Health and Safety

■Required safety equipment: hard hat, safety boots, gloves, safety glasses.

■Always follow all safety precautions as directed by the Occupational Safety and Health

Administration (OSHA-USA) or the Construction Safety Association (Canada).

■Please refer to Safety Data Sheets for all components and observe all recommended

safety precautions therein.

■The general codes of practice for protection at work and instructions of the manufacturers for

tools and components are to be observed at all times.

Recommended Materials

■DELTA®-FL

■DELTA®-MOISTUREPROOF TAPE

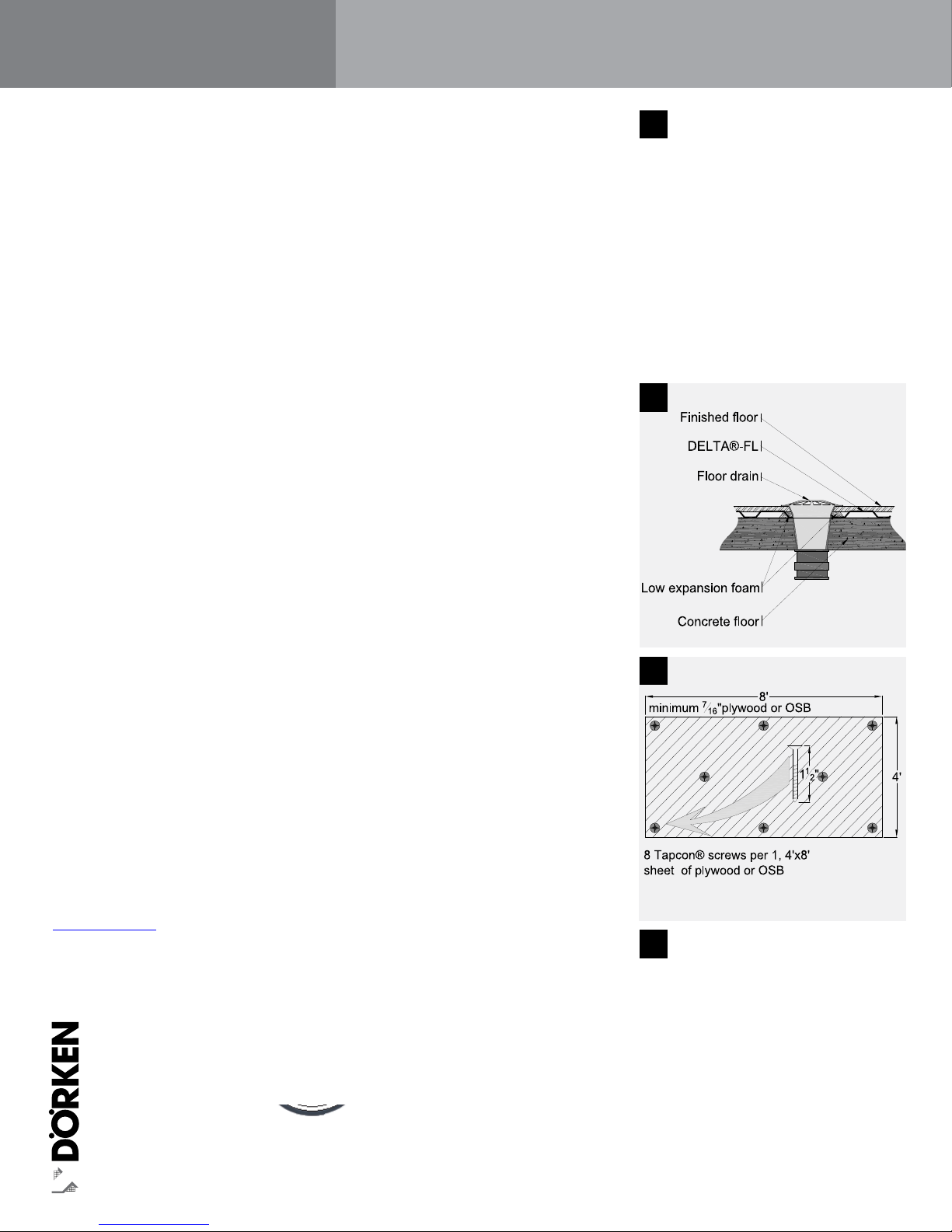

■Low expansion spray foam

■Self-leveling compound (if required)

■Other materials depending on final floor material:

■4’x 8’ plywood or OSB (minimum 7/16” thick)

■1/4” x 1 1/2”Tapcon® fasteners (Phillips head)

■Silicone sealant (recommended)

■Needle-punched geotextile (landscaping fabric)

Recommended Tools

■Broom and/or vacuum cleaner

■Measuring tape

■Utility knife or scissors

■Straight edge and/or carpenter’s square

■Circular saw and/or jigsaw

■Hammer drill

■Caulking gun

■Phillips screw driving bit

Preparing the Concrete for Installation

■The concrete floor and foundation walls should be dry, free of large cracks, excessive

moisture, leaks and flooding. DELTA®-FL is not meant to replace good foundation design or

maintenance.

■Any pre-existing unsound or moisture-sensitive flooring materials should be removed prior to

installation of DELTA®-FL.

■The floor should be as level as possible. Remove any bumps or ridges. In areas with

depressions greater than ¼”, self-leveling compound should be used.

■Thoroughly clean and vacuum the concrete floor.

■Ensure floor area is solid and free of mold and fungi.

■Optional: In case of uneven floors, installing a layer of needle-punched geotextile

(landscaping fabric) underneath the DELTA®-FL can reduce the potential for clicking noises.

Installation

■Beginning at the longest straight wall, roll out the DELTA®-FL, dimple side down and

cup side up.

■DELTA®-FL should be installed as tightly as possible to all walls (see Detail 1).

■For applications with stud walls already in place, lift the protective moisture barrier at the

bottom and place over top of DELTA®-FL (see Detail 2a).

■For applications with stud walls already in place that do not have a protective moisture

barrier underneath or applications directly against the foundation wall, seal the gap between

DELTA®-FL and bottom plate or wall with low expansion spray foam (see Detail 2b).

■For applications without stud walls already in place, non-load bearing stud walls may be

constructed on top of DELTA®-FL. Load-bearing walls should not be placed on

top of DELTA®-FL.

■End laps and side laps shall be placed tightly to the adjacent roll of DELTA®-FL. Do not overlap

or interlock the dimples. Seal all end laps and side laps with DELTA®-MOISTUREPROOF TAPE

(see Detail 3).

HIGH PERFORMANCE AIR & MOISTURE BARRIERS

DELTA®-FL

Keeping Floors Warm & Dry Installation Instructions.

PREMIUM QUALITY

1

2b

2a