DMC Alphatron PT-100 User manual

PAGE1OF2

PT-100

WIRE CRIMP PULL TESTER

COPYRIGHT©2001 ALLRIGHTSRESERVED REV. B 05/01 FILE # DS0026 DOC # PT-100-DS

123

4

5

6

7

15

14

13

12

11

10 98

SLOT DIMENSION

No.

1

2

3

4

5

6

7

8

Size (in.)

.031

.250

.047

.236

.063

.218

.080

.203

No.

9

10

11

12

13

14

15

Size (in.)

.094

.188

.110

.172

.125

.158

.141

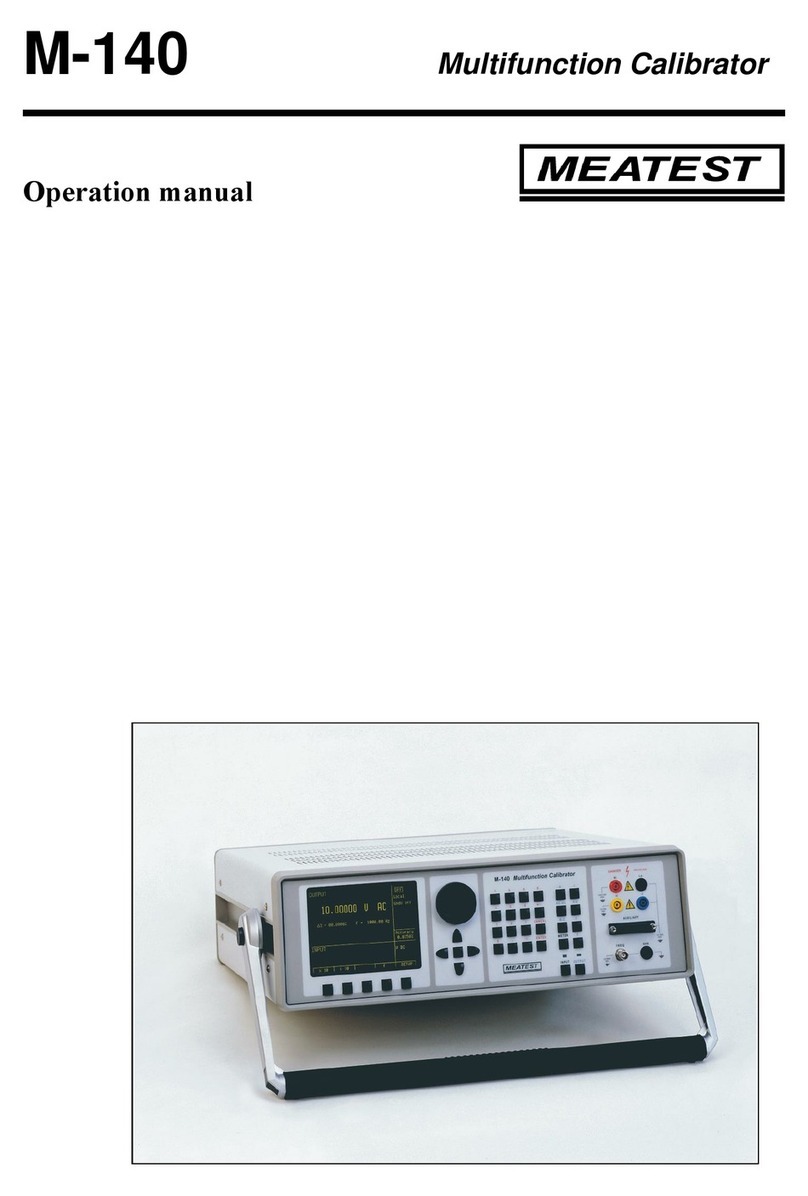

MAX MIN Dual Cam Action Grips

Upper Grips from 0 to .250" Diameter

Wire

UPPER GRIP

"Quick Grip"

LOWER GRIP

Standard Terminal Grip

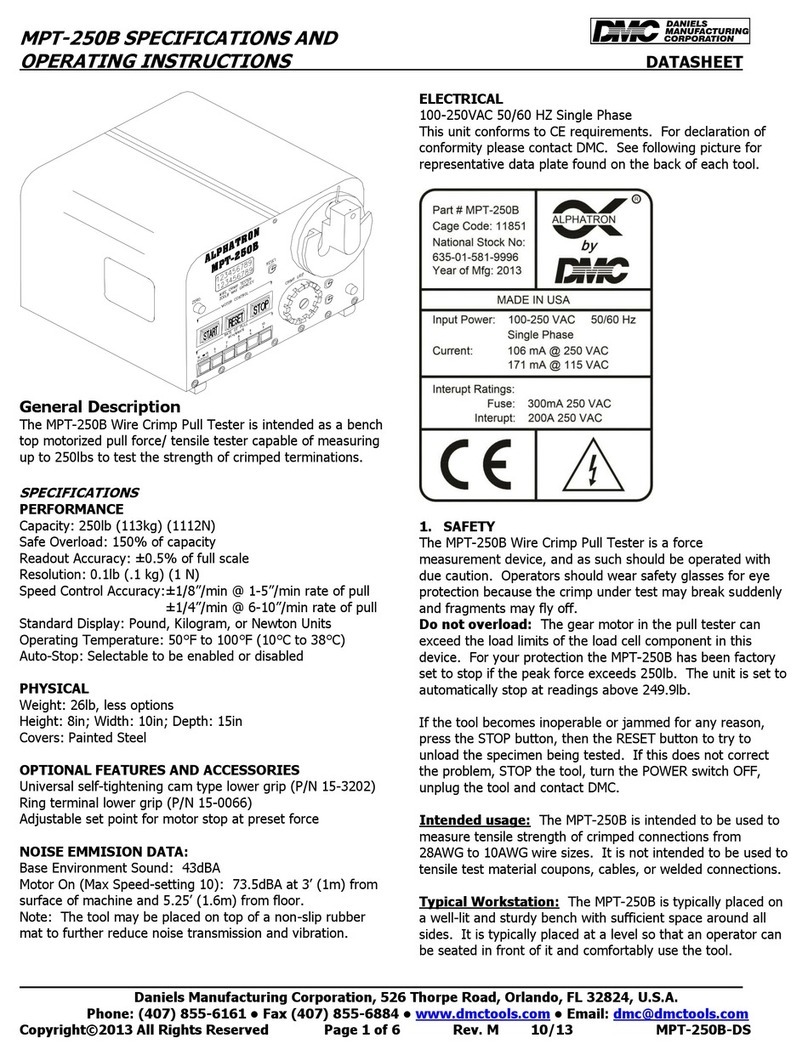

1. SAFETY

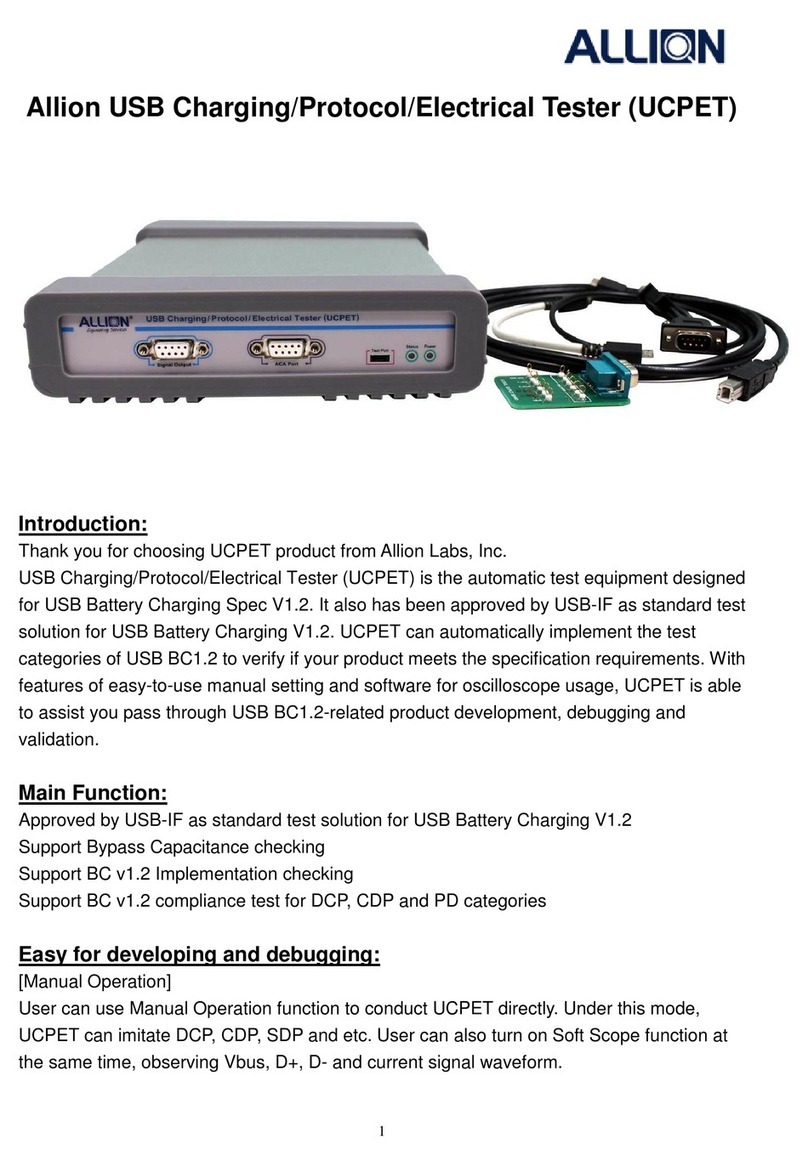

The Alphatron PT-100 Wire Crimp Pull Tester is a force

measurementdevice,andoperatorsshouldwearsafetyglasses

for eye protection because foreign objects can be thrown from

the piece under test.

Topreventfireandshockhazard,donotexposethisequip-

ment to moisture. Always unplug the AC line cord prior to ser-

vicing.

Do not exceed the rated force capacity (100 lb., 45 kg.) of

the PT-100. The unit may be damaged, and the operator or

others in the immediate vicinity injured under extreme force

conditions.

2. SETUP

The Alphatron PT-100 is shipped from the DMC factory

assembled, calibrated, and tested. For best results, users

should familiarize themselves with the setup and operation of

the unit before placing it in service.

To operate, set the PT-100 on a flat, level surface in an

upright position. To prevent damage to the force sensing de-

vice, handle the unit by the main support post and base only.

Threemounting holesin thebase areprovided topermanently

bolt it in position, if desired.

Setthemeteralongsidethebase. Be careful to avoidstrain

on the cord between the meter and the load cell. The meter

has folding legs to permit the operator to adjust the viewing

angle.

3. OPERATION

With the switch on the front of the meter turned off, plug

the PT-100 into a 115VAC or appropriate outlet. Turn it on and

the display will light up to indicate that the unit is operational.

Allow 5 minutes warm-up prior to operating the unit. Zero the

display by alternatively turning the zero knob and momentarily

pressing the reset toggle. The display should read 00.0. It is

important to push the reset toggle before taking the next read-

ing. To select the correct "lower grip" slot for the wire/terminal

lead to be tested proceed as follows:

Rotate the grip to find the slot in which the lead wire fits

best. Select the slot that is the same width as the wire diam-

eter or one increment larger.

Insert the wire into the slot with the terminal down and

clear of the bottom surface of the "lower grip". Next, pass the

wire between the knurled upper grip cams and raise the lever

arm on the left hand grip to the "min" position to hold the wire

in place. Check to be sure that when you pull down on the

operating lever, the wire will be pulled as nearly vertical as

possible. Adjust the "lower grip" as necessary to make this

alignment.

Pull the operating lever downward in a slow and consis-

tent motion while holding the "upper grip" lever until its self

tightening action takes over. The indicator will begin to display

PT-100

DATASHEET

DANIELS MANUFACTURING CORP., 526 THORPE ROAD, ORLANDO, FL 32824, USA

DONOTEXCEEDTHE

RATEDFORCEOF100LB

BASE

METER

KNURLEDSURFACE ON O.D.

PAGE2OF2 REV. B 05/01 FILE # DS0026 DOC #PT-100-DS

1. Allow PT-100 to warm up for 5 minutes.

2. Depress the reset toggle momentarily.

3. Zero the display by alternatingly turning the zero knob

andmomentarily pressingthe resettoggle untilthe dis-

play reads 00.0.

4. Press the R-cal button on the back of the unit. Press

the reset toggle to zero the display. Repeat this pro-

cess several times to assure a repeatable value. The

display value (R-cal # X .005 = tolerance

R-cal # plus & minus tolerance = range)

should be within .5% of the value recorded on the bot-

tom of the unit.

EXAMPLE: R-cal = 81.0

81.0 X .005 = .40

80.6 to 81.4 = range

5. If anyof the procedures in steps 2-4 do not producethe

expected results, the unit should be returned to DMC

forrepair andrecalibration.

6. SERVICE

Repairand calibration servicesfor thePT-100 Wire Crimp

Pull Tester is available from Daniels Manufacturing Corpora-

tion. Spare parts are also available.

Shoulditbe necessary to returntheunit for service,please

ship to the address on this datasheet, freight prepaid. Enclose

aletter, or purchaseorderwithcompany name, address,phone

number, the individual to be contacted and the reason for re-

turn.

COPYRIGHT©2001 ALLRIGHTSRESERVED

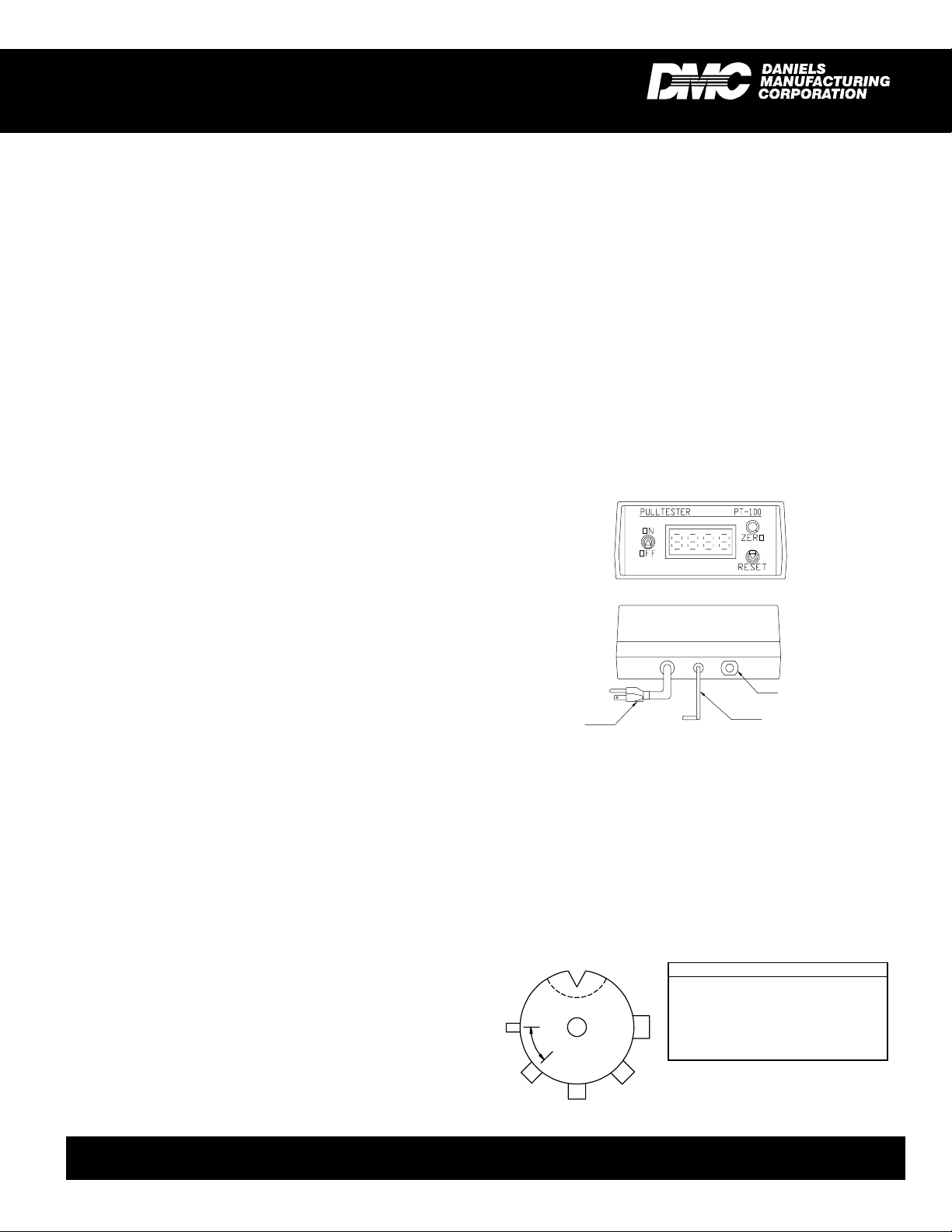

NOTE: This option is made of heavier

duty material and is useful specifically

for testing ring terminals. It also offers

a universal "V" groove for testing non-

standard terminal sizes.

the amount of force exerted on the crimp. As the force is

increased the display will continue to update the reading until

the force is no longer increasing. (Usually this is the point at

which the crimp is pulled loose, or the wire breaks.)

Upon completion of the test, release the wire and press

the reset button on the display prior to the next test.

Best results are obtained with the PT-100 using a slow,

consistent motion when pulling the lever. A quick, or hesitant

motion can cause the wire to slip within the self tightening

cams and the terminal also may become unseated within the

slot.

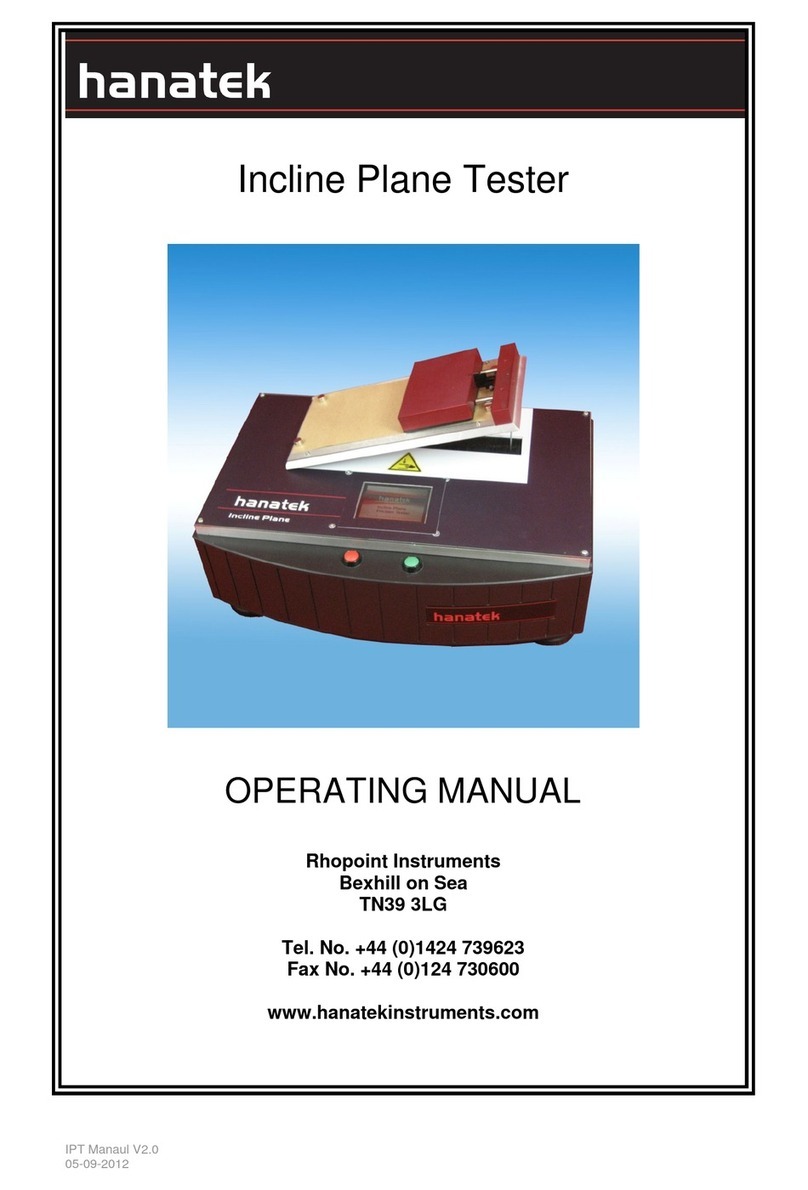

4. CHANGINGTERMINAL GRIPS

CAUTION: ThePT-100 utilizes aprecision load cellfor

its force measurement. Care must be exercised when

changing grips not to create excessive side load on the

load cell sensor.

To change or replace the terminal grip complete the fol-

lowing steps in sequence.

1. To provide more room to work raise the rack and pinion

lever arm assembly as high as possible. Loosen the

large black knob on the left hand side of the assembly,

raise the assembly and retighten the knob.

2. Using a 9/64 in. hex key and an 11/32 in. open end

wrench, loosen and remove the 8-32 locking hex nut

from the bottom of the sensor assembly.

3. Remove the 8-32 x 1-1/2 in. screw, slip washer, termi-

nal grip and spacer from the sensor.

4. When installing the optional ring terminal grip, the re-

cessed center hole must face up for proper operation.

5. Reassemble in this order: Install slip washer on screw,

followed by the terminal grip, and spacer. Insert the

screw with this assembly through the hole in the sen-

sor.

6. Install 8-32 locking hex nut.

7. Using the hex key and open end wrench, tighten until

some effort is required to rotate terminal grip. This is

necessary to avoid play between the terminal grip and

the sensor.

8. Lower the rack and pinion lever arm assembly to its

operating level and tighten knob to secure.

5. FUNCTIONALCHECK

The PT-100 Wire Crimp Pull Tester is factory calibrated

with equipmenttraceable to the National Instituteof Standards

and Technology (NIST). We recommend recalibrating the unit

at intervals not to exceed one year in duration.

The funtional check is executed using the R-cal switch

built into the unit . The R-cal switch is located on the rear of

the unit, and its R-cal value is on the sticker applied to the

bottom of the unit.

A functional check can be performed at any time:

OPTIONAL RING TERMINAL GRIP

DATASHEET

DANIELS MANUFACTURING CORP., 526 THORPE ROAD, ORLANDO, FL 32824, USA

RING POSITION

1 Slot .200" to .03" @ .250" Depth

2 3/8" Dia. x .250" Pin

3 5/16" Dia. x .250" Pin

4 1/4" Dia. x .250" Pin

5 3/16" Dia. x .250" Pin

6 1/8" Dia. x .250" Pin

1

2

3

4

5

6

45° TYP.

LEADTOLOAD

CELL

R-cal

POWER

(115 VAC)

FRONTVIEW

REARVIEW

Other DMC Test Equipment manuals