EN - DORA METAL Spółka z o.o.

rotary movements. Remove the protective foil slowly to make sure no glue is left. However, if any glue is left,

remove it using an appropriate non-corrosive solvent, and then rinse with water and wipe dry.

For daily cleaning, use neutral soap, glass cleaners or liquid bio-degradable 90% detergent (to minimise

the amount of pollutions removed to the environment), and a soft cloth, following the polished direction,

rather than in rotary movements.

Do not use scouring agents, materials with steel wool which could scratch the surface and

agents containing aggressive acids. When washing, use a damp cloth, rather than water

stream.

Once washed leave the device to dry before plugging it to the mains.

The device should be placed away from any sources of heat, in location not exposed to direct

sunlight.

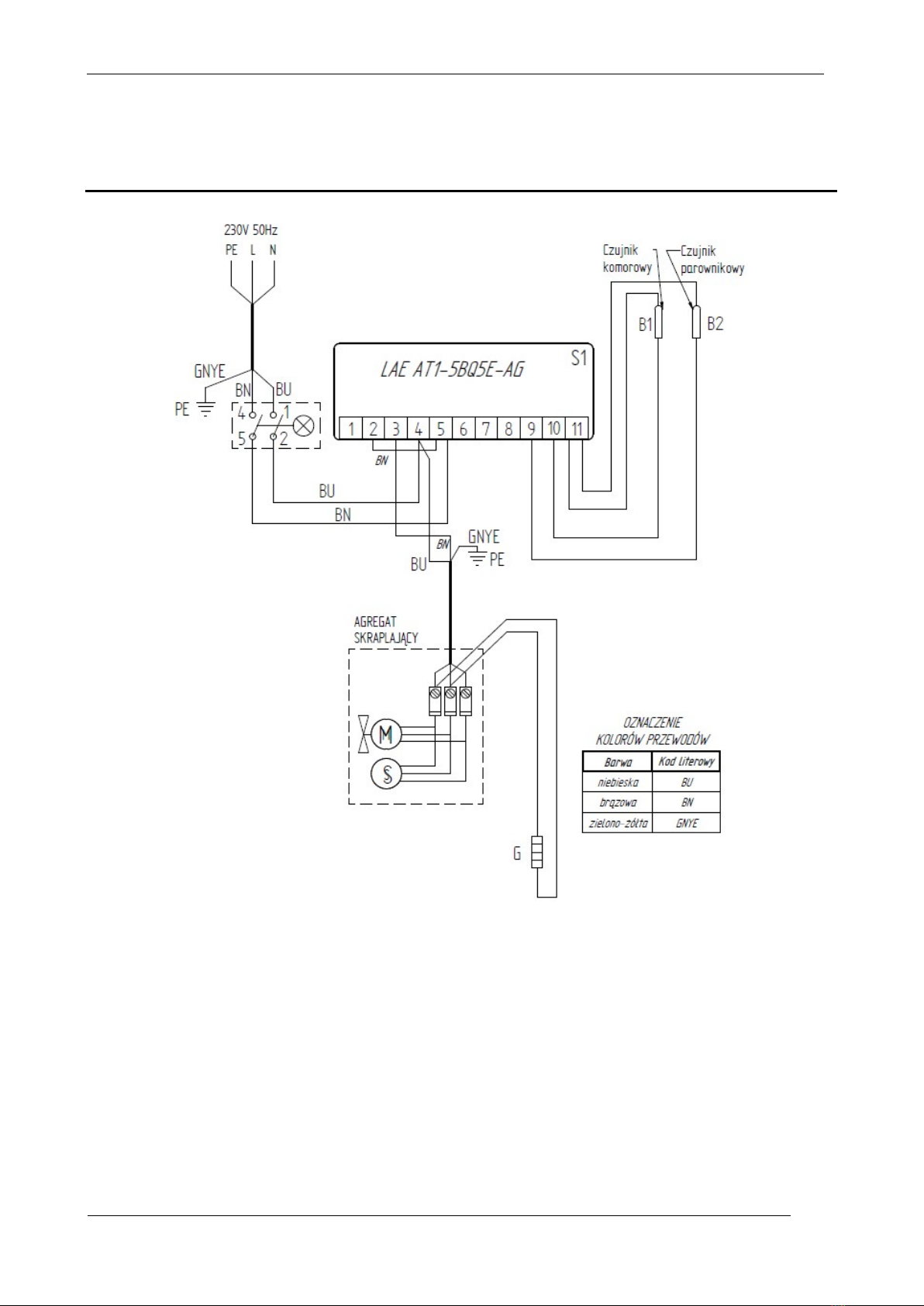

CONNECTING TO WIRING SYSTEM

The device is constructed in accordance with corresponding directives and harmonized standards:

- Low Voltage Directive 2006/95/EC

- EMC Directive 2004/108/EC

- PN-EN 60335-2-89, PN-EN 60335-1 Standards

- PN-EN 55014-1, PN-EN-55014-2, PN-EN 61000-3 Standards

The device is suitable for connection to the mains 230V 50Hz and should be powered from a separate

low-voltage circuit. A grounded wall socket must be fitted with shock protection selected in accordance with

requirements of local standards and regulations based on parameters on the data plate. Parameters of

residual current circuit breaker (RCD) should be selected according to the current value shown on data plate

of the device. The devices are fitted with flexible power cord type HO5VV-F (3x1.5mm², including protective

conductor). If the power cord is found damaged, have it replaced by a service technician or a qualified

person holding adequate qualifications

The devices are fitted with a terminal for connection of external equipotential bonds marked with .

Before the device is connected, check for correct connection and function of equipotential bonds in

accordance with PN-IEC-60364-4-41

The device can be started only after the function of shock protection is confirmed based on

measurement results taken in accordance with regulations in force.

The device can be connected to the wiring system only after the system is found to meet the above

requirements. To connect the device, put the power cord plug to a wall socket. The device prepared in such

manner is ready for operation.

When in transport the device can be tilted from the vertical by an angle greater than 30

,

therefore before it is connected to the mains, please wait about 3

4 hours. Otherwise

condensing unit can be damaged.

USAGE

The device is designed for cooling of surface for display of products chilled beforehand.

Display time of products depends on their initial temperature and ambient temperature which should not

exceed +25ºC.

After operation is over, make sure to turn off the device, and put the products in undercounter

refrigerators.

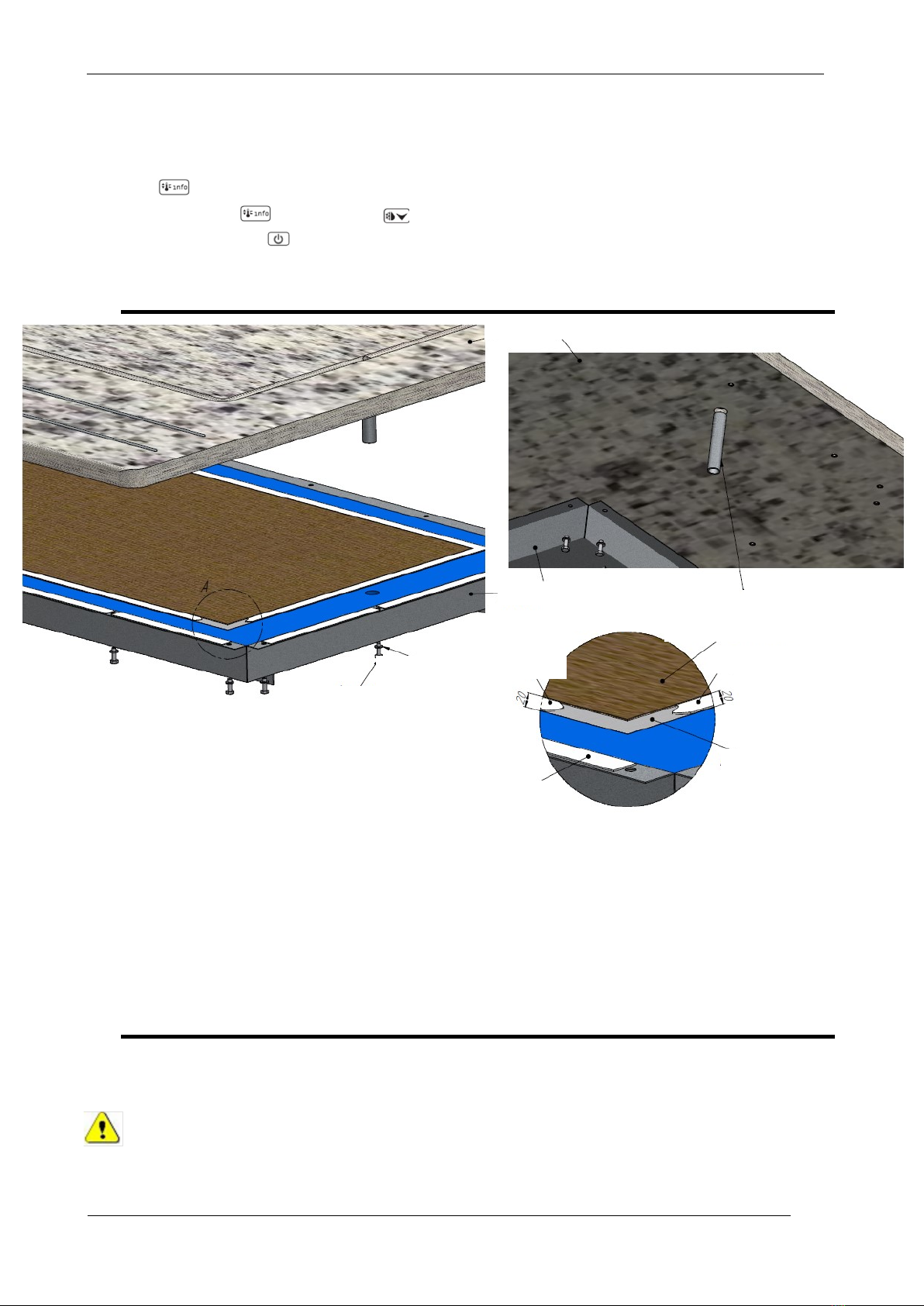

Before operation wipe dry the display surface with a cloth or sponge to remove water being result of

defrosting, and then chill the chamber, and put the chilled products afterwards.

All settings necessary for a normal operation of the device have been carried out by the manufacturer.

Temperature of the chilled space and work cycle of the unit are subject to change. They depend on

ambient temperature, amount of fresh products placed, and external heat flow. Therefore it is necessary to

avoid putting warm foods with temperatures exceeding storage temperatures considerably. Since, it can

extend time of chilling of products considerably.