9. Fit Discharge Riser assembly to the Pumpset with

appropriate thread sealant or tape. With the

Pumpset stationary, screw Discharge Riser into

Pumpset ensuring 8 full threads minimum

engagement. The end of the thread of the

Discharge Riser must completely overlap the three

set screws in the top of the Pumpset. This

connection should be gas-tight.

10.Tighten (screw) Discharge Riser into Pumpset until

both inlet centreline identification marks on the

Pumpset are in line with the mark previously placed

on the edge of the Pump Housing Cover. Check this

alignment with a stringline. Do not loosen (back off)

Discharge Riser to achieve angular alignment.

11.Check overall length of Pumpset/Discharge Riser

from Cathodic Insulation Gasket to end of Pumpset

to ensure 5mm (min) clearance to bottom (inside) of

Pump Housing.

12.Using Loctite 243 or equal, fit the three set screws

in the top of the Pumpset. Tighten set screws

against Discharge Riser.

NOTE: These screws must be tight

13.Lubricate the protruding conduit with light oil to

prevent galling when fitting the 1" NPT bored-

through compression tube fitting.

14.Fit the 1" NPT bored-through compression tube

fitting to the Discharge Riser assembly with

appropriate thread sealant or tape, ensuring 8 full

threads minimum engagement.

NOTE: This connection must be gas tight.

NOTE: Do not tighten nut at this stage. Once this

nut is tightened, the only way of removing the

connector housing from the Discharge Riser is by

cutting through this fitting and the conduit.

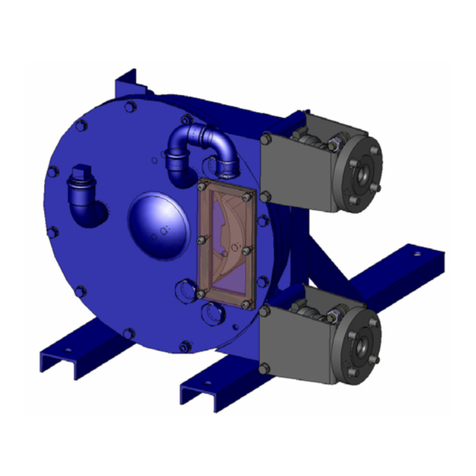

15.Carefully lift the Pumpset/Discharge Riser assembly

into a vertical position.

NOTE: When raising or lowering the

Pumpset/Discharge Riser assembly, take care

not to damage the Pumpset, Motor Leads or

conduit. Lift carefully with slings, chains etc.

16.Carefully lower the Pumpset/Discharge Riser

assembly into the Pump Housing making sure that

the Pumpset does not bind or drag on the sides of

the Pump Housing.

NOTE: Before the Pumpset/Discharge Riser

assembly is completely inside the Pump

Housing, remove the adhesive tape holding the

Cathodic Insulation Gasket to the Pump

Housing Cover. Carefully fit the Cathodic

Insulation Gasket to the Turret Cover.

17.Fit Pump Housing Cover to Turret Cover with

appropriate cathodic insulators/washers for bolts

and nuts. Align marks on Pump Housing Cover and

Turret Cover. The seal between the Pump Housing

Cover and the Turret Cover must be gas tight.

18.Check that the Pumpset/Discharge Riser is

electrically insulated from the tank. If not insulated,

rectify as required.

NOTE: Do not use sealing tape or sealant on

NON-GAS electrical connections.

19.Determine basic location and orientation of Junction

Box, DPS etc. Based on this determination,

assemble Electrical Fitting Kit (Australian

Certification only) and DPS as follows:

a) Remove Junction Boxcover.

b) Fit DPS to Junction Box (For Junction Boxes

which are not fitted with a 1/2" NPT(F) thread, use

adaptor supplied) Take care when fitting to avoid

damaging electrical leads.

c) Fit 25mm hexnipple to Junction Box.

d) Fit 25(F)M side of Conduit Seal to hex nipple.

e) Fit 3/4" NPT compression tube fitting to 3/4"(F)

NPT side of Conduit Seal.

f) Fit 25mm plug/s to unused Junction Box port/s.

g) Fit 25mm Barrier Gland to Junction Box.

20.Fit duplicate Pumpset/Motor identification tag over

Motor Leads and over conduit as shown in Figure 6

21.Remove adhesive tape from wire protection tube

and slide tube off Motor Leads.

22.Slide wire protection tube half way into 3/4" NPT

compression fitting. See Figure 6

23.While holding the wire protection tube in place,

carefully slide the Motor Leads through the wire

protection tube and into the Junction Box.

24.Test the resistance from each lead to the conduit to

ensure that they are electrically insulated. Rectify

any fault as required.

25.Mount Junction Box to insulated support bracket if

required.

NOTE: If Junction Box requires a support

bracket, this must be electrically insulated from

the Turret Cover and Tank.

26.Trim excess wire from Motor Leads and DPS Leads

(leave adequate length for connection without

tension).

27.Temporariliy cap the free ends of the leads with

insulating tape ensuring that the cores are covered.

28.Coil the leads in the Junction Box.

29.Fit Cover and Gasket to Junction Box.

3.1.8 Discharge Pipe Fittings

1. A DN25 (min) full bore pneumatically actuated

ball valve is required immediately downstream of

the Discharge Riser to isolate the discharge line.

2. After this ball valve, a DN25 (min) branch is

required for connection to the EBSRAY Inline

RV18-NRV Bypass Valve.

3. A port is required in the discharge line to accept an

isolation valve. This valve is for isolation of the

pressure gauge and the high pressure side of the

DPS.

4. The line from the valve must be fitted with a 'Tee'

arrangement to connect to a 0-2500kPa (0–25

Bar) pressure gauge and to the high pressure side

of the DPS via a ¼" OD SS tube.

3.1.9 DPS (Differential Pressure Switch)

1. Fit the high pressure side ¼" tube as mentioned

in 4 above.

2. A low pressure side (vapour pressure) port must be

provided through the Pump Housing Cover. This

port is required to accept a valve for isolation of the

pressure gauge plus the 1/4" tube fitting for the low

pressure side of the DPS.