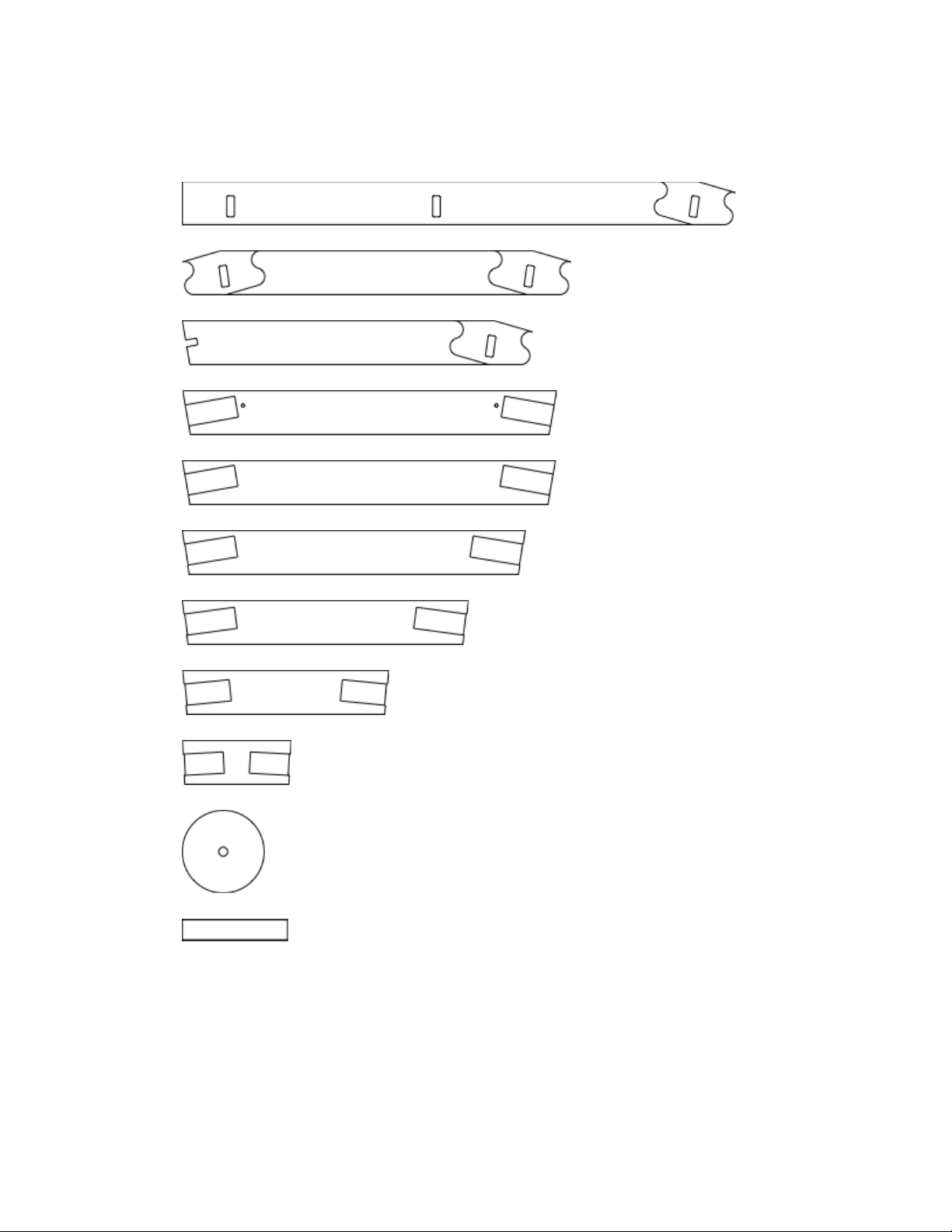

Before proceeding with the assembly of the frame, prepare sawn OSB

elements,15 mm thick (map of pattern see below), a screws, a screwdriver and

drills for pre-drilling under self-tapping screws. All of this you will need during

assembly.

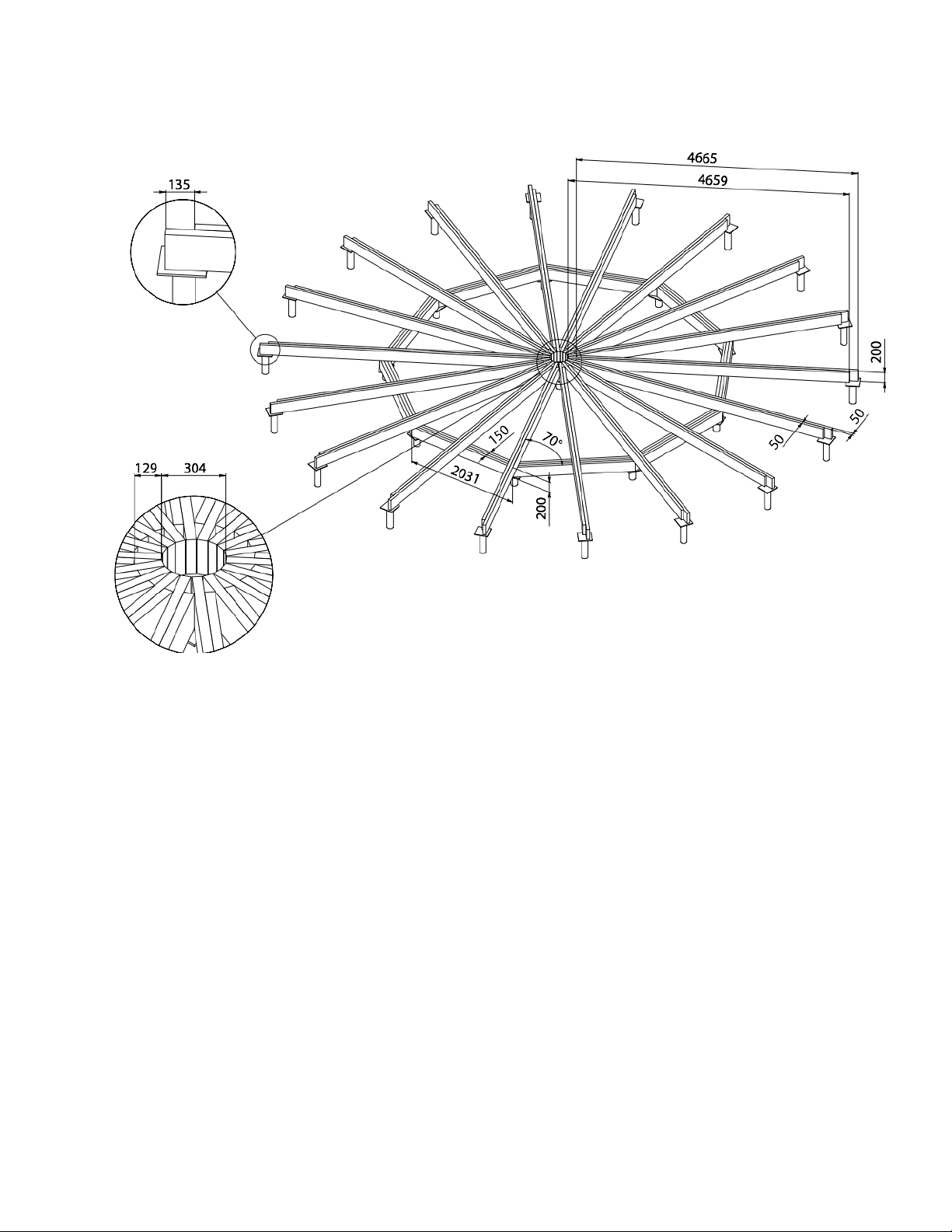

During assembly, be sure to fix a frame, securing the cladding on each

assembled horizontal tier. The cladding, sawn exactly in size, is also a template

for precise positioning of beams and the braces of the frame for correct

convergence in the upper anchorage.

For installation of the cladding, please use galvanized screws 5х70 every 20 cm

perimeter.To drill 3 mm by 53 mm deep into the frame.

To piece together the constituent elements of the cladding, consisting of several

parts is required.

Nagel must be attached to the braces with bolts and nuts and with washers as

indicated in the instructions.

The frame must be fixed on metal plates on top of the pile with a bolt screw

from below through the head to the vertical beam with preliminary drilling with a

depth of 120-150 mm.

© Factory «Dobrosfera», 2018. Version 3.0 us.dobrosfera.com 3