Quick Trigger Clamp User Manual Version A Original User Manual Page 3of 19

1. SAFETY NOTES

BEFORE installing and operating clamps, please read this manual carefully and pay

attention to the information provided. Use this manual to familiarise yourself with the clamp,

its proper use and safety regulations.

DANGER: Indicates a hazardous situation which, if not avoided, will result in death or

serious injury. This signal word is to be limited to the most extreme situations.

WARNING: Indicates a hazardous situation which, if not avoided, could result in death or

serious injury.

CAUTION: Indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury.

NOTICE: address practices not related to personal injury.

SAFETY INSTRUCTIONS: is used for lists of steps, procedures or instructions that might

otherwise substitute a DANGER, WARNING or CAUTION notification.

2. GENERAL

Doughty Quick Trigger clamps series consist of various clamps used to lift loads or make

structural connections. Clamps are used in the entertainment market. They can be used for

permanent support structures in places of entertainment such as museums, event venues,

theatres etc.

The use of clamps is solely seen as for professional use as lifting loads is inherently

dangerous.

Only competent persons are permitted to install and use Doughty Quick Trigger clamps. A

competent person in this respect is an individual with relevant technical education, training

and/or experience enabling him or her to perceive risks and to avoid hazards occurring

during use of a product.

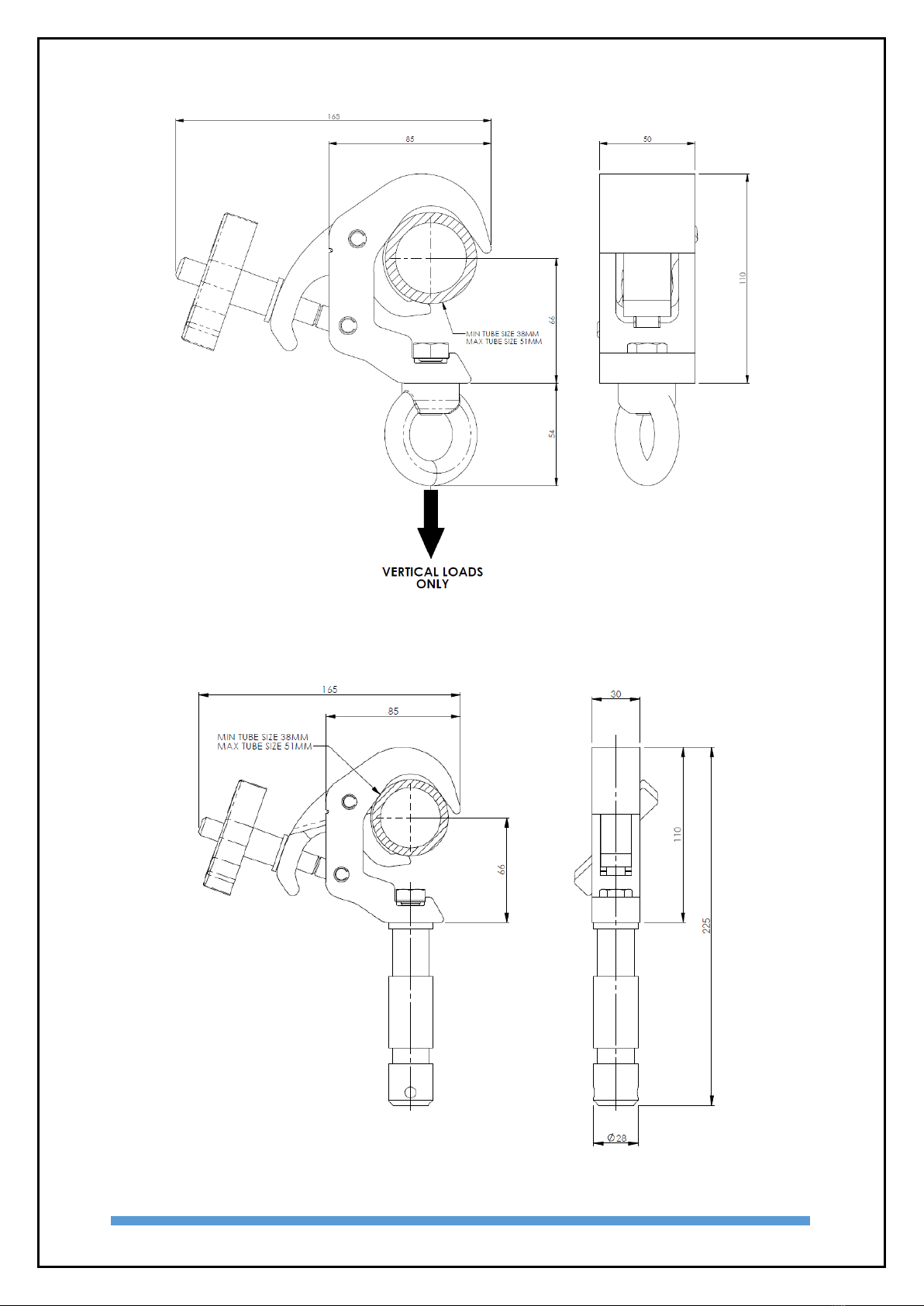

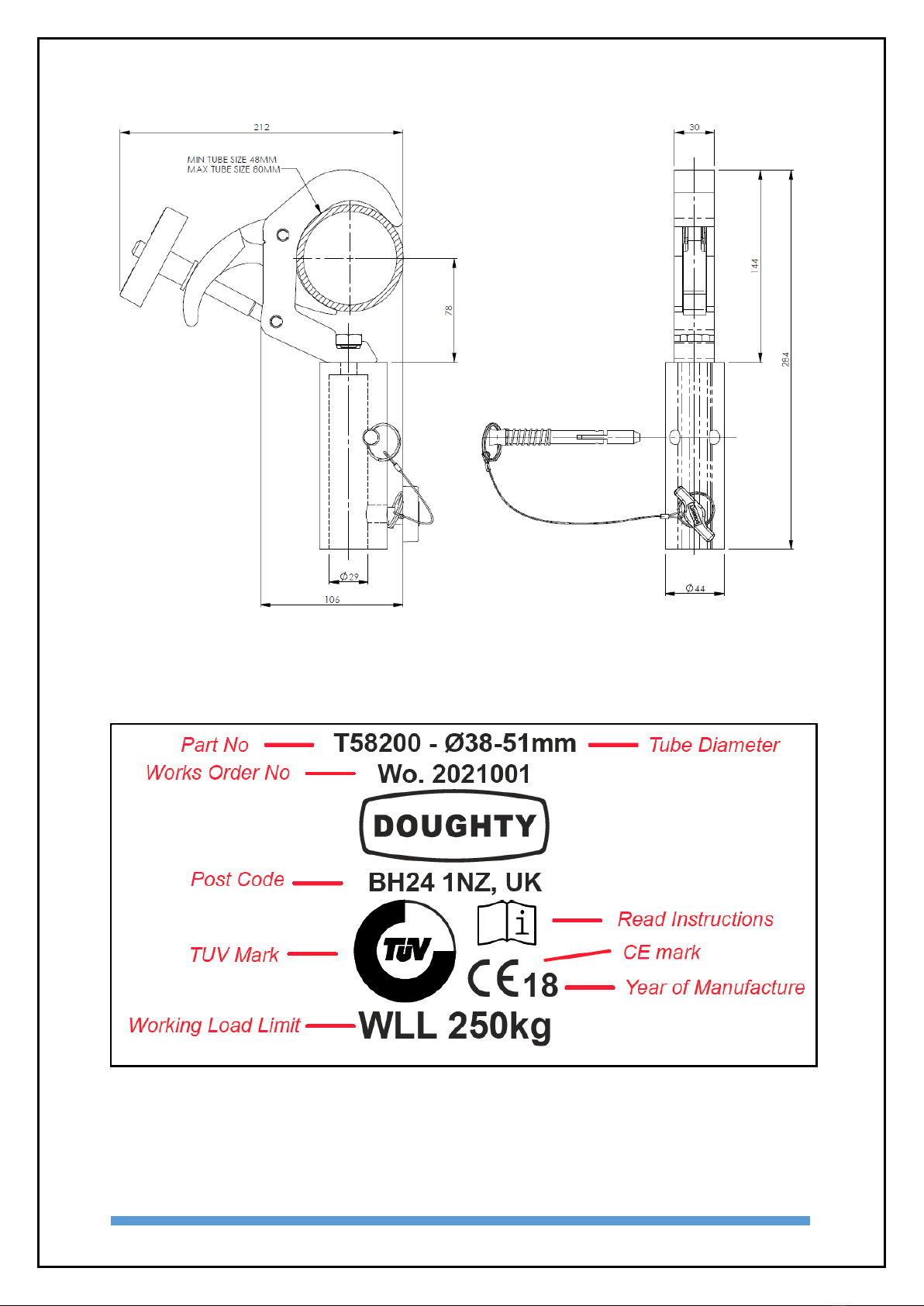

The load capacity differs depending on the model and the safety factor required. Quick

Trigger clamps are suitable to fit steel or aluminium tubes with diameters ranging from 38mm

- 80mm. Clamps stamped with the maximum working load.

Most clamps are available in Silver (polished aluminium) and black powder coating.

Special attention has been taken to safety. Therefore the TUV test certificates indicate

multiple working loads. Depending on the application or local applicable legislation max

working load can be chosen.