5. WIRING OF ACCESSORIES

· Complete all wiring. Refer to the wiring diagrams in Sections 11 and 18. Be sure to complete

the wiring for any accessories that may be required as well:

· Activation Sensors

· Safety Sensors

· Safety Beams

· On-O Switch

· Emergency Breakout Switch

· Electric Carriage Lock (accessory)

· Reduced Opening Switch (accessory)

· 1-Way Switch (accessory)

6. DRIVE BELT AND BRACKET INSTALLATION

· Upon completion of all wiring, the drive belt, related brackets, and idler pulley may be installed.

Refer to the detailed dimensions drawing that came with the package to determine all mounting

locations. When complete, install the drive belt and tension to result in approximately 1" to 2"

deection overall up and down at the center of the greatest span between clamp and pulley. The

belt may need to be cut to the correct length. Use a strong pair of wire cutters to make a clean

cut.

· Check to make sure there are no wires that could be potentially caught by the moving parts.

With the belt installed and tensioned, move the doors manually to their full open and then full

closed position and ensure that they slide without biding or obstruction.

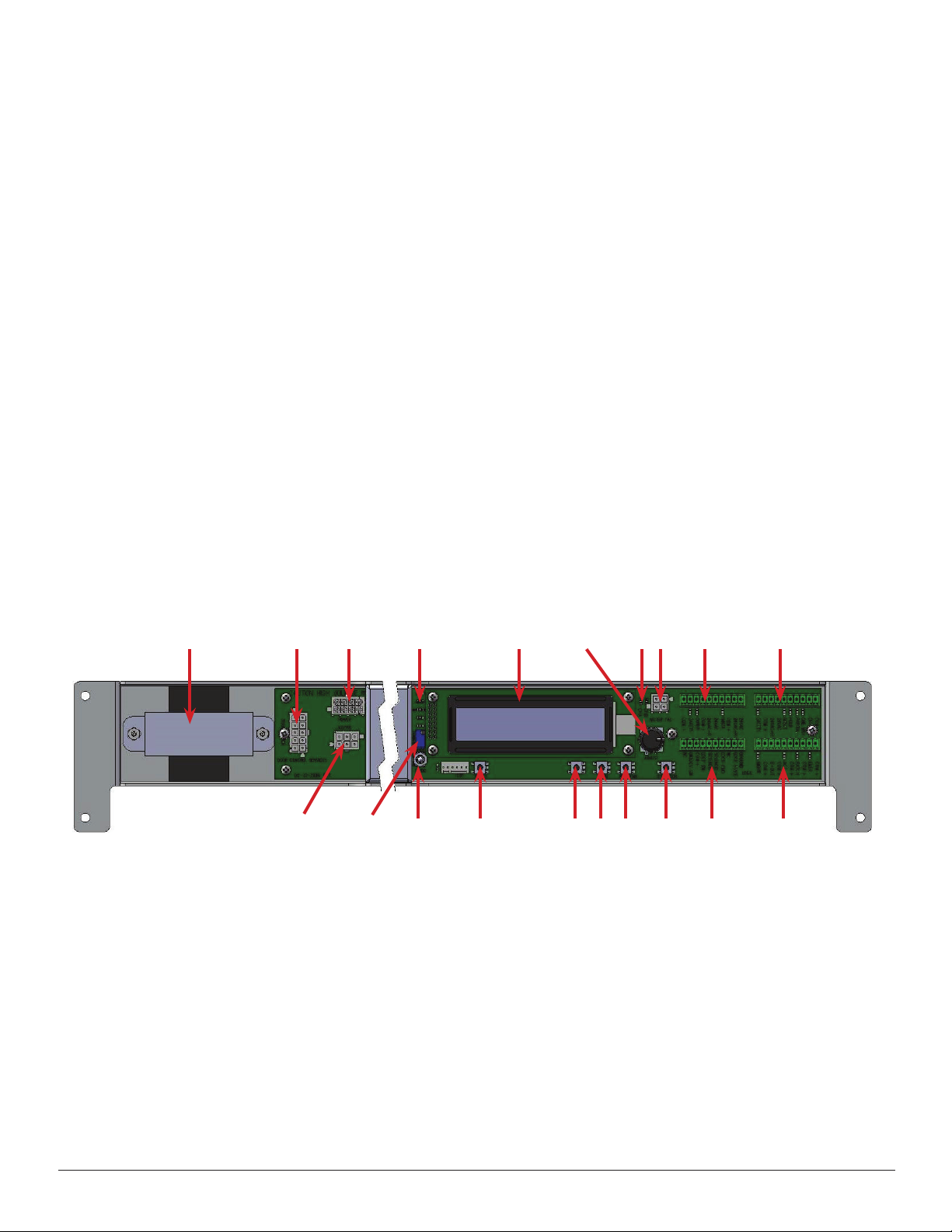

7. CONNECTING POWER

· Connect and apply main power to the control.

· Perform a factory reset - Refer to Sections 12 and 13.

· Press the TEST button on the DC One control to trigger an activation cycle.

· When the learn cycle is complete, normal operation will resume according to default values set

in the control. Fine-tuning of the control may be necessary at this point. Other than door handing

and breakout polarity, the most common adjustments are for speed, force and time. Although

there are more adjustments if needed. See Sections 12 & 13 for further instructions.

8. WALK TEST

· Check all functions to ensure proper operation

· REMEMBER - Even if a door is designated for

1-way trac, a secondary activation sensor is still

required at the side not intended for approach.

The activation zone must extend to at least 24″

out from the face of the door

· With the door switch o, make sure the doors are

fully closed. Check alignment of doors for proper

weather-seal and ensure that door locks properly.

· Use walk-test aides such as the dimensional mat

shown below, to help outline key distances for

testing sensor patterns.

Installation Manual

DC One V3

321 VZ County Road 4500 ·Ben Wheeler, TX 75754 ·Phone: 800.437.3667 ·Fax: 800.356.8858 ·DoorControlsUSA.com

5

Rev050819