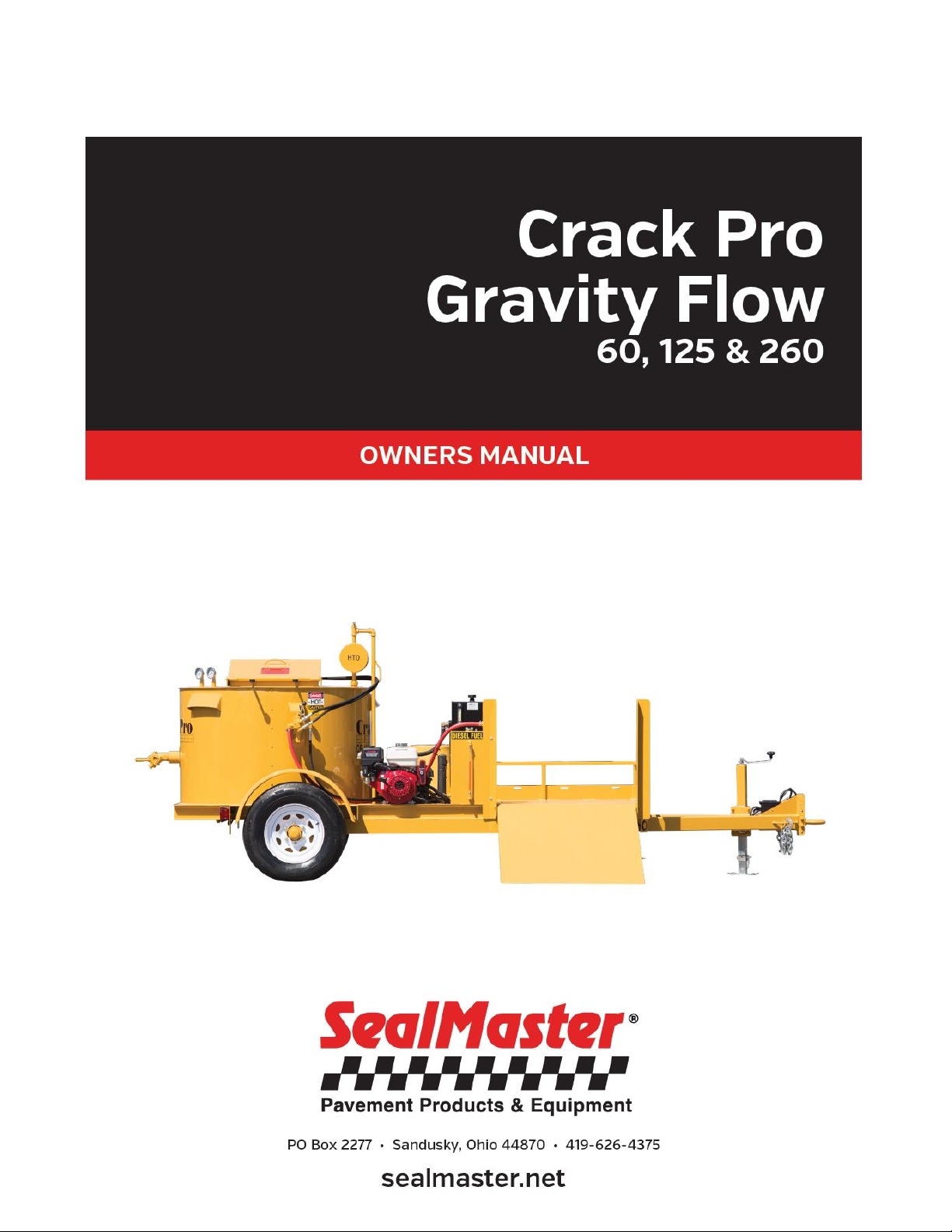

SealMaster CRACK PRO 60 User manual

S:\Engineering\13-Operator Manuals\Current\CRACKPRO_GRAVITY_V2.0_JUNE2019.docx

CRACK PRO GRAVITY FLOW

Owner’s Manual

Version 2.0

Issue Date: June 2019

Effective Date: April 2019

Version

Date

Changes

Approval

1.0

Original Issue

2.0

6/19

New Format and Updates

DS

Table of Contents

CORRESPONDENCE................................................................................................ 3

SealMaster® LIMITED WARRANTY ........................................................................ 4

SAFETY PRECAUTIONS AND CAUTIONS................................................................. 5

PRECAUTIONS..................................................................................................... 5

CAUTIONS........................................................................................................... 5

FIRST AID ............................................................................................................ 6

MANUAL COVERAGE............................................................................................. 7

CRACK PRO® GRAVITY FLOW .............................................................................. 7

CRACK PRO® DIRECT FIRE MELTER...................................................................... 7

OPERATING INSTRUCTIONS - DIESEL FUEL BURNER ............................................. 8

CHECKLIST........................................................................................................... 8

BEFORE STARTING THE ENGINE .......................................................................... 8

STARTING THE ENGINE ....................................................................................... 9

STARTING TEMPERATURE CONTROL..................................................................10

ADDING MATERIAL ............................................................................................12

MATERIAL TEMPERATURE .................................................................................12

POURING MATERIAL ..........................................................................................13

OPERATING INSTRUCTIONS - LP GAS BURNER.................................................... 14

CHECKLIST..........................................................................................................14

BEFORE STARTING THE ENGINE .........................................................................14

STARTING THE ENGINE ......................................................................................15

OPERATING INSTRUCTIONS - LP GAS BURNER.................................................... 16

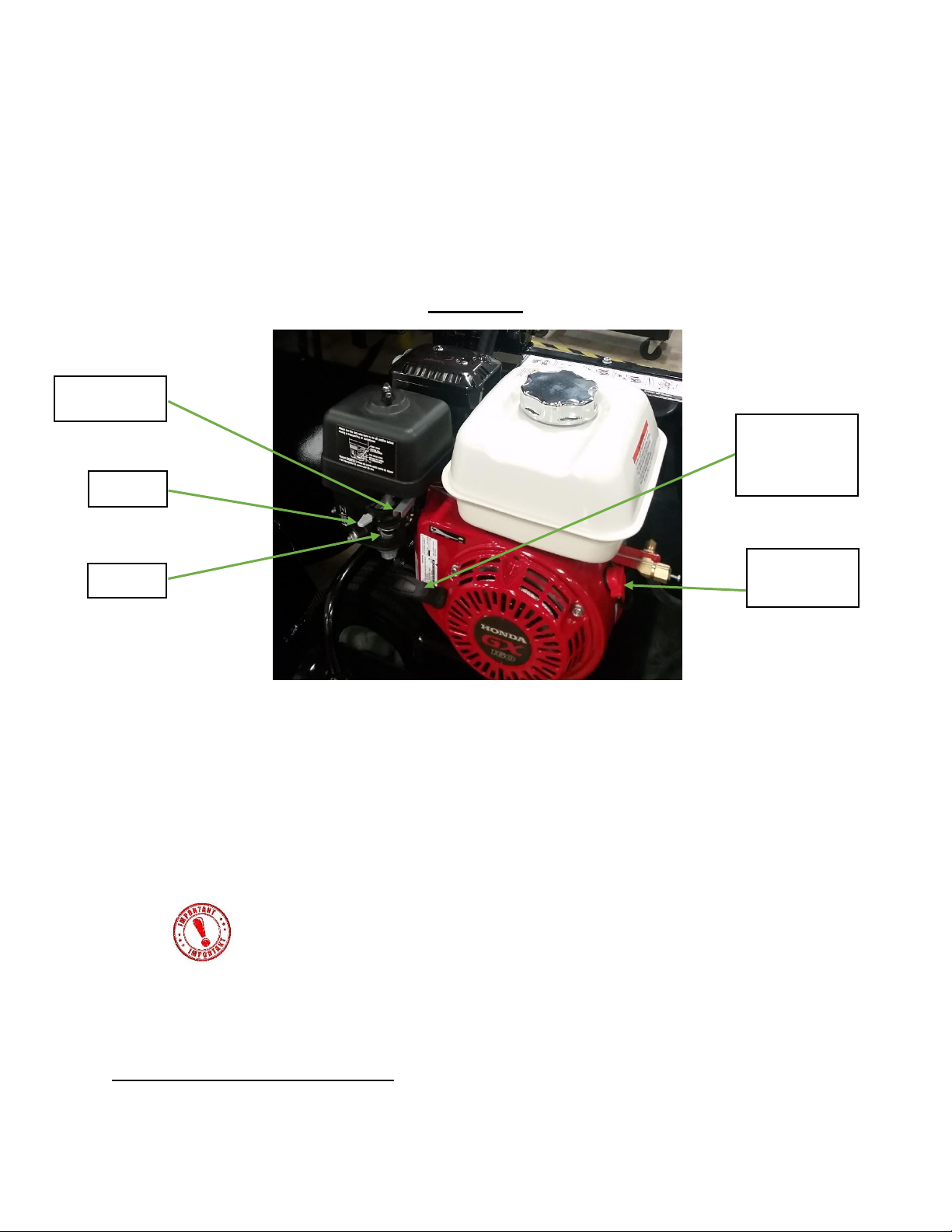

LP GAS BURNER PICTURES .................................................................................17

STARTUP............................................................................................................18

ADDING MATERIAL ............................................................................................18

MATERIAL TEMPERATURE .................................................................................18

POURING MATERIAL ..........................................................................................20

2

MACHINE MAINTENANCE ................................................................................... 21

MAINTENANCE SCHEDULE.................................................................................21

TROUBLESHOOTING DIESEL FUEL BURNER ........................................................22

TROUBLESHOOTING LP GAS BURNER ................................................................23

HYDRAULIC OIL SHEET......................................................................................... 24

SAFETY DATA SHEET............................................................................................ 26

WIRING DIAGRAMS............................................................................................. 32

TEMPERATURE CONTROL BOX...........................................................................32

WIRING DIAGRAMS............................................................................................. 33

ELECTRIC BRAKES AND RUNNING LIGHTS ..........................................................33

MACHINE PICTURES AND PARTS LIST ................................................................. 34

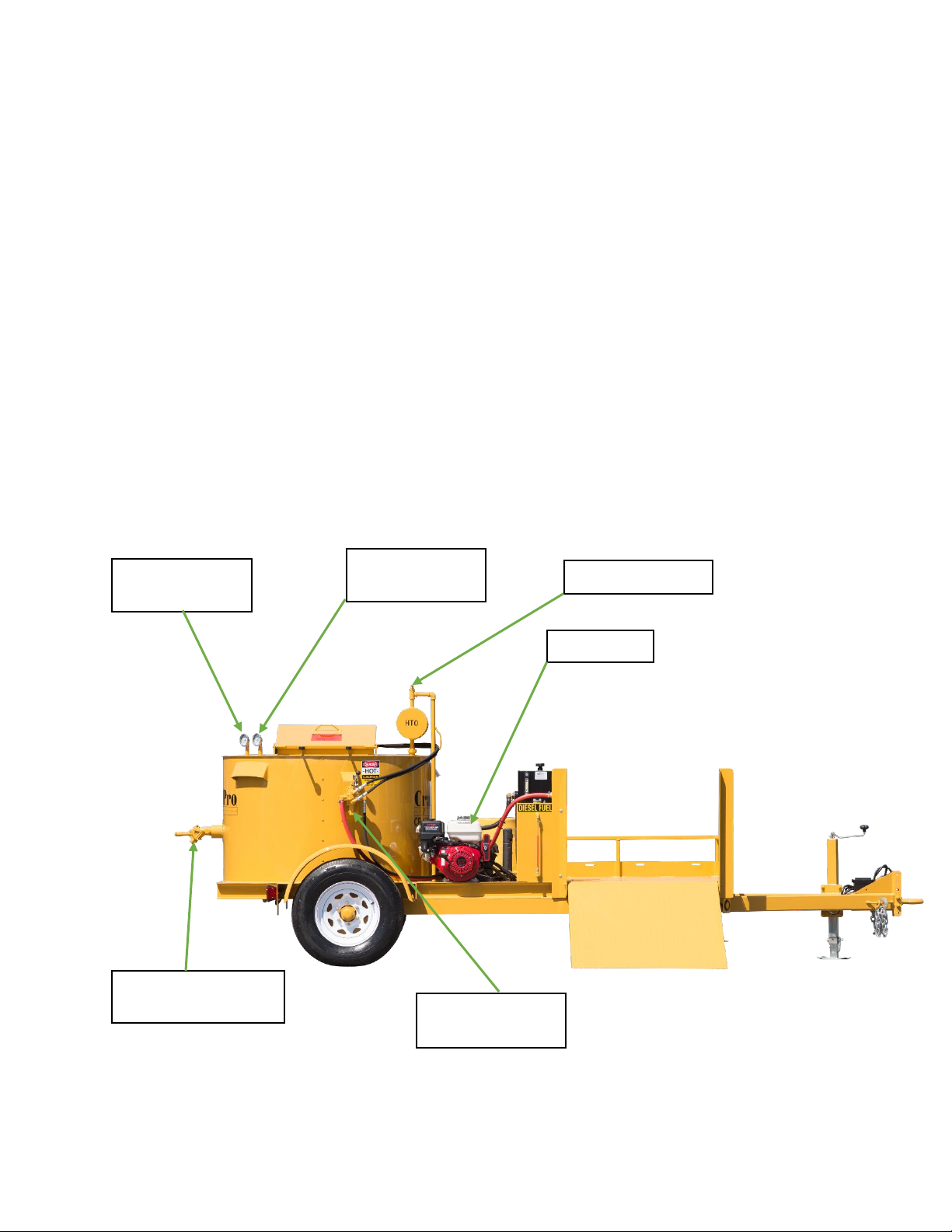

PARTS LIST PICTURE-1........................................................................................35

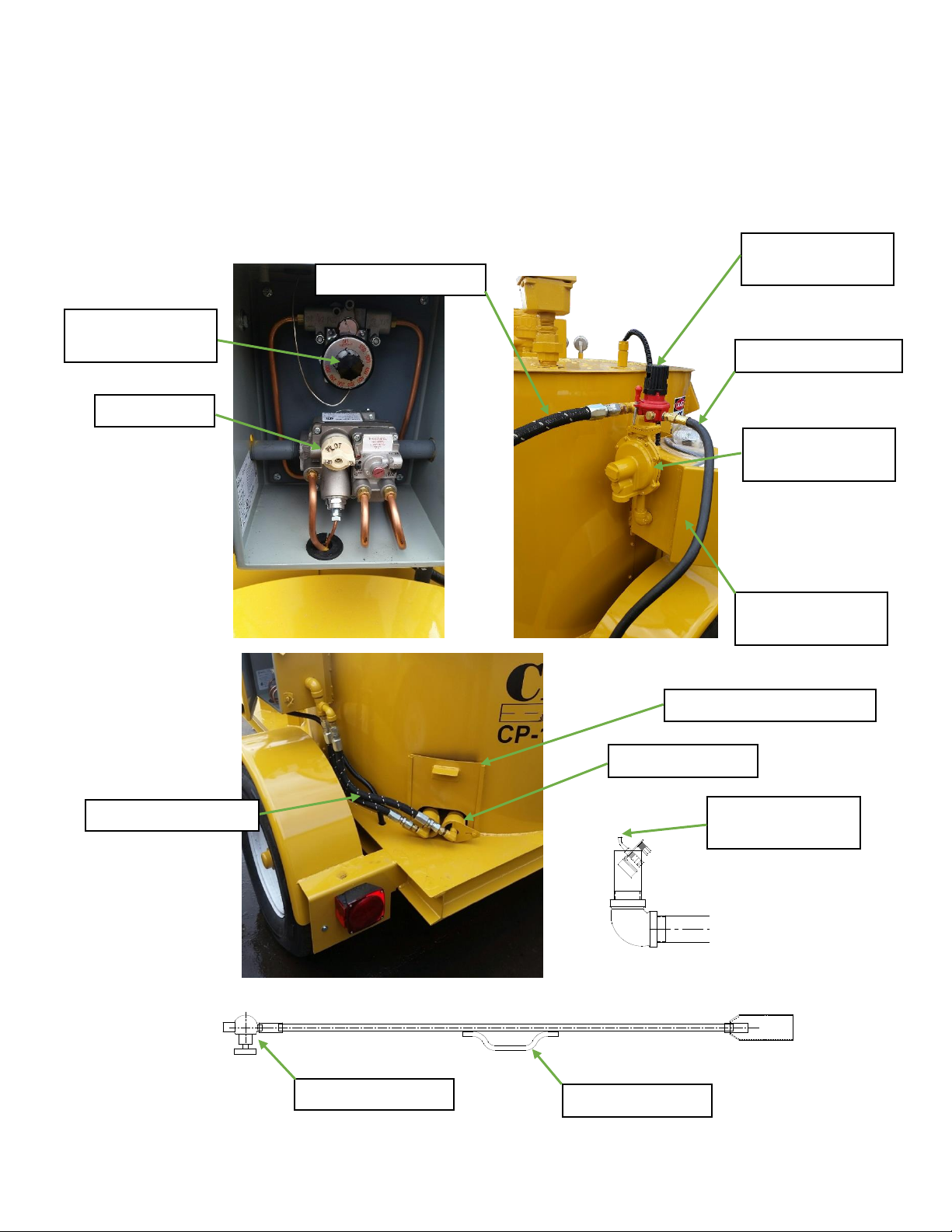

PARTS LIST PICTURE-2........................................................................................37

PARTS LIST PICTURE-3........................................................................................39

PARTS LIST PICTURE-4........................................................................................41

PARTS LIST PICTURE-5........................................................................................43

3

ThorWorks Industries, Inc.

Purchased by __________________________ Model NO. _______________________

Company Name _______________________ Serial NO. _______________________

Address ________________________________ Acceptance Date ________________

City _____________ State______ Zip _______

CORRESPONDENCE

All Correspondence regarding this equipment, as well as general correspondence should be addressed to:

ThorWorks Industries, Inc.

PO Box 2277

Sandusky, OH 44870

In referring to the equipment, kindly state the Model Number, Serial Number and any part number involved

`

4

SealMaster® LIMITED WARRANTY

SealMaster warrants that its products are of quality material and workmanship. SealMaster

agrees to replace, within a period of one (1) year from date of delivery, or at its option, repair,

without charge, any part of their manufacture which proved defective. The repair or

replacement will be free of charge F.O.B. Sandusky, Ohio, proving the damaged part or parts

are returned, freight prepaid, to SealMaster and investigation show such repair or replacement

is made necessary by an inherent defect of material or workmanship.

It is hereby understood that engines, motors, pumps, or other components purchased by

SealMaster for use on its equipment are not warranted by SealMaster and are sold only with

the standard warranty of the manufacturer of that component.

SealMaster will make no allowances for repairs or alterations completed by outside sources

unless authorization is in writing and approved by an authorized SealMaster representative.

Any claims for defective material or workmanship must be made prior to the expiration of thirty

(30) days from the date failure occurs, and in all cases prior to the expiration of the warranty

period of one (1) year. It is the intent of this paragraph to limit SealMaster’s liability solely to

the cost of replacement parts, F.O.B. factory, or at the option of SealMaster to repair of the

defective part or parts. No allowances for damages, lost time, or any other claim will be

recognized.

This warranty is null and void if other than genuine SealMaster parts are used.

SealMaster is constantly striving to improve their products. Changes in design and

improvement will be made whenever the manufacturer believes the efficiency of the product

will be improved, without incurring any obligation to incorporate such improvements in any

machines which have been shipped or are in service.

In an effort to continue to improve product quality, SealMaster reserves the right to change

specifications without notice.

Any modification or alteration of this machine without prior approval of the manufacturer may

void this warranty.

5

SAFETY PRECAUTIONS AND CAUTIONS

PRECAUTIONS

•Always wear eye and ear protection, long sleeve shirt, face shield

and gloves.

•Be aware of all CAUTION, WARNING, DANGER signs on the unit.

•Read all Owners Manuals that come with this unit.

•Make sure the operator is familiar with the units’ operation.

CAUTIONS

•Keep hands, feet, and clothing away from moving parts.

•Do not operate the machine without all guards in place.

•Stop the Agitator when opening the lid for any reason.

•Never fill the fuel tank with a lit burner.

•WARNING! When checking oil levels, never check when HOT!

6

SAFETY PRECAUTIONS AND CAUTIONS

FIRST AID

7

CRACK PRO® GRAVITY FLOW AND DIRECT FIRE MELTER

APPLIES TO ALL DIESEL FUEL BURNER & LP GAS BURNER

MANUAL COVERAGE

CRACK PRO® GRAVITY FLOW

This manual covers the oil jacketed CRACK PRO® model sizes 60,125 and 260 gals.

CRACK PRO® DIRECT FIRE MELTER

This manual also covers the non-oil jacketed CRACK PRO® model size 125 gallons.

Because there is not an oil jacket, the burner reacts differently.

Upon turning on the temperature control, the burner blower motor will come on

for a second and then shut off. The burner control is now sensing all parameters.

It will take upward of two minutes for this to happen, and once all parameters are

met, the burner will fire, starting the heating cycle.

Every time the temperature control calls for heat, the burner will go thru this

two-minute cycle.

8

CRACK PRO® GRAVITY FLOW AND DIRECT FIRE MELTER

APPLIES TO ALL DIESEL FUEL BURNERS

OPERATING INSTRUCTIONS - DIESEL FUEL BURNER

STARTUP

CHECKLIST

•Check engine oil level. Follow manufacturers guidelines as to

type and frequency of changes.

•Check hydraulic oil level. Use grade AW68 hydraulic oil.

•Check heat transfer oil level with oil dipstick #25. Use a good

quality grade 68 turbine oil or heat transfer oil.

NEVER CHECK WHEN HOT!

•Fill fuel tank with gasoline for the engine.

•Fill fuel tank with diesel for the burner.

NEVER FILL FUEL TANK WITH A LIT BURNER!

•NOTE: Direct Fire Melter’s do not have heat transfer oil or oil

thermometer.

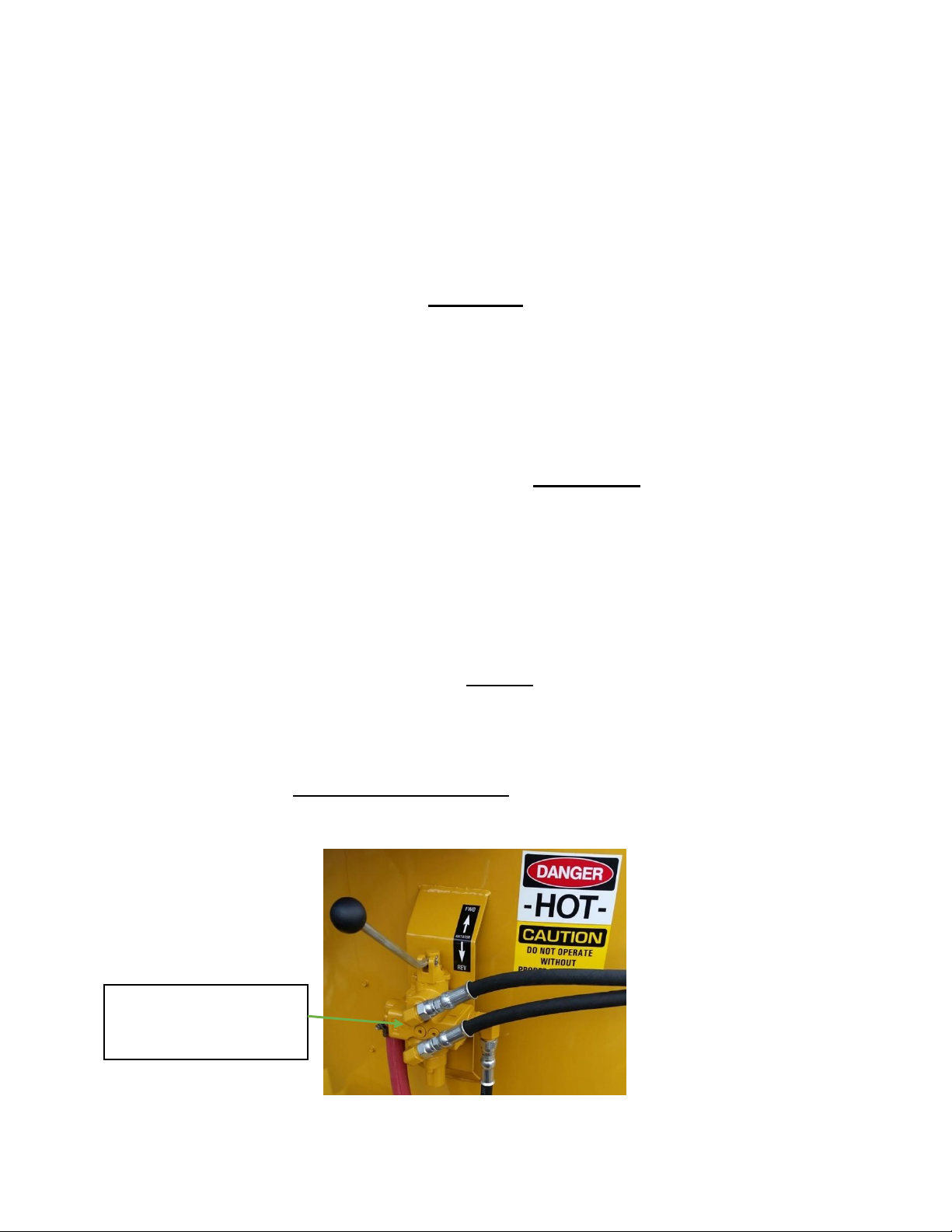

BEFORE STARTING THE ENGINE

Make sure the agitator control valve #23 is in the neutral position.

23 AGITATOR

CONTROL VALVE

9

CRACK PRO® GRAVITY FLOW AND DIRECT FIRE MELTER

APPLIES TO ALL DIESEL FUEL BURNERS

OPERATING INSTRUCTIONS - DIESEL FUEL BURNER

STARTUP

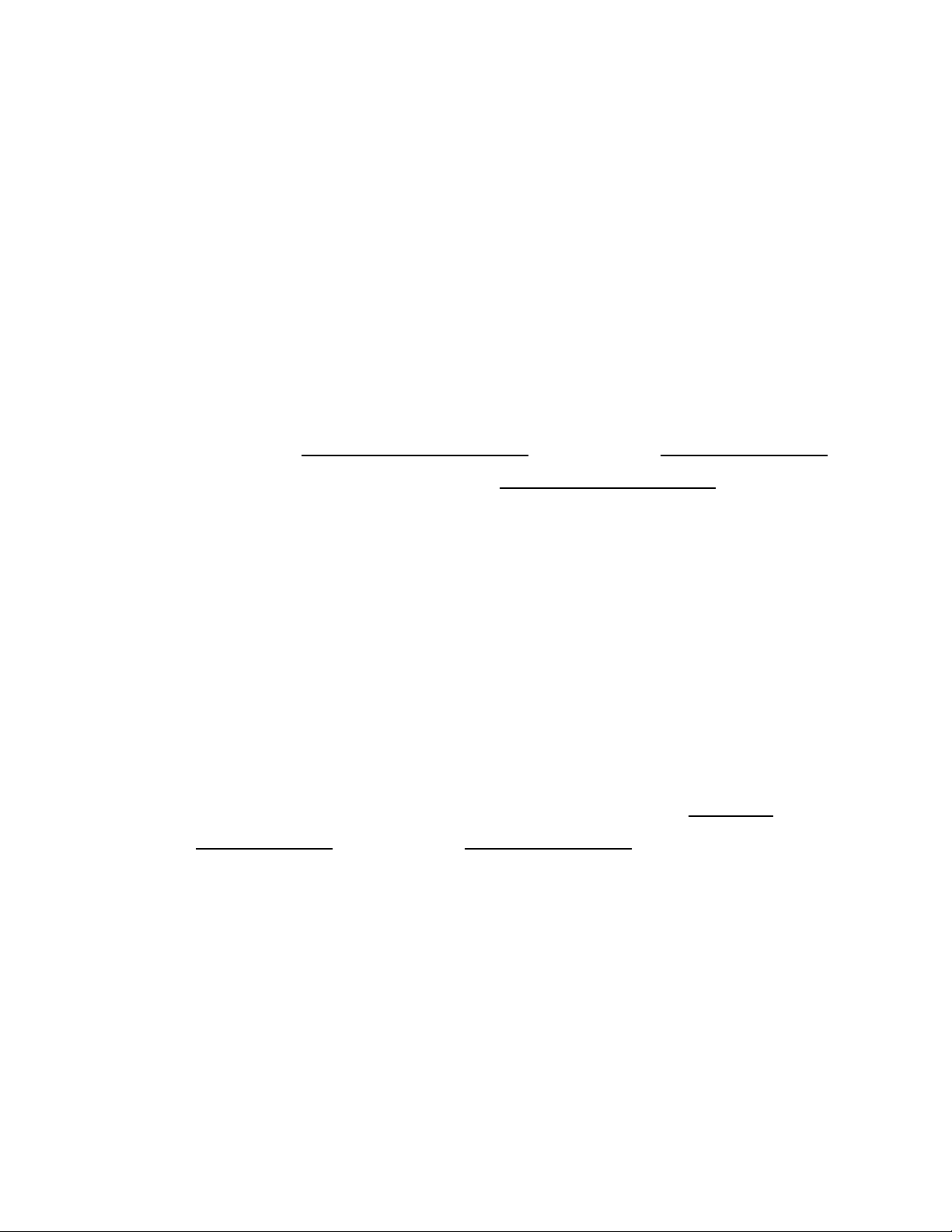

STARTING THE ENGINE

•Set the fuel shutoff and choke levers to the on position.

•Set the throttle lever at ½ open.

•Turn the engine switch to the start position.

•It is important that when you are done running the engine

that the fuel shutoff lever is turned to the off position. This keeps

gasoline from mixing with oil as you are driving.

Refer to the engine manual.

ENGINE

SWITCH

CHOKE

FUEL

THROTTLE

10

CRACK PRO® GRAVITY FLOW AND DIRECT FIRE MELTER

APPLIES TO ALL DIESEL FUEL BURNERS

OPERATING INSTRUCTIONS - DIESEL FUEL BURNER

STARTUP

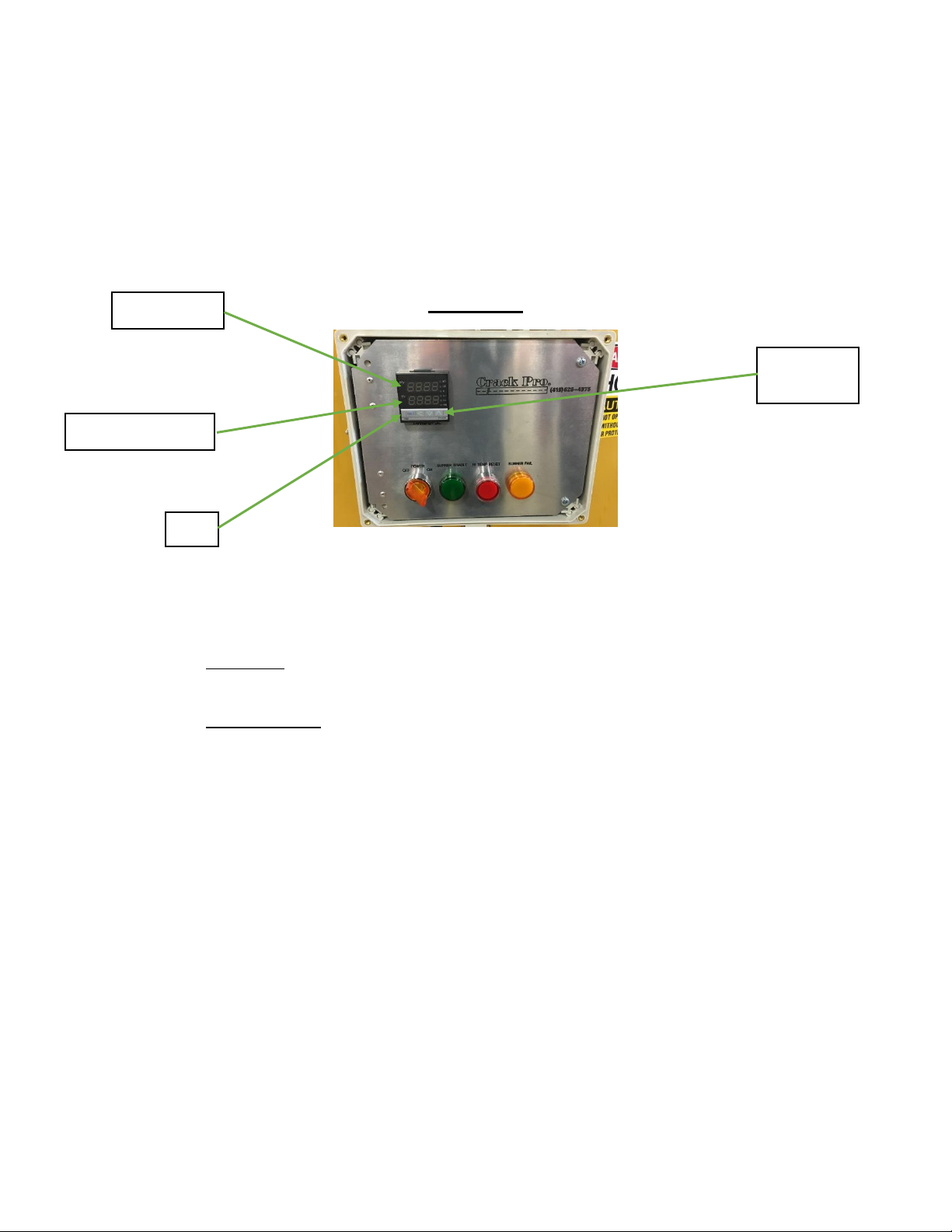

STARTING TEMPERATURE CONTROL

•The top scale is the ambient temperature of the heat transfer oil or

material temperature for SM-125.

•The bottom scale is the set temperature that you want the oil to be heated

to or material temperature for SM-125.

•NOTE: For SM-125 Refer to recommend pouring temperature on the

material box.

•The burner shuts off when your setting is exceeded by 10°.

•It comes back on when the temperature drops to 10° under your setting.

•The sequence for setting 475° temperature is:

1) Press the left arrow 3 times, then up or down for the 4.

2) Press the left arrow again, then up or down for the 7.

3) Press the left arrow again, then up or down for the 5.

4) Press SET.

NOTE: Factory set temperatures: CP Gravity Oil - 475° / SM-125 Material - 375°

ARROW

SETTINGS

BOTTOM SCALE

SET

TOP SCALE

11

CRACK PRO® GRAVITY FLOW AND DIRECT FIRE MELTER

APPLIES TO ALL DIESEL FUEL BURNERS

OPERATING INSTRUCTIONS - DIESEL FUEL BURNER

23 AGITATOR

CONTROL VALVE

21 ENGINE

16 MATERIAL

THERMOMETER

15 OIL

THERMOMETER

30 MATERIAL

DISCHARGE VALVE

25 OIL DIP STICK

12

CRACK PRO® GRAVITY FLOW AND DIRECT FIRE MELTER

APPLIES TO ALL DIESEL FUEL BURNERS

OPERATING INSTRUCTIONS - DIESEL FUEL BURNER

ADDING MATERIAL

1. Open the material tank lid and place three boxes of material

inside. Close the lid.

MATERIAL TEMPERATURE

2. When the material thermometer #16 and the oil thermometer

#15 reaches 300°, engage the agitator control valve #23 to the

forward position. If the agitator will not turn, return the valve

to the neutral position. Try again in a few minutes.

3. NOTE: When there are a few inches of liquid material in the

tank, you can add more blocks.

CAUTION: ALWAYS STOP THE AGITATOR WHEN OPENING THE

LID FOR ANY REASON!

4. As the material temperature gets close to the recommended

pouring temperature, you need to lower the digital

temperature controller setting down so that the material

thermometer #16and the oil thermometer #15 readings are

close together. When constantly adding blocks of material, the

digital temperature should be set about 50° higher than the

material pouring temperature.

5. If the material temperature starts to climb over the

recommended pouring temperature, open the lid and add

more blocks. Leaving the lid open will also help drop the

temperature.

13

CRACK PRO® GRAVITY FLOW AND DIRECT FIRE MELTER

APPLIES TO ALL DIESEL FUEL BURNERS

OPERATING INSTRUCTIONS - DIESEL FUEL BURNER

POURING MATERIAL

6. Set pour pot or applicator under the material discharge valve

#30 and raise the handle to open.

CAUTION: ALWAYS WEAR LONG SLEEVE SHIRT, GLOVES, AND

A FACE SHIELD WHEN PERFORMING THIS OPERATION!

7. Fill the crack filler pour pot to the desired level and pour into

cracks. Follow with a V-shaped squeegee if desired.

8. To stop for the day, perform the following steps:

•Turn the burner control switch to the off position, at least

a 1/2 hour before completing work.

•Put agitator control valve #23 in neutral.

•Shut off the engine #21.

BURNER CONTROL

SWITCH

14

CRACK PRO® GRAVITY FLOW AND DIRECT FIRE MELTER

APPLIES TO ALL LP GAS BURNERS

OPERATING INSTRUCTIONS - LP GAS BURNER

STARTUP

CHECKLIST

•Check engine oil level. Follow manufacturers guidelines as to

type and frequency of changes.

•Check hydraulic oil level. Use grade AW68 hydraulic oil.

•Check heat transfer oil level with oil dipstick #25. Use a good

quality grade 68 turbine oil or heat transfer oil.

NEVER CHECK WHEN HOT!

•Fill fuel tank with gasoline.

NEVER FILL FUEL TANK WITH A LIT BURNER!

•Check if the agitator control valve is in the neutral position.

•NOTE: Direct Fire Melter’s do not have heat transfer oil or oil

thermometer.

BEFORE STARTING THE ENGINE

Make sure the agitator control valve #23 is in the neutral position.

23 AGITATOR

CONTROL VALVE

15

CRACK PRO® GRAVITY FLOW AND DIRECT FIRE MELTER

APPLIES TO ALL LP GAS BURNERS

OPERATING INSTRUCTIONS - LP GAS BURNER

STARTUP

STARTING THE ENGINE

•Set the fuel shutoff and choke levers to the on position.

•Set the throttle lever at ½ open.

•Set the engine on/off switch to on position.

•Pull start the engine.

•It is important that when you are done running the engine

that the fuel shutoff lever is turned to the off position. This keeps

gasoline from mixing with oil as you are driving.

Refer to the engine manual.

CHOKE

FUEL

THROTTLE

ON/OFF

SWITCH

ENGINE

PULL START

HANDLE

16

CRACK PRO® GRAVITY FLOW AND DIRECT FIRE MELTER

APPLIES TO ALL LP GAS BURNERS

OPERATING INSTRUCTIONS - LP GAS BURNER

16 MATERIAL

THERMOMETER

15 OIL

THERMOMETER

25 OIL DIP STICK

21 ENGINE

23 AGITATOR

CONTROL VALVE

30 MATERIAL

DISCHARGE VALVE

30 MATERIAL

DISCHARGE VALVE

17

CRACK PRO® GRAVITY FLOW AND DIRECT FIRE MELTER

APPLIES TO ALL LP GAS BURNER

LP GAS BURNER PICTURES

9GAS VALVE

8TEMPERATURE

CONTROL

3HAND TORCH

REGULATOR

4LP GAS HOSE 1/4”

2LP GAS HOSE 1/2”

6MAIN BURNER

REGULATOR

7TEMPERATURE

CONTROL BOX

11 NEEDLE VALVE

12 GAS BURNERS

10 LP GAS HOSE 1/2”

5HAND TORCH

31 BURNER ACCESS DOOR

14 PILOT LIGHT

ASSEMBLY

18

CRACK PRO® GRAVITY FLOW AND DIRECT FIRE MELTER

APPLIES TO ALL LP GAS BURNERS

OPERATING INSTRUCTIONS - LP GAS BURNER

STARTUP

1. Open the temperature control box #7, and turn the temperature control

knob #8 all the way clockwise to its lowest setting. This will prevent the

burners from lighting prematurely. Remove burner access door #31.

2. Open the LP gas tank valve.

3. Turn the pilot knob on the gas valve #9 to the pilot position. Light the

hand torch #5 and place it in the burner opening. Position it by the pilot

light assembly #14, depress the pilot knob and remove the hand torch

when you see that the pilot flame is lit. Hold the pilot knob in for at least

30 seconds. Release the knob and turn it to the ON position.

4. Turn the thermostat control to its 500° setting, the burner will now light.

Replace the burner access door #31.

ADDING MATERIAL

5. Open the material tank lid and place three boxes of material inside.

Close the lid.

MATERIAL TEMPERATURE

6. When the material thermometer #16 reaches 300°, start the engine and

engage the agitator control valve #23 to the forward position. If the

agitator will not turn, return the valve to the neutral position. Try again

in a few minutes.

7. NOTE: When there are a few inches of liquid material in the tank, you

can add more blocks.

CAUTION: ALWAYS STOP THE AGITATOR WHEN OPENING THE

LID FOR ANY REASON!

This manual suits for next models

2

Table of contents

Popular Truck manuals by other brands

U-Line

U-Line Magliner H-1382 manual

Noblelift

Noblelift EPT15 Service maintenance manual

EINHELL

EINHELL TC-PT 2500 Original operating instructions

Still

Still RX70-20/600 Original instructions

Total Source

Total Source TRP0007 operating manual

freightliner

freightliner Custom Classic MT45 2022 Maintenance manual