Page 8/ 16

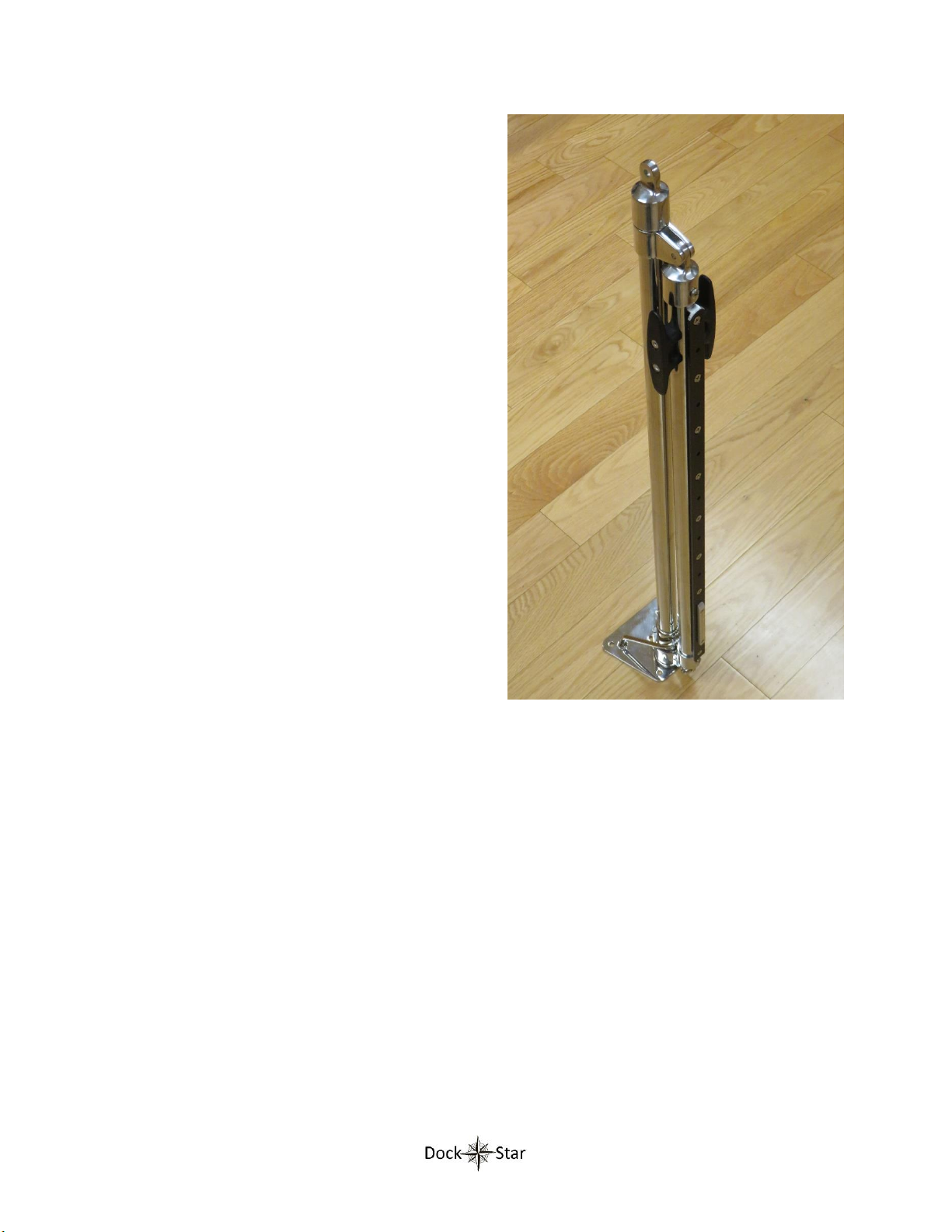

The T-track is 22” long, the stainless tube is 48” long, and the over-all length is 53.5”. This is

intentionally over-sized to allow the stainless tube to be cut to length to fit the particular rail of your

boat.

The other elements of the kit are shown to the right. The lanyard is shown at the

top. Two sets of flat-head screws, fender washers, and nylock nuts are shown in the

middle. These are used to secure the swivel hinge to the swim step. No hardware is

required to secure the stainless tube to the handrail since this is done by the

clamping action of the hinged top-slide. At the bottom of the pictures is the block

and sling used to attach the lanyard to the Smart Thruster. How this is attached is

shown later in this document.

Also included is a plastic nut holder, 10-32 nut, and 10-32 pan-head screw (shown

right above the sling). These are used to secure the top end-cap to the stainless

tube once the stainless tube is cut and properly oriented in the end-cap.

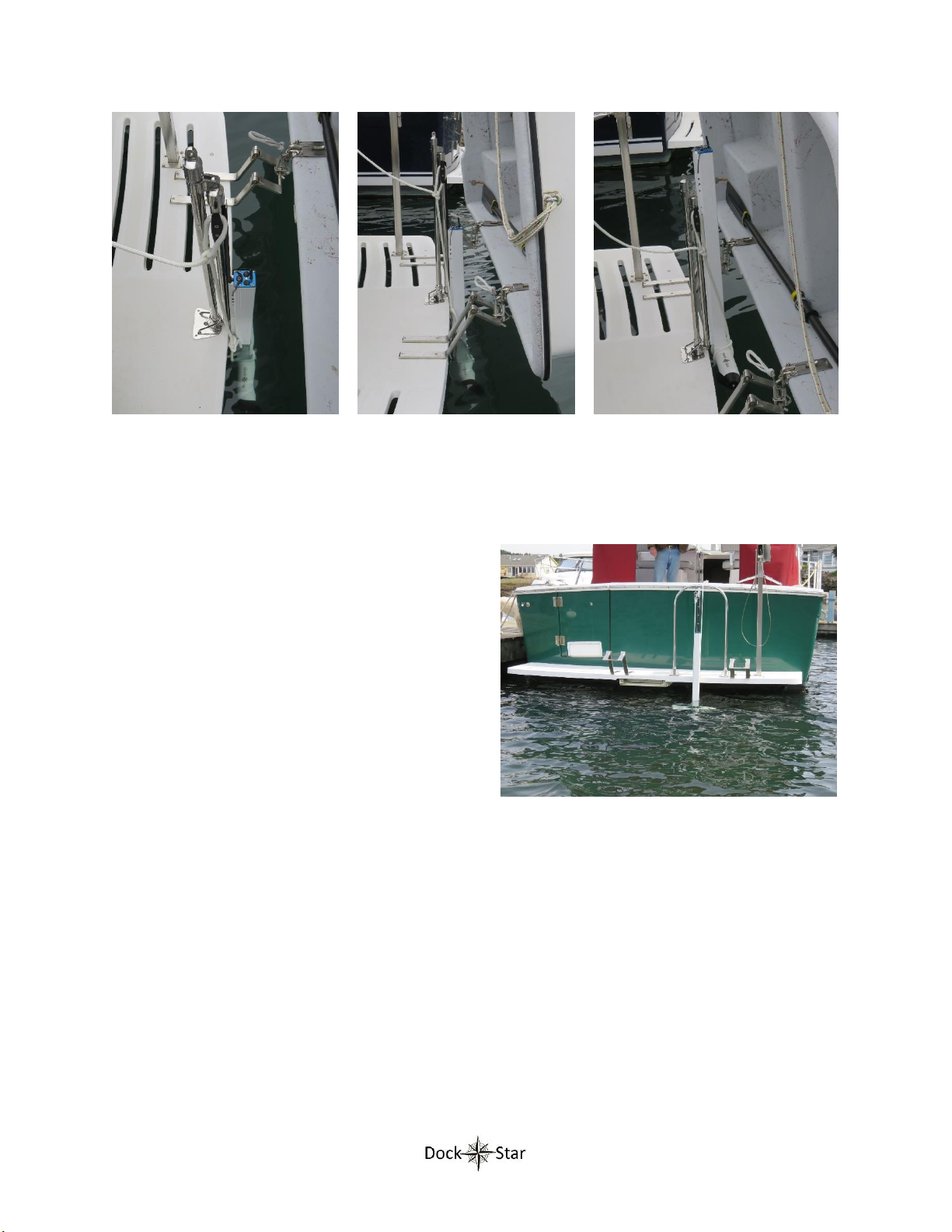

Since various hand-rails are at different heights, it is necessary to cut the stainless

tube to fit the height of the boat’s particular hand rail. The bottom swivel hinge

should be mounted to the swim step (with the hinge’s included rubber spacer in

place) in the appropriate position. Care should be taken to align the rotation of the

lower swivel hinge such that the face of the T-track is parallel to the aft edge of the

swim step. This will ensure that the thruster motors run parallel to the aft edge of the swim step.

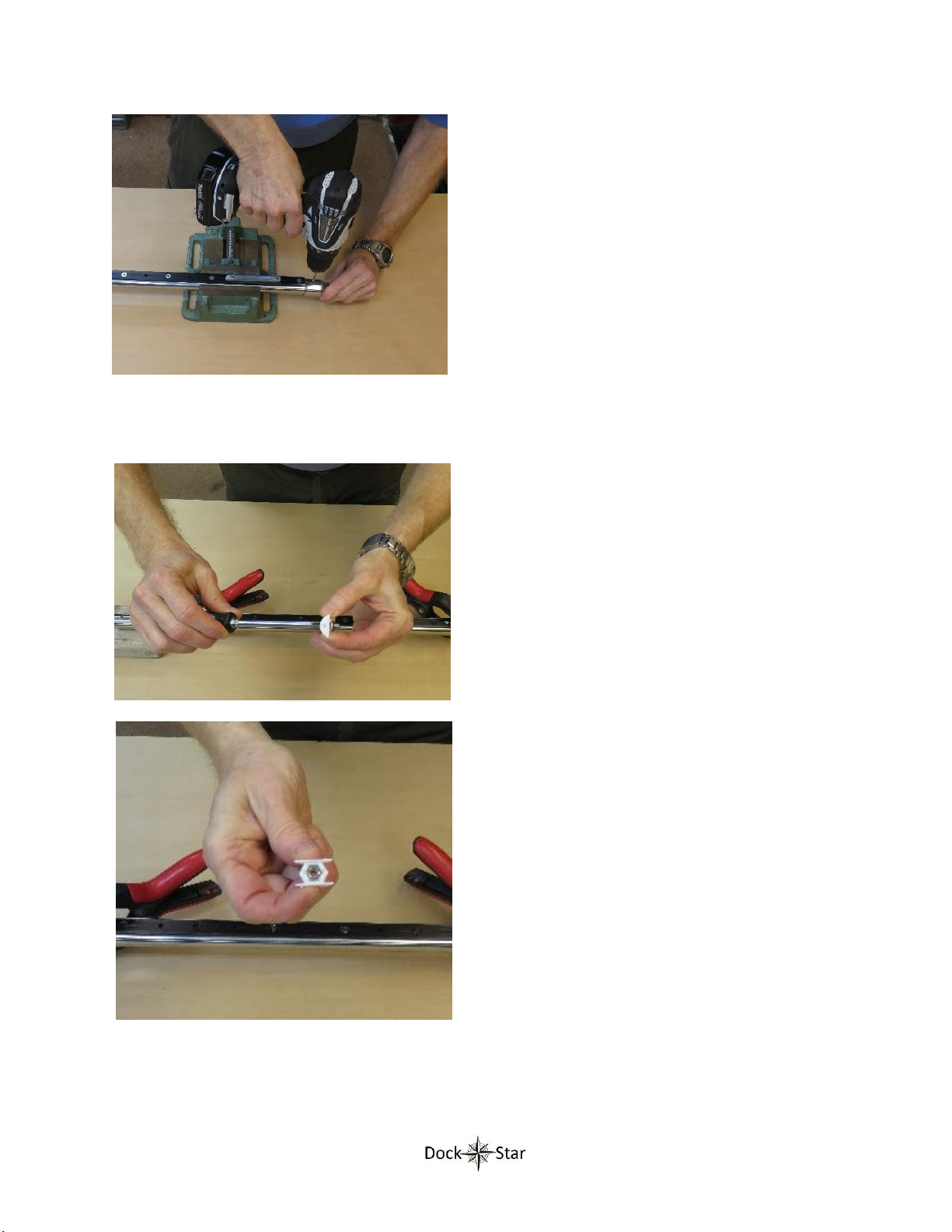

It is best to not remove the bottom end-cap from the stainless tube. To separate the stainless tube from

the bottom swivel hinge for mounting the swivel hinge, unscrew the hinge screw holding the end-cap to

the swivel hinge.

The top hinged top-slide should be clamped to the handrail and aligned to the bottom hinge. The top

and bottom hinge fittings should be placed so that the stainless tube when mounted is perpendicular to

the aft edge of the swim step at the point of the lower hinge fitting.

It is now time to determine the proper length to cut the stainless tube. With the stainless tube still

secured into the bottom end-cap reattach the bottom end-cap to the swivel hinge. With the stainless

tube not inside the top end-cap, the tube can be placed alongside the top end-cap to measure where to

cut the excess tubing (from the top). Measure this length and record it for comparison to the next

measurement.

As a check, perform a second measurement to determine the distance between the inside bottoms of

the two end-caps. The internal dimension of each end cap is nominally about 1.2 inches. Thus the

length of the stainless tube is equal to the distance between the rims of the two end-caps plus 2.4”. Be

sure to make this measurement very carefully. This measurement should give you the same length

result as the first measurement. If not, recheck. Also, make sure the two hinge fittings are properly

located so as to allow clearance for the Smart thruster to come off the rail at the top of the T-track and

to slide clear of the edge of the swim step and any obstacles at the aft of the boat. Remember, once

you cut the stainless tube it cannot be lengthened.