8-8-2006

Handleiding

EN STF V1.0 www.doco-international.com

3

1. Symbols and warning signs

General symbol for DANGER!!

Symbol for ATTENTION!!

Carefully read the text with this symbol!!

Symbol: Risk of physical injury!!

Carefully read the text with this symbol!!

Use safety gloves Use Face protection

2. General warnings

This manual has been prepared for use by qualified personnel and therefore not by

trainees or “do it yourselfers”

In case of doubt about the assembly and/or maintenance, please contact DOCO

International.

To avoid severe personal injury, carefully read and observe all indications and warnings in this manual.

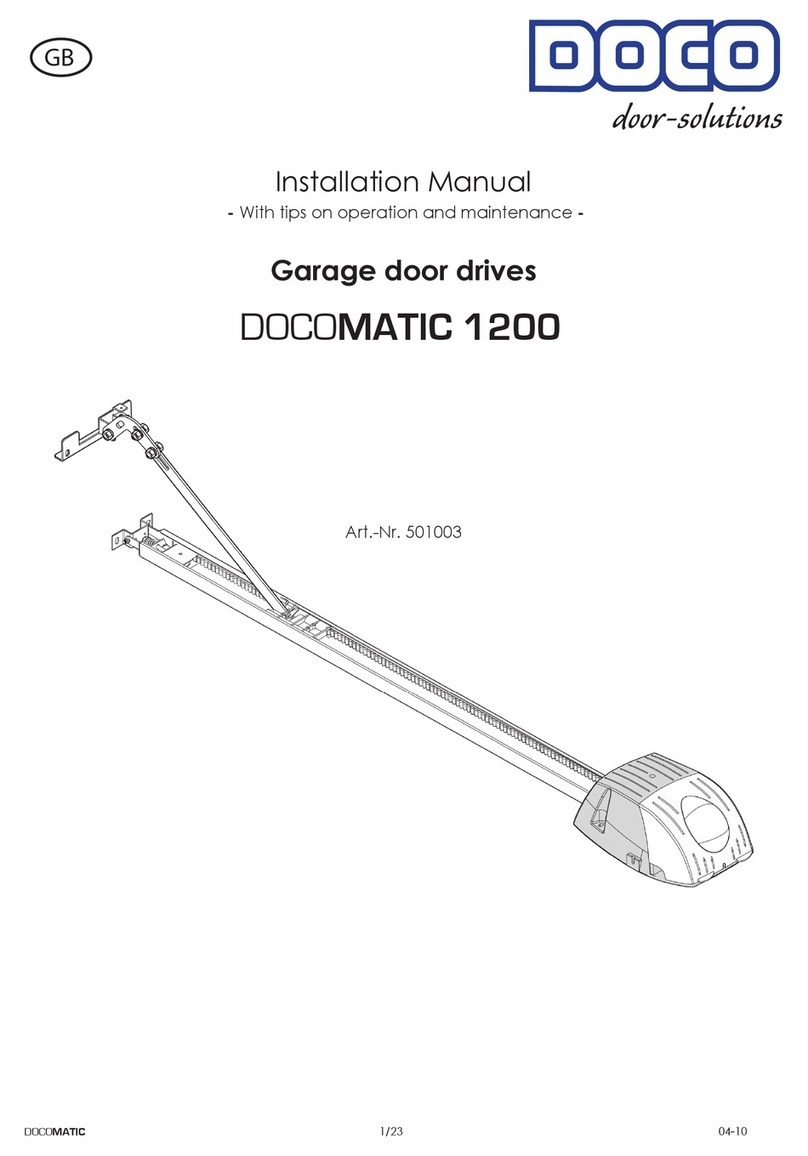

-This manual describes the assembly and disassembly of residential set of fittings ST ; this may be

supplemented by other manuals, for instance the door operator manual (if applicable.)

-Your set of fittings has been designed according to the latest European standards; however you have to

check yourself whether this standard corresponds with the local national standard.

-Adding or leaving out parts can affect the working and therefore the safety of the eventual sectional

door and is therefore strongly discouraged!

-All indications concerning the assembly the mounting right / left are always viewed from the assembly

location, that is from the inside to the outside!

-All measures are in millimetres unless otherwise specified.

-Check after the assembly whether the CE marking has been completed and attached.

-Keep this manual in a safe place.

-Subject to technical changes, without written notice.

2.1 Safety requirements for assembly and first use.

-The garage door may only be mounted, connected and put into operation by qualified personnel.

-Make sure that the power is switched off and remains switched off while electrical work is carried out!

-Never bridge safety devices !

-Some parts contain sharp edges: use protective gloves.

-Never use the sectional door in case or visual damage on the safety devices.

-When performing assembly/maintenance, always wear at least gloves and safety boots and during

drilling wear safety goggles!

-Make sure that you can always perform your work in a stable environment.

-Secure the assembly/maintenance site with safety ribbon to keep others (children!) at a distance.

-Maintenance must only be performed by a qualified company and/or qualified personnel.

-Make sure there is enough light.

-Only use appropriate tools, especially when tensioning the torsion springs.