SICO 3 Series User manual

® SICO is a registered trademark of SICO Incorporated.

TRI-HEIGHT

STAGE SYSTEM

Series 3

Printed in USA (11-99) Part No. 111452 Rev. A

To avoid injury, read

and understand

these instructions

before you start to

set up the stage.

OWNER’S MANUAL: Instructions and Warnings

BEFORE YOU BEGIN... TOOLS REQUIRED

WARNING

zHex wrench (provided) to unlock decks for reversing

the surfaces -- if reversible decks were ordered.

zTwo 9/16-in. wrenches to attach hand rails to stair-

ways.

If you have any problems when installing,

contact SICO Customer Service at

1-800-328-6138.

INTRODUCTION

Stage Configurations

A Tri-Height Stage System consists of individual

4x8-ft or 6x8-ft stage sections that can be folded

for storage.

The stage sections are available in the following

height combinations:

z30 - 36 - 42 in. (762 - 914 - 1067 mm)

z24 - 30 - 36 in. (610 - 762 - 914 mm)

z24 - 32 in. (610 - 813 mm)

z18 - 24 - 30 in. (457 - 610 - 762 mm)

z16 - 24 in. (406 - 610 mm)

z12 - 18 in. (305 - 457 mm)

z8 in. (203 mm) nonadjustable

z6 in. (152 mm) nonadjustable

zOther combinations on special order

To set up a stage, you will:

1. Adjust the legs to match the desired height

of the stage.

2. Unfold individual sections.

3. If desired, reverse the deck surfaces (if

optional reversible decks were ordered).

4. Secure individual sections to each other.

5. Attach stairways, ramps, guard rails, table/

chair stops, backdrops, and closure draper-

ies.

These steps are explained in detail on the

following pages.

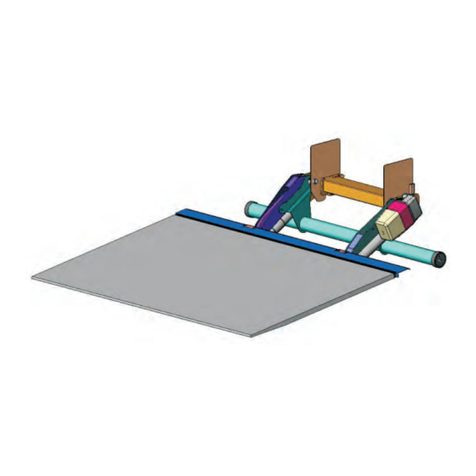

IMPORTANT: Construct the stage by starting in

one corner. Position the first stage section in

one of the two positions shown, so the three

unit-to-unit connector brackets face the remain-

der of the stage. Additional stage sections will

be hooked onto these brackets to secure the

sections together. Build the stage out from the

corner, positioning each section so its unit-to-

unit connectors are oriented the same as those

on the first unit.

Multiple Heights: If multiple heights will be

used in the same stage setup, start with the tall-

est units and work toward the lower units.

Position 1

Stage

Unit-to-Unit

Connector Brackets

Position 2

2

POSITIONING THE FIRST SECTION

NOTE: Adjustable-height stage sections

are shown in all illustrations.

1. Move the first section approximately to its

desired location.

CAUTION: When moving, push or pull from

the end of the folded unit. Pulling on the

crossbar along the side of the unit could un-

lock the stage and allow it to open. Pushing

on the side of the unit could cause it to tip

over.

Nonadjustable-Height Stages. Skip Steps

2 and 3, and go directly to Step 4.

2. Adjustable-Height Stages. Adjust the

height of the four end legs (refer to the illus-

trations):

a. On one side of the stage section, pull the

end leg lock crossbar out to its unlatched

position (refer to the upper illustration).

b. On one of the end legs, pull the lock

handle straight out to retract the leg lock

pin (refer to the middle illustration).

c. Move the leg extension in or out to get

the desired height.

d. Release the leg lock handle, and be sure

the leg lock pin engages in the hole in

the leg.

e. Repeat Steps 2b through 2d for the other

end leg on that side of the stage section.

f. Repeat Steps 2a through 2e on the other

side of the stage section.

3. Adjustable-Height Stages. Adjust the

height of the four foldout legs:

NOTE: The foldout legs must be used at all

stage heights.

a. Swing the leg out to a 90º angle with the

deck, as shown.

b. Pull the leg lock handle straight out to

retract the leg lock pin.

c. Move the leg extension in or out to get

the desired height.

d. Release the leg lock handle, and be sure

the leg lock pin engages in the hole in

the leg.

3

End Leg

Lock

Crossbar

End Leg

Adjustment

Foldout

Leg

Adjustment

Step 3a

Step 3b - 3d

POSITIONING THE FIRST SECTION -- continued

4. Adjustable-Height Stages. On one side of

the stage section, pull out on the end leg

lock crossbar.

Nonadjustable-Height Stages. Discon-

nect one end of the bungee cord and lower

the deck locking tube to the floor.

5. On the same side of the unit, grasp the

edge of the deck frame and the end leg lock

crossbar. Pull the deck toward you and

slowly lower it until the end legs touch the

floor.

6. In the same manner, pull down the other

side of the unit, and slowly lower it until the

end legs touch the floor.

Continue pulling the deck down until the

foldout legs on that side are also in contact

with the floor.

7. Go back to the first side of the unit, and pull

that side down until all four foldout legs and

all four end legs are in contact with the floor.

8. Move the stage into position (see IMPOR-

TANT note on page 2).

4

INSTALLING ADDITIONAL SECTIONS

REVERSING THE DECK SURFACE

1. Move a second frame unit next to the first

one.

2. Set up the second unit in the same way you

did the first one.

3. Lift the edge of the second unit’s deck onto

the unit-to-unit connector bracket(s) Aof the

first unit.

NOTE: If the second unit is set up at a

lower height than the first unit, hook the

edge of its deck onto the small brackets B

that are welded to the legs of the first unit

(instead of hooking it onto the deck brack-

ets A).

4. Repeat the above procedure for all remain-

ing sections.

Optional reversible decks are available for the

stage sections

To reverse these decks:.

1. Use the hex wrench supplied with the stage

system to remove the large socket-head

screw at each corner of the deck.

A spring will lift one corner of the deck out

of the frame so that it is easy to grasp.

2. Turn the deck over. Set the edge of the

deck that is opposite the spring into posi-

tion on the frame.

CAUTION: In the following step, work

slowly to avoid pinching fingers between the

deck and frame.

3. Grasp the corner of the deck where the

spring is located, and slowly lower the deck

onto the spring. When the spring is sup-

porting the deck weight, release the deck.

4. Reattach the deck to the frame using the

four large socket-head screws. Use the hex

wrench to tighten just until snug -- don’t

overtighten.

5. Repeat the procedure for the other decks to

be reversed.

IMPORTANT: The decks must be locked

with the four screws, or they may fall off

when the units are folded.

5

A

B

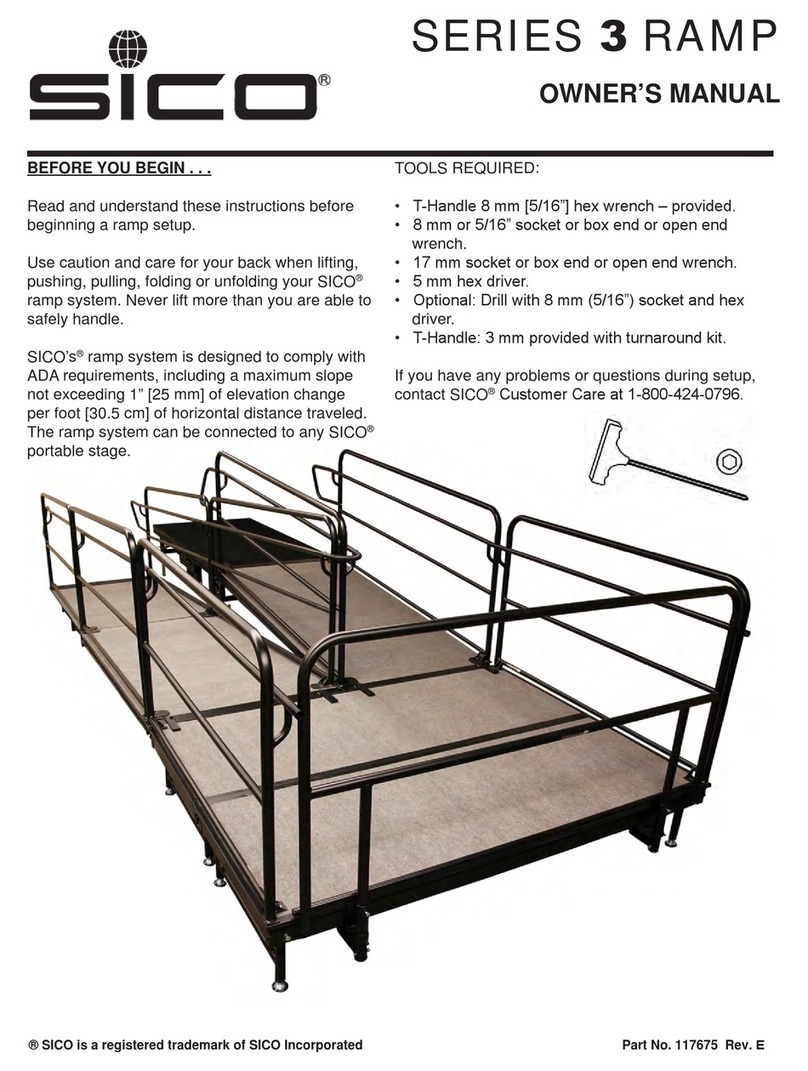

ATTACHING A RAMP

ATTACHING A THREE-HEIGHT STAIRWAY

NOTE: SICO ramps are provided in 6-ft or

8-ft (183 or 244 cm) section lengths, with an

incline of one in. per foot (83 cm per meter).

Detailed instructions for attaching a ramp to the

Tri-Height Stage are shipped with the ramp.

Follow those instructions, and abide by all local,

state, and federal regulations regarding ramp

design.

The same instructions include information on

installing SICO ramp guard rails, which are

designed for use by those in wheelchairs.

The Three-Height Stairway is adjustable to

three stage heights.

To change the steps to a higher setting:

1. Pull up on the bottom edge of the steps.

There is a height adjustment latch on each

side of the stairway: you will hear the

latches click each time they reach another

height setting.

2. When they are at the desired position, push

down on the steps to seat the stairway side

rails firmly into the appropriate notch of the

latches.

NOTE: Before the stairway is first used,

attach the two side rails as shown in the

illustrations. Use two 9/16-in. wrenches to

secure the rails with the screws and nylon-

insert lock nuts that are provided. Be sure

the rails are installed with their longer loops

at the high end of the stairway.

To transport the Three-Height Stairway, roll it on

its four casters. For easiest maneuvering, push

from the high end of the stairway.

Move the stairway to its desired location.

6

ATTACHING A THREE-HEIGHT STAIRWAY -- continued

To change the steps to a lower setting:

NOTE: Two people are required.

1. Simultaneously pull out on the latch handles

on each side of the stairway, and lower the

steps until the latches are in the appropriate

notch.

2. Release the latch handle. Check that the

stairway is stable.

To attach the stairway to the stage:

NOTE: Two people are required.

1. The stairway has two yellow bars extending

from the top step. Lift the high end of the

stairway and rest the yellow bars on the

deck.

2. Pull down on the ring to activate the spring-

loaded lock pin.

3. Push the stairway against the stage until the

lock pin releases and latches against the

inside of the stage frame.

4. Check to be sure the stairway is locked

firmly in place.

7

WARNING

Secure stairway to

stage to avoid

movement.

Failure to do so

could result in

serious injury.

ATTACHING A TWO-HEIGHT STAIRWAY

To transport the Two-Height Stairway, tip it to

the side as shown.

Move the stairway to its desired location.

The stairway is adjustable to either of two stage

heights by installing the lock pin assembly onto

the appropriate studs.

To attach the stairway to the stage:

1. The stairway has two yellow bars extending

from the top step. Lift the upper end of the

stairway and rest the yellow bars on the

deck.

2. Pull down on the ring to activate the spring-

loaded lock pin.

3. Push the stairway against the stage until

lock pin releases and latches against the

inside of the stage frame.

4. Check to be sure the stairway is locked

firmly in place.

8

WARNING

Secure stairway to

stage to avoid

movement.

Failure to do so

could result in

serious injury.

Lock Pin

Assembly

ATTACHING GUARD RAILS AND BACKDROP

Use platform guard rails in all Tri-Height

Stage setups. These rails are availabe in 3-, 4-,

6-, and 8-ft versions.

NOTE: Instructions on installing ramp guard

rails are shipped with the ramp. Flat sections of

ramps use the standard platform guard rails

shown here.

To install a platform guard rail:

1. Lift the rial into place so its jaws slip all the

way onto the edge of the deck.

To install a backdrop section:

Backdrop units install the same way as the guard

rails.

2. Securely clamp the rail onto the edge of the

deck, by turning the large yellow knobs coun-

terclockwise (as viewed from above).

3. Install the remaining rails in the same way.

WARNING

Attach guard rails to

platform to avoid

falls. Failure to do

so could result in

serious injury.

9

ATTACHING TABLE/CHAIR STOPS

Table/chair stops are available in 3-, 4-, 5-, 6-,

and 8-ft versions for locations where a platform

guard rail is not used (guard rails have a built-in

chair stop).

To install a table/chair stop, position it on the

edge of the deck as shown and firmly tighten the

large knob near each end.

1. Adjust the drapery length to match the stage

height. The hook Velcro®strip on the bottom

of the drapes can be mated with the loop

Velcro strips on the back of the drape.

2. Tri-Height stage sections are supplied with

a Velcro strip around the perimeter of the

deck. Attach drapery sections to this strip.

Overlap adjacent sections as shown in the

inset drawing.

The drape can be installed behind stair-

ways, by looping it over the posts below the

top step.

10

ATTACHING CLOSURE DRAPERY

DISASSEMBLING THE STAGE

Disassemble the stage by reversing the setup

procedure.

1. Remove any backdrops and closure draper-

ies.

2. Remove the guard rails and table/chair

stops.

3. Remove the stairway(s) by pulling down on

the rings to release the deck lock pin on

each side (see Page 7 or 8).

4. Fold each stage section for transport and

storage:

a. Lift one side of the section to its upright

(folded) position. It usually works best,

especially at higher setup heights, to pull

the stage section toward you as you lift

on the edge of the deck. For added lev-

erage, if necessary to force all four cast-

ers to the floor, lift on the foldout leg.

IMPORTANT: Lift on the bottom edge of

the deck -- do not let your hands get over

the top edge of the deck when folding.

b. Adjustable-Height Stages. Lock that

same side of the stage section in the

folded position by pushng in on the end

legs or cross tube. If the unit was used

at the 40- or 42-in. (1016- or 1067-mm)

height, adjust the end legs to a shorter

position.

Nonadjustable-Height Stages. Rotate

the deck lock tube until it contacts the

deck just under the cross tube.

c. Repeat Steps 4a and 4b on the other

side of the unit.

Nonadjustable-Height Stages. Hook

the bungee cord hook into the hole on

the opposite side of the stage.

d. Fold the four foldout legs in against the

deck.

11

CAUTION

When folding the

unit, don’t put

your fingers

between the decks.

To receive assistance for:

- Selecting replacement parts / decals

- Repairing the product

- Adjusting and operating the product

- Obtaining On-line assistance

TELEPHONE: 1-800-424-0796

FAX: (952) 829-5141

WEB SITE: WWW.SICOINC.COM

SICO AMERICA INC.

7525 Cahill Road

Minneapolis, MN 55439 USA 12

Other manuals for 3 Series

1

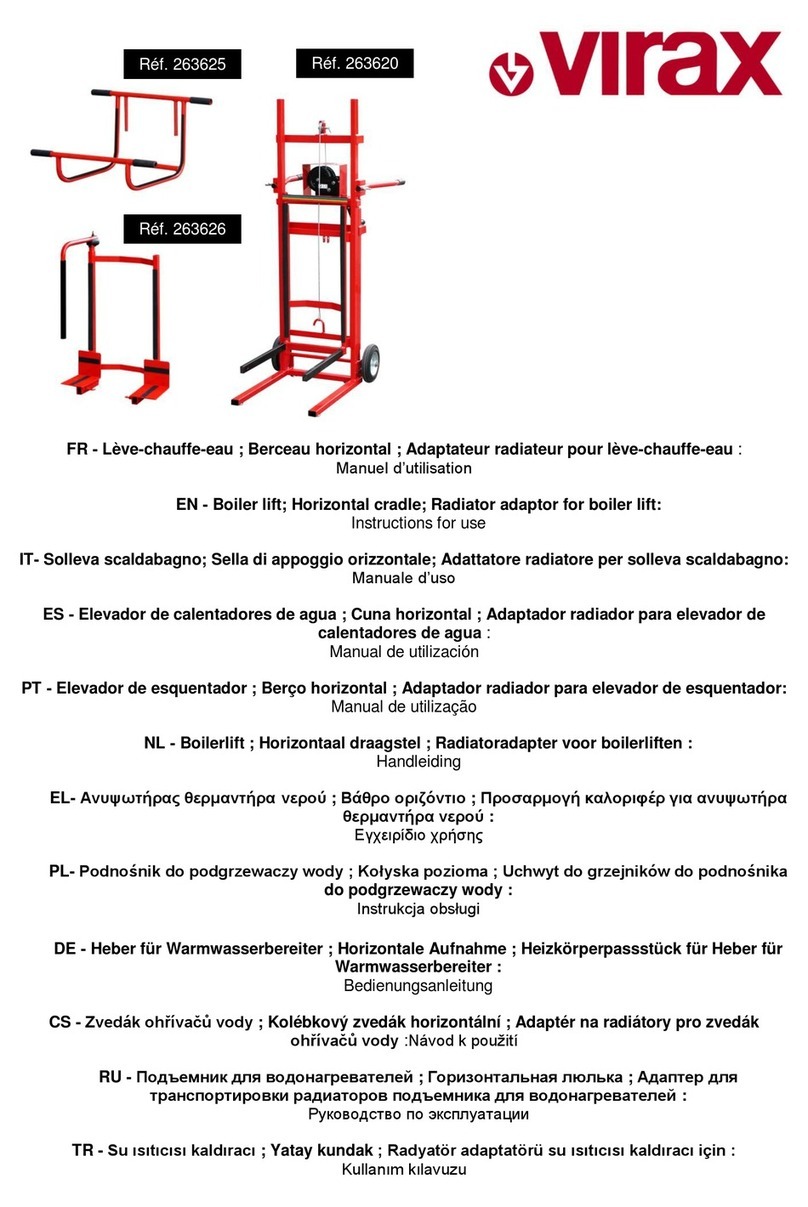

Other SICO Lifting System manuals

Popular Lifting System manuals by other brands

TradeQuip

TradeQuip 2002T owner's manual

Tractel

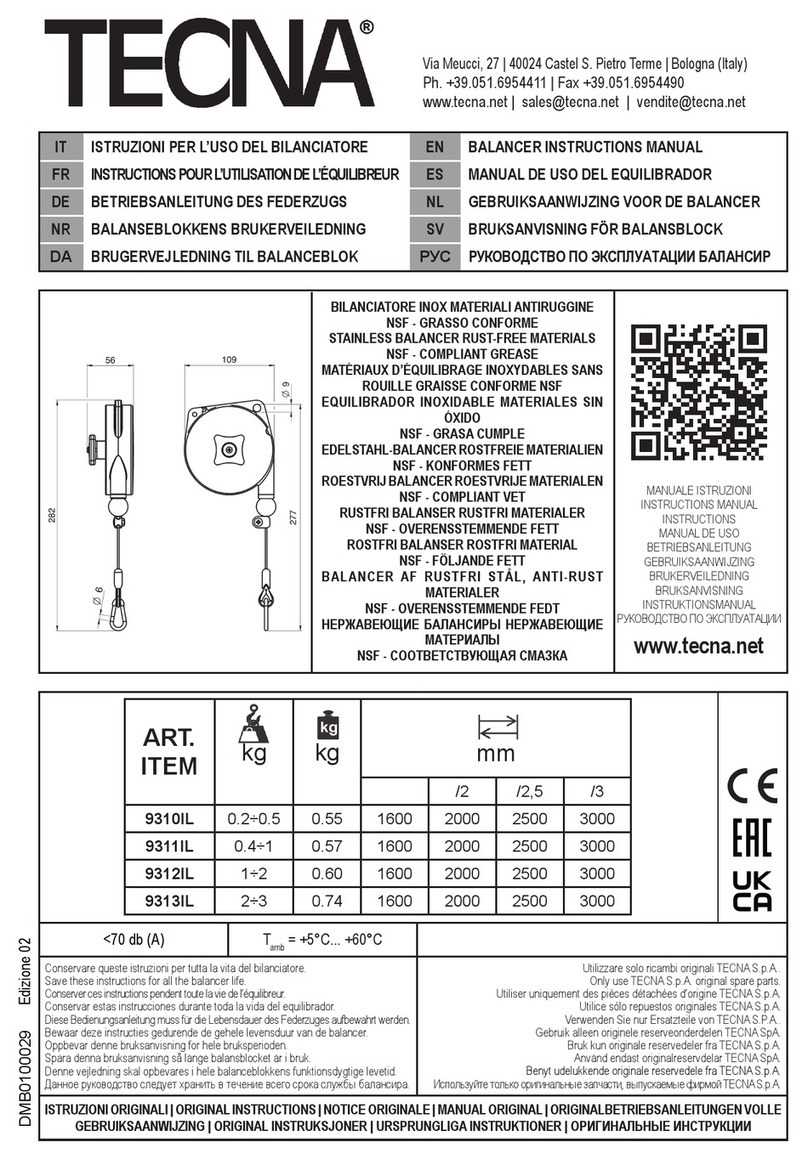

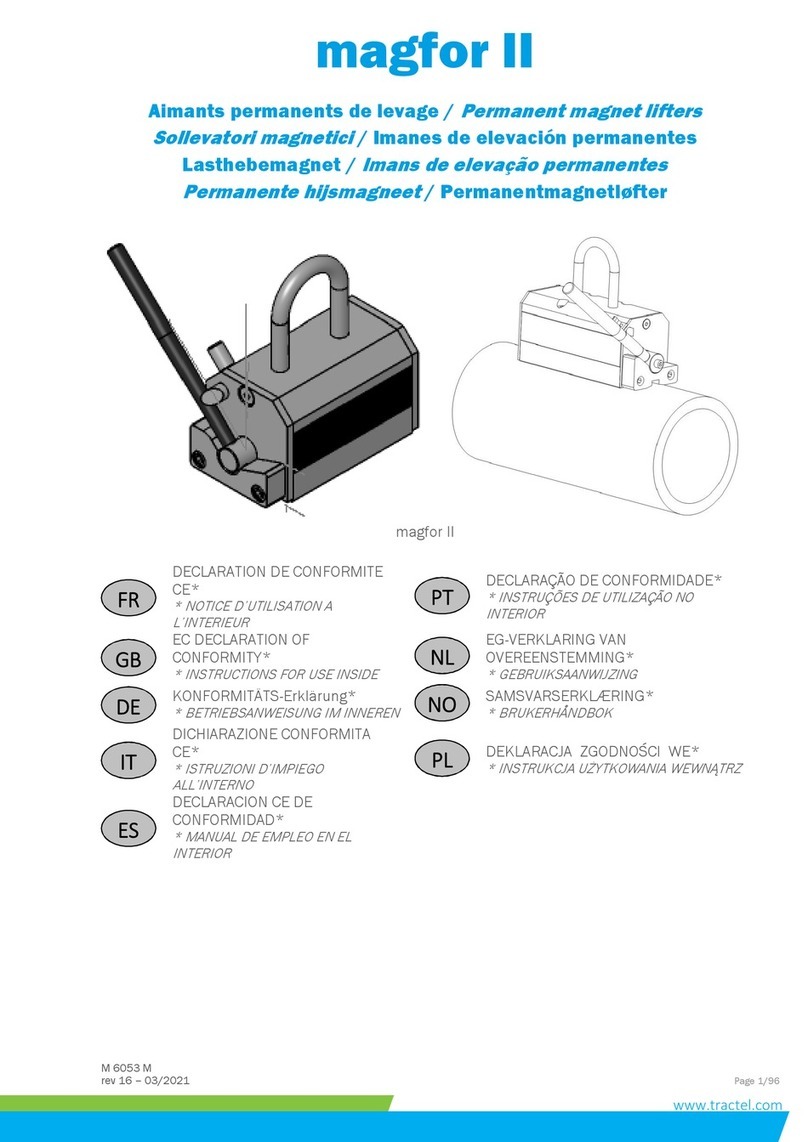

Tractel magfor II100 Instructions for use

TOOLCRAFT

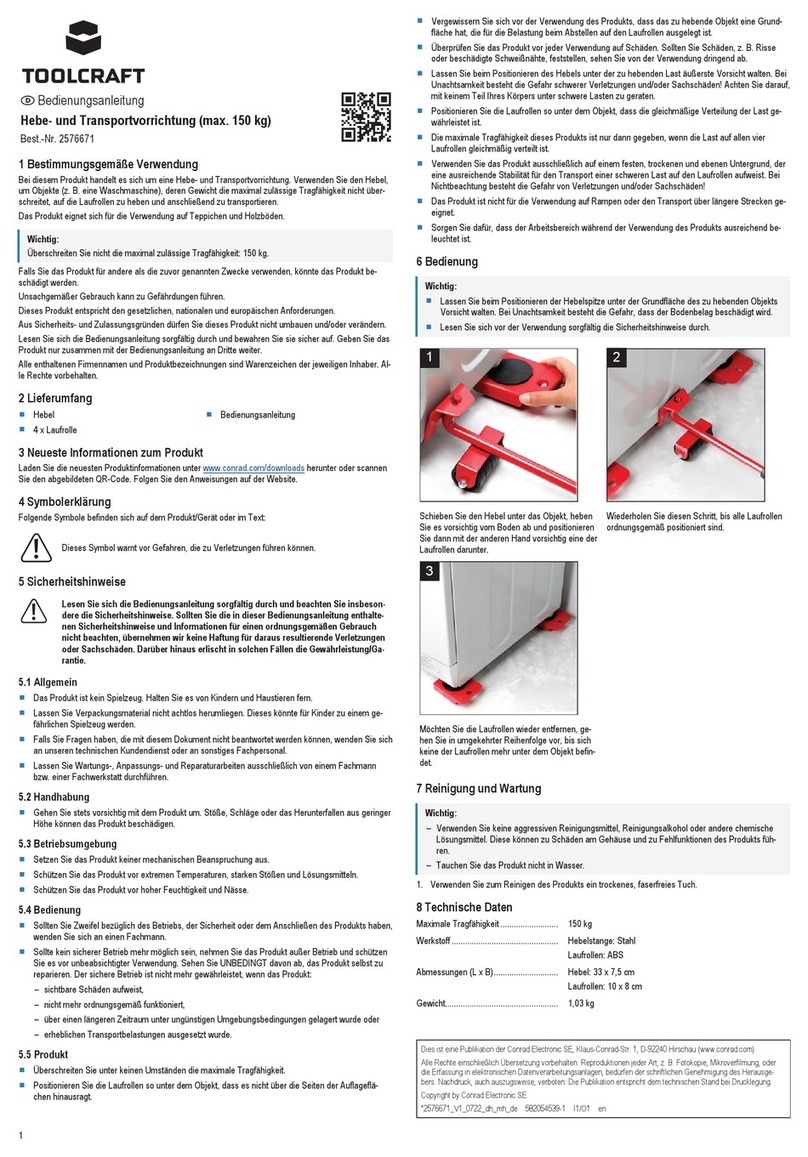

TOOLCRAFT 2576671 operating instructions

QSP

QSP LM-200-R2 Operation instructions

Aqua Creek Products

Aqua Creek Products F-03EZPLNA Installation, assembly and operation manual

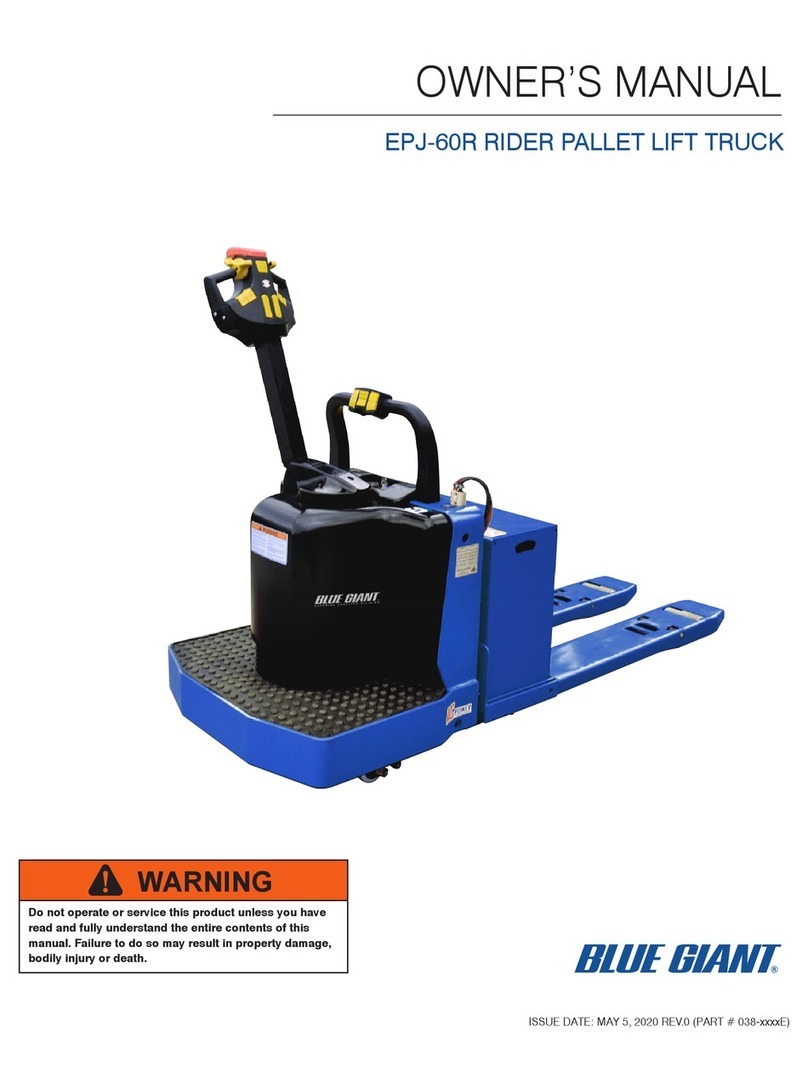

Blue Giant

Blue Giant H7012 Installation & technical manual