206.05.21 en / 393A

The device is supplied with DC auxiliary voltage via terminals A1(+) / A2.

Switching on the auxiliary voltage (Power-On) is followed by an internal

self-test for 12 sec (see „Device test functions“). The test process is visible

in the display. After this, measurement of the insulation resistance in the

measuring circuits begins and the the colour of the backlight changes

into green.

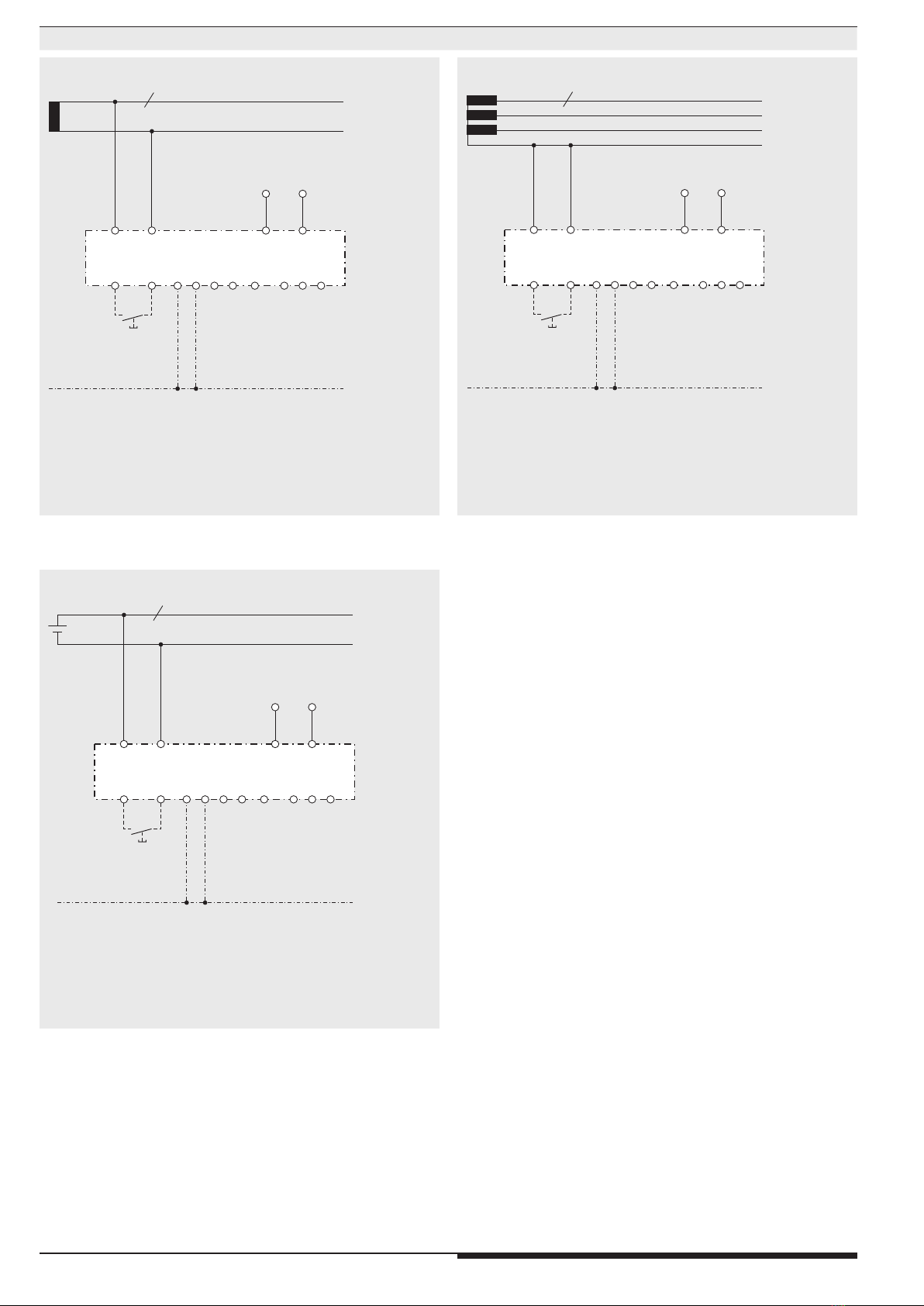

Measuring circuit

(Insulation measurement between terminals L(+) / L(-) and PE1/PE2)

The terminals L(+) and L(-) of the insulation monitor are connected directly

to the voltage system to be monitored. A broken wire detection creates a

fault signal if there is no low-ohmic connection between both terminals.

The type of network (AC, DC, 3NAC) has to be selected.

Also the terminals PE1 and PE2 have to be connected with 2 separate

wires to the protective earth. An interruption of a wire also causes a fault

signal (see section ”Behavior on faulty connection”). The monitoring of

the PE connection cannot be de-activated.

To measure the insulation resistance an active measuring voltage with

changing polarity is connected between L(+)/L(-) and PE1/PE2.The

momentary polarity of the measuring cycle is shown on the display by 2

curser segments („MP+“ for positive phase and „MP-“ for negative phase).

The duration of the positive and negative measuring phase depends on

the setting of the max. leakage capacity („CE[µF]“ in programming mode),

the actual leakage capacity of the monitored system and in DC systems

also on the level and duration of possible voltage variations. This allows

a correct and fast measurement in different network conditions.

At the end of a measuring cycle the actual insulation resistance is produced

and indicated. The actual value is shown on the display. The relays for alarm

K1 and pre-alarm K2 switch when dropping under the adjusted response

values. In addition the backlight of the display changes to orange color

on pre-alarm or to red color on alarm. An asymmetric earth fault either to

„+“ or „-“ is also indicated on the display (only in DC- systems, or with a

fault on the DC-side of a system).

Manual reset of fault message

Using the display menu in programming mode, the manual reset function

for insulation failures can be selected. If manual reset is activated the

insulation fault signals of the measuring circuit are stored when dropping

under the adjusted response values also if the insulation resistance goes

back to healthy state. The minimum value is stored and can be shown

on the display. Pressing the „Reset“ button on the front side, the alarm

signal and the stored minimum value are reset if the actual insulation

resistance is in healthy state.

Indicator relay for insulation fault signal

For the indicator relays K1 (contacts 11-12-14, for alarm) and K2 (contacts

21-22-24, for pre-alarm) the function can be set in programming mode to

energized on trip or de-energized on trip when the insulation resistance

drops below the adjusted response value.

The status of the indicator relays is shown on the display with the two cursor

segments "K1" and "K2". When the relay is energized, the corresponding

curser lights up.

Broken wire detection

As described in section "Measuring circut", the measuring circuits L(+)/L(-)

and the protective conductors PE1/PE2 are constantly monitored for wire

breaks – not only at Power-On or a manual or occasional automatic test.

The response time of monitoring is only a few seconds. Broken wire

detection between L(+) and L(-) is performed via coupled alternating

voltage. This alternating voltage is short-circuited if the terminals are

connected to the connected mains at low-resistance. The device detects

that the mains to be monitored is properly connected.

Since this broken wire detection is carried out with alternating voltage, large

capacitances should be avoided between L(+) and L(-), since the capacitive

reactance of these capacitances also short-circuits this alternating voltage.

The device would no longer detect a connection fault on L(+)/L(-).

Especially parallel lines should be prevented over larger distances.

If larger capacitances between L(+)/L(-) cannot be avoided or if the coupled

alternating voltage interferes with the system, the broken wire detection can

be de-activated using the display menu in programming mode. Monitoring

deactivated, monitoring only during device test or continuous monitoring

(every 2 minutes for 10 sec) are the possible options. If the broken wire

detection on L(+)/L(-) is de-activated no AC voltage is injected.

The broken wire detection on PE1/PE2 cannot be de-activated.

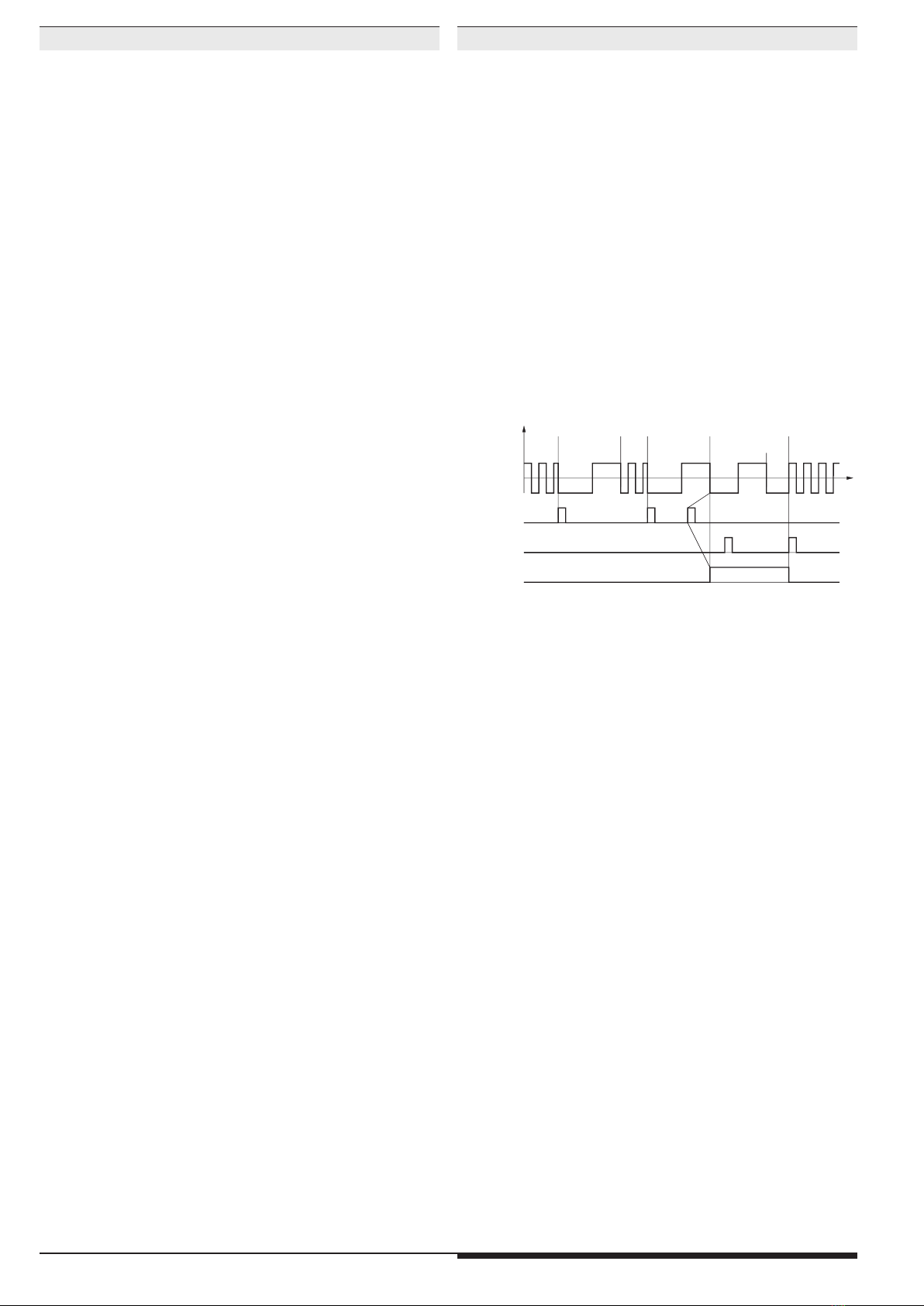

Device test functions

Principally, 2 different test functions are implemented: The "self-test" and

the "expanded test":

The self-test of the device is performed automatically after Power-On and

every full operating hours. It can also be triggered manually at any time by

pressing the "Test" button at the device front for 2 sec.

With the self-test, contrary to the expanded test, the status of the Indicator

relays is not affected; the sequence is as follows:

The display backlight colour changes into orange.For approx. 2 s all pixels

and segments of the LCD are shown. After that the text “Test1” comes up

and the measuring pulse is switched for approx. 5 s to negative test phase.

The polarity of the test voltage is also indicated on the display by curser

segments. Within these 5 s the internal measuring circuit is checked for

failures. Then the measuring pulse is switched for approx. 5 s to positive

test phase and more internal tests take place. If no failures turned up and

had been recognized, the measurement continuous. The extended test

procedure is started when during or at the end of the above described

12 s self-test the test button is pressed again for 2 s.

The sequence is similar to the self-test (2 measuring phases of 5 s each) but

in addition the output relays go in alarm stated. The display shows “Test2”.

The test phases of the extended test will be repeated continuously. The

extended test can be finished after the first complete sequence (approx.

10 sec) by pressing the "reset" button for 2 seconds. The device starts

the insulation monitoring again.

Test signal 1)

Reset signal 2)

Relay state K1 and K2

Measuring voltage

Positive

Alarm

No Alarm

Insulation

measurement Insulation

measurement

Insulation

measurement

3)

4)

Self test (Test 1)

Duration: approx. 12s

Self test (Test 1)

Duration: approx. 12s

Duration: approx. 10s

Continuous extended

test (Test 2)

Negative

U

t

1) Test signal: Button Test > 2 s or X1/X2 < 3 s

2) Reset signal: Button Reset > 2 s or X1/X2 > 3 s

3) To initiate the extended test (Test 2) the test signal must be operated

within the self test (Test 1) again..

4) The reset signal has here no function, as the first complete sequence

of extended test (Test 2) is not finished.

FunctionFunction