Note: Swimming pool gates, fences and their hardware systems are designed to aid and not subs tute for adult supervision. To

the extent this product is used around a pool, prior to installing, consult local licensing and safety authori es for approvals and/

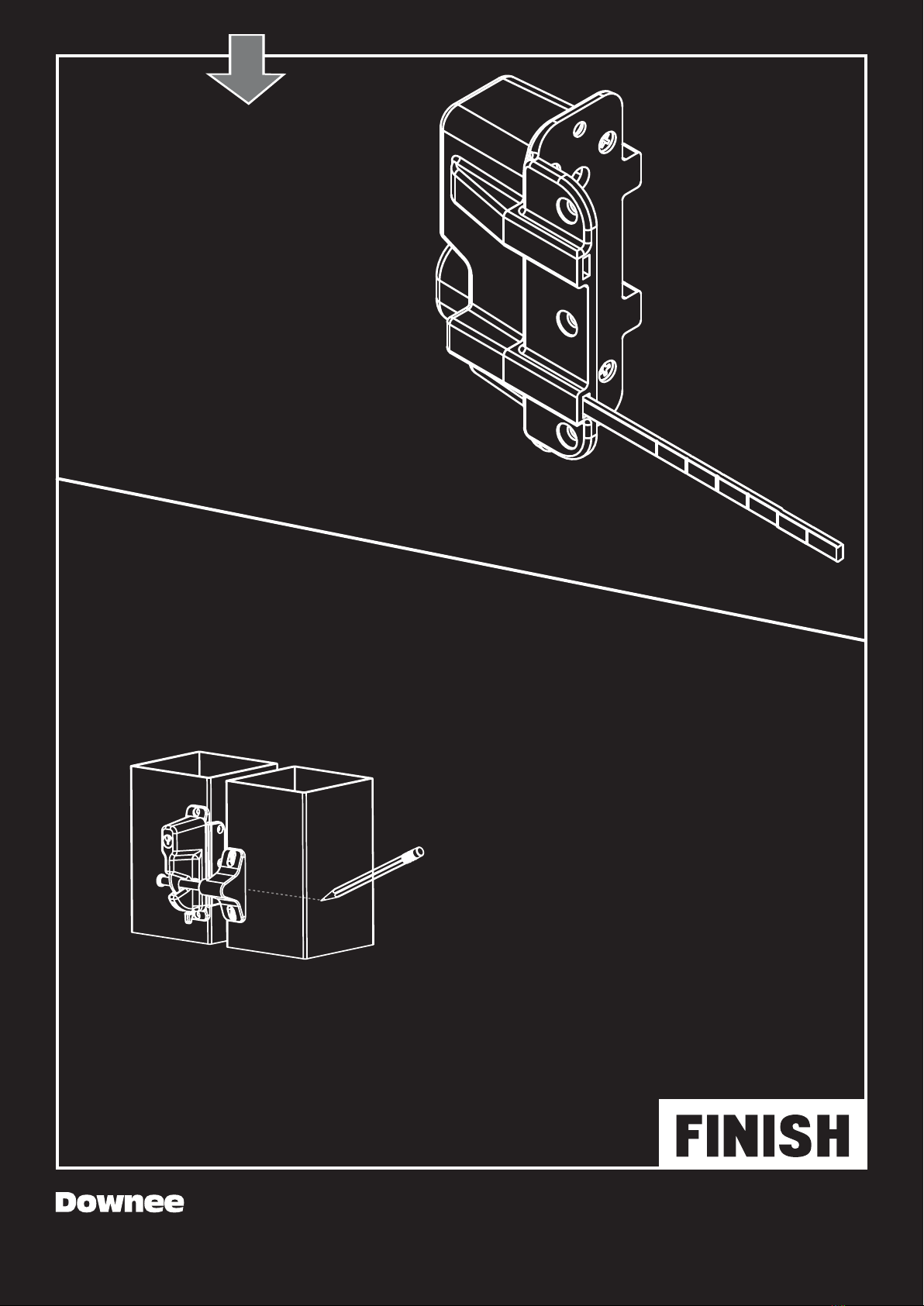

or requirements. The Keystone® will operate properly only if installed in accordance with instruc ons.

Maintenance: The Keystone® latches should be inspected annually, or more frequently if the gate is used o en. Use a non-toxic

lubricant on all moving parts. Use mild soap & water to clean exterior body or unit. Always remove key upon locking.

Occasionally re ghten all moun ng screws to assure proper opera ons. Please make sure product is adjusted properly per

originally supplied instruc ons.

WARRANTY

MANUFACTURER’S

NATIONWIDE INDUSTRIES Tampa, Florida 33619 USA

Keystone® Series Latches

What Does This Warranty

Cover? This warranty covers

materials and workmanship

as well as any loss of

func onality in your new

Keystone®, with the

excep ons stated below.

What Will Na onwide Do?

In the event of any defect in

material or workmanship or

loss of func onality in the

product coveredunder this

warranty, manufacturer will

replace such Keystone® with

a new Keystone® (or, in the

event the Keystone® is no

longer available, a latch

similar thereto) at no charge.

How Does State Law Apply?

This warranty gives you

specifi c legal rights, and you

may also have other rights

which vary from state to

state.

How Long Does the

Coverage Last? This warranty

to the original purchaser (end

user) runs for the dura on

of one million cycles of use.

Na onwide Industries assumes

this is a true life me of use on

residen al applica ons, and

for commercial applica ons

will use an es mate of usage

based on each applica on.

How Do You Get Service?

In the event of any defect in

material or workmanship, or

failure in the Keystone® latch

covered under this warranty,

return the product, please

return the Keystone® postage

paid, together with proof of

purchase and a brief wri en

descrip on of the problem to

Na onwide Industries, 10333

Windhorst Road, Tampa,

Florida 33619, A en on:

Customer Service Manager.

What Does This Warranty Not Cover? This warranty is void

in its en rety in the event the Keystone® is tampered with,

altered, misused, eglected, damaged, improperly installed

or maintained, repaired or a empted to be repaired by an

unauthorized person, or used in any manner which is not in

accordance with the instruc ons provided by manufacturer.

Manufacturer’s aggregate liability in damages or otherwise

shall not exceed the payment, if any, received by manufacturer

for the Keystone® furnished to you which is the subject of

a claim or dispute. In no event shall manufacturer be liable,

whether in contract, in tort, under warranty, in negligence or

otherwise for incidental, consequen al, or special damages of

any kind whatsoever, howsoever caused.

DISCLAIMER: A pool owner or operator is always responsible

for the safety of those in or around the pool and, to the extent

this product is used around a pool, the manufacturer and sup-

plier of this device cannot and will not accept such responsibil-

ity. In addi on, the manufacturer and supplier of this device

cannot and will not accept responsibility for unauthorized

modifi ca ons to or for defec ve or inadequate maintenance

of this device. No modifi ca on to this device whatsoever is to

be made other than with respect to the adjustments outlined

in the installa on instruc ons. If this device fails to func on

properly, it should be returned promptly to the supplier for

replacement.

Eff ec ve for products sold a er 1/1/15.

Million Cycle Warranty and Liability Limitation