When planning the location of the device there should be taken into account the space for free opening of the

doors, drawers and blinds to remove freely the refrigeration unit for servicing and for free achievement of free

access to clean the condenser.

The devices should be moved away from the wall to ensure free air circulation through the condenser.

Check if the floor is levelled where the device is to be located. Then, level the device, using adjusting

feet, checking whether the door is closed well at the same time.

In accordance with the EN378 standard it should be ensured that the room where the

device with 290 medium is to be located has the proper volume. 1 m3 is required for 8

g of 290 refrigerant. The amount of 290 refrigerating medium is specified on the

rating place of the device.

CONNECTION TO ELECT IC SYSTEM

The construction of the device is made according to the appropriate directives and harmonised

standards:

- low voltage directive 2014/35/UE,

- electromagnetic compatibility directive 2014/30/UE,

- PN-EN 60335-2-8 :2012, PN-EN 60335-1:2012 standards,

- PN-EN 55014-1:2017-06, PN-EN-55014-2:2015-06 standards,

- PN-EN 61000-3-2:201 -04, PN-EN 61000-3-3:2013-10 standards.

The device is adapted to be supplied from the 230V 50Hz line and should be supplied from a separate

low voltage circuit. A grounded plug-in socket must be equipped with anti-shock protection selected,

according to the requirements of local standards and regulations, in compliance with the parameters

specified on the rating plate. The parameters of a residual current device should be selected according to

the current value, specified on the rating plate. The devices are provided with a flexible power supply cable

of HO5VV-F type (3x1,5mm², including protective conductor). The damaged power supply cable should be

replaced by a specialist from technical service or by a skilled person with appropriate qualifications.

The devices are equipped with a terminal to connect external equipotential bonding, marked by a

symbol . Before connecting the device the installation correctness and effectiveness of equipotential

bonding operation should be checked in accordance with PN-IEC-60364-4-41.

The device can be started when effectiveness of anti-shock protection is confirmed by

results of measurements carried out according to the regulations in force.

The device can be connected to the electric system when it is stated that the electric system fulfils the

afore-mentioned requirements. The device is connected by inserting a plug of connecting cable into the

plug-in socket. A device, prepared in such a way, is ready to operate.

Because during transport the device could be inclined by more than 30

from the vertical,

wait about 3

4 hours before connecting the device to the power supply system. Otherwise,

the condensing unit can be damaged.

OPE ATION

The temperature of chilled space and operating cycle of the refrigeration unit can vary. It depends on

the ambient temperature, amounts of inserted fresh products and heat inflow from outside. Therefore it is

necessary to avoid opening the door when unnecessary and inserting warm foodstuffs with temperatures

that significantly exceed the storage temperatures. Otherwise, it can considerably increase the chilling time

of products.

It is recommended to avoid a long contact of the skin with cold surfaces of the device or cold products.

The protective clothing should be used in case of longer contact. The failure to use the protective clothing

can cause torpidity or frostbite.

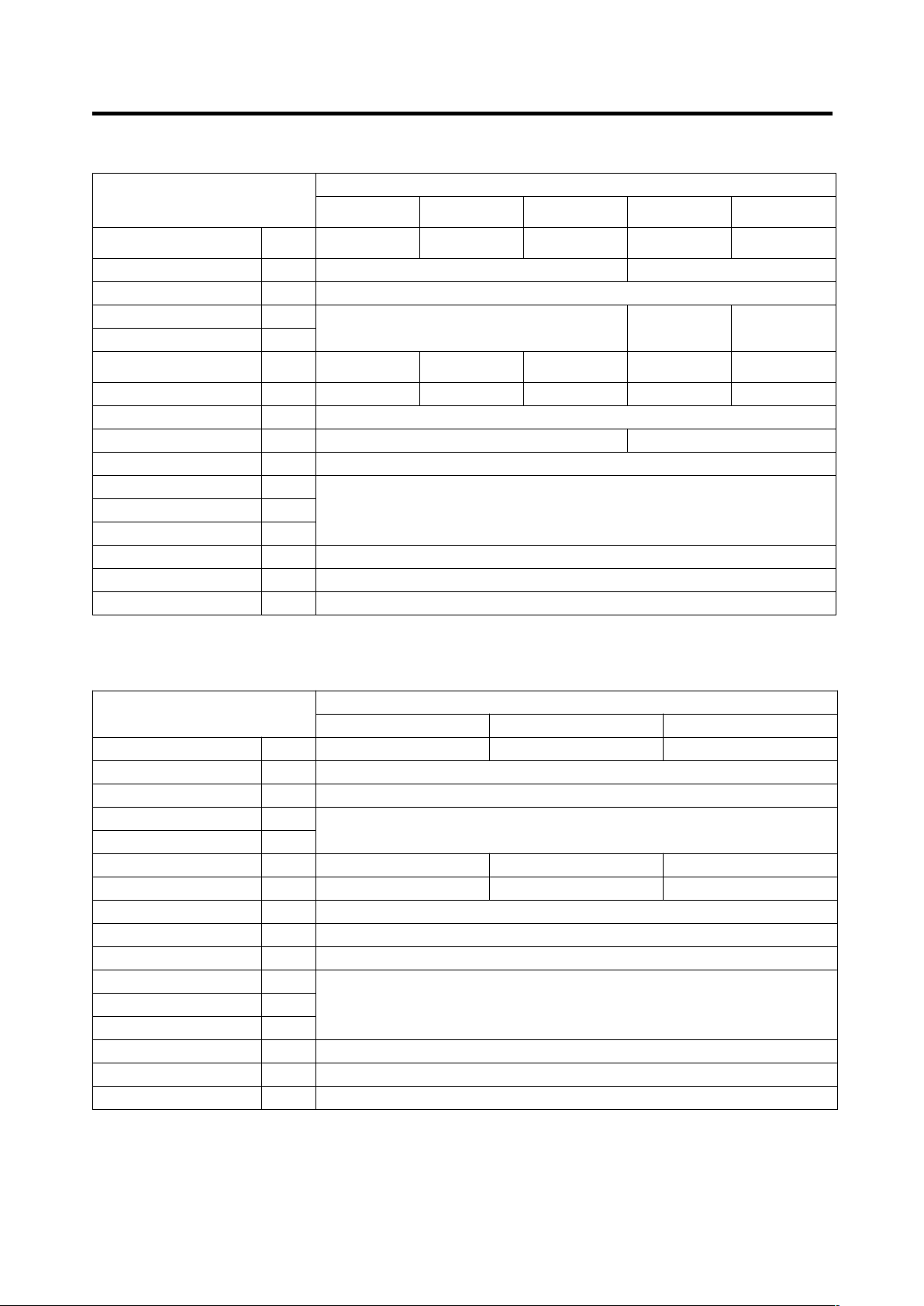

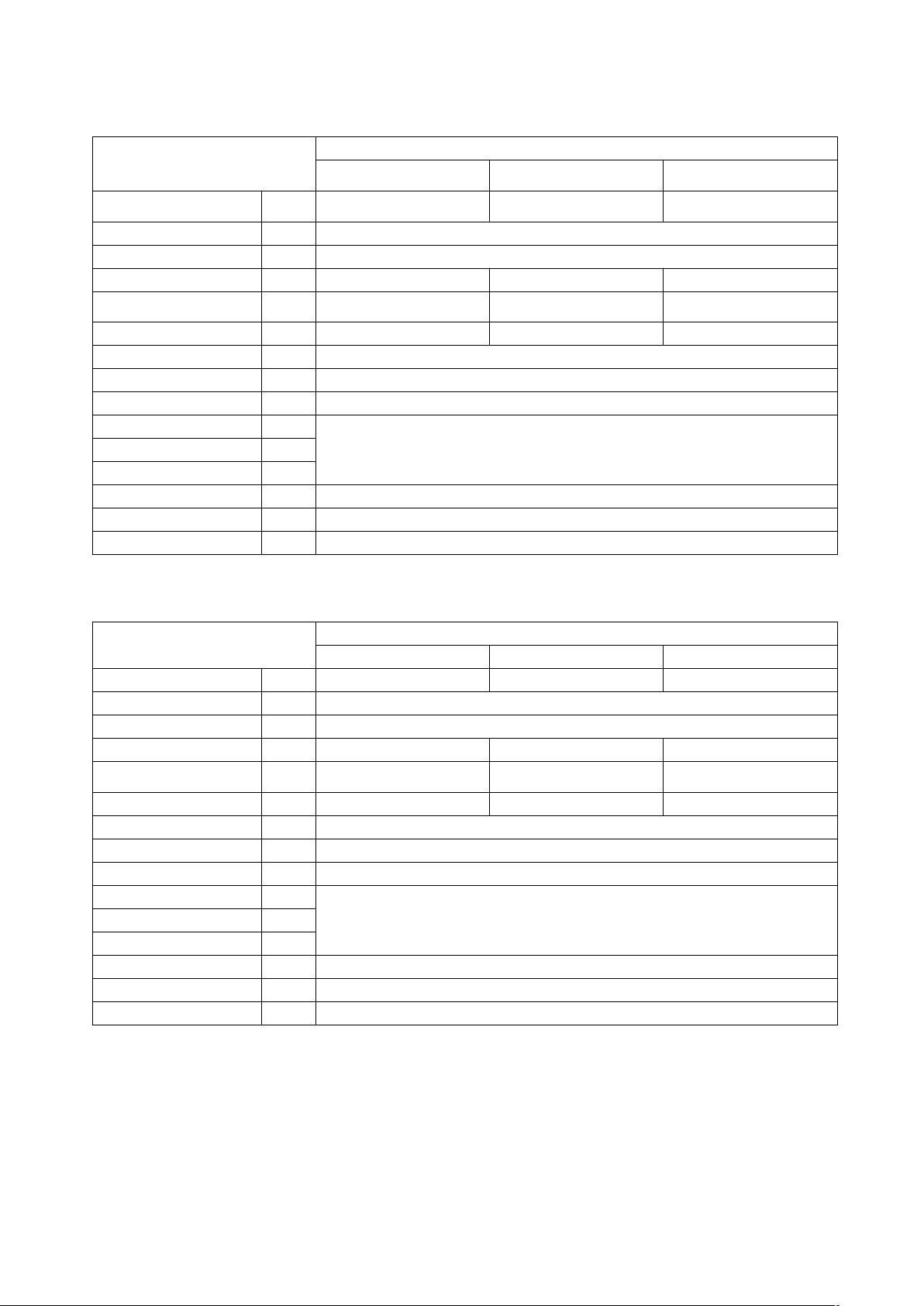

During operation of the device, observe the rule that the maximum load does not exceed the values

specified in the table and the red symbol in the device chamber. The products should be arranged in such a

manner to allow free air circulation in the undercounter refrigerator or freezer.

The first filling of the refrigerated space should be done after cooling it earlier to the

operating temperature (the required time for the first cooling of the unloaded undercounter

refrigerator or freezer to the set-up temperature: ~ 2h). This rule should be observed also

after a longer break in operation.