PL - DORA METAL SPÓŁKA Z O.O.

After wash ng, before connect ng to the electr c system, leave the dev ce to dry completely.

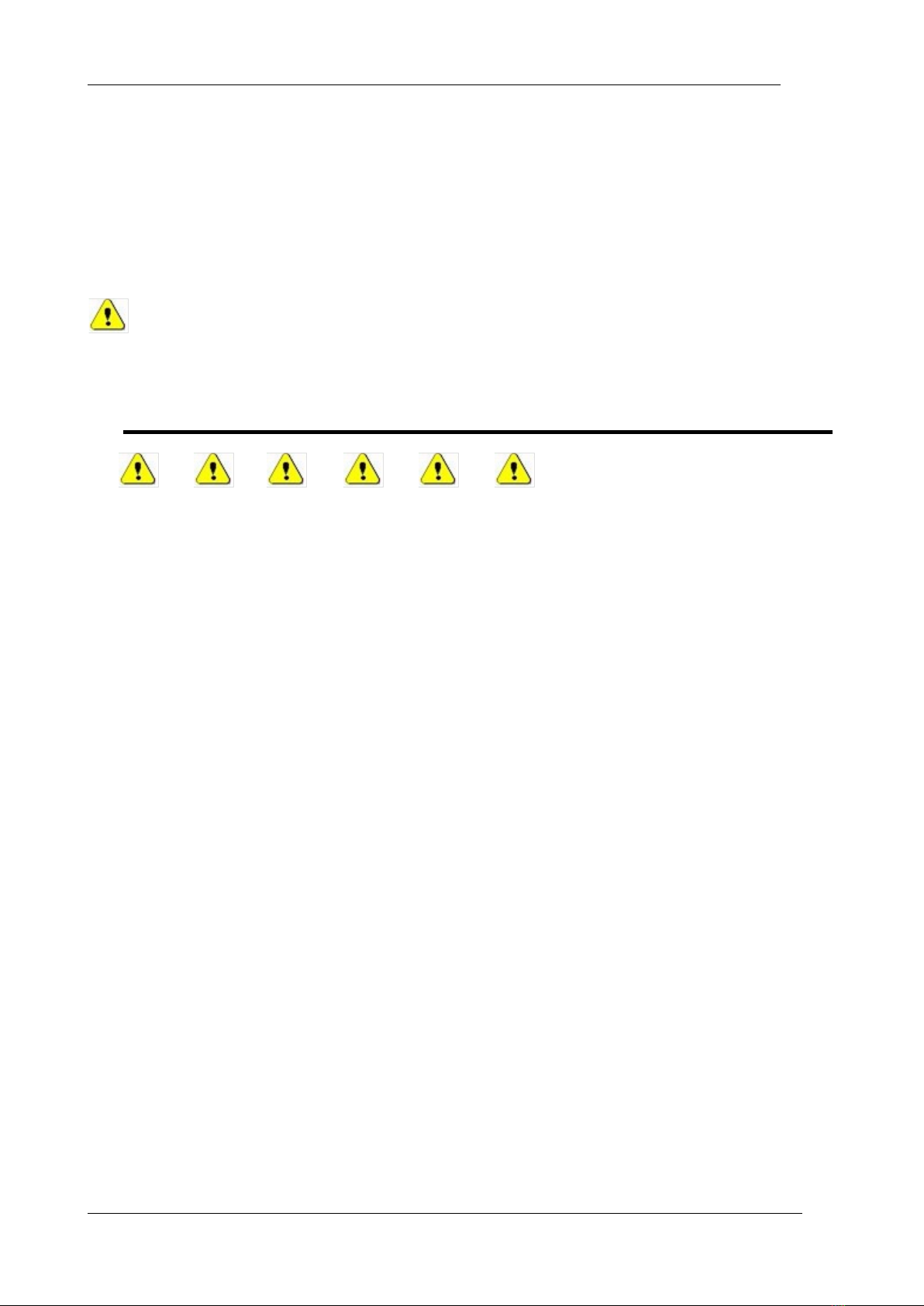

When plann ng the locat on of the dev ce there should be taken nto account the space for free open ng

of the doors. The dev ces should be moved away from the wall to ensure free a r c rculat on through the

condenser. It s necessary to leave 40 cm of free space at least above the dev ce and not less than 10 cm of

free space on the s des and at the back wh ch ensures a proper a r c rculat on for the correct operat on of the

dev ce.

Check f the floor s levelled where the dev ce s to be located. Then, level the dev ce, us ng adjust ng

feet, check ng whether the door s closed well at the same t me.

In accordance with the EN378 standard it should be ensured that the room where the

device with R290 medium is to be located has the proper volume. 1 m3 is required for 8

of R290 refri erant. The amount of R290 refri eratin medium is specified on the

ratin place of the device.

CONNECTION TO ELECTRIC SYSTEM

The construct on of the dev ce s made accord ng to the appropr ate d rect ves and harmon sed

standards:

- low voltage d rect ve 2014/35/UE,

- electromagnet c compat b l ty d rect ve 2014/30/UE,

- PN-EN 60335-2-89:2012, PN-EN 60335-1:2012 standards,

- PN-EN 55014-1:2017-06, PN-EN-55014-2:2015-06 standards,

- PN-EN 61000-3-2:2019-04, PN-EN 61000-3-3:2013-10 standards.

The dev ce s adapted to be suppl ed from the 230V 50Hz l ne and should be suppl ed from a separate

low voltage c rcu t. A grounded plug- n socket must be equ pped w th ant -shock protect on selected,

accord ng to the requ rements of local standards and regulat ons, n compl ance w th the parameters

spec f ed on the rat ng plate. The parameters of a res dual current dev ce should be selected accord ng to the

current value, spec f ed on the rat ng plate. The dev ces are prov ded w th a flex ble power supply cable of

HO5VV-F type (3x1,5mm², nclud ng protect ve conductor). The damaged power supply cable should be

replaced by a spec al st from techn cal serv ce or by a sk lled person w th appropr ate qual f cat ons.

The dev ces are equ pped w th a term nal to connect external equ potent al bond ng, marked by a

symbol . Before connect ng the dev ce the nstallat on correctness and effect veness of equ potent al

bond ng operat on should be checked n accordance w th PN-IEC-60364-4-41.

The device can be started when effectiveness of anti-shock protection is confirmed by results

of measurements carried out accordin to the re ulations in force.

The dev ce can be connected to the electr c system when t s stated that the electr c system fulf ls the

afore-ment oned requ rements. The dev ce s connected by nsert ng a plug of connect ng cable nto the plug-

n socket. A dev ce, prepared n such a way, s ready to operate.

Because durin transport the device could be inclined by more than 30

from the vertical,

wait about 1 hour before connectin the device to the power supply system. Otherwise, the

condensin unit can be dama ed.

OPERATION

The temperature of ch lled space and operat ng cycle of the refr gerat on un t can vary. It depends on

the amb ent temperature, amounts of nserted fresh products and heat nflow from outs de. Therefore t s

necessary to avo d open ng the door when unnecessary and nsert ng warm foodstuffs w th temperatures

that s gn f cantly exceed the storage temperatures. Otherw se, t can cons derably ncrease the ch ll ng t me

of products.

It s recommended to avo d a long contact of the sk n w th cold surfaces of the dev ce or cold products.

The protect ve cloth ng should be used n case of longer contact. The fa lure to use the protect ve cloth ng

can cause torp d ty or frostb te.

Upr ght refr gerators and freezers 5