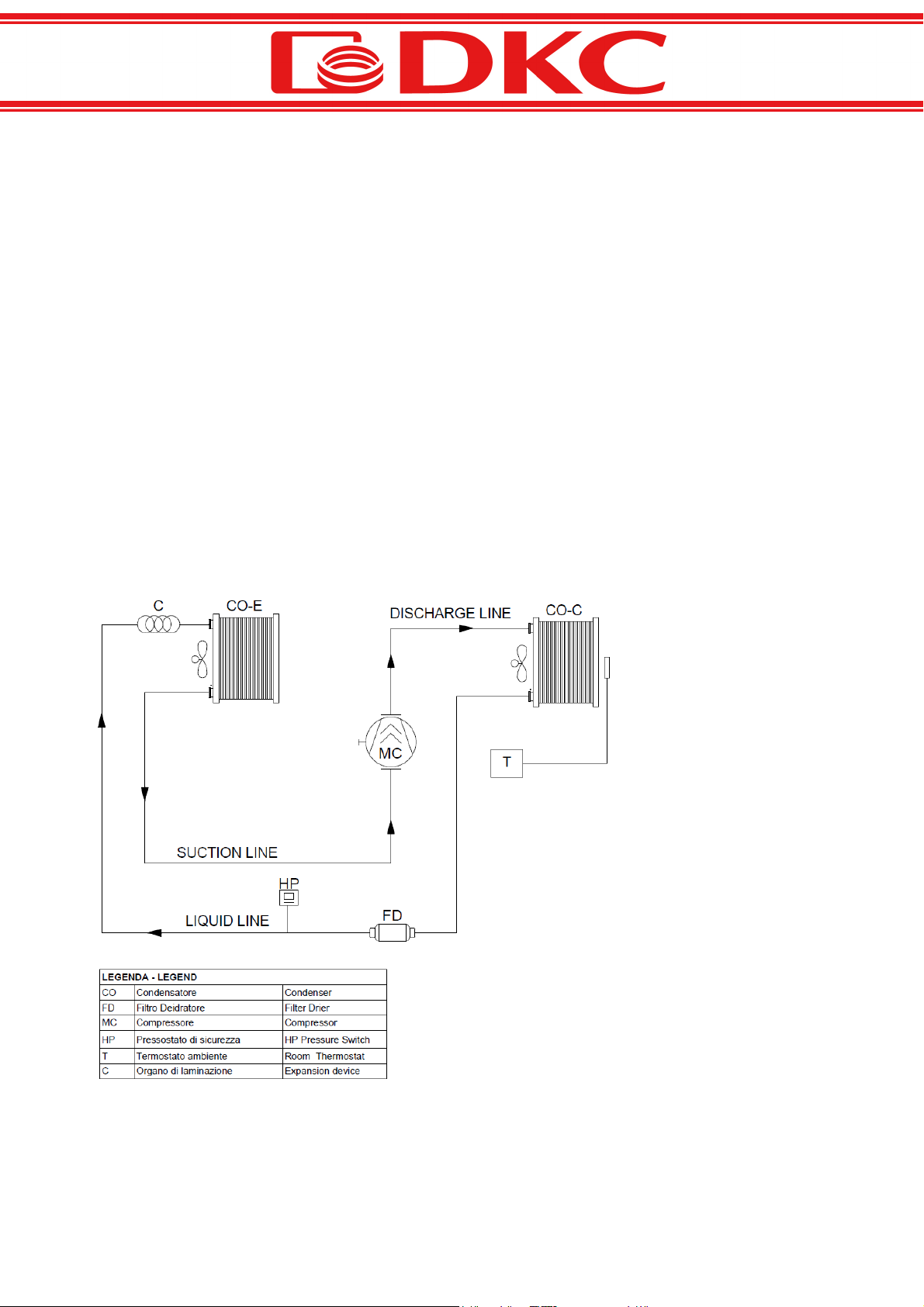

At the inlet of the evaporator the expansion device is located (capillary or thermostatic valve), purposed to

reduce the cooling fluid pressure to a value, which allows its evaporation in the cold exchanger.

The coolant passing through the evaporator changes its state taking the heat away from the source (air

inside the enclosure to be conditioned) by means of the low temperature.

The evaporator is then connected to the compressor, so the fluid in the state of overheated vapour is

drawn by the compressor to be reintroduced into the circuit.

ACCEPTANCE AND STORAGE

Upon delivery of the products it is necessary to make sure they had been transported in the position

indicated by the symbols printed onto the package.

It is necessary to ensure the packing materials are undamaged and most importantly do not show oil spots,

which denote a leakage of cooling fluid.

The cooler is designed so that the compressor remains always in upright position. It may never be laid

down; if this happens, it is necessary to put it in upright position and then wait for 8 hours before setting it

in operation.

Do not set the unit in operation if a coolant leakage is found.

Installation, maintenance and repair activities must be carried out only by qualified personnel. Only filter

substitutions may be performed by a non-specialized staff.

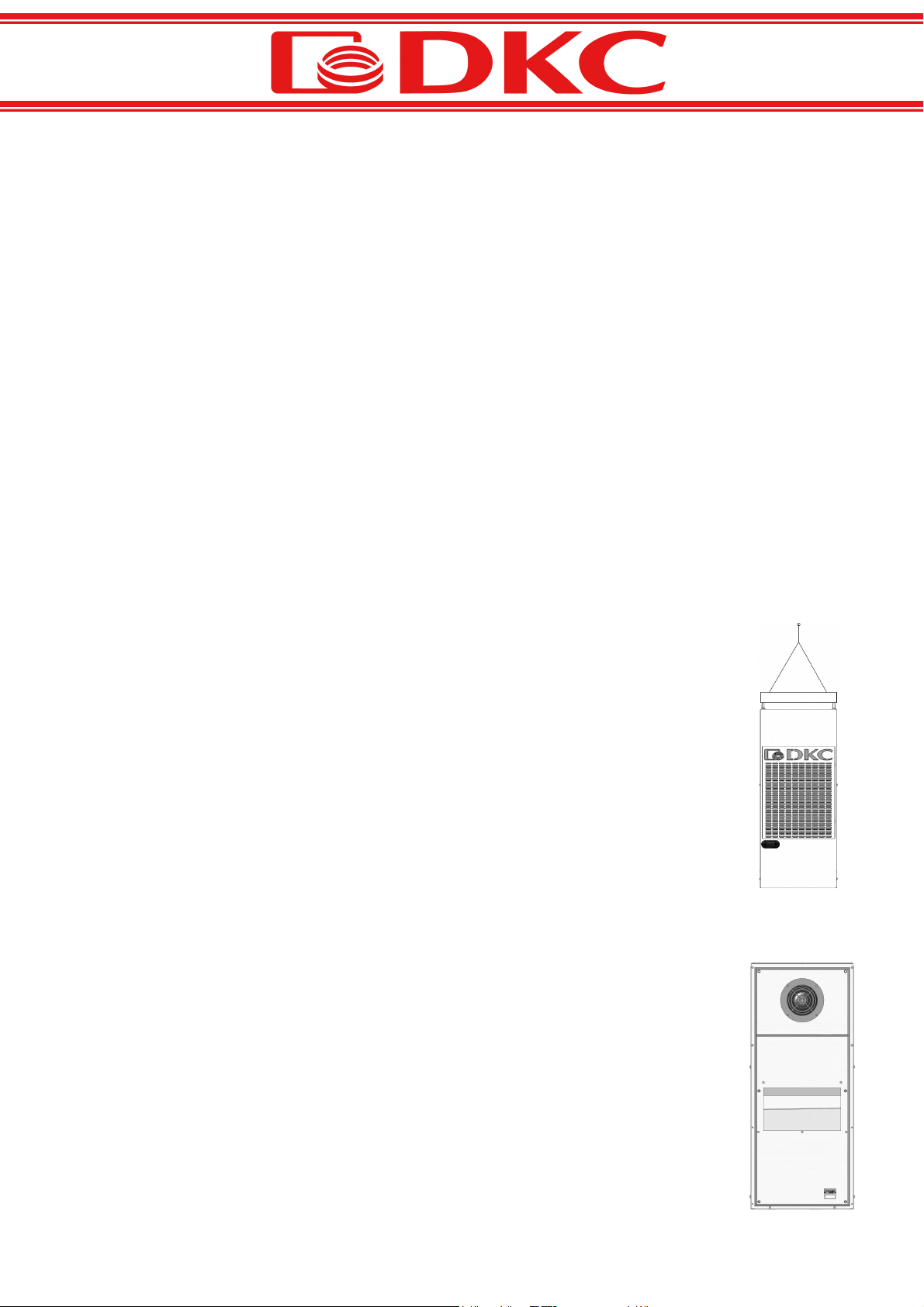

During the operations of handling and storage wall mount coolers are to be kept in vertical

position, while roof mount ones in horizontal position, at the temperature in the range

between -10°C and + 0°C.

HANDLING

Having removed the packing materials, coolers are to be handled using the dedicated fixing

points located in the upper part. Use the supplied eyebolts paying attention to balance the

cooler and to avoid any impact.

INSTALLATION

Having removed the packing materials, make sure that there are no leakages of oil or gas and

that no parts or documents are left in the package. The supply voltage indicated on the device

name plate is to be in conformity with the requested one.

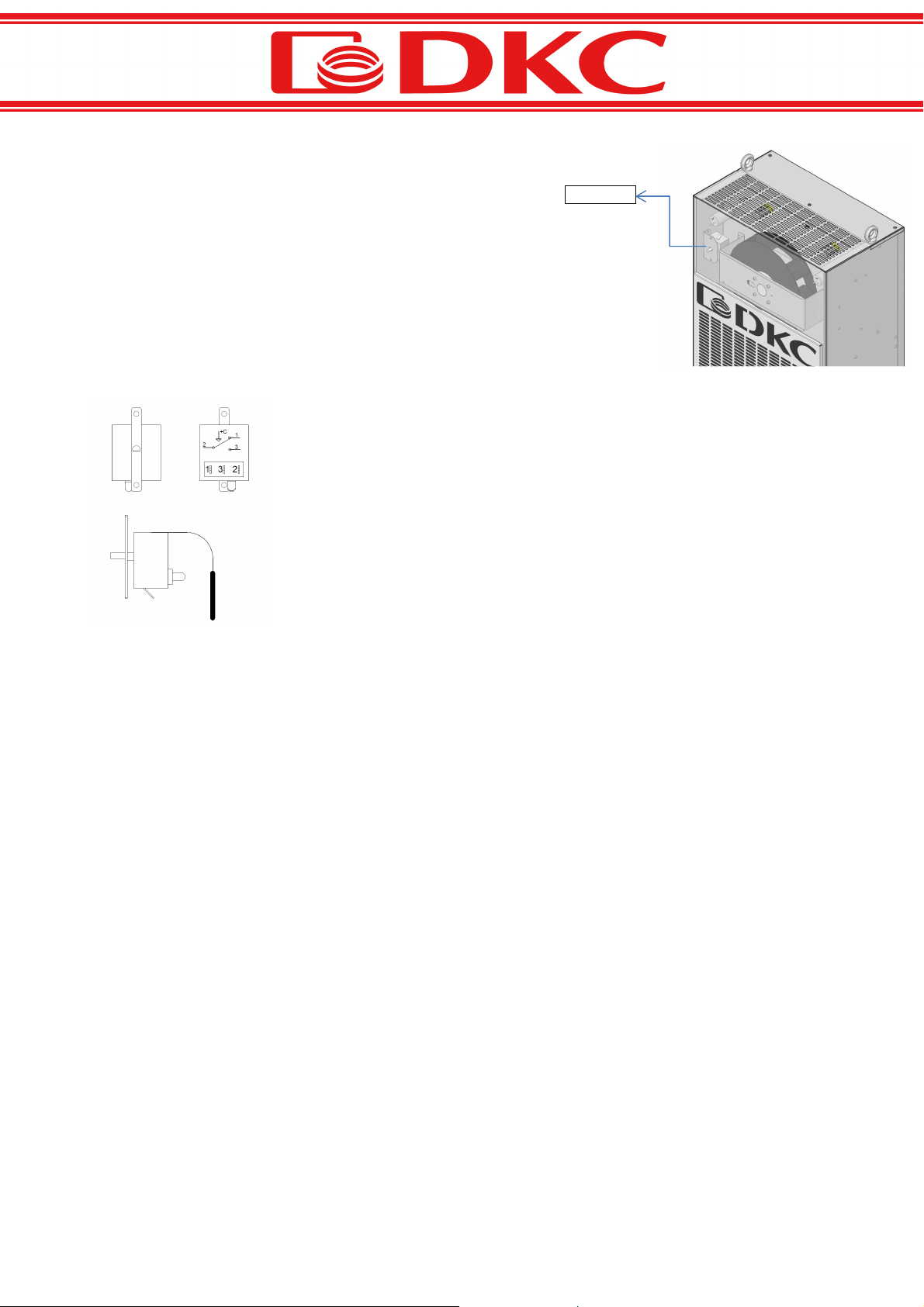

MECHANICAL MOUNTING

The coolers may be mounted inside or outside the enclosure. The cooler must always be

installed in upright position (with the compressor in the bottom) with the maximum standoff

from the upright position equal to 2°.

Before mounting it is necessary to ensure the enclosure minimum protection degree is IP54

in order avoid problems caused by external air condensing.

In case of a cooler mounting onto a door, it is necessary to verify if the hinges are capable to

sustain the device weight.

In any case the cooler is to be mounted as high as possible in order to draw out the hottest

air from the enclosure. To perform the installation it is necessary to cut the sheet steel with