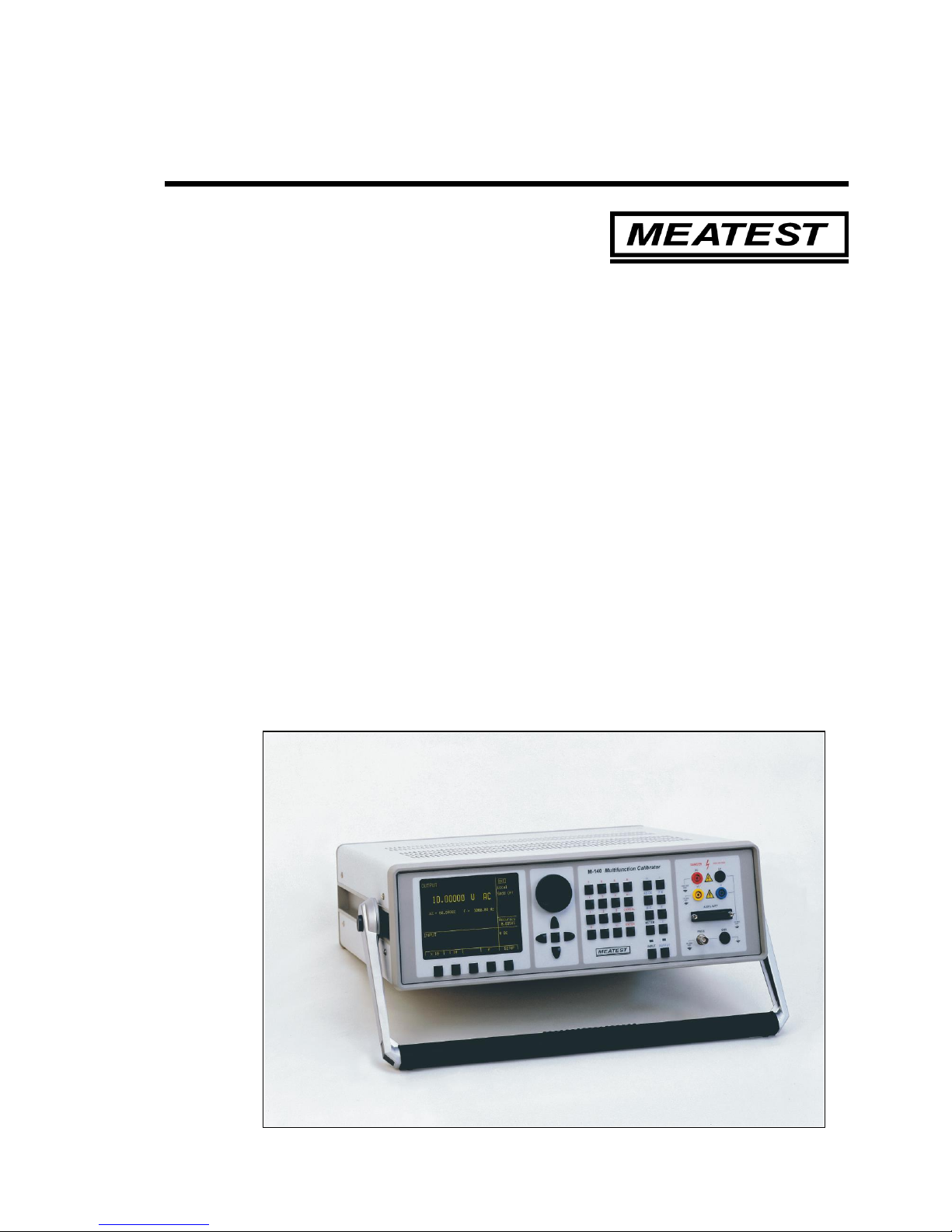

MEATEST M-140 Multifunction Calibrator

Operation manual v46 3

Basic Information

M-140 Multifunction Calibrator is a multifunction calibrator-tester, to be used primarily as a standard

for calibration laboratories. It can be used for calibration of any measuring instrument which measures voltage,

current, resistance, capacitance and frequency. It generates fixed non-harmonic signals to allow calibration

of measuring instruments using signals with non-zero harmonic distortion. Frequency, amplitude and duty cycle

of output signal can be adjusted. M-140 Multifunction Calibrator is also suitable for basic calibration

of oscilloscopes.

The calibrator includes a function which simulates resistance and thermocouple temperature sensors and

a built-in multimeter, which can be used simultaneously. Transducers of various types, regulators and sensing units

can be therefore checked without the need for additional measuring instruments.

Programmable functions of the calibrator, when used as a tester, include programming of a 10-step testing

procedure, which completes automatically and displays a PASS/FAIL information in the end. This feature is linked

to an independent relay output, which allows the control of other equipment.

Basic features of the calibrator include: generation of calibrated DC and AC voltage in the range of 0 V

to 1000 V, DC and AC current in the range of 0 A to 20 A(50 Ato 1000 A when using a 50-turn coil). Maximum

precision of the calibrator is 0.0035 % for DC voltage, 0.03 % for AC voltage, 0.013 % for DC current and 0.055

% for AC current. Maximum frequency range is 20 Hz to 50 kHz. The calibrator can generate periodic

non-harmonic signal with defined duty cycle. This facilitates especially the checks of multimeters and their

accuracy when measuring non-harmonic DC signals.

The calibrator can also simulate a resistance or capacitance. Resistance range is 0 to 50 M;

capacitance range is 1 nF to 50 F, the accuracy suits the calibration of common multimeters. Basic accuracy

of resistance ranges is 0.03 %. Basic accuracy of capacitance ranges is 0.5 %. The resistance can be used with AC

signals up to 300 Hz to 1 kHz, depending on set-up value.

Frequency ranges of the calibrator can generate a squarewave signal with definable and calibrated duty

cycle and amplitude in the 1 mV to 10 V range and 0 to 10 kHz frequency range. Moreover, squarewave signal

with very steep rising edge can be generated up to 20 MHz. Frequency ranges can be used to calibrate the

corresponding frequency ranges of multimeters, as well as to calibrate the input sensitivity and time bases of

oscilloscopes.

Powermeter mode can be used to calibrate DC and AC single phase powermeters and energy meters.

Voltage range is up to 240 V and current range is up to 10 A, power factor range is -1 to +1 and the resolution is

1 % in the 40 Hz to 400 Hz frequency range. The voltage output can supply loads up to 30 mA, which allows the

calibration of mechanical powermeters.

Simulation of temperature sensors is yet another feature which can be used to calibrate thermometers and

heat sensing units. The calibrator allows the simulation of all common Pt and Ni resistance sensors and R, S, B, J,

T, E, K, N type thermocouples. Compensation of cold junction of thermocouple is achieved by entering

the respective temperature using the calibrator’s keyboard. The accuracy of simulated temperature sensors depends

on the value and type of sensor and ranges from 0.04 oC to 0.5 oC for resistance sensors and from 0.4 oC to 4.3

oC for thermocouples.

Internal multimeter with 20 mA, 20 mV, 200 mV and 10 V basic ranges and 0.01 % accuracy can be used

to measure normalized signals coming from transducers, external thermocouples or resistance sensors or to

measure pressure and force using strain gauge sensors.

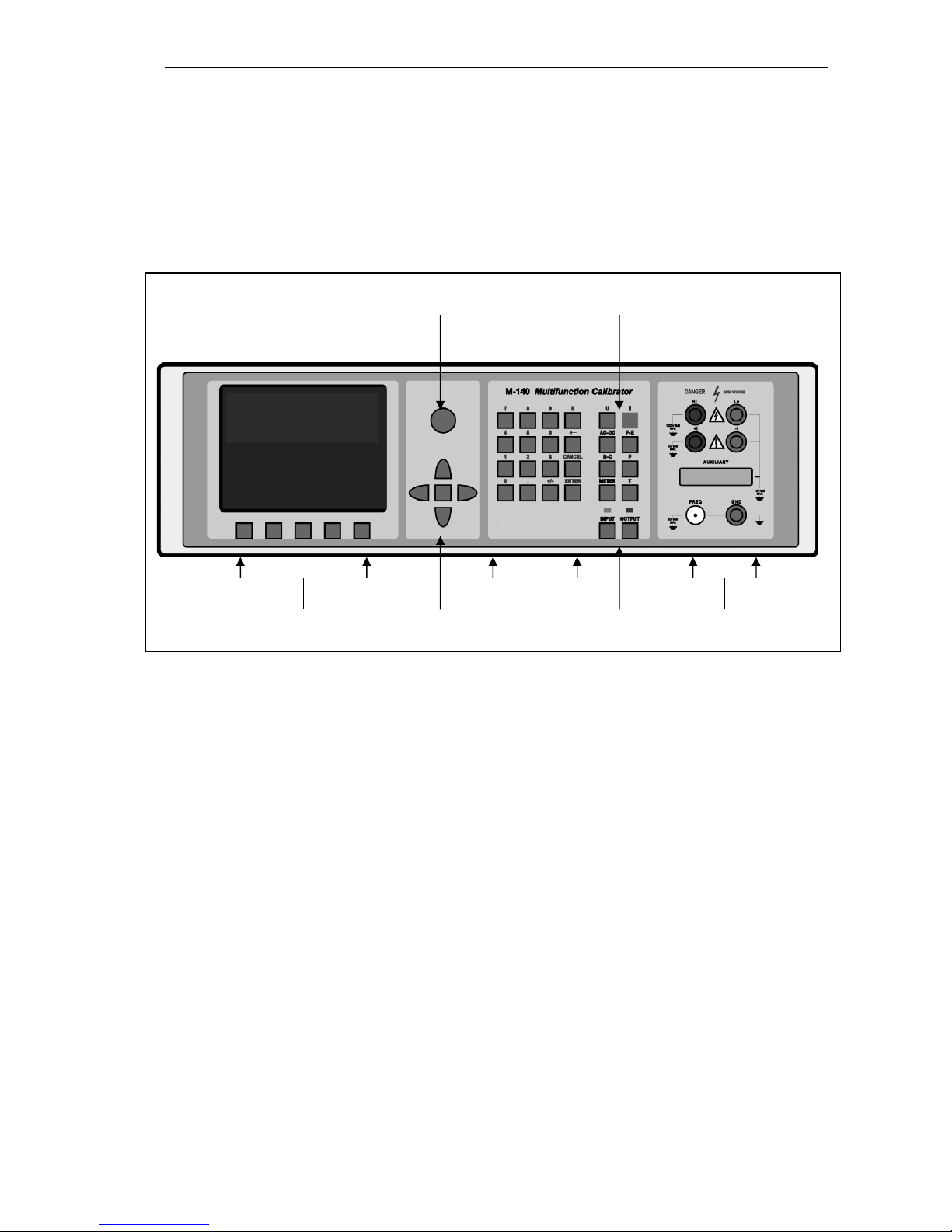

The calibrator includes many other features which facilitate easy use. For example relative deviation from set value

of the output, currently displayed uncertainty of the output signal, calibration and testing procedures etc. The

concept of calibrator control and indication of its status is based on flat luminiscent display, which provides all

necessary information. The calibrator is controlled by opening menus on the display and selection from menus.

Frequently used functions are assigned direct-control keys. The calibrator comes with standard GPIB bus and RS-

232 serial line, which allow the calibrator to be controlled from a PC.

The calibrator can easily fit within calibration systems featuring MBASE/WinQbase software support.