AUTOCAR ACTT Xspotter 2018 User manual

autocartruck.com

Preventive Maintenance

AWE 00006 Rev. 005a

ACTT

Service

Manual

Preventive Maintenance

Important Notice

This Service Manual has been prepared by Autocar Industries, LLC (“Autocar”) for reference and use

by technicians who have been trained to repair and service Autocar products.

Autocar has exercised reasonable care and diligence to present accurate, clear and complete

information and instructions regarding the techniques and tools required for maintaining, repairing

and servicing Autocar products. However, despite the care and effort taken in preparing this general

Service Manual, Autocar makes no representations or warranties that (a) the Service Manual or any

explanations, illustrations, information, techniques or tools described herein are either accurate,

complete or correct as applied to a specic Autocar product, or (b) any repairs or service of a

particular Autocar product will result in a properly functioning unit.

The vehicles and components referenced in this manual are under continuous development. Vehicles

and components produced after the manual release date may therefore have different specications

and repair methods.

This manual covers service of Autocar products as congured when they leave the factory. This

manual does not cover or apply to Autocar products that have been modied after leaving Autocar’s

factory. Autocar is not liable for any damage or failure of components added by a body builder or any

other modication company not contracted by Autocar, or the failure of original components caused

by any modication or alteration of the Autocar product.

Autocar is dedicated to protecting the environment. When servicing Autocar products, please dispose

of all removed material, oils and coolant in an environmentally responsible manner.

Autocar Industries, LLC

Hagerstown, Indiana, U.S.A.

Document Number: AWE 00192 Rev. 000

Copyright © 2018 Autocar Industries, LLC

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or

transmitted in any form by any means - electronic, mechanical, photocopying, recording or otherwise

- without the prior written consent of Autocar.

This page left blank intentionally.

AWE 00192 Rev. 000 TOC-1

877-973-3486

Preventive Maintenance

Table of Contents

Safety Denitions.................................................................................................................... 3

Safety Information .................................................................................................................. 3

General Safety ...................................................................................................................... 3

Lifting..................................................................................................................................... 4

Jacking Up the Vehicle.......................................................................................................... 4

Pneumatic (Compressed Air) Components ........................................................................... 4

Hydraulic Components.......................................................................................................... 4

Working on CNG/LNG Trucks ............................................................................................... 5

Working on CNG Fuel Systems ............................................................................................ 5

CNG/LNG Safety................................................................................................................... 5

Welding and Hot Work Near CNG and LNG Trucks.............................................................. 5

CNG Cylinders ...................................................................................................................... 5

CNG Fuel Container Pressure Relief Devices (PRDs).......................................................... 6

Eye, Ear and Skin Protection ................................................................................................ 6

Testing the Equipment........................................................................................................... 6

Road Testing the Vehicle....................................................................................................... 7

While Servicing the Vehicle................................................................................................... 8

Ground Straps and Antistatic Mats........................................................................................ 8

Power Steering...................................................................................................................... 8

Lockout / Tagout Procedures ................................................................................................ 8

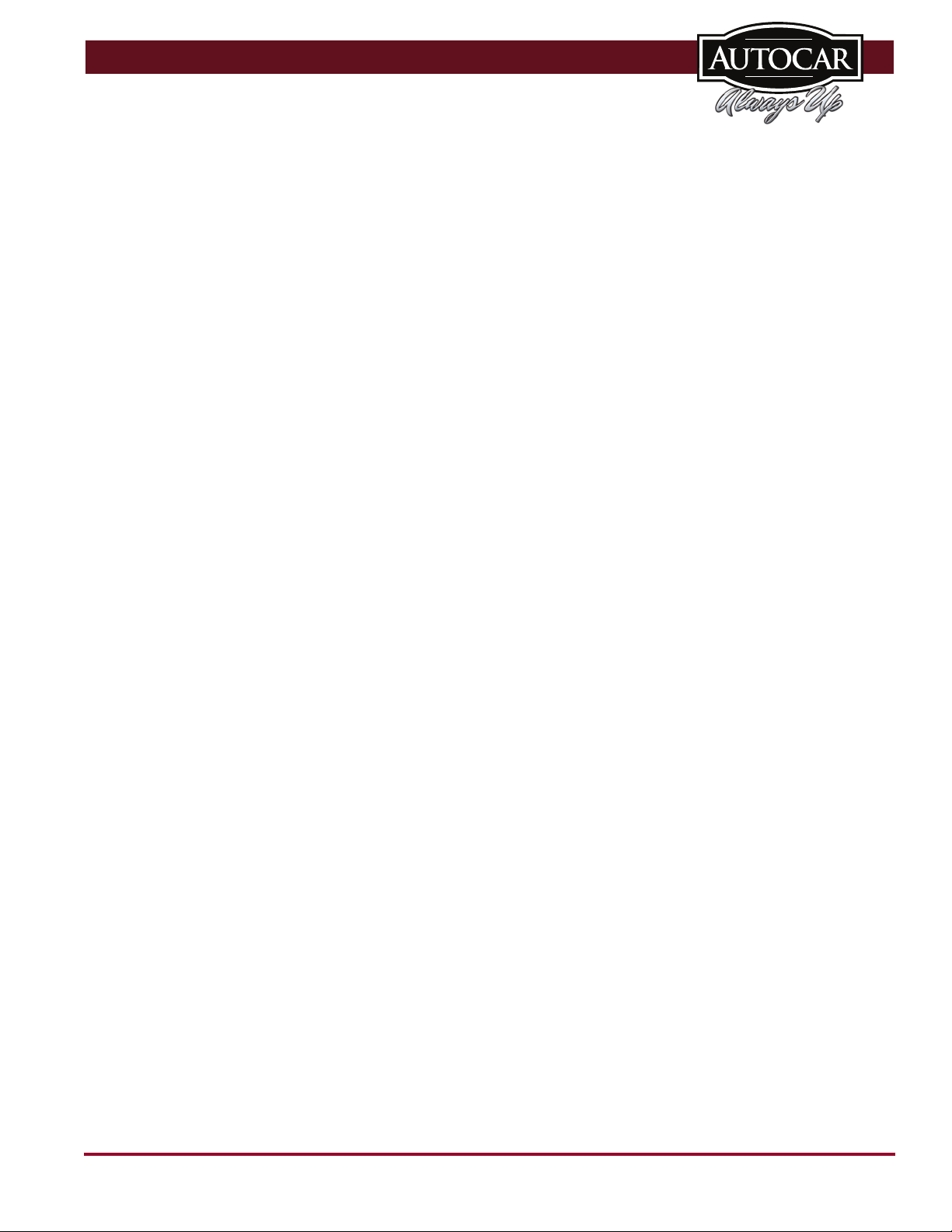

Introduction............................................................................................................................. 9

PREVENTIVE MAINTENANCE PROGRAM............................................................................ 9

A Inspection .......................................................................................................................... 9

B Inspection........................................................................................................................... 9

C Inspection .......................................................................................................................... 9

D Inspection .......................................................................................................................... 9

INSPECTION 150 HRS INTERVAL........................................................................................ 10

Exterior Inspection (150 Hours)........................................................................................... 10

Walk-Around Inspection ...................................................................................................... 10

Fuel System ........................................................................................................................ 13

Braking System ................................................................................................................... 15

Electrical System................................................................................................................. 16

Electrical System................................................................................................................. 16

Engine Compartment .......................................................................................................... 17

Cooling System ................................................................................................................... 18

Intake Air Piping .................................................................................................................. 19

877-973-3486 AWE 00192 Rev. 000TOC-2

ACTT Xspotter Service Manual

Under Tractor Inspection (150 Hours).................................................................................. 19

Description ........................................................................................................................... 19

Lubrication............................................................................................................................ 20

Steering and Suspension ..................................................................................................... 22

Interior and Instrumentation................................................................................................. 23

Road Test (150 Hours) ......................................................................................................... 27

Post Road Test Inspection (150 Hours)................................................................................ 29

Inspection 300 Hrs Interval ................................................................................................... 29

Walk-Around Inspection (300 Hours) ................................................................................... 29

Cooling System Service........................................................................................................ 32

Coolant Drain and Fill Deaeration Procedure....................................................................... 32

Complete Cooling System Maintenance Procedures........................................................... 34

Fan Clutch Service................................................................................................................. 40

Fan Drive Inspection ............................................................................................................ 40

Additional Checks for Two-Speed Fan Drives...................................................................... 42

Air Conditioning Refrigerant ................................................................................................. 42

Under Tractor Inspection (300 Hours).................................................................................. 42

Road Test (300 Hours) ......................................................................................................... 43

Post Road Test Inspection (300 Hours)................................................................................ 44

Inspection 1,200 Hours Interval............................................................................................ 44

Description and Operation (1,200 Hours)............................................................................. 44

Walk-Around Inspection (1,200 Hours) ................................................................................ 45

Under Tractor Inspection (1,200 Hours)............................................................................... 45

Inspection 2,400 Hours Interval............................................................................................ 46

Description and Operation (2,400 Hours)............................................................................. 46

Walk-Around Inspection (2,400 Hours) ................................................................................ 47

Brake System....................................................................................................................... 47

Under Tractor Inspection (2,400 Hours)............................................................................... 47

Preventive Maintenance Intervals ........................................................................................ 48

Special Torque Chart ............................................................................................................. 51

Lubricant and Fluid Requirements ....................................................................................... 52

Chassis Lubrication Chart (Top View) ................................................................................. 53

Chassis Lubrication Chart (Bottom View)........................................................................... 54

AWE 00192 Rev. 000 3

877-973-3486

Preventive Maintenance

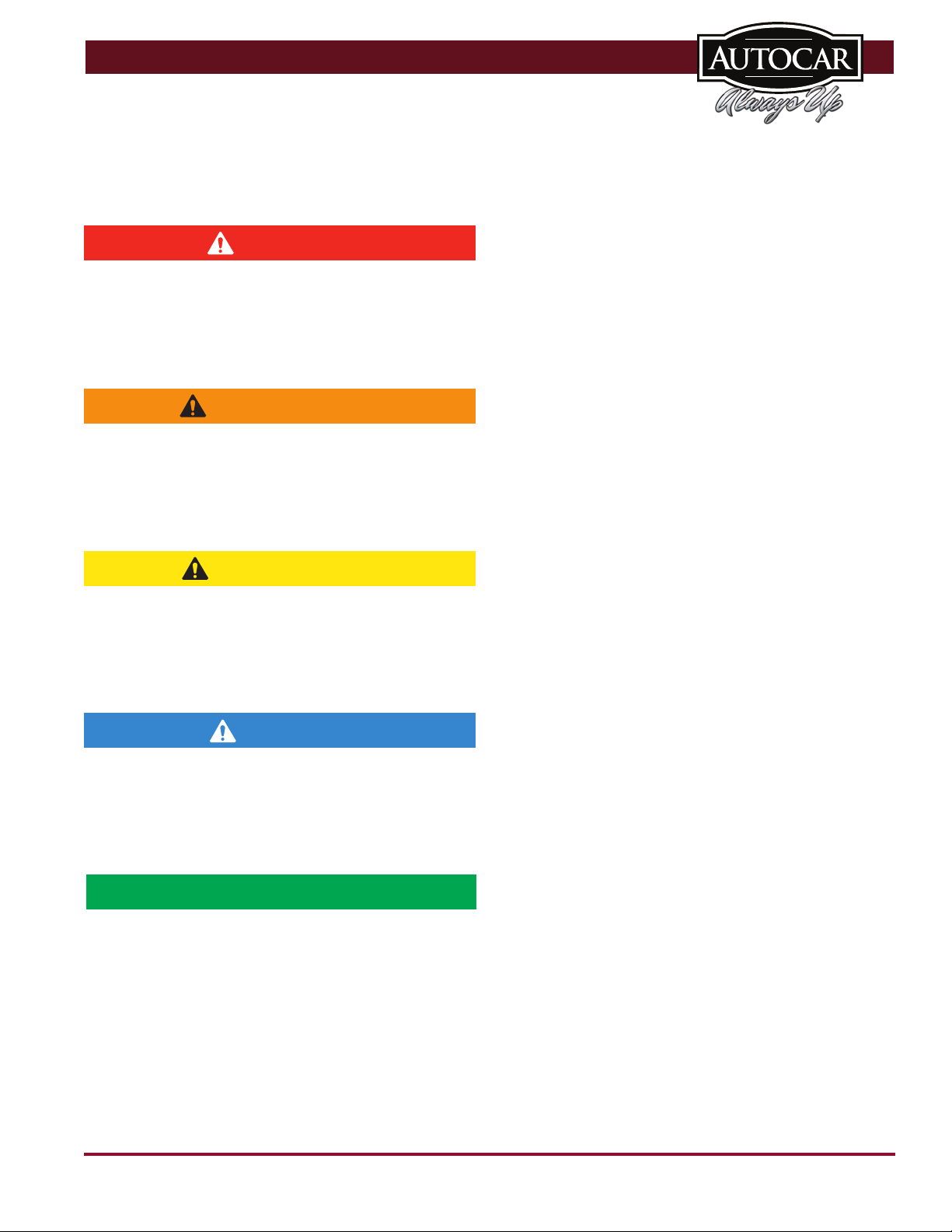

SAFETY DEFINITIONS

The following safety indicators are used in this

manual:

DANGER

DANGER indicates a hazardous situation

which, if not avoided, will result in death

or serious injury or damage to equipment

or other property.

WARNING

WARNING indicates a hazardous situation

which, if not avoided, could result in

death or serious injury or damage to

equipment or other property.

CAUTION

CAUTION indicates a hazardous situation

which, if not avoided, may result in

minor or moderate injury or damage to

equipment or other property.

NOTICE

NOTICE is used to address practices not

related to physical injury which, if not

complied with, may result in damage to

equipment or other property.

SAFETY

INSTRUCTIONS

Safety instructions (or equivalent)

indicate specic safety-related

instructions or procedures.

SAFETY INFORMATION

Ensure safe working conditions and

procedures at all times. Read and understand

this entire manual before servicing the vehicle.

You must be thoroughly trained and familiar

with the vehicle before working on it. This

equipment can cause severe injury if not

properly used and maintained.

Safety procedures are for your protection. Do

not operate the vehicle until you have read and

understood the Operator Manual supplied with

the vehicle.

General Safety

There is no substitute for common sense and

careful practices in the workplace. Improper

practices or carelessness can cause burns,

cuts, mutilation, asphyxiation, other bodily

injury or death. The sections that follow provide

general safety precautions and guidelines.

Additional safety precautions are listed in

specic procedures when they apply. Read and

understand all of the safety precautions and

guidelines before performing any repair.

The technician performing maintenance repairs

or service on Autocar products must (a) inspect

the vehicle for abnormal wear and damage,

(b) choose a repair procedure which will not

endanger his/her safety, the safety of others,

the vehicle or the safe operation of the vehicle

and (c) fully inspect and test the Autocar

product to ensure that the repair or service

of the Autocar product has been properly

performed.

Autocar is dedicated to protecting the

environment. When servicing Autocar products,

please dispose of all removed material, oils

and coolant in an environmentally responsible

manner.

877-973-3486 AWE 00192 Rev. 0004

ACTT Xspotter Service Manual

WARNING

NEVER service any part of the fuel

system while smoking or in the presence

of ames, sparks or hot surfaces.

Clean up fuel spills immediately. Fuel

leaked or spilled onto hot surfaces or

electrical components can cause a re.

Before working in or around the vehicle,

apply the parking brake, block the wheels

and put the transmission in NEUTRAL.

WARNING

Immediately replace safety decals if they

become damaged, unreadable or missing.

Contact Autocar for replacement decals

when required.

Lifting

Use a hoist or other assistance when lifting

components that weigh 50 lb. (23 kg) or more.

Make sure all lifting devices such as chains,

hooks or slings are in good condition and have

the correct capacity. Make sure hooks are

positioned correctly. ALWAYS use a spreader

bar when necessary. The lifting hooks MUST

NOT be side loaded.

Jacking Up the Vehicle

NEVER work under a vehicle supported only

by jacks. Jacks can slip out from under the

vehicle or fall over. ALWAYS use jack stands

under the vehicle. Failure to do so can result in

the vehicle falling.

The Antilock Brake System (ABS) MUST be

disabled on vehicles equipped with Automatic

Traction Control (ATC) prior to jacking up the

vehicle and placing it on jack stands. If the ABS

is not disabled and one of the wheels starts to

spin, the ATC will compensate and the vehicle

may come off the jack and/or jack stands.

Refer to the “Antilock Braking System

Service Manual - AWE 00178 Rev. 000” for

information on disabling the ABS system.

Pneumatic (Compressed Air)

Components

DANGER

Pneumatic components such as air

reservoirs and park brake chambers

store compressed air and can separate

violently during disassembly or removal.

Before servicing any part of the

pneumatic (air) system, completely

release the compressed air from the

entire system.

Stay clear when inating or deating air

bags. Drain ALL air reservoirs and ALL

air suspension components including

auxiliary, tag or pusher axle suspensions

before working under or around a vehicle.

Hydraulic Components

DANGER

Hydraulic systems and fuel injection

systems can operate under extremely

high pressures and can remain

pressurized long after shutdown. Before

servicing any part of the hydraulic system

or fuel injection system, carefully relieve

the pressure completely. Escaping uid

under high pressure can penetrate the

skin causing severe injury. NEVER check

for leaks using your hand.

To pinpoint the origin of the leak use a

mirror, a piece of wood or cardboard held

with long-nose pliers in the vicinity of the

leak.

AWE 00192 Rev. 000 5

877-973-3486

Preventive Maintenance

Working on CNG/LNG Trucks

SAFETY

INSTRUCTIONS

If you store or dispense Compressed

Natural Gas (CNG) or Liqueed Natural

Gas (LNG), or if you work on CNG or

LNG trucks, your location must be

fully compliant with applicable codes,

regulations and standards, including

National Fire Protection Associate (NFPA)

codes, Society of Automotive Engineers

(SAE) standards, American National

Standards Institute (ANSI) Natural Gas

Vehicle (NGV) standards, the United

States Code of Federal Regulations (CFR)

and your state and local re and other

applicable codes (including, for example,

the California Code of Regulations and

the Texas Administrative Code).

Contact your local re department for

guidance and additional compliance

information.

Technicians working on Autocar trucks

with CNG or LNG engines must be trained

in the proper repair of CNG and LNG

trucks and engines and the safe storage

and dispensing of CNG and LNG.

Working on CNG Fuel Systems

WARNING

CNG fuel systems include a high pressure

(3600 psi [24 820 kPa]) system for fuel

storage and a low pressure system (125

psi [860 kPa]) for consumption by the

engine. Understanding the characteristics

of CNG and how the fuel system works

will prevent injury and damage to persons

and property.

Attempting to operate or maintain any

CNG fuel system without proper training

is dangerous. Complete training and

consult instructional bulletins from the

CNG system suppliers, such as Agility

Fuel Systems’ Field Service Bulletin:

Safely Working on CNG Fuel Systems.

CNG/LNG Safety

WARNING

Welding and Hot Work Near CNG and

LNG Trucks

Welding, grinding and other “hot work”

can be safely performed on or near a CNG

or LNG vehicle, but certain precautions

must be followed. Understand and

perform the necessary precautions

provided by the CNG and LNG system

suppliers, such as Agility Fuel Systems’

Field Service Bulletin: Welding and Hot

Work Precautions Near CNG and LNG

Vehicles.

CNG Cylinders

WARNING

CNG fuel containers must meet Federal

Motor Vehicle Safety Standard (FMVSS)

304 (Compressed Natural Gas Fuel

Container Integrity) and/or ANSI/

CSA NGV2 (Basic Requirements for

Compressed Natural Gas Vehicle Fuel

Containers). Both standards specify a

detailed visual examination every three

years.

Ensure that every truck owner completes

the required inspections, in accordance

with the applicable standards and other

resources, such as the Clean Vehicle

Education Foundation and NGVAmerica’s

Compressed Natural Gas (CNG)

Container Visual Inspection Advisory.

877-973-3486 AWE 00192 Rev. 0006

ACTT Xspotter Service Manual

FMVSS 304 also requires that cylinders

not be used after the end of life (EOL)

date provided on the tank label. The

EOL date is also displayed in the

engine compartment and at the fueling

connection of each truck. If there is any

question as to proper decommissioning

of a cylinder, contact the manufacturer,

whose name and address is also required

to be on the label.

CNG Fuel Container Pressure Relief

Devices (PRDs)

WARNING

PRDs must be properly maintained and

positioned for safe operation of a CNG

fuel system. Missing vent caps can

allow moisture into PRDs and vent lines,

which can freeze and damage these

safety components. Debris which clogs

the PRDs and/or vent lines can prevent

proper function.

PRDs must be positioned to vent upward,

not outward, from a vehicle.

Ensure that every truck owner completes

periodic inspections of the PRDs and

vent lines and systems, in accordance

with guidance provided by the system

component suppliers.

Alert First Responders to CNG

and LNG

DANGER

In the event of a re or other emergency,

alert rst responders to the presence

and location of CNG fuel systems,

tanks and dispensers. Ensure that

emergency personnel are aware of proper

precautions, such as those provided in

Agility’s First Responder Guide: CNG and

LNG Vehicle Fuel Systems.

Eye, Ear and Skin Protection

WARNING

ALWAYS wear appropriate eye protection

to prevent the risk of eye injury. Wear

safety glasses to prevent eye contact

with debris and uids. Wear a welding

face mask to protect eyes and face when

welding.

ALWAYS wear ear plugs when working

around loud noises to prevent the risk of

hearing loss and damage.

ALWAYS wear appropriate gloves to

protect the hands. Wear welding gloves

to protect the hands when welding.

Wear appropriate gloves when handling

extremely hot or cold equipment and

uids.

Testing the Equipment

WARNING

Exhaust gases contain deadly poison.

When testing a vehicle with the engine

running, conduct the test outdoors or use

a properly vented exhaust hose.

Use caution when installing testing

equipment. Keep away from hot engine

or transmission components or uids.

A hot engine, transmission or uids can

permanently damage test equipment and

can cause personal injury.

If a vehicle is to be operated with testing

equipment connected, take precautions

to ensure that all equipment and related

components are securely attached, to

prevent movement and interference.

All items within the cab must be secured

before the vehicle is serviced or driven.

AWE 00192 Rev. 000 7

877-973-3486

Preventive Maintenance

Road Testing the Vehicle

When operating the vehicle on streets and

highways while testing, ALWAYS have one

person drive while another performs the test.

Failure to do so may cause a collision, which

can result in serious injury or death.

WARNING

NEVER operate the starter without rst

placing the transmission in NEUTRAL

and applying the parking brake. Failure to

follow these instructions may result in the

unintentional movement of the vehicle.

NEVER release or drive a truck on the

road that has a brake defect – no matter

how minor – until it has been repaired or

corrected. Failure to repair brake defects

can result in compromised braking and

lead to loss of control of the vehicle.

NEVER drive the vehicle without power

assisted steering. When the power assist

has failed, the effort required to turn the

steering wheel is much greater, especially

in sharp turns or at low speeds.

A speed retardation device (such as a

“Jake Brake®,” “C-Brake®” “Exhaust

Brake” or “Allison™ Retarder”) is not

intended to replace the service brake

system on the vehicle and cannot be

relied on to bring the vehicle to a stop. A

vehicle speed retardation device is only

intended to regulate the speed of the

vehicle under certain conditions.

WARNING

DO NOT EXCEED 15 MPH (24 KM/H)

WHEN TOWING TRAILERS.

Operating at speeds in excess of 15 mph

(24 km/h) may lead to loss of vehicle

control. NEVER take turns at excessive

speeds, this may cause the vehicle and

trailer to roll over.

The majority of roll over accidents are

caused by excessive cornering speed.

Roll over accidents may lead to serious

injury or death.

WARNING

Never tow trailers without BOTH the

service and emergency brake lines

connected to the trailer.

Never tow trailers without functioning

service and emergency brake systems.

Operating the vehicle while towing

trailers without functioning trailer brake

systems may lead to loss of control of the

vehicle, serious injury or death.

WARNING

Never tow a trailer above the minimum

height required to clear the landing gear

from the ground. Lifting the fth wheel

and trailer too high drastically raises

the center of gravity of the trailer and

increases the chance of a roll over.

877-973-3486 AWE 00192 Rev. 0008

ACTT Xspotter Service Manual

SAFETY

INSTRUCTIONS

Before driving the vehicle, be certain

that you have read and understand the

driving and handling information in the

Operator Manual. Be certain that you

fully understand and follow all safety

warnings.

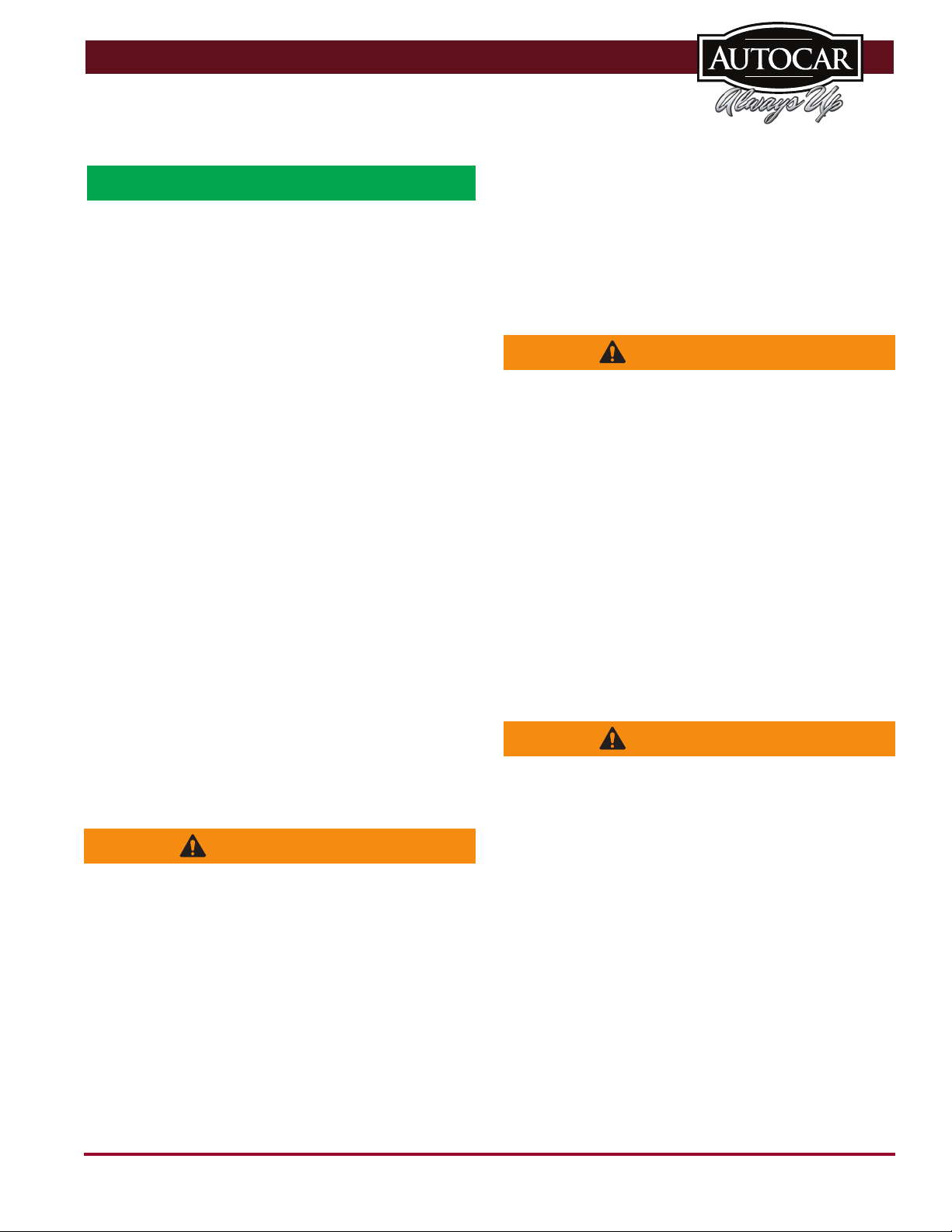

While Servicing the Vehicle

CAUTION

Read and understand the precautions

and guidelines in each component

manufacturer’s service information

before performing any service on the

components. If you are not properly

trained and certied in a procedure, ask

your supervisor for training before you

perform it.

Ground Straps and Antistatic Mats

SAFETY

INSTRUCTIONS

ALWAYS work with proper grounding

straps and antistatic mats around

electronic components.

Power Steering

SAFETY

INSTRUCTIONS

Maintain cleanliness of the power

steering hydraulic system at all times.

Clean the area around any component

prior to disconnecting or connecting.

NEVER add used power steering uid

to the system. Dirt in the power steering

system can damage the pump or other

components.

LOCKOUT / TAGOUT PROCEDURES

WARNING

Before entering the vehicle or vehicle

body, read and follow OSHA regulations

concerning entry and working in

“CONFINED SPACE” OSHA 1910.146

and “LOCKOUT/TAGOUT” OSHA

1910.147. Follow OSHA regulations while

performing any work on the vehicle. The

vehicle must be disabled by the following

steps before performing any work on the

vehicle:

1. Place the transmission in NEUTRAL.

2. Set the parking brake.

3. Shut the engine OFF.

4. Lock the cab doors. Keep the key in your

pocket. Block the wheels before entering

the body or performing any work on the

vehicle.

5. Turn the battery disconnect switch OFF, if

equipped, and lock it in that position.

6. Completely drain the air from the

primary/A system and secondary/B

system by opening the drain valves on

the air tanks themselves or by using the

drain manifold if supplied. When draining

the air tanks, do not look into the area

where air is draining. Dirt or sludge

particles may be expelled in the air

stream and can cause eye injury.

7. Place magnetic “DANGER” signs on both

cab doors before entering the body or

performing any work on the vehicle.

8. Take proper precautions before working

under the vehicle. Use ramps approved

for the weight of your vehicle, or use oor

jacks and stands. Never work under a

vehicle or auxiliary, tag or pusher axle

supported by jacks alone. Always use

jack stands to support the vehicle and

auxiliary, tag or pusher axles.

AWE 00192 Rev. 000 9

877-973-3486

Preventive Maintenance

INTRODUCTION

This manual has been designed to reect

a work-efcient approach to preventive

maintenance.

Periodic servicing, inspection, adjustment

and maintenance are essential to the ongoing

dependability and efciency of the vehicle.

Vehicles that receive proper preventive

maintenance operate more effectively and

economically.

One of the most important part of the vehicle’s

maintenance is lubrication and oil changes.

However, despite of the high quality of the

lubricants and oils available today, natural wear

does occur necessitating adjustments and

repairs.

A thorough Preventive Maintenance Program

can dramatically reduce breakdowns

and increase service life. This Preventive

Maintenance Program has been developed

to help prevent unexpected downtime and

continuously maintain the vehicle in good

operating condition. Following these guidelines

will also help ensure the vehicle meets all

federal, state, and local regulations, which is

the responsibility of the owner.

This manual is intended as a general guide.

Individual users may need to alter these

recommendations based upon the application

in which the truck will be used. For example,

more severe applications may require

shortening the interval between chassis

lubrication. Contact your authorized Autocar

dealer to develop the Preventive Maintenance

Program that is best suited to your application.

The vehicle be serviced based on operating

hours. Maintenance intervals based on months

or mileage do not take into consideration actual

operating hours.

Major vehicle components such as engine,

transmission, axles and retarders, may

have their own recommended preventive

maintenance intervals. Refer to each

component’s maintenance manual for service

intervals and procedures. If no manufacturer

recommendation exists, follow the guidelines

in the Preventive Maintenance Program in this

Service Manual section.

PREVENTIVE MAINTENANCE

PROGRAM

A Inspection

Perform this inspection every 150 hours

of operation (maximum recommended

interval). This includes, but is not limited

to, basic inspection of the vehicle and may

include engine oil and lter change, as well

as complete chassis lubrication. Refer to

manufacturer’s recommendations for further

information.

B Inspection

Perform this inspection every 300 hours of

operation (maximum recommended interval).

This inspection includes everything done

during the A inspection, plus additional items

requiring inspection at this interval.

C Inspection

Perform this inspection every 1,200 hours of

operation (maximum recommended interval).

This inspection includes everything done

during the A and B inspections, plus additional

items requiring inspection at this interval.

D Inspection

Perform this inspection every 2,400 hours of

operation or yearly (maximum recommended

interval), whichever comes rst.

877-973-3486 AWE 00192 Rev. 00010

ACTT Xspotter Service Manual

NOTICE

For tractors that do not accumulate

2,400 hours per year, the D inspection

must be done annually to ensure proper

maintenance of the vehicle.

This inspection includes everything done

during the A, B and C inspections, plus

additional items requiring inspection at this

interval.

Use the Preventive Maintenance Inspection

Form when completing this inspection. Copies

of this form can be obtained through the

Autocar website (www.autocartruck.com).

Each service should follow the recommended

sequence: A-B-A-B-A-B-A-C-A-B-A-B-A-B-A-D,

etc. See “Preventive Maintenance Intervals”

Chart in this section.

INSPECTION 150 HRS INTERVAL

Perform this inspection every 150 hours of

operation (maximum recommended interval).

This includes, but is not limited to, basic

inspection of the vehicle and may include,

engine oil and lter change, as well as

complete chassis lubrication.

Major vehicle components such as engine,

transmission and axles may have their

own Preventive Maintenance Inspection

procedures, and Autocar recommends

reviewing each component’s documentation for

its recommended maintenance schedule.

While conducting these inspections record

the results using the Preventive Maintenance

Inspection form available from Autocar.

EXTERIOR INSPECTION

(150 HOURS)

Walk-Around Inspection

Fluid Leaks

Before beginning the actual inspection, check

the ground under the tractor as you approach,

looking for evidence of uid leaks.

Glass, Mirrors and Brackets

Figure 1

• Check windshields; must be free of

damage, hazing or discoloration within

certain guidelines.

• Check the windows, vents and back window

for cracks.

• Check mirrors, they should be free of

damage, hazing and discoloration. Brackets

should be secure.

• If the mirrors are motorized, check the

operation.

Wiper Blade and Arm

• Check condition of wiper blade and arm for

looseness, bends, tension, etc.

Exhaust Stack

• Check that the exhaust stack is not

damaged and is securely mounted

• Check all ex pipes

• Check all exhaust blankets..

AWE 00192 Rev. 000 11

877-973-3486

Preventive Maintenance

Supply Lines and Wires

• Check that all air lines, fuel lines, diesel

exhaust uid lines and electrical wires are

properly routed and clamped securely.

Cab

• Check the operation of cab tilt and cab

latch mechanism Refer to the “Tilting the

Cab” section in the Operators Manual for

complete procedures and warning for tilting

the cab.

WARNING

Close and securely latch the LH side and

rear door BEFORE tilting the cab. Failure

to do so could result in personal injury

and damage to the door(s) and/or cab

structure. If the door must be opened

once the cab is in the tilted position, the

door must be properly supported. DO

NOT allow the weight of the door to be

supported by the door check strap alone.

• Check that cab mounts are securely

bolted to the frame.Check air suspension

components for condition, proper mounting,

and operation. Check for rust or cracks

around mounts (Figure 2). Figure 2

• Check latches for adequate tension.

• Check the cab hinges (Figure 3).

Figure 3

877-973-3486 AWE 00192 Rev. 00012

ACTT Xspotter Service Manual

Frame Rails and Crossmembers

• Check the frame rails and crossmembers

for cracks, damage or distortion.

• Check the frame for loose bolts.

Tighten any loose bolts to proper torque

specication.

• Check the condition of the paint and

overall appearance of the tractor. Note any

damage, rust or corrosion.

• Check the condition of the cab access

steps, platforms and grab handles. They

should be secure, undamaged and free

from slick spots (Figure 4).

Figure 4

Wheels and Tires

• Check for the presence and condition of

mudguards or aps. Inspect the condition of

the mounting brackets and hardware.

• Tighten the wheel nuts to the proper torque

(Figure 5). All disc wheels used on the

ACTT series require a torque of 450 lb.ft

(610 N·m). For all other wheels, refer to the

decal afxed to the frame rail, or if no decal

is found, refer to the wheel manufacturers’

specication.

Figure 5

DANGER

Failure to properly torque-tighten the

wheel nuts can result in breakage of the

wheel studs and the subsequent loss

of the wheels. Loss of vehicle control

resulting in serious injury or death may

occur.

• Inspect the wheels for elongated or

distorted mounting holes. Examine the inner

and outer wheels for cracks and for rust

streaks around the lug nuts.

• Examine each tire for unusual or uneven

wear patterns.

• Check the valve stems and extensions on

each wheel for leaks.

AWE 00192 Rev. 000 13

877-973-3486

Preventive Maintenance

• Check and record pressure in each tire. The

tire ination pressure is specied by a decal

located near each tire. If there is no decal,

refer to the air pressure as indicated on

each tire.

• Using a tire tread depth gauge, check

the tread depth in the center of the tread.

Record the tread depth in 1/32s of an inch.

Autocar recommends that front (steering

axle) tires with less than 4/32 in. tread

depth should be replaced, and rear (drive)

tires with less than 2/32 in. tread depth

should be replaced (Figure 6).

Note: The tires should be rotated

periodically to maximize tire life. Typically,

rear drive axle tires will wear more rapidly

than front drive axle tires, due to them

travelling on the outside of the turning

circle. No specic interval can be given,

as the requirement changes depending on

operational conditions.

1/8 in.

(3 mm)

1/16 in,

(6 mm)

Steer

Tire

Drive

Tire

Figure 6

Fuel System

Fuel Tank(s)

• Inspect fuel tank for damage, leaks or

rust (Figure 7).

Figure 7

• Examine the mounting straps for cracks,

and ensure that the rubber insulators are

secure.

• Ensure that the tanks have not rotated in

their mounts.

• Inspect and clean the vent in each tank.

• Inspect the operation of the shutoff valves.

• Drain water and sludge from all fuel tanks.

• Place a container under the fuel tank and

loosen the drain plug until water begins to

runout.

• Allow the fuel tank to drain until the water

and sludge are gone and only fuel is

draining. Install and tighten the drain plug.

Fuel Filters

• B Inspection: Change engine fuel lter.

• Drain the fuel lter/water separator and

clean the outside of the unit (Figure 8 or

Figure 9)

• Inspect all fuel lines for wear, damage and

secure clamping.

877-973-3486 AWE 00192 Rev. 00014

ACTT Xspotter Service Manual

Figure 8

Figure 9

Diesel Exhaust Fluid (DEF) System (On-

Highway Models Only)

1. Inspect DEF reservoir (Figure 10) for

damage, leaks or rust:

• Examine the mounting straps for cracks

or other damage.

• Clean any debris from around the base

on the tank in the mounting bracket.

2. Inspect all DEF and DEF heater lines for

wear, damage and secure clamping.

Figure 10

3. D Inspection or annually - Replace DEF

system lter (Figure 11).

Figure 11

AWE 00192 Rev. 000 15

877-973-3486

Preventive Maintenance

Braking System

DANGER

NEVER release a vehicle that has a

defect in the brake system – no matter

how minor the defect. Failure to repair

brake system discrepancies can result

in compromised brake efciency leading

to loss of control, resulting in severe

personal injury or death.

Air Lines and Hoses

• Inspect all air lines and hoses for routing,

secure clamping, chang, cracks and

evidence of air leaks.

• Inspect air brake hoses for cracks or

damage.

• Inspect all air ttings to ensure that they are

tight.

• Check all valves for secure mounting and

listen for audible air leaks.

WARNING

Before beginning any service work on

any part of the air system, be certain

that the air pressure has been released.

Failure to do so may cause a component

to violently separate, which can result in

serious personal injury.

Air Dryer

• “D” inspection or annually: Change

desiccant cartridge.

Note: Desiccant may require more frequent

service in humid climate operation.

• Check mounting, wiring and connections.

• Check operation per equipment

manufacturer’s recommendation.

• Check heater element, if equipped. Refer

to manufacturer’s recommendation for

inspection procedures.

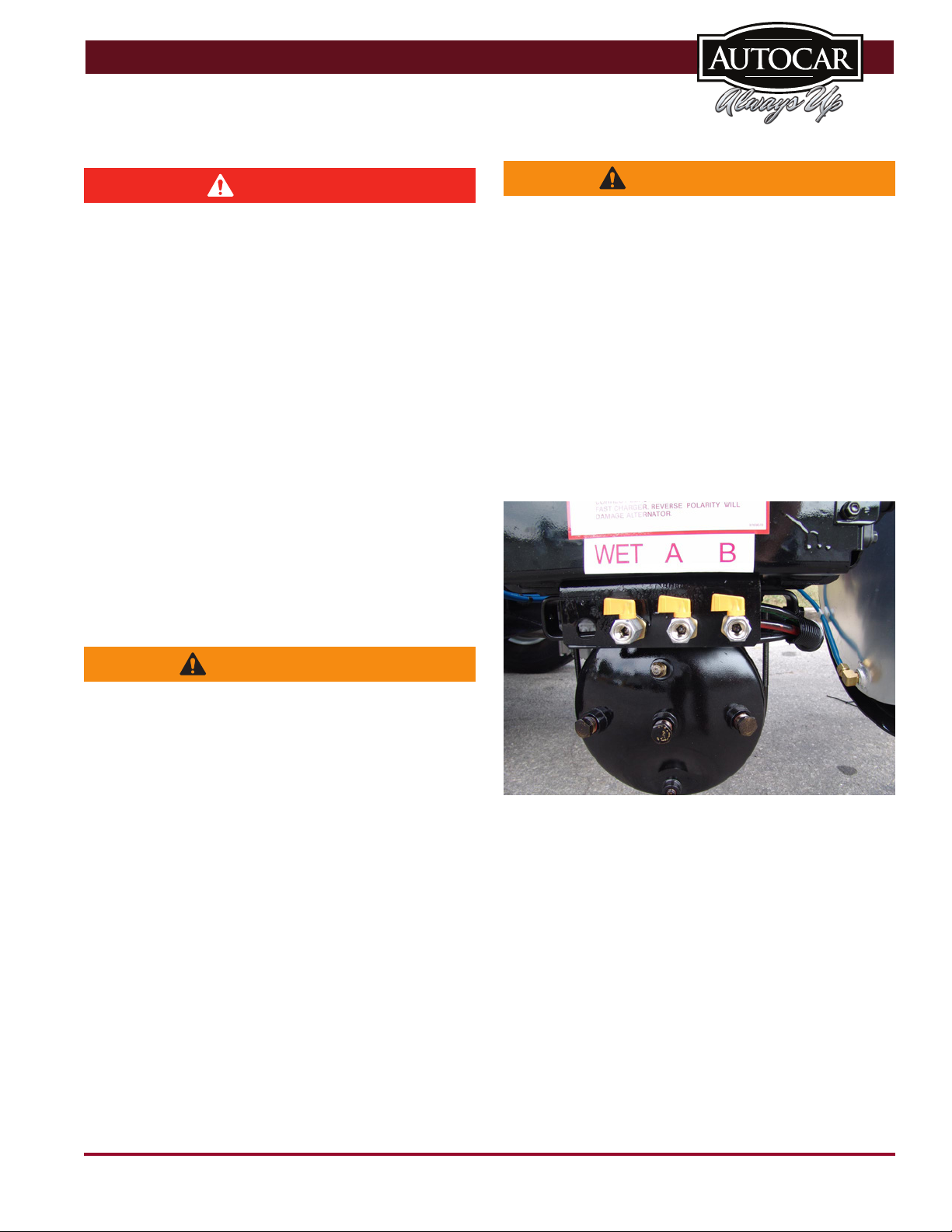

Air Reservoirs

WARNING

When draining the air tanks, do not look

into the area of the escaping air. Dirt or

sludge particles may be expelled and

cause eye injury.

• Open petcocks or pull drain cables on air

reservoirs to drain-off moisture If excessive

oil or water comes from the tank, make a

note on the inspection form for follow-up

(Figure 12).

Note: As shown in Figure 12, some tanks

may be equipped with remote drains.

Figure 12

Dual Air Brake System

• Apply full air brake pressure to the air brake

system and verify there is no more than two

psi (20 kPa) pressure loss per minute.

• Charge both A and B air systems.

• Drain the air tank for the A system.

• Apply the brakes. Ensure that there is an

application of the slack adjusters for the

front brakes.

• Charge both A and B air systems again.

• Drain the air tank for the B system.

• Verify gauge reading.

877-973-3486 AWE 00192 Rev. 00016

ACTT Xspotter Service Manual

• Apply the brakes. Ensure that there is an

application of the slack adjusters for the

rear brakes.

Slack Adjuster

• Inspect the slack adjuster operation,

mounting and adjustment (Refer to

equipment manufacturer’s documentation

for service intervals, procedures and

specications).

Chamber Plug

• Remove chamber plug and discard, then

inspect for hung-up caging plate. After

inspection is complete, install new chamber

plug.

S-Cams and Springs

• Examine S-cams, springs and

miscellaneous braking components for wear

and general condition.

Brake Lining

• Measure and record the brake lining

thickness. Replace lining and shoe

assembly if 0.250 in. (6.35 mm) or less

remains at the middle of the shoe. Check

the brake lining for cracks. Check and

note drum-to-lining clearance. Maximum

acceptable clearance is 0.063 in. (1.60

mm).

Note: For a complete listing of preventive

measures and their intervals refer to the

“Preventive Maintenance Schedule” in this

manual.

Electrical System

Battery Hold-Down Hardware

• Inspect the battery hold-down hardware and

fasteners for proper placement. Ensure the

batteries are secure and free of corrosion

(Figure 13, Item [2]).

Figure 13

Electrical System

Batteries and Cables

• Inspect the cables for proper length and

broken insulation or strands. Check the

cables for chang and proper routing.

Check that the terminal ends are secure

and free of cracks (Figure 13, Item [1]).

• Remove any corrosion from the cable ends

and battery posts. After thorough cleaning,

spray the area with a corrosion-preventive

compound.

• Ensure that all ground connections are

clean, free of corrosion and secure. Check

the terminal connections.

Table of contents

Other AUTOCAR Truck manuals