SERIES I4 · Model I4F

Section INDUSTRIAL . ISOLATED SIGNAL CONVERTERS

www.fema.es 3

If this is the rst time you are conguring the instrument, below

are the steps to follow during a rst installation. Read all the

manual sections in order to have a full and clear view of the

characteristics of the instrument. Do not forget to read the installation

precautions at section 20.

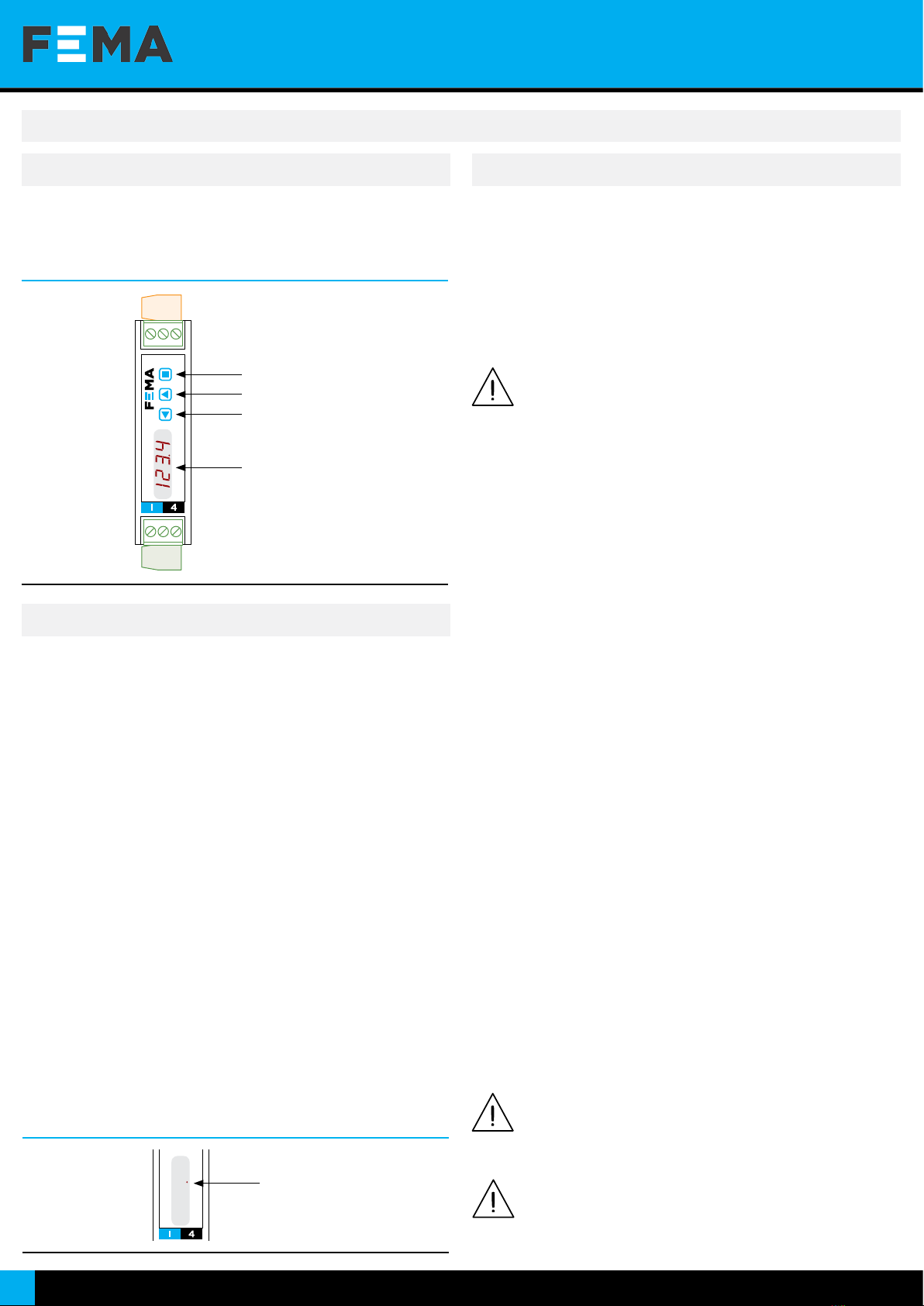

1. Install the instrument at the DIN rail

2. Read how to operate the instrument (see section 12)

3.

Connect the input, the output and the power terminals

(see section 11).

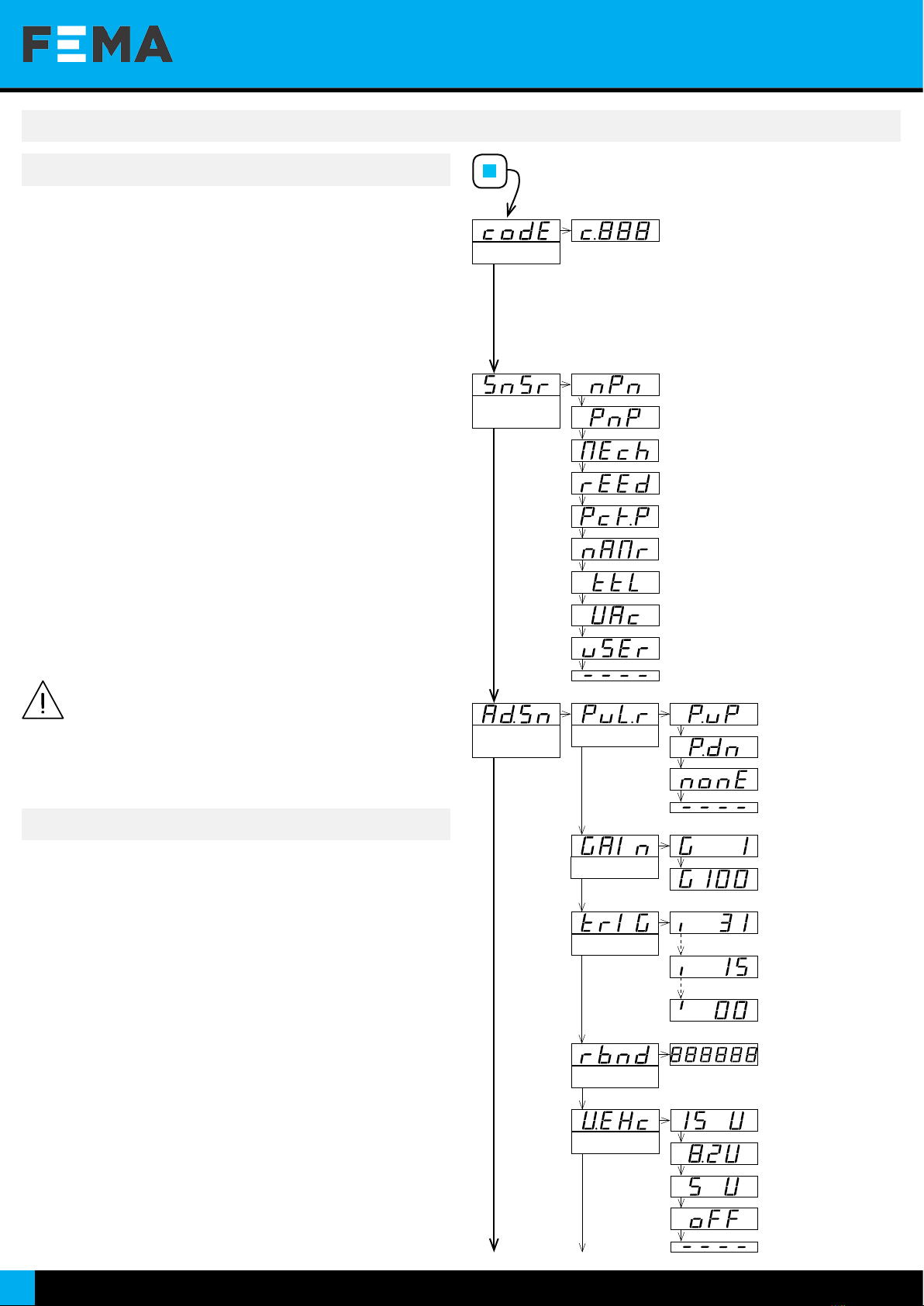

4. Congure the sensor

• choose one of the predened sensors (see section 9)

• congure the sensor at the instrument (see section 16.1)

5. Congure the input and output signals

• choose a predened conguration code (see section 8)

• introduce the code at the instrument (see section 16.1)

6. If

needed, customize the input and output signal ranges (see section 16.5)

7. If needed, congure the display reading (see section 16.6), the key ‘UP’

(5) ‘force’ menu (see section 16.7), and the key ‘LE’ (3) ‘messages’ function

(see section 16.8),

8. If needed, block access to the ‘conguration menu’ (see section 16.9)

4. Installation and start-up

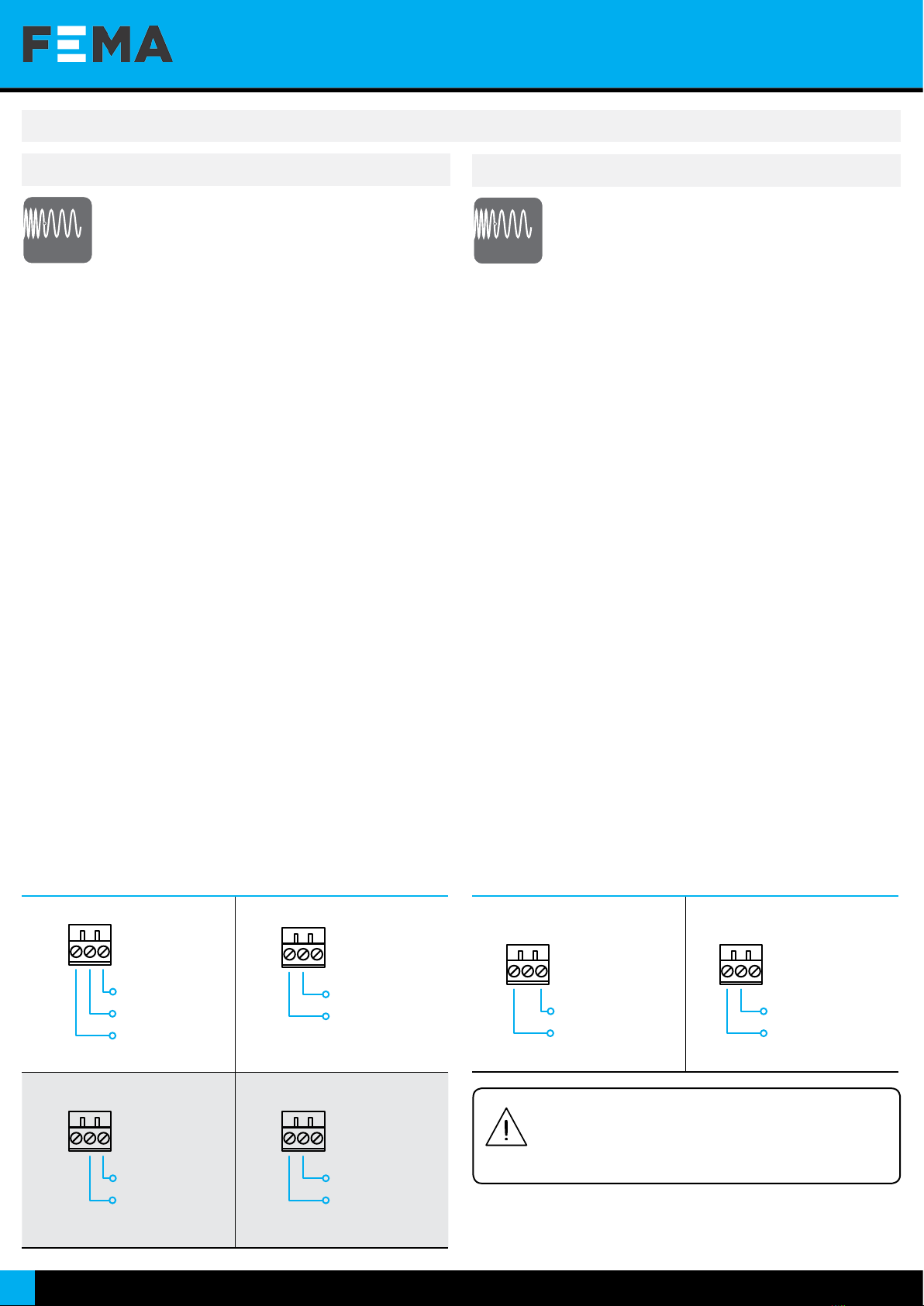

To measure frequency signals from low voltage sensors such as NPN,

PNP, Namur, pick-up and similar. To measure frequency signals from

ow meters. To measure frequency signals from AC power networks up

to 600 Vac. Signal acquisition, linearization and transmission to remote

acquisition devices. Isolation between circuits provided. Ranges can be

scaled to the desired range.

5. Typical applications

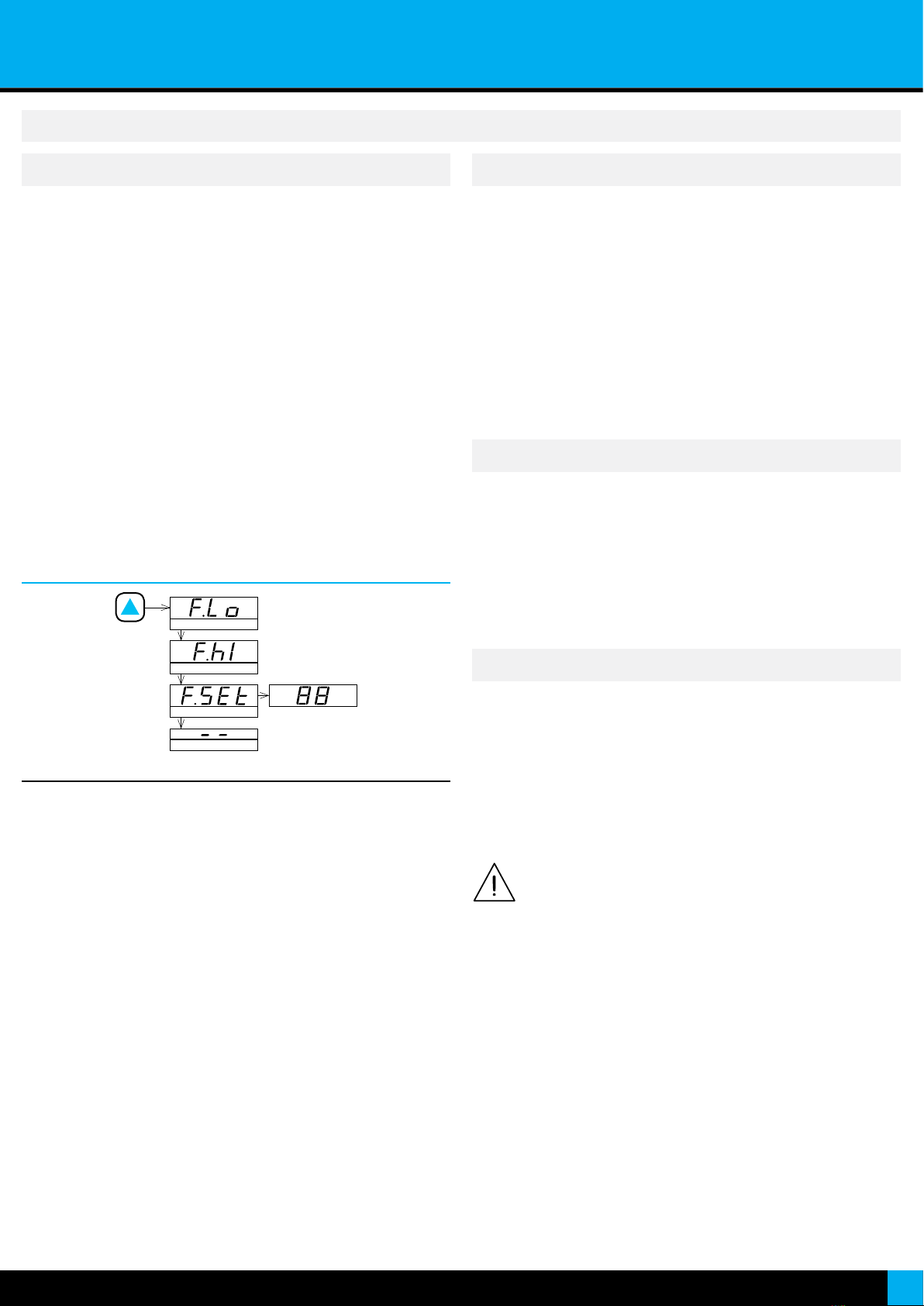

The instrument includes a congurable ‘messages’ function that provides

advanced system information on the display, available to the operator

with a single click at the front key ‘LE’ (3).

This information is helpful during start-up, installation, system

verication, routine maintenance and troubleshooting, as messages and

values provide information on the actual input and output signal value,

actual percentage of the input signal compared to the full scale and

scaled process values.

This information is available at any time, and is displayed sequentially

when requested. Access to this information reduces maintenance

time, improves time invested in failure location, and helps for an easy

resolution of the problem.

Additionally, each instrument can be assigned a custom label code of up

to 8 characters (see Table 1), that can be displayed at the front display

or at the messages sequence, making system identication of each

instrument an easy task.

To congure the ‘messages’ function, see section 16.8.

The instrument includes a congurable ‘SOS mode’ function that provides

a way to manually congure a xed output signal. This output signal

remains xed, independent of the input signal value or sensor state.

This function allows to perform urgent maintenance or repair tasks at the

input section of the system, for example replacing sensors, shunts, or

deactivating power lines, while the instrument still provides a controlled

signal that allows for the process to continue its activity, under human

surveillance. When the maintenance or repair task has been performed,

the instrument can be taken back to the standard working mode, where

the output signal is proportional to the input.

When manually activated, the ‘SOS mode’ generates the output signal

congured, and the front display remains ashing with the message

‘SoS’. All other systems are disabled, which means that :

• no error messages will be shown on display

• no key ‘UP’ (5) ‘fast access’ menu is accessible

• no key ‘LE’ (3) ‘messages’ function is accessible

• no ‘Eco’ mode activates

Only key ‘SQ’ (<) is accessible, to access the ‘conguration menu’

(eventually this access can be password locked) in order to deactivate

the ‘SOS mode’. Deactivation of ‘SOS mode’ must be performed manually

by conguring the function to ‘oFF’.

To congure the ‘SOS mode’ function, see section 16.9.

6. SOS mode

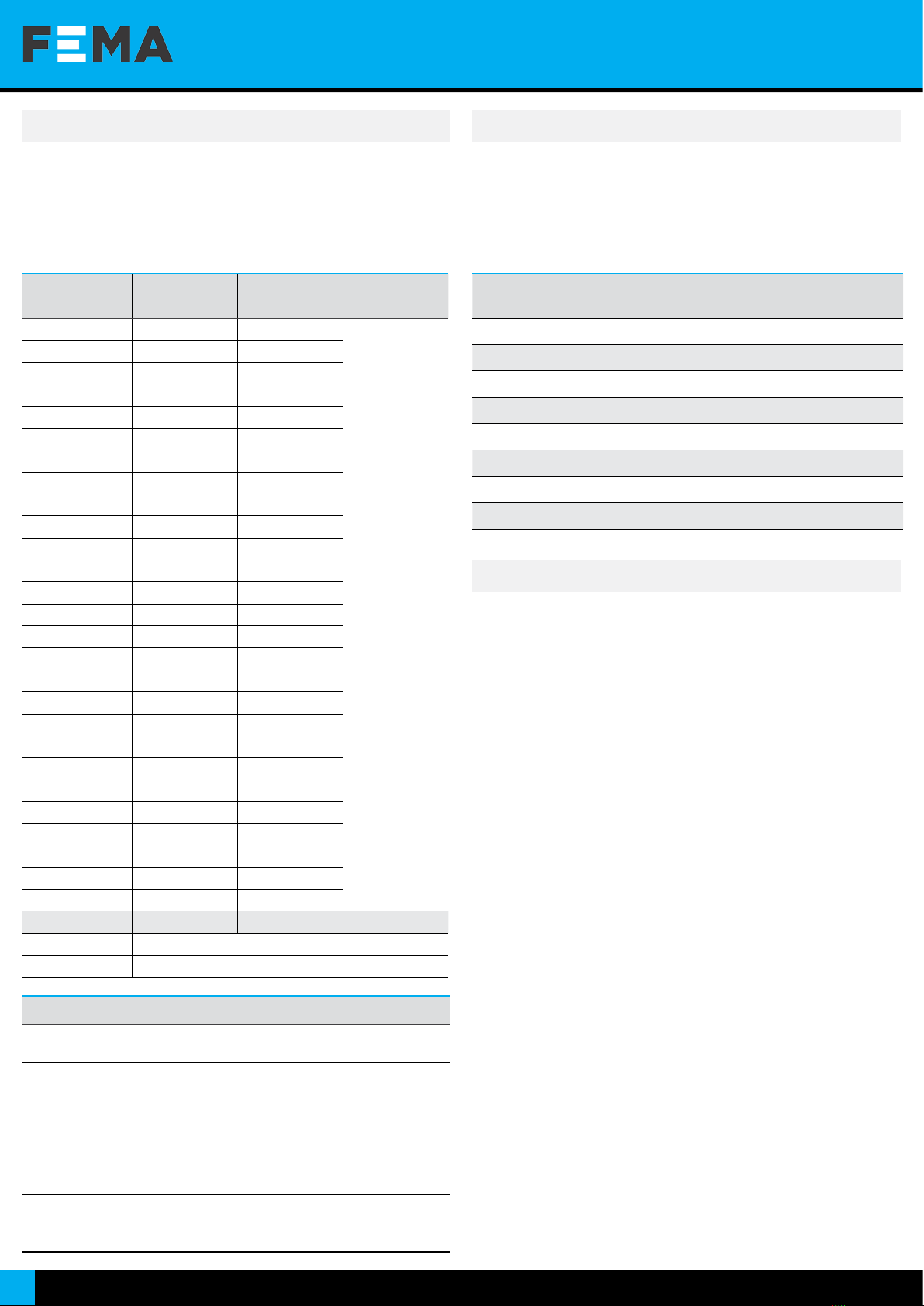

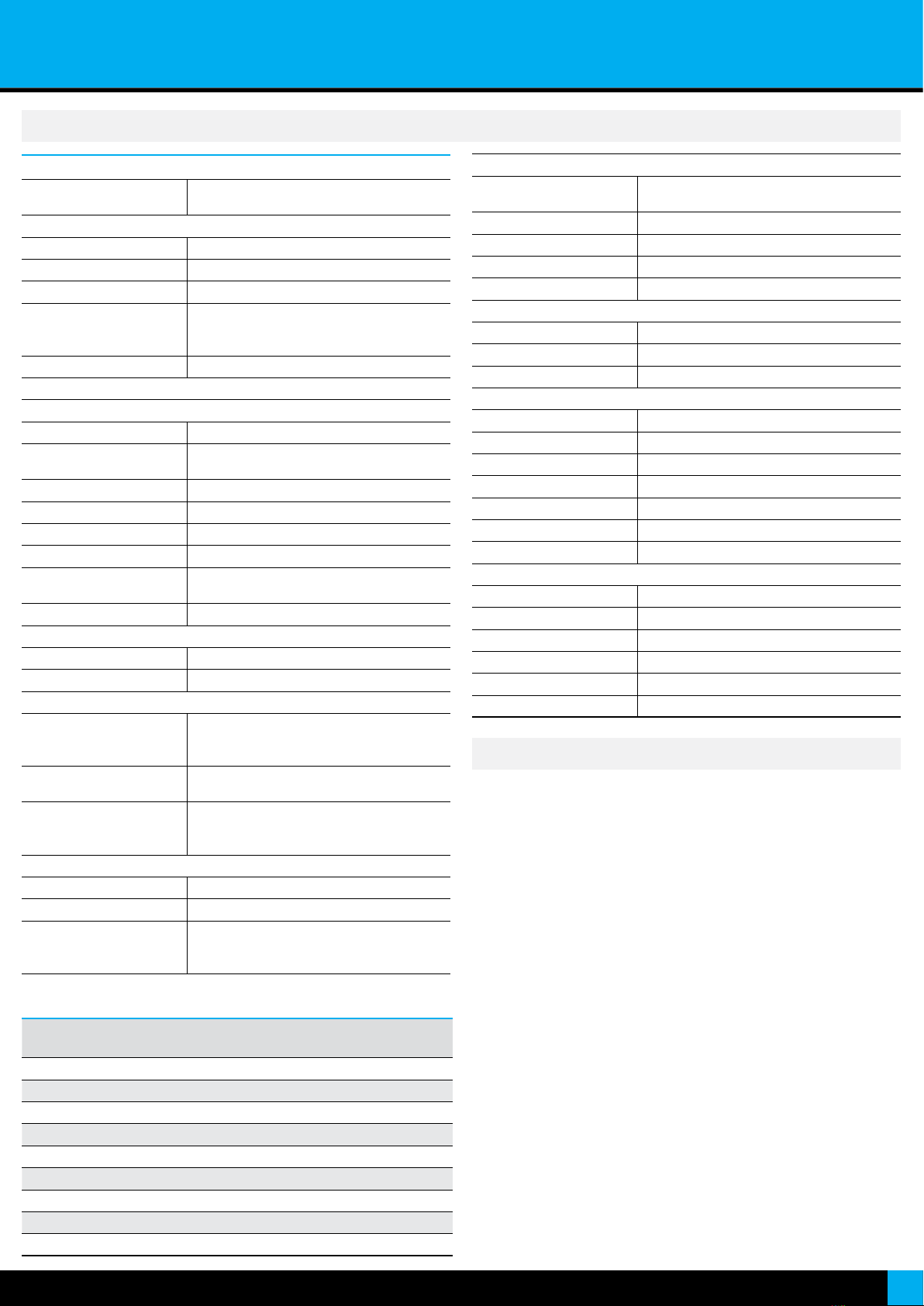

Table 1 | Available label codes (‘Label’ parameter)

Letters Numbers Special

An 0 -

bo 1 _

cP 2 .

d q 3 (blank)

E r 4

FS 5

G t 6

hu 7

I V 8

J W 9

KX

L Y

M Z

7. Messages

Labeling examples (‘Label’ parameter): for an application with multiple

engine control, where RPM is being measured for three engines, and

converted to 4/20 mA for retransmission to PLC or SCADA. Three I4F

converters are being used, to measure 0/1000 Hz. Each I4F can be

congured the following label for easy identication :

• Label for engine 1 frequency measurement : Eng1.hZ

• Label for engine 2 frequency measurement : Eng2.hZ

• Label for engine 3 frequency measurement : Eng3.hZ