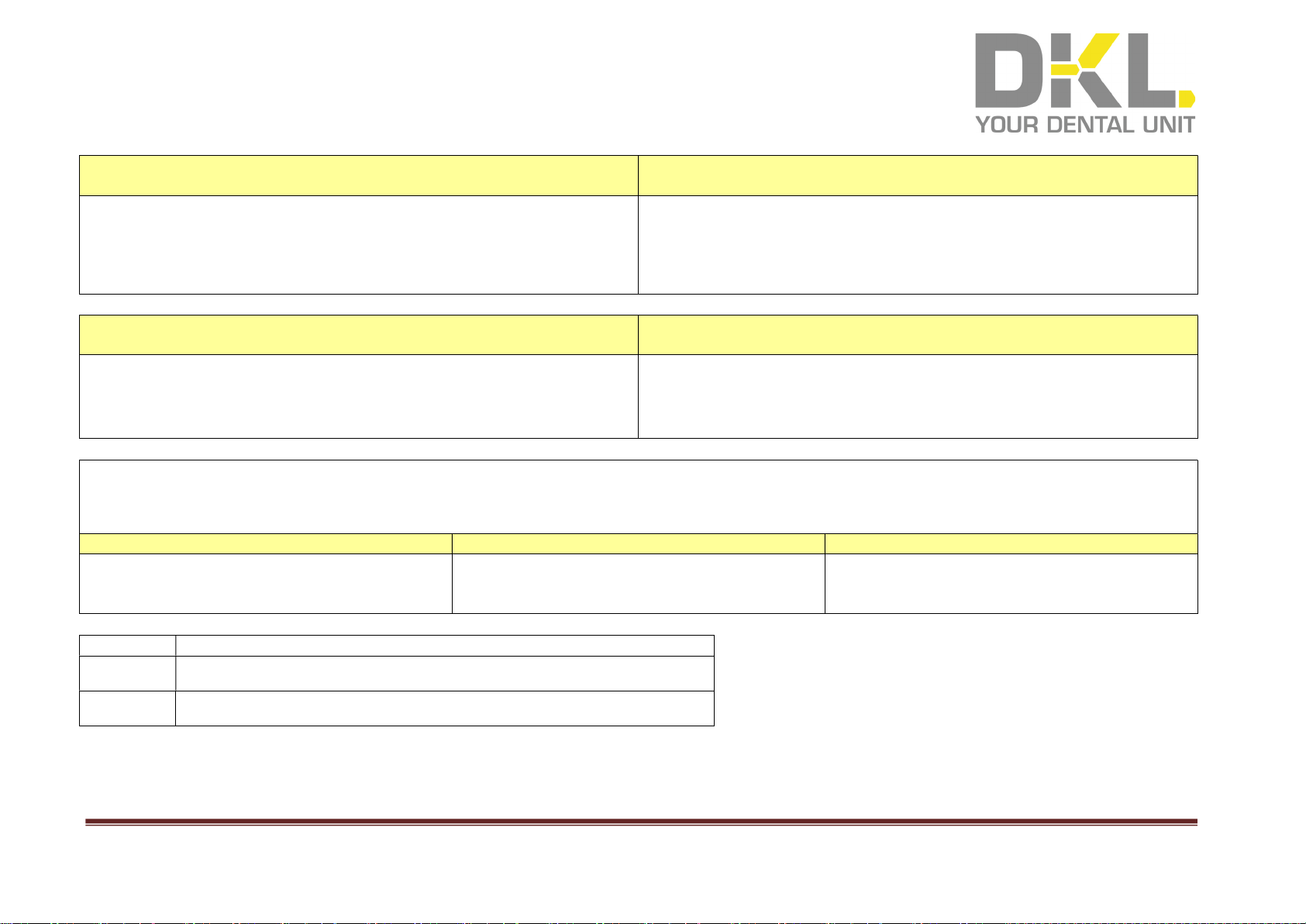

Maintenance log L2-Range and D2-Range

page 7

8. Cuspidor

Replace the biofilter in the cuspidor. Once a year L2-Range

D2-Range Bio filter maintenance set

210620-W

(included in

maintenance

1

Glass filler: check drain cock at the retainer for leaks; if necessary, replace O-rings.

Remove any deposits of substances in water from the drain cock (mechanically or

in an ultrasonic bath).

Every 3

years

L2-Range

D2-Range O-ring 8x1

640003

(not included in

maintenance set

2

Cuspidor bowl: check the drain of the cuspidor bowl for leaks; replace the O-seal if

necessary; clean the funnel.

Every 3

years

L2-Range

D2-Range O-ring seal 42x2,5

640019

(not included in

maintenance set

1

Cuspidor bowl: check drain sieve (gold catcher) and replace. Once a year L2-Range

D2-Range Sieve

410081

(included in

maintenance

1

With spitton valve 3: Perform a visual leak test.

Observe the manufacturer’s (Dürr) maintenance instructions.

❯ Check compressed air supply ❯ Perform a functional test, clean the yellow coarse

filter or replace it if required.

Once a year L2-Range

D2-Range Protective strainer

0700-702-06E

(order from

DÜRR Dental)

-

With cuspidor valve 3: Perform a visual leak test.

Observe the manufacturer’s (Dürr) maintenance instructions. ❯ Clean the float

monitor in the collection vessel. ❯ Clean the seal on the float sensor for ventilation

and replace if required, clean the yellow coarse filter or replace it if required.

Every 3

years

L2-Range

D2-Range Protective strainer

0700-702-06E

(order from

DÜRR Dental)

-

Dürr rinsing unit II: Perform a visual leak test.

Check and clean the fine filter. Check the amount of dirt on the float monitor

(outlet) and to clean this where required.

Once a year L2-Range

D2-Range - - -

With amalgam separator CAS1: Perform a visual leak test. Check function and

suction power: Observe the manufacturer’s (Dürr) maintenance instructions.

❯ Cleaning of the suction unit in accordance with the operating instructions.

❯ Clean the float. ❯ Replace the bellows.

Once a year L2-Range

D2-Range Bellows

7117-420-25E

(order from

DÜRR Dental)

-

With amalgam separator CAS1: Perform a visual leak test. Observe the

manufacturer’s (Dürr) maintenance instructions. ❯ Replace the rubber grommets on

the connections. ❯ Replace the float.

Every 3

years

L2-Range

D2-Range Service kit (3-year interval)

7117-980-32

(order from

DÜRR Dental)

-

With amalgam separator CAS1: Perform a visual leak test. Observe the

manufacturer’s (Dürr) maintenance instructions. ❯ Replace the centrifuge drum and

seal. ❯ Replace all O-rings (from the replacement parts kit) in the device. ❯ Replace

the rubber grommets on the connections. ❯ Replace the float.

Every 5

years

L2-Range

D2-Range Service kit (5-year interval)

7117-980-30

(order from

DÜRR Dental)

-