EN - DORA METAL

Upright refrigerators and freezers

PURPOSE

The devices produced by DORA METAL belong to a group of professional chilling and freezing

equipment. They are intended for short-term storage of foodstuffs at work place. The devices can be used in

restaurants, confectioners' shops, cafés, networks of stores in which it is necessary to display foodstuffs in a

chilled or frozen state allowing maintaining their taste, smell and aesthetic values.

The temperature adjustment ranges for particular types of devices are specified in the technical data.

Note: The devices are not designed for the operation outside the buildings and they cannot be

exposed to the direct effects of adverse weather conditions (snow, rain, sunlight).

The devices are not intended to store drugs, blood plasma, laboratory resources and other

substances and products specified in the directive 2007/47/CE.

The producer does not assume responsibility for any improper use of the device, contrary to its

purpose.

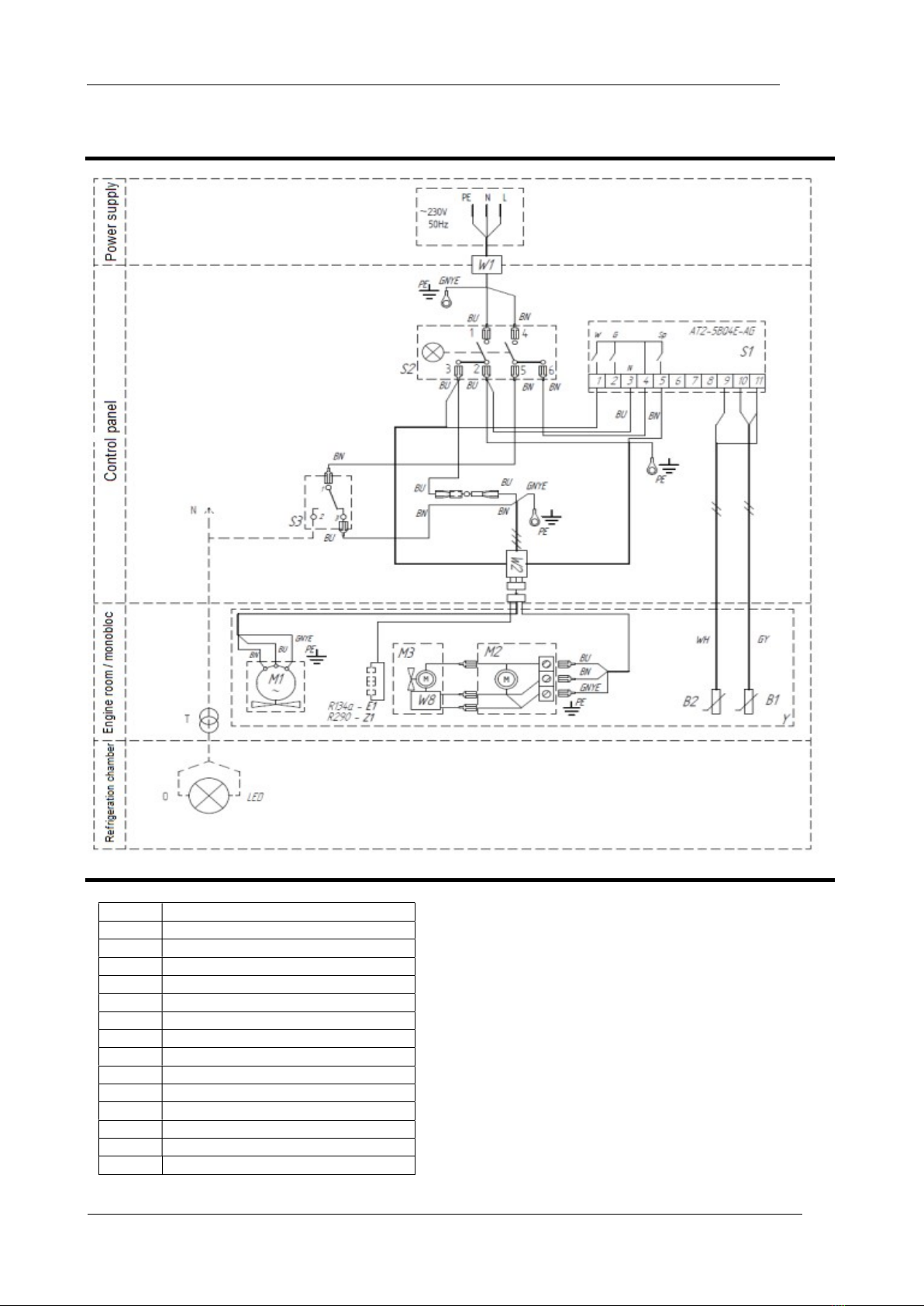

REFRIGERATED SYSTEM OPERATION

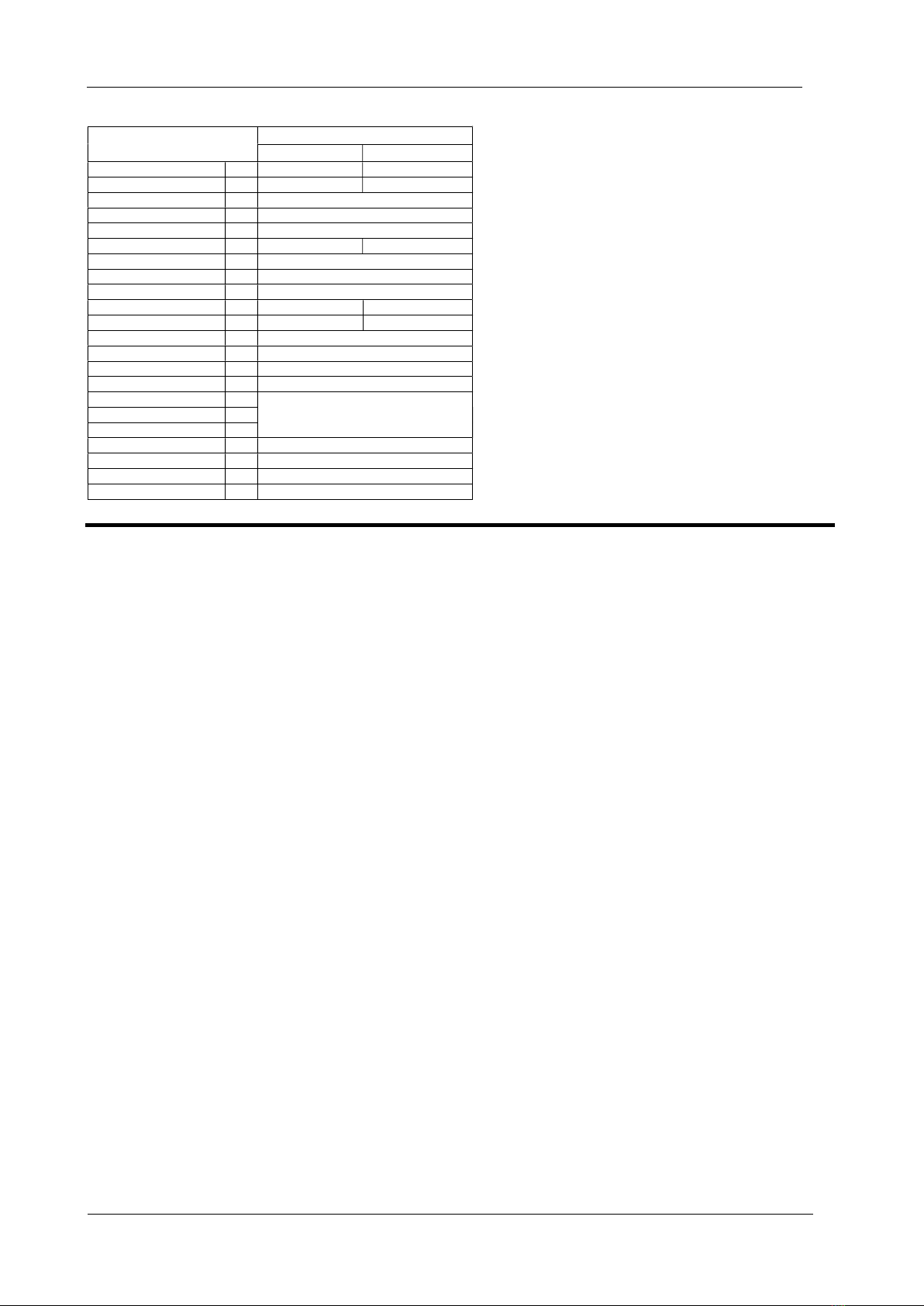

There is one-step, compressor’s refrigerating cycle in the device. The refrigerated system is filled with

an ecological refrigerating medium (depending on the model: R404a, R134a or R290 – data specified on the

rating plate).

INTERIOR TEMPERATURE SET-UP

An electronic temperature controller sensor is located in the rear part of the chamber ceiling. The

controller is programmed in such a manner that the device achieves an interior temperature specified in the

technical data. For the method of the required temperature set-up – see page 14 or 15 (depending on the

used controller).

START-UP PREPARATION. CLEANING AND MAINTENANCE

The first start-up and daily maintenance may be carried out by the operating personnel, provided that

the below-mentioned recommendations are strictly observed. The producer shall not take responsibility for

any operation carried out on the device without observing the recommendations specified in this user

manual.

Disconnect the device from the power supply system before starting any maintenance works.

The removal of any safety systems is forbidden.

Remove a protective foil before the first start-up. Wash external and internal surfaces with warm water

with an addition of degreasing agent, used for washing kitchen utensils, with a soft cloth in accordance with a

direction of the joint, never by circular movements. The protective foil should be removed slowly to avoid

leaving remains of adhesive. If the adhesive is left, it can be removed by means of proper non-corrosive

solvent – after this operation the surface should be washed out and dried.

In daily cleaning, use neutral soap, window cleaners or 90%-degradable liquid detergent (to minimize

amounts of contaminants disposed to the surrounding environment) and a soft cloth, always in accordance

with a direction of the joint, never by circular movements.

It is forbidden to use scouring agents, materials including steel wool that can scratch the

surface and agents containing aggressive acids. Do not use a stream of water but only a

damp cloth wipe while washing.

After washing, before connecting to the electric system, leave the device to dry completely.

When planning the location of the device there should be taken into account the space for free opening

of the doors. The devices should be moved away from the wall to ensure free air circulation through the

condenser. It is necessary to leave 40 cm of free space at least above the device and not less than 10 cm of

free space on the sides and at the back which ensures a proper air circulation for the correct operation of the

device.

Check if the floor is levelled where the device is to be located. Then, level the device, using adjusting

feet, checking whether the door is closed well at the same time.