General Principles

GL-3

Maintenance Rule

Maintenance Schedule

It's necessary for periodical inspection and maintenance of truck to prolong its service life, improve its power

performance and fuel economy, so periodical inspection and maintenance should be carefully carried out accord-

ing to the following items. Then it will achieve the max economic and social benefits.

The following schedule is not only for maintenance items of 80,000km, but also for normal maintenance

items after 80,000Km.

△—maintenance mileage at running-in period (1,500~2,500km)

☆—maintenance items at running-in period

★—maintenance items at regular driving period

Note:

Customers should carry out the inspection and maintenance intervals according to the different area

condition. Properly shorten the maintenance intervals can ensure the truck to get the reasonable maintenance and

move reliability. Never prolong the intervals.

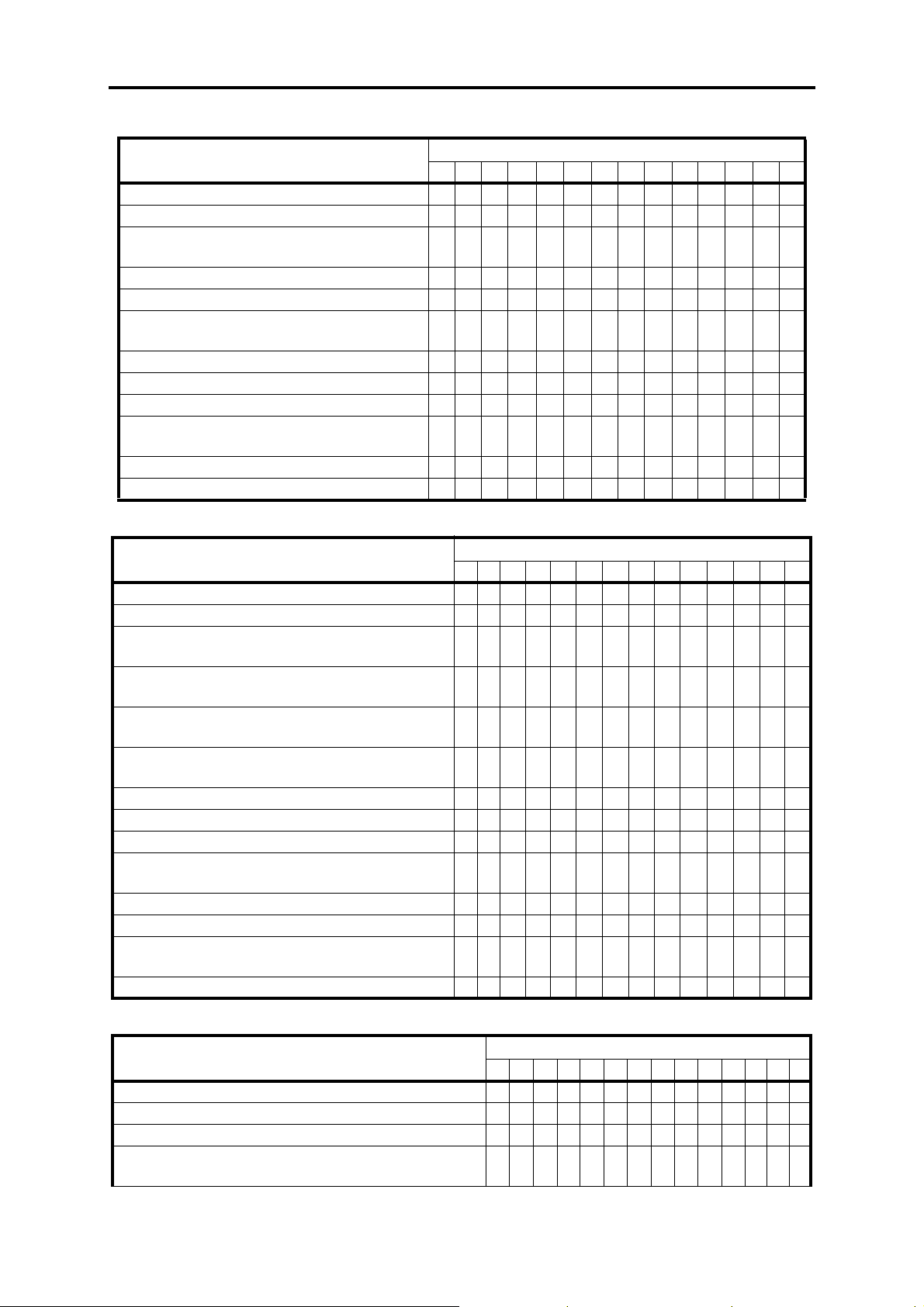

Dongfeng Cummins Diesel Engine

Maintenance Item Maintenance Mileage Interval( ×1,000km)

△4 8 12 16 20 24 28 32 36 40 44 48 80

Clean engine assembly ★★★★★★★★★★★★

Check acceleration capability and decelerability ☆★★★★★★★★★★★★

Check exhaust status ☆★★★★★★★★★★★★

Check the leakage of eninge lubricant ☆★★★★★★★★★★★★

Check the cleanness and reserves of lubricant ★★★★★★★★★★★★

Check the leakage of fuel ☆★★★★★★★★★★★★

Check the leakage in cooling system ☆★★★★★★★★★★★★

Check the damage of fan belt ☆★★★★★★★★★★★★

Remove the deposit in fuel prefilter ☆★★★★★★★★★★★★

Check and clean air filter element ☆★ ★ ★ ★ ★ ★

Replace engine lubricant ☆★ ★ ★ ★ ★ ★

Replace oil filter ☆★ ★ ★ ★ ★ ★

Check and adjust valve clearance ☆★★★★

Replace fule filter and oil & water seperator ★★★★

Replace air filter element ★★

Check the compression pressure in cylinder ★

Check the injection pressure of injector ★

Check injection timing ★

Check the injection volume of injection pump ★

Check the working conditions of delivery pump ★

Check the working conditions of thermostat ★

Check the working conditions of radiator ★

Clean the cooling system of engine ★

Check the working conditions of supercharger,

replace while necessary ★★