8()

Book No. 23307366 (06/08)

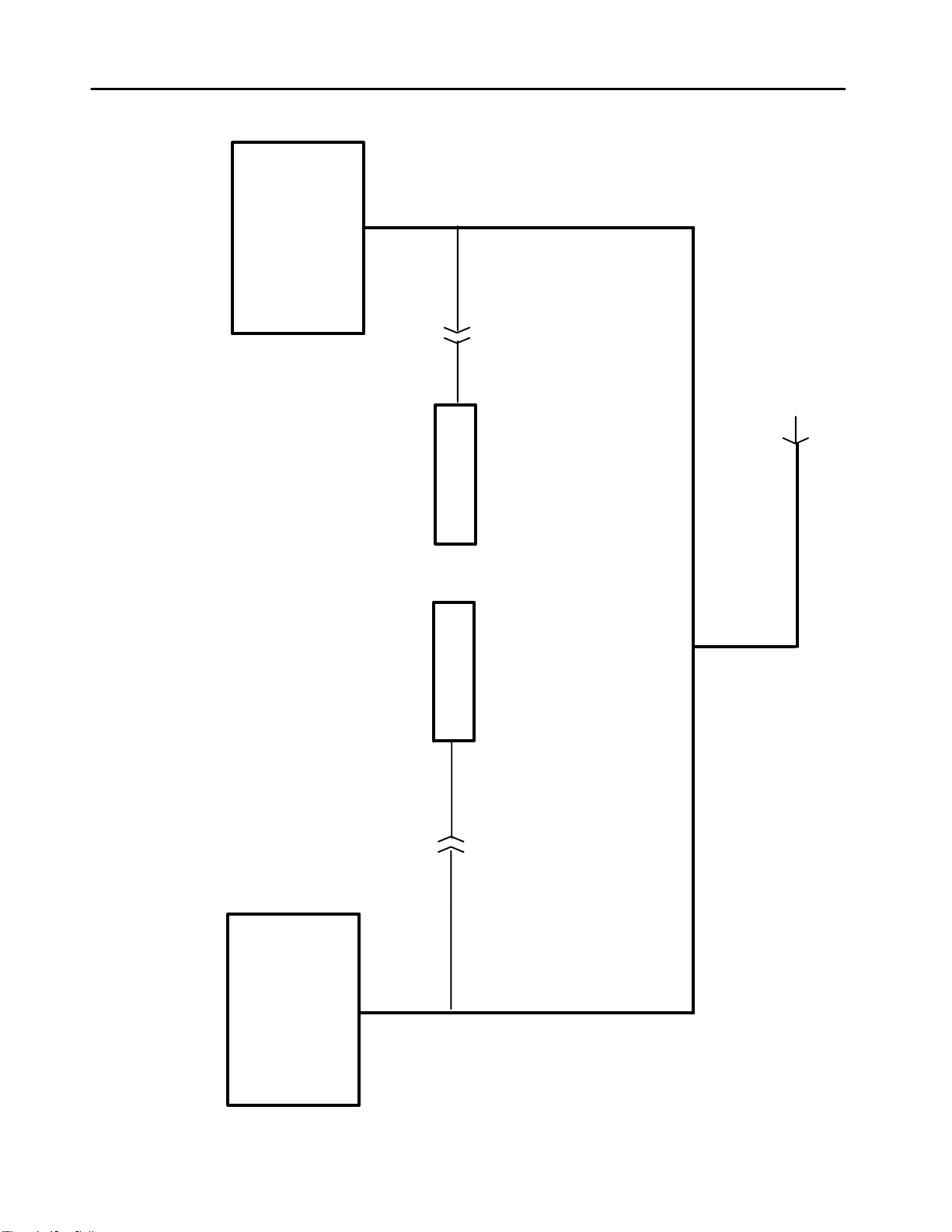

Figure 2--2 shows the signals between the engine

controller and the SECU controller.

Sensors and Transducers

The electronics system contains sensors and trans-

ducers that are used to collect data from the compres-

sor. The temperature is measured by a thermistor.

This device exhibits a change in resistance as the tem-

perature changes. The resistance change causes an

input voltage change to the controller input and is inter-

preted as a temperature change.

The electronics system also uses pressure transduc-

ers to measure compressor pressure changes. These

devices have an output signal of 0.5 VDC to 4.5 VDC,

corresponding to 0 psi and the maximum measured

psi for a particular device. The maximum pressure

transducer range is 100 psi. The transducer is pro-

vided with 5 VDC excitation to power the device. It is a

three wire device: excitation, signal and ground.

Digital Inputs and Outputs

The controller scans digital inputs such as switch

contacts. These are either “ON” (12VDC) or “OFF” (0

VDC). These digital inputs are connected to switches

within the package such as the key start switch and air

filter switches.

The controller provides 12 VDC digital outputs to

control solenoids. These are 12 VDC “ON” and 0 VDC

“OFF”. They are current limited and short circuit

protected.

Controller Outputs

The controller has outputs to activate relays, hourmet-

er, fuel lift pump and starter solenoid.

Engine speed control is performed by a command sent

over the J1930 CAN Network from the SECU to the

Engine Control Module.

Pressure Control

The discharge pressure is controlled by manipulating

the engine speed and compressor inlet valve position.

The inlet valve position is controlled pneumatically and

the engine speed is determined by the controller.

The controller measures the pneumatic system regu-

lation pressure and computes an engine throttle set-

ting. This throttle setting is sent to the engine via the

J1939 throttle.

J1939 Data Link

The CAN network is a single twisted pair cable located

with the W1 main harness. Figure 2--3 shows a layout

of the CAN harness or “backbone” as it is referred to.

The termination resistors (Terminator) are important to

prevent reflections on the transmission line and must

be in place for the network to function properly.

The engine diagnostics connector is located on the left

side of the engine. This is used to connect the engine

manufacturer’s service tools to the CAN network. This

connector also provides 12 VDC to power these

service tools.

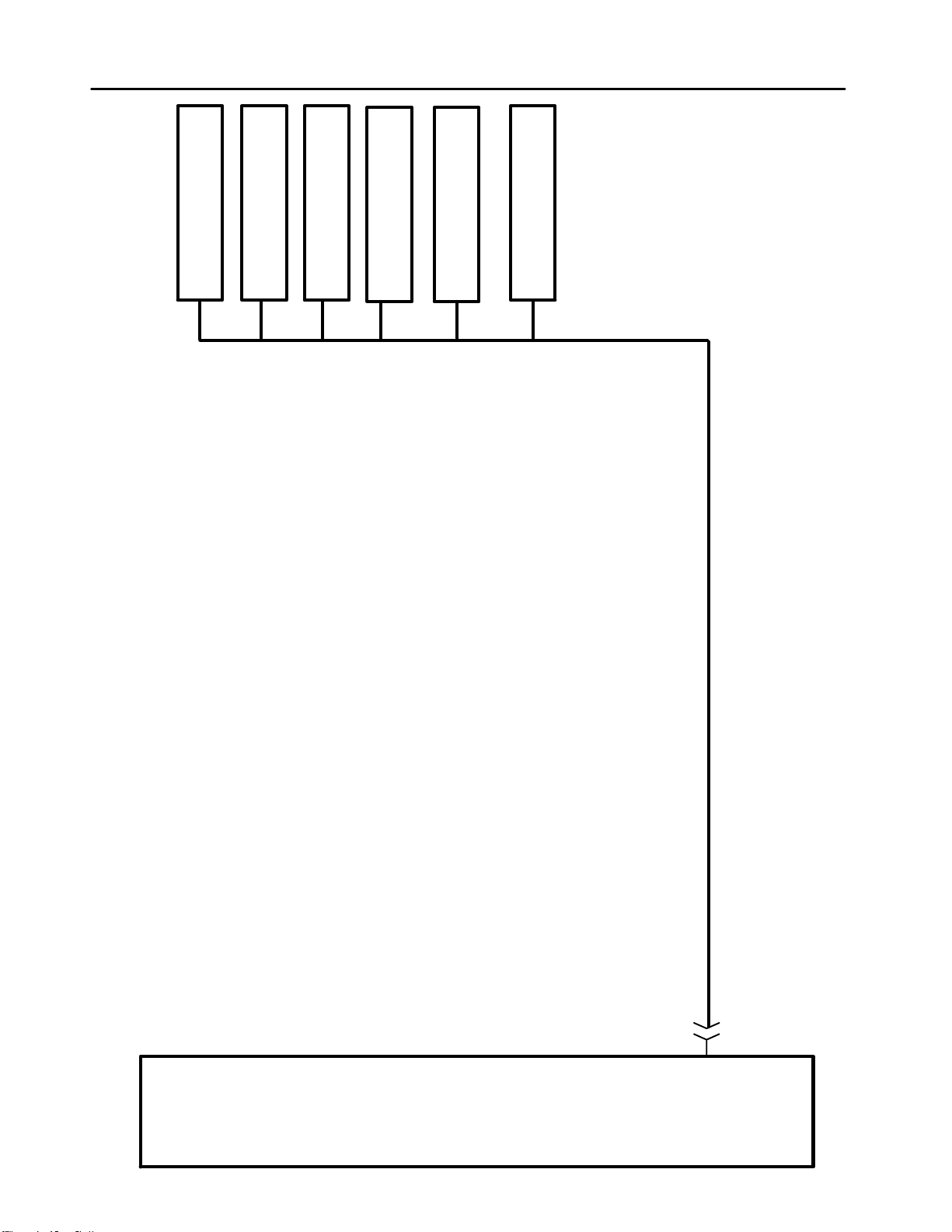

Electrical System

The schematic diagrams show the wiring harness con-

nections. Figure 2--1 is a system schematic showing

harness connection with devices and controllers. Sec-

tion 8 includes information on connectors used in the

harness.

The electrical circuits are protected using ATC style

fuses. A fuse should only be replaced with one of the

same rating. Replacing a fuse with one of a large

rating could lead to harness damage. If a fault occurs

and the circuit does not have the appropriate size fuse,

wires could be burned in the harness and damage

other circuits.