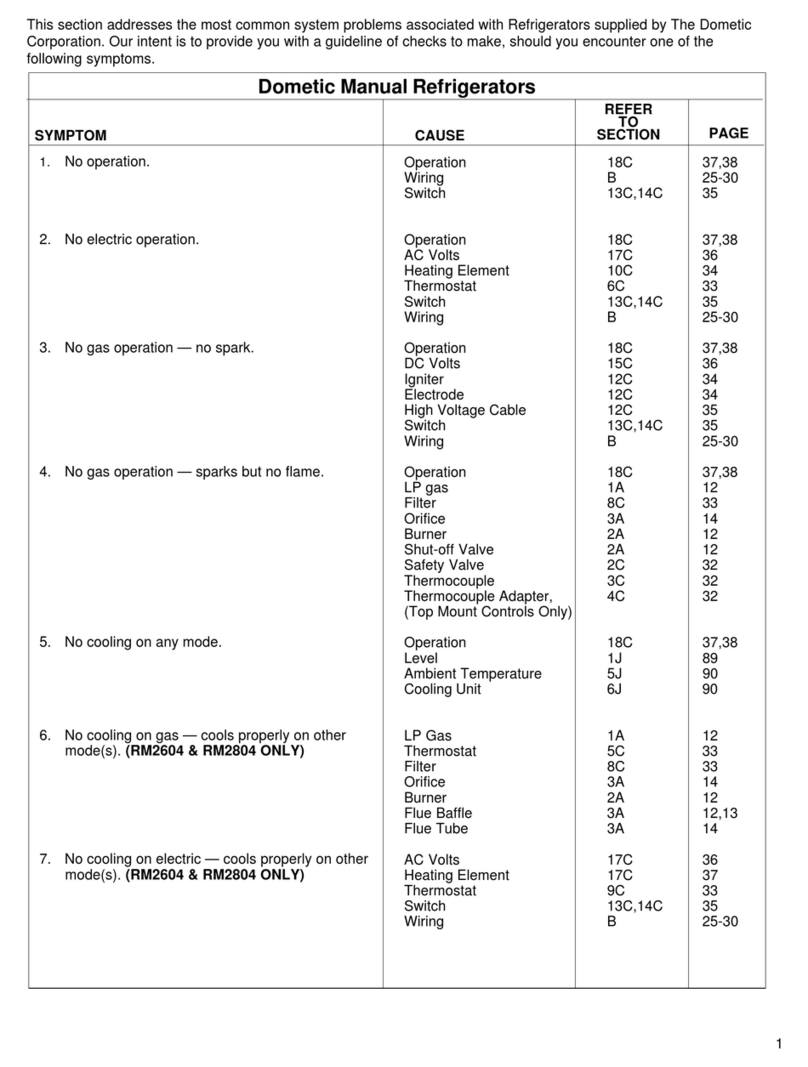

D.

E.

After

the

flame lights, continue to hold button “C”

for an additional ten (10) seconds. Release the

button “C” and check the flame view port

“E”

to

makesurethe burnerdoes notgoout. Ifthe burner

goes out, repeat the lighting procedure Steps A.

through D.

Toshut off the refrigerator, turn Knob

“A”

to the

“OFF” position.

4.

Electric operation

A.

B.

P

Check to be sure the power cord is properly

connected tothe power supply. (See Fig.9).Ifthe

refrigerator isequipped for 12volt DCoperation,

the tow vehicle or caravan engine should be

running to prevent discharging the battery.

Turn Knob “A” to the position marked

“ELEC”

for 120volt AC operation or

“12V”

for 12volt DC

operation. (See Fig. 13).

Turn the thermostat Knob “6” one quarter (l/4)

“r

of a turn from the “OFF” position.

D. To

shut offthe refrigerator, turn Knob “A”

to the

“OFF” position.

5. Thermostat

The refrigerator isequipped with athermostat that can

be adjusted byturning knob “6” to a different setting

to maintain the desired cabinet temperature (See Fig.

13).

A

B.

C.

“OFF” Setting of the Thermostat: In gas

operation, the thermostat closes its main valve

and the burner runs continuously at the bypass

rate or pilot. In electrical operation, the contacts

in the thermostat are open and the heating

elements are off.

“MAX” Setting of the Thermostat: In gas

operation the thermostat allows the burner to

remain on high flame continuously. In electric

operation, the heating element is “ON”

continuously.

The thermostat can beadjusted between “MAX”

and “OFF” to obtain the desired cabinet

temperature. The closer the knob isto “MAX” -

the colder thecabinet temperature. The closerthe

knob is to “OFF” - the warmer the cabinet

temperature.

When the thermostat reaches the set

temperature, itwill cut the burner back to bypass

or, in electric operation, shut off the heating

element.

The setting ofthe thermostat isnotcritical, butwe

recommend it be adjusted to maintain adry frost

on the cooling fins. Adjust the thermostat knob

closer to “MAX” when the outside temperature

becomes warm.

6.

How to use the refrigerator

A. Food Storage Compartment

The food storage compartment is completely

closed and unventilated, which is necessary to

maintain the required low temperature for food

storage. Consequently, foods having a strong

odor or those that absorb odors easily should be

covered. Vegetables, salads, etc. should be

covered to retain their crispness.

The coldest

positions in the refrigerator are under the cooling

fins and at the bottom of the refrigerator. The

warmer areas are on the upper door shelves. This

should be considered when placing different types

of food in the refrigerator.

One-half of the lower door shelf is equipped

with fingers. The fingers are designed to prevent

largecontainers(half-gallonof milkorjuice)from

shifting or spilling while traveling.

B. Frozen Food Storage Compartment

Place

quick frozen

soft fruits and ice cream in the

coldest part of the freezer compartment, which is

at the bottom of the aluminum liner. In models with

a shelf, place these foods on or just below the

freezer shelf. Frozen vegetables may be stored in

any part of the freezer compartment.

This compartment is not designed for the

deep or quick freezing of food. Meat or fish,

whether raw or prepared, can be stored in the

frozen food storage compartment provided it is

first pre-cooled in the refrigerator. It can be stored

about three times longer in the frozen food

compartment as compared to the fresh food

compartment. To prevent food from drying out,

keep it in covered dishes, containers, plastic bags

or wrapped in aluminum foil.

C. Ice Making

Ice cubes can be made in the tray. Fill tray with

water to within l/4 inch @mm) from the top. For

faster ice making, place the tray in direct contact

with the freezer shelf.

To release the ice cubes, hold the tray with

both hands and twist the tray. Preferably, unused

cubes should be replaced in the tray. Refill the tray

with water and place the tray on the freezer shelf.

-9-