DMC EMP Series User manual

- 2 -

20A4A4-00002E-1

Table of Contents

Introduction ..................................................................................... 3

Notes .......................................................................................... 3

Precautions for Safe Use ......................................................................... 3

Warnings..................................................................................... 4

Cautions ..................................................................................... 5

Handling of LCD Panels ........................................................................ 7

Handling of Touchscreens ...................................................................... 7

Packaged Contents .............................................................................. 8

Name of Parts................................................................................... 9

External Interface ............................................................................... 10

Power/ Communication/ Contact Output I/F....................................................... 10

6-1-1 Emergency Stop Switch Output ....................................................... 11

6-1-2 Enable Switch Output ................................................................ 12

6-1-3 Selector Switch Output............................................................... 13

Wiring......................................................................................... 14

EMP Connection ............................................................................. 14

Calibration..................................................................................... 15

Touchscreen Coordinate Calibration ............................................................. 15

Boot-up ....................................................................................... 16

Maintenance ................................................................................... 16

Display ..................................................................................... 16

Regular Maintenance ......................................................................... 16

Optional Items ................................................................................. 17

Warranty and Repairs ........................................................................... 18

Inquiries .................................................................................... 18

Warranty .................................................................................... 18

Production Discontinuance..................................................................... 18

Repair Condition ............................................................................. 18

Others ........................................................................................ 19

- 3 -

20A4A4-00002E-1

Introduction

Thank you for choosing DMC products.

Please read this manual carefully and use our product correctly.

This manual describes the teaching pendant equipped with 7” LCD and analog resistive touchscreen.

In this manual, the teaching pendant will be referred to as EMP.

Notes

◼Reproduction and/or duplication of this product and/or this manual, in any form, in whole or in part, without

permission is strictly prohibited.

◼Contents of this product and/or this manual are subject to change without prior notice.

◼Although all efforts have been made to ensure the accuracy of this product and/or the contents in this manual,

should you notice any errors or have any questions, please contact and notify us.

◼DMC shall not be held liable in any way for damages or losses, nor be held responsible for any claims by a

third party as a result of using this product.

Precautions for Safe Use

Precautions are noted in this manual for the product to be used safely. Read this manual along with other related

manuals carefully to understand the correct handling and functions of the EMP.

Safety Symbol Legends

Safety symbols listed below are noted throughout this manual for the EMP to be used correctly. These symbols stand

for important safety information as noted below.

Warning

Indicates a procedure, condition, or statement that, if not strictly observed, could result in

severe human injuries or loss of life.

Caution

Indicates a procedure, condition, or statement that, if not strictly observed, could result in

human injuries or property damage.

Indicates a procedure, condition, or statement that is strictly prohibited for correct use of the

equipment. (Forbidden)

Indicates a procedure, condition, or statement that must be strictly followed for correct use

of the equipment. (Mandatory)

- 4 -

20A4A4-00002E-1

Warnings

Warning!

Warnings for Design

D esigning switches that might cause human injuries and/or property damages on the touchscreen is strictly

prohibited.

Unintentional output signals due to malfunction of the main body, units, and/or cables, etc. can cause serious

injuries. Please design the system so that switches with major functions are equipped on device other than the

EMP.

Designing equipment safety related switches on the touchscreen is prohibited

For safety related switches, such as emergency stop switches, use a hardware switch from a different system.

Design the system so that the machine will not malfunction due to communication abnormalities between the

EMP and the host controller.

Failure to do so may result in injuries to the human body or property damages.

Do not use EMP as a major warning system that may cause injuries/ serious property damages, and or production

stoppage. Control devices related to critical warning displays and warnings should be structured by an

independent, redundant hardware system or a mechanical interlock.

EMP is not intended for use for aircraft equipment, aerospace instruments, trunk line communication equipment,

nuclear power control equipment, and medical equipment that concerns life support, and or other equipment that

concerns high reliability and safety. It cannot be used for these purposes.

When using the EMP for purposes that concern high reliability and safety functions and accuracy such as

transport equipment (trains, automobiles, ship, etc.), crime/disaster prevention devices, various safety devices,

and medical equipment that does not concern life support, be sure to have safety features including redundancy

and false operation prevention measures incorporated into the entire system.

Display will black out when the backlight goes out. If mistakenly operated in this condition, it might result in

improper operation. Do not design touch-switches that might cause human injuries and property damages on the

EMP.

Following phenomenon as below will occur when the backlights go out:

(1) Display will go out even if the Backlight OFF function is not set.

(2) Display does not recover at touch after the backlight goes off while the Backlight OFF function is set.

Warnings for Handling

Do not modify/disassemble the EMP. Doing so may cause fire and/or electric shocks.

Do not use around flammable gas. Doing so may cause explosions.

Do not put any kind of liquid, such as water, or metal into the product. Doing so may cause fire and/or electric

shocks.

- 5 -

20A4A4-00002E-1

Warnings for Wiring

For wiring and installation, please refer to the manual and specifications in order to conduct it correctly. Failure

to do so may cause fires and/or electric shocks.

Before installing the power cable, make sure power is not being supplied from power source. Failure to do so

may cause electrical shocks.

Do not use power voltage other than the voltage specified. Doing so may cause fire and/or electric shocks.

Warnings for When Turning the Power ON and During Maintenance

Do not connect/disconnect the communication cable with the host while the power is ON.

Cautions

Cautions!

Cautions for Installation

Make sure cables are securely connected to connectors to avoid incorrect input and output due to loose

connection.

Cautions for Wiring

Make sure foreign objects such as chips and scraps do not enter the EMP. Failure to do so may cause fires,

damages, and/or malfunctions.

Cautions for Disposal

When disposing the product, please treat it is as industrial waste.

- 6 -

20A4A4-00002E-1

To Avoid Malfunctions

Do not press down hard on the display area of the EMP with hard objects. Doing so may break the touchscreen

LCD panel and may cause injuries. Also, do not press down on the panel with sharp objects such as mechanical

pencils and drivers. Doing so may cause damages.

Installing the EMP in areas outside the range of the specified temperature may cause failures.

Avoid using in areas where temperature may build up rapidly. Failure to do so may cause failures.

Avoid using in areas where rapid temperature change could cause condensation. Failure to do so may cause

failures.

Do not put water, any kind of liquid, and conductive objects such as metal parts, inside the EMP. Doing so may

cause failures or electric shocks.

Do not use or keep EMP in locations with exposure to direct sunlight, high temperatures, fine particles, humidity,

and /or vibration.

Avoid using and storing in areas where chemicals are vaporized and emanating in the air, or in places where

chemicals can adhere to the product.

Acids, Alkalis, and other saline chemicals: May cause failures due to corrosion.

Organic solvents: May cause fires.

If the surface of EMP gets dirty, wipe with a dry, soft cloth damped with a neutral detergent then wrung dry. Do

not wipe with thinner or organic solvents.

T he liquid crystal in the display will deteriorate by ultraviolet rays. Do not use or keep in areas with strong

ultraviolet rays.

When stored in sub-ambient storage temperature, the liquid crystal in the display may coagulate and damage

the panel. If stored in over-ambient storage temperature, the liquid crystal will turn isotropic liquid and will not turn

back to its original state. Please store in the specified ambient temperature range.

After turning off the power of EMP, leave it off for a while before turning the power back on. It may not function

normally if failed to do so.

Be sure to take back-up of the data in the EMP assuming the loss of data in an event of an unexpected accident.

- 7 -

20A4A4-00002E-1

Handling of LCD Panels

1) The LCD contains skin-irritating materials. If liquid materials flow or spill out due to damages and comes in contact

with the skin, immediately wash the area under running water for at least 15 minutes and consult a physician.

2) The LCD might have uneven brightness according to the contents being displayed. Please note that this is not a

malfunction.

3) Minute spots (black or bright) may occur in the LCD elements. Please note that this is a basic characteristic of

LCD and not a malfunction.

4) When the display of the LCD is viewed from outside the specified viewing angle, the displayed color might seem

different. Please note that this a basic characteristic of the LCD.

5) When a same image is displayed for a long period of time, it may remain as an afterimage. Please note that this

is a basic characteristic of the LCD.

To avoid afterimages, follow the below procedures:

1. When leaving the same image displayed, use the “Display OFF” function.

2. Change the image displayed periodically and do not display the same image for a long period of time.

Handling of Touchscreens

1) Please be warned that applications that require for one point to be pressed for a prolonged time may cause

failures due to the touchscreen s structural characteristics.

2) The touchscreen is made of glass. Glass breaks easily if scratched. Please handle with care and avoid glass from

coming in contact each other and hard objects.

3) Due to the characteristics of the touchscreen, touching slightly outside the display area may be detected as the

coordinates of the edge of the touchscreen. Please consider the above when designing the application.

4) Touchscreen coordinates may shift due to aging or depending on its operating environment. If the touchscreen

coordinate shifts, conduct calibration of the touchscreen to correctly set the coordinates.

5) Please be careful when handling the glass. The glasses are not chamfered and can easily cause injuries.

- 8 -

20A4A4-00002E-1

Packaged Contents

Below are included in the package. Please check before use.

*Maximum number of units that could be stored: 1unit

<Note>

Although all efforts have been made to ensure the quality and packaging at shipment, should you notice any damage

or shortage of parts, please contact your dealer or DMC for additional instructions before use.

Main Unit 1unit/ Box*

- 9 -

20A4A4-00002E-1

Name of Parts

No

Name

Contents

1

Hole for hooks to hang on walls*1

Bracket for temporarily hanging the EMP on walls

2

Emergency Stop Switch

Emergency Stop Switch

Contact Output

・Device side output Form B contact x 2

・Internal use *2 Form B contact × 1

3

Enable Switch

Enable Switch

3 position type switch: not pressed (released), pressed to the

middle position, pressed completely (closed).

Contact output

・Device side output 3 position contact x 2

・Internal use*2 Recovery monitor contact x 1, Push-in monitor

contact x 1

4

Selector Switch

MODE Changing Switch

Contact Output

・Device side output Form B contact x 2

・Internal use *2 Form C contact × 1

5

Membrane Sheet Key Switch 12 points

Recognized as function keys F1~F12*2

6

Status LED*3

LED Status color: 2 (Red, Green)

7

External Interface

(Power/ communication/ contact output I/F)

Interface to connect power (24VDC), communication (ethernet),

and contact output

*1: Please do not operate or wire the EMP hung on a wall. Doing so may cause the EMP to drop and cause injury or

damage to the equipment.

*2: Can be detected by software. Please read the software manual for details

*3: Can be controlled by software. Please read the software manual for details.

7W TFT

Touchscreen

5

3

7

2

1

4

6

⑪F11

⑨F9

⑦F7

⑤F5

③F3

①F1

⑫

F12

⑩

F10

⑧F8

⑥F6

④F4

②F2

Key layout

- 10 -

20A4A4-00002E-1

External Interface

Power/ Communication/ Contact Output I/F

Round Connector: HR22-12WTRA-20pc (73) (by HRS)

Contact: Gold plated

Pin

No

Signal

Remarks

1

LAN_RXD+

Ethernet

2

LAN_RXD-

3

LAN_TXD+

4

LAN_TXD-

5

NC

Not connected

6

S_NC1

Selector contact 1

(Form B contact)

7

S_C1

8

S_NC2

Selector contact 2

(Form B contact)

9

S_C2

10

NC

Not connected

11

A_NC1

Emergency stop contact 1

(Form B contact)

12

A_C1

13

A_NC2

Emergency stop contact 2

(Form B contact)

14

A_C2

15

E_NO1

Enable contact 1

(Form A contact)

16

E_C1

17

DC24V-(GND)

DC24V Power

18

DC24V+

19

E_NO2

Enable contact 2

(Form A contact)

20

E_C2

Round connector pin number

- 11 -

20A4A4-00002E-1

Contact

Signal

Details

Emergency Stop

Contact 1

A_NC1

Form B contact

Contact rating: 1A/DC30V (Resistive load), 1A/DC30V

(Inductive load)

(Reference value Minimum applicable load DC5V 1mA)

A_C1

Emergency Stop

Contact 2

A_NC2

Form B contact

1A/DC30V (Resistive load), 1A/DC30V (Inductive load)

(Reference value Minimum applicable load DC5V 1mA)

A_C2

Activating the emergency stop switch will contact output.

To deactivate the emergency stop (lock), pull the button forward or turn in the direction of the arrow.

The conduction state of A_NC1-A_C1 and A_NC2-A_C2 when the emergency stop switch is pressed is as follows:

Contact

Signal

Deactivated

Activated

Emergency Stop

Contact 1

A_NC1

Close

Open

A_C1

Emergency Stop

Contact 2

A_NC2

Close

Open

A_C2

A_NC1

A_NC2

A_C2

A_C1

- 12 -

20A4A4-00002E-1

Contact

Signal

Details

Enable Contact 1

E_NC1

Form A contact [3 position]

Contact rating: 1A/DC30V (Resistive load), 0.7A/DC30V

(Inductive load)

(Reference value Minimum applicable load DC5V 1mA)

E_C1

Enable Contact 2

E_NC2

Form A contact [3 Position]

Contact rating: 1A/DC30V (Resistive load), 0.7A/DC30V

(Inductive load)

(Reference value Minimum applicable load DC5V 1mA)

E_C2

There are three positions for the enable switch: not pressed (released), pressed to the middle, and fully pressed (fully

closed).

The conduction state of E_NC1-E_C1 and E_NC2-E_C2 at each switch position are as follows:

Contact

Signal

Not pressed

Pressed to the

middle

Fully pressed

Enable Contact 1

E_NC1

Open

Close

Open

E_C1

Enable Contact 2

E_NC2

Open

Close

Open

E_C2

E_NC1

E_NC2

E_C2

E_C1

- 13 -

20A4A4-00002E-1

Contact

Signal

Details

Selector Contact 1

S_NC1

Form B contact

Contact rating: 1A/DC30V (Resistive load), 0.7A/DC30V

(Inductive load)

(Reference value Minimum applicable load DC5V 1mA)

S_C1

Selector Contact 2

S_NC2

Form B contact

Contact rating: 1A/DC30V (Resistive load), 0.7A/DC30V

(Inductive load)

(Reference value Minimum applicable load DC5V 1mA)

S_C2

Switching the selector switch will contact output.

Selector Switch can be manually switched between 2 notches: [〇(left)], [|(right)].

The conduction state of A_NC1-A_C1 and A_NC2-A_C2 when selector switch is switched are as follows:

Contact

Signal

〇(left)

|(right)

Selector Contact 1

S_NC1

Close

Open

S_C1

Selector Contact 2

S_NC2

Close

Open

S_C2

*Key can be pulled out from both sides.

S_NC1

S_NC2

S_C2

S_C1

- 14 -

20A4A4-00002E-1

Wiring

EMP Connection

Connecting with external interface.

・Compatible connector: HR22-12WTPA-20SC (by HRS) (Contact: gold plated)

*Option cable ‘SWHC-F1-001’ can be used.

・When inserting and removing the connector, be sure to turn off the power of the circuit.

・Be sure to engage the screw lock mechanism when using the connector (Tighten the screw securely and

completely).

Power, communication, and contact output can be easily connected by using the conversion board included in our

development kit [SWDK-103]

SWHC-F1-001

EMP

External Interface

LAN cable

SWHC-F1-001

Connector to be use on device

Assembly

Conversion board of development kit

[SWDK-103]

SWHC-F1-001

DC24V Power

PC for debugging, etc.

Contact Output

Contact control jig, etc.

- 15 -

20A4A4-00002E-1

Calibration

Touchscreen Coordinate Calibration

If there is a large misalignment between the pressed location and the detected coordination, please conduct

calibration.

- 16 -

20A4A4-00002E-1

Boot-up

Make sure the power wiring is complete before turning the power ON.

After the startup screen appears, the OS will start up.

Maintenance

Display

When the surface or the frame of the display gets dirty, wipe with a soft cloth damped in diluted neutral detergent and

wrung tightly.

Do not use thinner, organic solvents, or strong acid solvents

Regular Maintenance

To use the EMP in its best condition, please conduct maintenance on a regular basis.

□Surrounding Environment Check

(1) Ambient temperature is within specification range (0°C to 40°C).

(2) Ambient humidity is within specification range (10 to 90%RH).

(3) Operating pressure is within specification range (800 to 1114hpa).

□Electronic Specification Check

(1) Voltage is within permissible range (24VDC±20%).

□Installation Check

(1) Make sure the connection cables are inserted firmly and completely.

- 17 -

20A4A4-00002E-1

Optional Items

■Development Kit

Model

Specifications (Configuration)

SWDK-103

1 Conversion board with composite cable terminal block

1 set of IS-APP Development Environment

■Option Cable

Model

Specifications (Configuration)

SWHC-F1-001

1 Cable (length: 5m)

Separated wire on HOST connection side (with semi-stripped tip)

- 18 -

20A4A4-00002E-1

Warranty and Repairs

Inquiries

In case of failures or when repair is needed for DMC products, feel free to contact us.

When making inquiries, please confirm the issue or the symptom beforehand. Also, when shipping the product,

please include a fully filled “Repair Request” form with the issues or the symptoms noted.

Please make sure the product is well packaged so it will not get damaged during shipment.

Warranty

The warranty period is limited to 12 months from the date of shipment. Any defects that occur under the

environmental conditions noted within the specification will be repaired free of charge (factory repair).

The warranty for defects of the same repaired area is limited to three months.

You will be liable for all repair fees even within the warranty period for any conditions listed below.

(1) Any malfunctions and/or damages caused by dropping or impact during transportation and transferring of the

product after delivery.

(2) Any malfunctions and damages caused by natural or human-made disaster.

(3) If the product is used under any condition, environment, or method other than those described in the product

specification, catalogs, manuals, or others.

(4) Replacement of consumables.

(5) Any malfunctions and damages caused by failure of associated equipment and inappropriate consumables and

medias.

(6) Any malfunctions caused by science or technology that could not be predicted at the time of sales.

(7) Other malfunctions, damages, and/or defects that is considered to be caused by the user.

The warranty covers only the delivered product and does not cover the damages caused by the failure of the product

and/or on-site repairs and replacements.

Production Discontinuance

In the event of production discontinuance, an announcement will be made six months prior to the last possible order

reception date

Repair Condition

(1) Only DMC products can be repaired. Options are exempt.

(2) Programs and data might be lost during repair. Please be sure to take back-up in advance. DMC will not be held

liable for programs or data lost during repair.

(3) Although all user information stored in our product will be handled and managed with much care, we ask that any

important confidential/security information be delete before repair.

(4) Repairs will be performed in our factory workshop. All shipping costs to our factory will be charged to the customer.

(5) DMC will have all ownership of the parts exchanged at repair.

- 19 -

20A4A4-00002E-1

Others

For comments or inquiries, feel free to contact us via e-mail.

North South America area

technical-global@dush.co.jp

Asia Pacific area

technical-global-asia@dush.co.jp

Europe, Middle East, Africa area

technical-global-eu@dush.co.jp

FAQ

www.dush.co.jp/english/support/faq/

1st Edition November 2023

DMC Co., Ltd.

Office hours: 9:00a.m to 5:00 p.m. (JST)

(Except Saturdays, Sundays, national holidays, and year-end and New Year holidays)

URL: https: //www.dush.co.jp/english/

This product and document are protected by the copyright law. Photocopying, duplicating, reproducing, and

modifying of this product or document in part or by whole is prohibited.

Copyright(C) 2023 DMC Co., Ltd. All Rights Reserved

This manual suits for next models

2

Table of contents

Other DMC Touchscreen manuals

Popular Touchscreen manuals by other brands

Elo Touch Solutions

Elo Touch Solutions ET3201L user manual

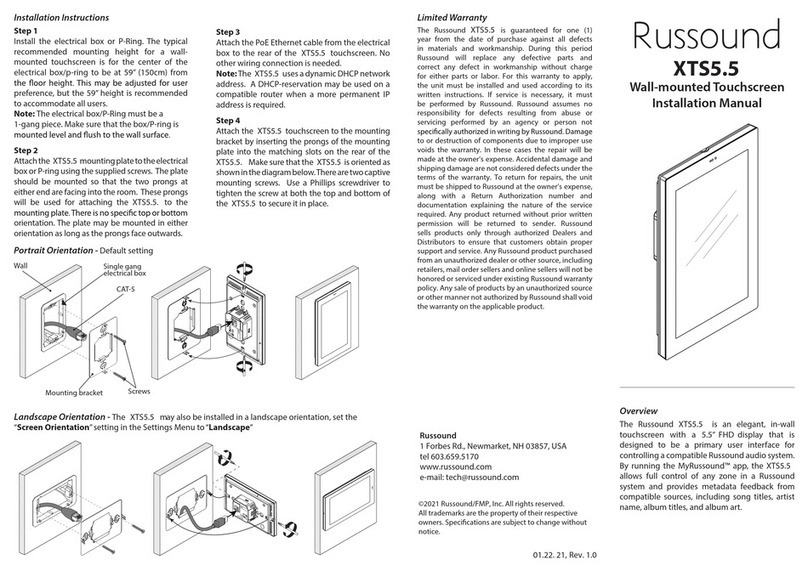

Russound

Russound XTS5.5 installation manual

Prowise

Prowise ProLine Plus quick start guide

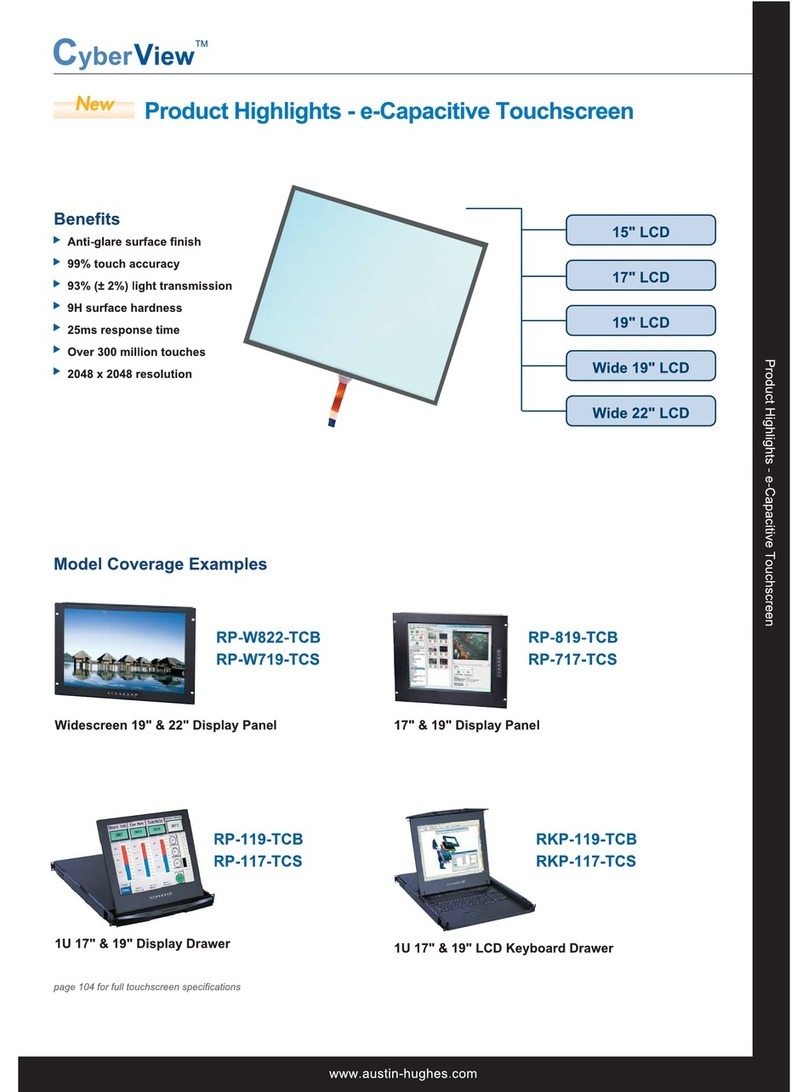

Austin Hughes Electronics

Austin Hughes Electronics CyberView RP-117-TCS Specifications

Winmate

Winmate R12IBWS-MHM2 user manual

interactive scape

interactive scape Scape Tangible 43 operating manual