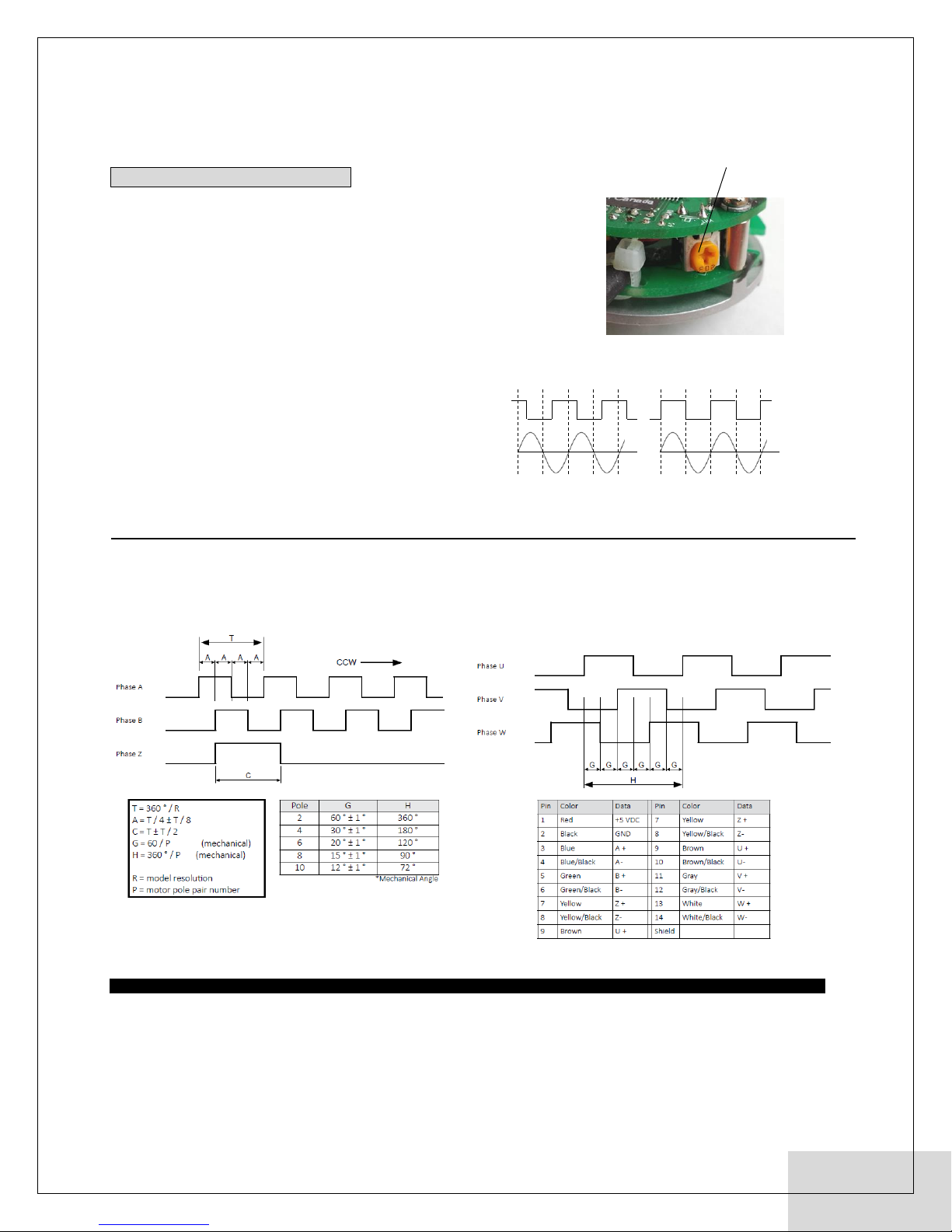

Step 4. Commutation phase adjustment

*This step applicable only to models with commutation output.

For motor applications only.

Power up the encoder with supply voltage.

The commutation phase reference mechanical location is adjusted

using the on-board potentiometer. The mechanical phase angle

can be adjusted up to 180°.

Externally actuate the motor shaft so the motor generates back-EMF,

and the encoder rotary is also rotated. Synchronize the motor back-EMF

voltage with the encoder output U + signal (or V + or W +) by

adjusting the on-board potentiometer.

Rotate the potentiometer while viewing the U + signal and motor

back-EMF voltage to zero synchronize the commutation signal.

Once the motor back-EMF and encoder commutation are matched,

the U,V,W commutation adjustment process is complete.

Ensure the potentiometer dial cannot be unexpectedly moved

during normal operation.

Interface

□A leads B for CCW rotation - viewed from encoder shaft/mounting side

□Line Driver Output

□14-position, 0.4mm O.D. copper conductor

□6mm O.D. interface cable

□Max. Cable Distance = 100m

PRODUCT TERMS

All specified data subject to change without notice to reflect updates and improvements made to product. DMM Technology Corp. warrants the quality and performance of for one year

starting date of shipment from original factory. DMM Technology Corp. assumes no responsibility for damages resulting from user related errors or improper use of product, in which

case the warranty terms will be void. Safety precautions should be considered for all applications. As this product does not include safety conditions, always design a higher level

feedback to reduce the risks of product or bodily harm. All information included in this manual represents data measured under DMM Technology Corp’s own test conditions. Actual

performance may vary and the user is responsible for optimizing the application with respect to the encoder’s capabilities.

DMM Technology Corp. ©2013

Installation Manual DMMDSN05_INMT | rev. A1.4 | 09/13

DMM Technology Corp.

3125 - 21331 Gordon Way

Richmond, BC V6W 1J9

Canada

TEL : +1.604.370.4168

WEB : www.dmm-tech.com

Tuning complete!

Motor back E.M.F

Measured between U,V

motor power wires