DMC DUSH TM Series User manual

TM Series Instruction Manual i

Introduction

Thank you for purchasing DMC’s products.

This manual describes the functions of the TM series.

Please read this manual carefully and use the product properly.

The product will be referred to as “TM” hereinafter.

Please note, specifications described in this manual are subject to change without prior notice.

Copyrights and Trademarks

■The copyright of this instruction manual is rightfully owned by DMC Co., Ltd.

■Reproduction and/or duplication of the product and/or this manual, in any form is strictly

prohibited.

■Contents of this product and/or this manual are subject to change without prior notice.

■Although all efforts have been made to ensure the accuracy of this product and/or the

contents in this manual, should you notice any errors or have any questions, please contact

and notify us.

■We will not be held liable in any way for damages or losses, nor be held responsible for any

claims by a third party as a result of using this product.

■Other product and company names mentioned herein are trademarks or registered

trademarks of their respective owners。

Safety Precautions

Please go through and follow the below precautions before use.

Safety Symbols

Safety symbols are noted throughout this manual to ensure the proper use of the TM.

The indications and meaning of the symbols are as follows.

Warning

Indicates a procedure, condition, or statement which, if not strictly observed, could

result in severe personal injuries or death.

Caution

Indicates a procedure, condition, or statement which, if not strictly observed, could

result in severe personal injuries or property damage.

Indicates a procedure, condition, or statement that must not be done for correct use

of the product. (Prohibited)

Indicates a procedure, condition, or statement that should be strictly followed for

correct use of the product. (Mandatory)

TM Series Instruction Manual ii

Warnings

Warnings for Design

Designing switches that might cause human injuries and/or property damage on the

touchscreen is strictly prohibited. Unintended output signals due to malfunction of the main

unit and/or cables can lead to serious injuries. Design the system so that switches that

perform critical operations are equipped on devices other than the TM itself.

Designing safety related switches on the TM is prohibited. Switches related to safety, such

as emergency stop switches, should be installed on a different hardware.

Do not use this product as a critical warning device that may cause injuries, serious property

damage, or production stoppage. Critical warning indications and alert-related controls

should be structured on an independent and redundant hardware or mechanical interlocks.

The TM is not intended for use in applications that require extremely high reliability and safety

such as aircraft equipment, aerospace equipment, trunk line communication equipment,

nuclear power control equipment, and life sustaining medical equipment. It is not intended

for use in these applications.

When using the TM for purposes that concerns high reliability and safety in terms of functions

and accuracy such as transport equipment (trains, automobiles, ship, etc.), disaster

prevention and security equipment, various safety devices, medical equipment that does not

concern life sustaining, be sure to have safety features including redundancy and

malfunction prevention measures into the entire system which it will be incorporated.

Display will black out when the backlight goes out. If mistakenly operated in this condition, it

might result in improper operation. Do not design touch-switches that might cause human

injuries and material damages due to improper operation on the TM.

Warnings for Handling

Do not modify or disassemble the TM. Doing so may cause fire and /or electric shock.

Do not use around flammable gas. It may cause explosions.

Do not allow any kind of liquid, such as water, and metals to get inside of the product. It may

cause fire and/or electric shock.

In any abnormality such as smoke, unusual odor, or unusual noise is detected, disconnect

the power plug, and discontinue use. If use is continued, it may cause fire or electric shock.

Warnings for Wiring

For proper wiring and installation, please refer to the manual and specifications. Failure to

do so may cause fires and/or electric shocks

Before installing the power cable, make sure power is not being supplied from the power

source. Failure to do so may cause electrical shocks.

Do not use power voltage other than what is specified. Failure to do so may cause fires and/or

electric shocks.

TM Series Instruction Manual iii

Cautions

Cautions for Disposal

When disposing the product, please treat it as industrial waste.

Precautions for Safe Use

Do not press the display with strong pressure or hard objects. It may break the display and

cause injuries.

Please use this product within the specified ambient temperature and humidity range. If not

used properly within the specified range, it may cause malfunctions.

Do not press down on the display area with sharp objects such as mechanical pencils or

screw drivers. It may damage the display.

If the surface of the TM gets dirty, wipe with a dry, soft cloth damped in a neutral detergent

then wrung out tightly. Do not use thinner or organic solvents.

Avoid using the TM in areas where rapid temperature change that can cause condensation.

It may cause malfunctions.

In order to prevent product temperature from rising, avoid using in areas where heat can

build up. Also avoid storing or using in areas of high temperature.

Avoid storing or using the product in direct sulight, dusty areas, or in areas where it can be

exposed to oil fumes and/or water vapor.

Do not use or store all precision equipment including the TM in areas where it is subject to

shock or vibration.

Avoid using or storing in areas where gasified chemicals are diverged into the air or where

chemical adhereing to the product can occur.

When using power source with slow rise-time and fall-time, it may not operate properly. Be

sure to drop the voltage to 0V when turning the power back on after once turning the power

off. It may not boot correctly.

Handling of LCDs

1) The LCD display contains skin-irritating materials. If liquid materials flow out due to damage and comes

in contact with skin, wash the area under water for more than 15 minutes. If it gets in the eyes, wash

your eyes immediately under running water and consult a doctor.

2) Please note that The LCD display may show uneven brightness depending on the contents being

displayed. This is not a malfunction.

3) Then LCD display may have minute spots (black or bright). This is a basic characteristic of the LCD

display and not a malfunction

4) When the LCD display is viewed outside the specified view angel, the display color might seem to

change. Please note this is a basic characteristic of the LCD display and not a malfunction.

5) When displaying a same image for a long period of time, it may cause afterimages. Please note that

this is a basic characteristic of the LCD and not a malfunction.

In order to avoid afterimages, change the display image periodically and avoid displaying the same

image for a long period of time.

TM Series Instruction Manual iv

Handling of Projected Capacitive Touchscreens (TMG)

1) Changes in the surrounding environment and/or elements that change the electric field, such

as capacitors with large capacitance, power supply units, metals, and other materials with

high dielectric constants are near, it may affect the coordinate detection. Keep as much

distance as possible from those unstable elements mentioned above when designing.

2) Connect the FG (Frame GND) of the TM main unit to FG (Field GND). Touchscreen

operation may become unstable.

3) Touchscreen operation may become unstable depending on the installation environment due

to the characteristic of the touchscreen. For correct use, please perform calibration of the

sensor sensitivity of the touchscreen when installing the equipment. For details, please refer

to “4.4 Calibation”.

4) Although the touchscreen is covered with tempered glass, please be careful when handling

as it may break when struck by hard objects.

5) The touchscreen may cause malfunction if there are drops of water on the surface of the

touchscreen. Please wipe it dry before use.

6) Due to the characteristics of the touchscreen, touching slightly outside the display area may

be detected as the coordinates of the edge of the touchscreen. Please take this into

consideration when designing applications.

Handling of Analog Resistive Touchscreens (TMH)

1) Applications that require a point on the touchscreen to be pressed for a long time may cause

failures due to its structural features. Please be careful.

2) The touchscreen is made of surface film and tempered glass. There is a possibility of the

touchscreen becoming inoperable due to cracks and/or other damages to the surface film.

Also, the tempered glass can easily damage if scratched. Please handle the touchscreen so

it does not come in contact with hard objects.

3) Due to the characteristics of the touchscreen, touching slightly outside the display area may

be detected as the coordinates of the edge of the touchscreen. Please take this into

consideration when designing applications.

4) The coordinates of the touchscreen may shift over time or depending on the environment of

use.

If the coordinates shift, please perform calibration (coordinate correction). For details, please

refer to “4.4 Calibation”.

5) Due to the structure of the touchscreen, sealing material may be visible at the edge (upper

right corner when viewed from the front) of the touchscreen.

Please refer to the Shipping Standards for details. (Please contact our sales

representatives.)

TM Series Instruction Manual A

Table of Contents

1. Features ....................................................................................................................1

1.1 Features........................................................................................................................................... 2

1.2 Line-Up ............................................................................................................................................ 3

2. Product Configuration .............................................................................................4

2.1 Names and Functions of Each Parts ............................................................................................... 5

2.2 Options............................................................................................................................................. 6

2.3 Installing the TM .............................................................................................................................. 8

2.4 Wiring............................................................................................................................................. 10

3. OSD..........................................................................................................................14

3.1 OSD Menu (Factory Default Setting)............................................................................................. 15

4. Touch Screen Properties .......................................................................................16

4.1 System Requirements ................................................................................................................... 17

4.2 Installation...................................................................................................................................... 18

4.3 Setting............................................................................................................................................ 22

4.4 Calibration...................................................................................................................................... 27

5. Maintenance............................................................................................................30

5.1 Maintenance .................................................................................................................................. 31

6. Troubleshooting .....................................................................................................32

6.1 Display ........................................................................................................................................... 33

6.2 Touchscreens................................................................................................................................. 34

7. Others......................................................................................................................35

7.1 Warranty and Repair...................................................................................................................... 36

7.2 Production Discontinuance ............................................................................................................ 37

7.3 Inquiries ......................................................................................................................................... 38

1Features

TM Series Instruction Manual 2

1.1 Features

■Front surface a full flat design.

■Slim type chassis.

■Supports HDMI video signal as a series.

■USB3.0 Upstream Port with shock-resistant “Standard Type B” connector.

■A lineup of projected capacitive touchscreens: TMG Series

-Supports five-point touch

■A lineup of light weight resistive touchscreen: TMH Series

-Resistive type that supports gestures such as flick, pinch in/out, rotate)

■Can be operated with gloves.

*Some glove may not be compatible depending on the type and the environment in which

they are used.

■Supports DC Power input (12V).

The connector uses DC jack with a screw when used with a compatible DC plug, it will prevent

disconnection.

AC adaptor with screw-lock is available as option.

It can also be used with a regular DC plug (without a screw-lock).

AC adaptor without a screw-lock is also available as option.

■Long-life, high-luminance LCD for industrial equipment.

■The IPS type LCD provides a wide view angle and can be displayed as either portrait or

landscape mode.

■Mounting angle of the VESA Box can be changed (variable angle: 90degress) /

Improved routing flexibility of the interface cable.

■Adoption of VESA mounting standard (100 x 100mm).

■Stand-alone made possible by using an optional free-stand.

1Features

TM Series Instruction Manual 3

1.2 Line-Up

Model

Specification

LCD size

Touchscreen type

Video Input

USB (Host I/F)

TMG-156FH01-01

15.6 inch

wide

Projected capacitive

HDMI

USB3.0 Type-B

(USB2.0 Type-B

connectable)

TMH-156FH01-01

15.6 inch

wide

Analog resistive※

HDMI

USB3.0 Type-B

(USB2.0 Type-B

connectable)

※Analog resistive touchscreen used in TM supports gesture operations such as flick, pinch in, pinch out,

and rotate. (Does not support two-point touch.)

2Product Configuration

TM Series Instruction Manual 4

2. Product Configuration

Chapter Contents

2.1 Names and Functions of Each Parts .........................................................5

2.2 Options ......................................................................................................6

2.3 Installing the TM ........................................................................................8

2.4 Wiring ......................................................................................................10

2Product Configuration

TM Series Instruction Manual 5

2.1 Names and Functions of Each Parts

TMG-156FH01-01,TMH-156FH01-01

*1 Connect an USB cable when using as a touchscreen monitor.

Part

No

Name

Function

①

USB Host I/F*1

USB3.0 Standard Type-B Connector

(USB2.0 Type-B connectable)

②

Power Input

Input power. (12VDC)

③

Image Input (Digital)

HDMI connector

④

FG Terminal

Connects to Field GND.

⑤

VESA Box

Can be rotated by customer

①

③

②

④

⑤

2Product Configuration

TM Series Instruction Manual 6

2.2 Options

“AC adaptor (with/without screw-lock)”, “Self-standing stand” are available as option.

2.2.1 AC Adaptor (with screw lock)

Model: ATS065T-P120B15210 (customized model)

Manufacturer: Toki Trading Ltd.

・AC Adaptor 1 unit ・AC cord 1pc

<Note>

Warranty coverage: Coverage within the AC adaptor manufacturer’s warranty.

Make sure the power cord provided conforms to the standards specified for the country or

region in which it will be used.

2.2.2 AC Adaptor (without screw lock)

Model: AKA-12050 (standard model)

Manufacturer: Aikoh Electronic Corporation

・AC Adaptor 1 unit ・AC cord 1pc

<Note>

Warranty coverage: Coverage within the AC adaptor manufacturer’s warranty. Make sure

the power cord provided conforms to the standards specified for the country or region in

which it will be used.

2Product Configuration

TM Series Instruction Manual 7

2.2.3 Self-Standing Stand

Model: SWST-01-001

2.2.3.1. Items included

・Stand (arm) 1unit ・Stand (base) 1 unit

・VESA mounting screw 4pcs ・List of included items 1copy

2.2.3.2. Assembly Instruction

1) Remove the screw attached to the arm.

2) Put together the arm and the base.

3) Screw together with the screw removed at 1).

1pc screw for

assembly included.

1)

2)

3)

Complete

2Product Configuration

TM Series Instruction Manual 8

2.3 Installing the TM

2.3.1 Installing Conditions (Precautions)

•To install the TM, use the M4 screw holes (VESA Standard 100mmx 100mm) provided in the

VESA box.

•When installing using a commercially available arm or stand, be sure to select one that can

withstand the weight of the TM.

•Please be careful not to drop the product as it may cause human injury or damage to the

product.

•Make sure there is enough room for inserting and removing of cables when installing.

•Use the product within the specified ambient operating temperature and humidity.

•Please install so the touchscreen does not come in contact with metal.

•If metal should come near the touchscreen, be sure to leave a space of 2mm or more between

the touchscreen and metal, otherwise it may cause malfunctions.

2.3.2 Installing of Optional Stand

Use the M4 screws provided with the optional stand for installation.

Tightening torque is 0.7 to 0.8N-m.

Angle adjustment range is +90° to -5°.

If installed to our option stand “SWST-01-001”, the angle can be adjusted for easy viewing.

Installation Stand adjustment range

SWST-01-001 Installation Diagram

2Product Configuration

TM Series Instruction Manual 9

2.3.3 Installing “VESA Standard”Arm

The TM can be installed to a commercially available arm and/or stand.

Parts to be used for installation shall meet the UL1678 standards.

Please refer to the manual of the arm for installation procedures.

Installing hole dimensions are as follows (VESA Standard 100mm x 100mm)

Use M4 screws with tightening torque of 0.7 to 0.8N-m

Please select the M4 screws so the penetration depth of the screw is 8mm or less from the

backside.

VESA Standard

VESA is the abbreviation for” Video Electronics Standards Association”, an industry organization that

establishes standards for computer displays.

VESA established SVGA standards and VL bus standards and standardized below 2 types of LCD

monitor installing dimensions as below.

●75mm×75mm pitch

●100mm×100mm pitch

TM complies with the VESA standard 100mm×100mm.

2Product Configuration

TM Series Instruction Manual 10

2.4 Wiring

Be sure no power is supplied when wiring and connecting to avoid the risk of electrical shocks.

Do not turn the power on until all connections have been made.

Prepare the cables to be used according to the specifications.

2.4.1 Wiring of Power Supply

■Compliant DC plug specifications

●DC Plug with screw lock

Outer diameter: Φ5.5mm, Inner diameter: Φ2.1mm, Screw lock: 5/16-32 UNEF-2B

Allowable voltage: 12V or more, Allowable current : 5A or more

unit: mm

●DC Plug without screw lock

Outer diameter: Φ5.5mm; Inner diameter: Φ2.1mm

Allowable voltage: 12V or more, Allowable current : 5A or more

unit: mm

■Power Supply Wiring Precautions

(1) Be sure to wire separately the power supply, input/output equipment, and the power

equipment of the TM.

(2) Do not bundle nor bring close together the main circuit line (high voltage, high current),

signal line, and power cable.

(3) Attach a ferrite core to the power cable if affected by noise.

(4) Connect a lightning surge absorber if necessary.

■Grounding Precautions

(1) FG should be dedicated grounding. “Installation should be D-class grounding, grounding

resistance of 100Ωor less.”

(2) SG (Signal Ground) and FG (Frame Ground) is connected internally inside the TM. When

connecting the connecting device and the SG, design the system so that there is no short

circuit loop.

(3) Use a grounding wire of 2mm2 or more. The grounding point should be near the TM at

shortest length. If ground wire becomes long, use a thick insulation wire when setting.

(4) The TM will be FG grounded if the VESA arm is grounded to FG because the VESA arm

surface is conductive.

*Shortest Value

*

*

*Recommended Value

2Product Configuration

TM Series Instruction Manual 11

2.4.2 Wiring Procedure

(1) You will need a “USB Cable” and a “Video Interface Cable” in order to connect to a computer.

(2) Make sure that the TM and the computer to which it is connected are not powered.

(3) Connect the TM and the computer as show in in below diagram.

*Connect to the power supply last.

*Attaching a ferrite core to each cable may be effective against noise.

Model

Image Interface Cable

USB Cable

TMG-156FH01-01

TMH-156FH01-01

HDMI

USB3.0 or USB2.0

(4) Standard orientation of the TM is vertical display installation. Set the TM display orientation

to “portrait (opposite orientation)” in the computer setting.

(5) For TMH-156FH01-01, refer to “4.4.2 Resistive Touchscreen” and click the box in front of

“Use EEPROM” to register.

(6) Calibration is not necessary for the TM in the factory default state. In case of touch

coordinate misalignment or unstable touch operation, please refer to “4.4 Calibration” and

perform calibration.

(7) Resetting of the touch coordinate (rotation) of the touchscreen is not necessary. However,

if the touch coordinates are rotated, please refer to “4.3.4 Touch Coordinate Rotation” and

rotate the touch coordinates.

Computer

AC Power supply

Note: Connect last

注:最後に接続すること

USB Cable

HDMI Cable

FG (Field Ground)

AC Adaptor

2Product Configuration

TM Series Instruction Manual 12

2.4.3 Rotating the VESA Box

The VESA box at shipment from the factory is oriented so the image interface is in the

longitudinal direction.

Video interface can be rotated and changed by the customer.

■Rotating the VESA Box

(1) Turn off the power of the main unit and disconnect any peripheral devices connected to the

TM.

(2) Place the main unit on a flat and stable surface, such as a desk, with the display side

facing down.

[Caution] Please be careful not to damage the display surface.

(3) Remove the four screws securing the VESA box.

[Caution] Please be careful not to drop the screws inside the main unit and/or lose them.

(4) Lift the VESA box gently about 1 to 2cm.

[Caution] Lifting the VESA box too high may break or damage the wires.

VESA Box

Fixing screws

(4 places)

Box side

Position mark

Unit side

Position mark

2Product Configuration

TM Series Instruction Manual 13

(5) Rotate the box 90 degrees clockwise so that the position marks on the body side and the

position marks on the box side are aligned.

[Caution] Rotating more than 90 degrees may cause disconnections or damages.

Attempting to forcibly remove the VESA box may break or damage the wires.

(6) Gently place the VESA box over the main unit so that there is no gap between the main

unit and the VESA box.

Screw in four places with the four VESA box fixing screws removed from the VESA box in

step (3). (Installation torque: 0.7 to 0.8N-m).

[Caution] Make sure that wires are not trapped between the box and the main unit.

If a screw is lost, make sure it is not inside the main unit.

If power is turned ON with the screw inside the unit, it may cause a malfunction.

(VESA box set screw: (+) pan head machine screw W-Sems diameter M4*8 NI

plated)

(7) After rotating the direction of the interface, turn on the main unit and set the computer

display (landscape view) and make sure the display is working correctly.

(8) If touch operation is unstable, perform calibration referring to”4.4 Calibration.

(9) There is no need to reset the touch coordinates (rotation) of the touch screen. If the

touch coordinates are rotated, please refer to”4.3.4 Rotation of Touch Coordinates “to

rotate the coordinates.

[Caution] Rotate the VESA box 90 degrees counterclockwise to return the interface

direction from the horizontal position to the shipped position (down position).

Rotating the VESA box more than 90 degrees may cause wire disconnection or

damage.

Box side

Position mark

Unit side

Position mark

VESA box

Fixing screws

(4 places)

Other manuals for DUSH TM Series

1

This manual suits for next models

2

Table of contents

Other DMC Touchscreen manuals

Popular Touchscreen manuals by other brands

Honeywell

Honeywell Galaxy TouchCenter Plus Installer manual

Elo TouchSystems

Elo TouchSystems E893866 Quick installation guide

IEI Technology

IEI Technology AFL2-12A-D525 Series user manual

InFocus

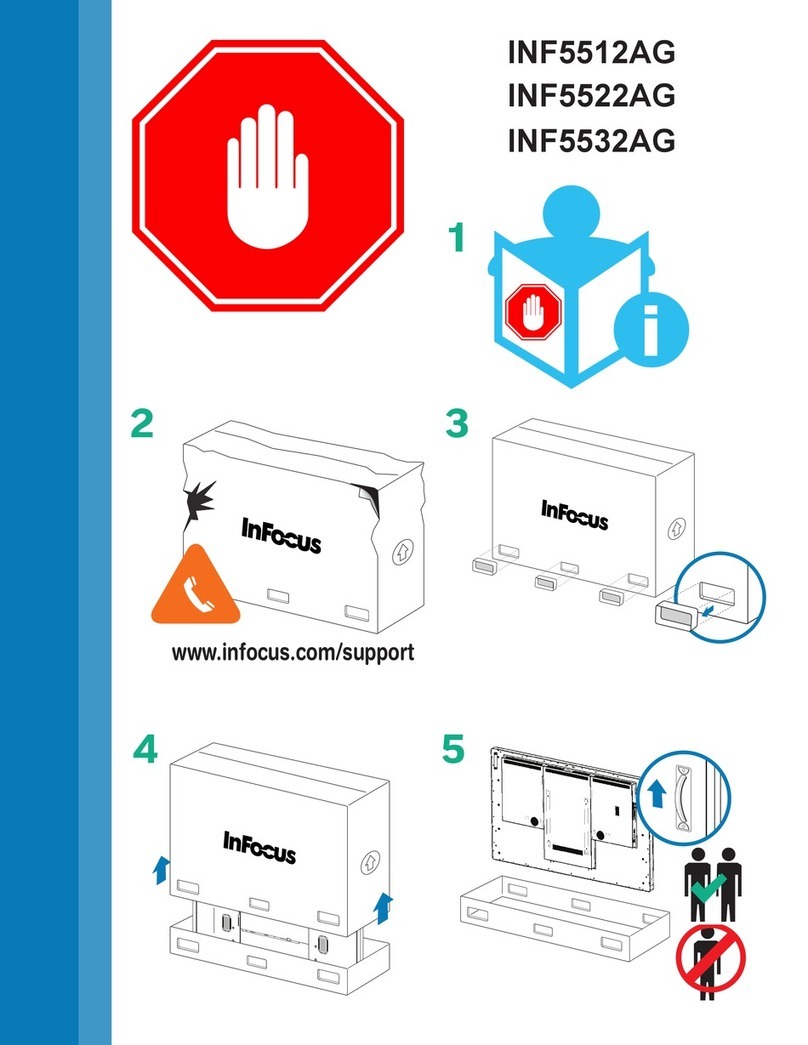

InFocus INF5532AG Handling guide

HDI

HDI Mobi OS Series Operation manual

COOPER FIRE

COOPER FIRE CTPR3000 installation manual