3

3. USER SAFETY OPERATIONS GUIDE

WARNING: RISK OF EXPLOSIVE GASES.

WORKING WITH RECHARGEABLE BATTERIES IS

DANGEROUS. EXPLOSIVE GASES DEVELOP DURING

NORMAL BATTERY OPERATION. READ THIS MANUAL

EACH TIME AND MAKE CERTAIN YOU FULLY

UNDERSTAND IT AND FOLLOW THE SAFETY AND

OPERATING INSTRUCTIONS AT ALL TIMES.

3.1. To reduce risk of battery explosion, follow all safety instructions below and

those published by the battery manufacturer. Review cautionary markings on

vehicle or equipment containing the battery.

3.2. DC-DC Converter contains no serviceable parts. If it fails during its warranty

period, contact your dealer for a warranty replacement or refer to last page of

manual for replacement procedure.

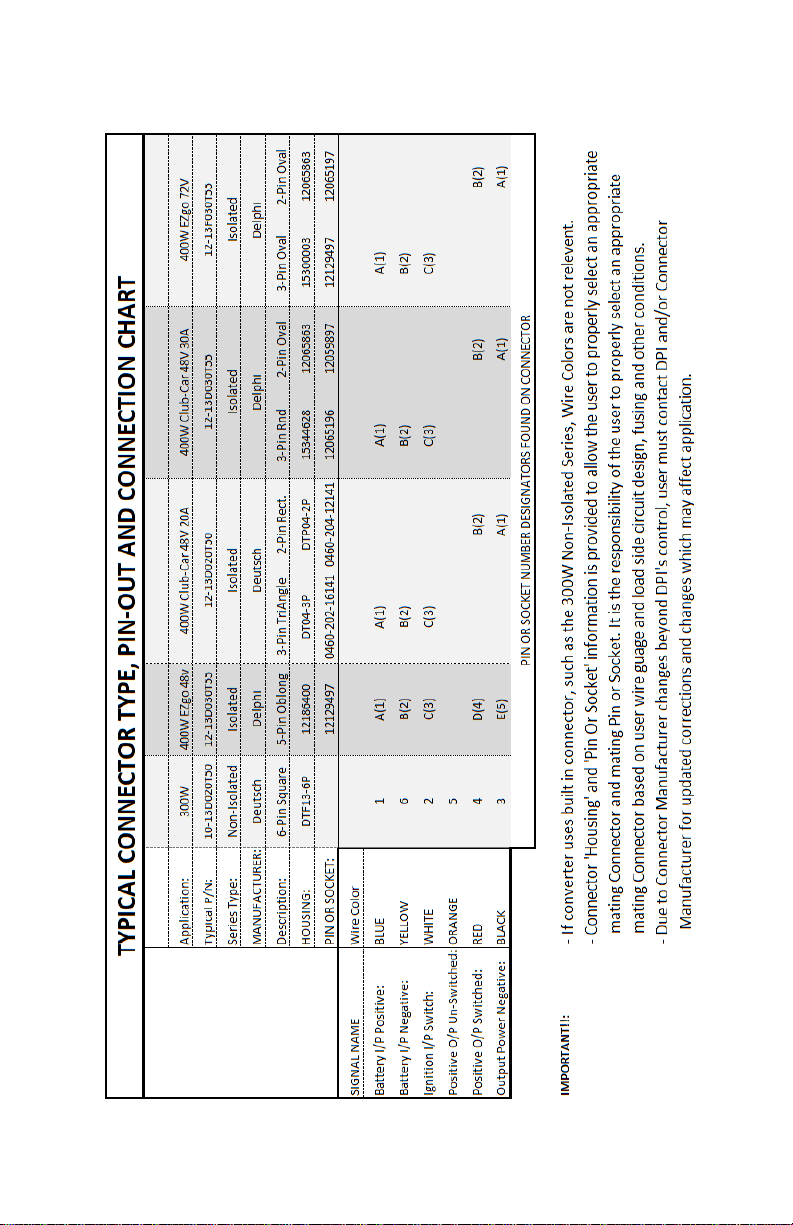

3.3. Construct cabling using DPI Approved and DPI supplied Connector Housing

and Connector pins and sockets.

3.4. The use of undersized conductors is STRICTLY prohibited. Ensure that any

wiring added to the input or output can safely carry the DC Current expected.

Plan to use wire gauges sufficient to carry input Currents of 15Amps typical

and output currents of 30amps typical. Wire and Cables must meet Automotive

and UL and/or CSA standards and routed to avoid being tripped over and not

subjected to damage or stress. Extension cables must be properly wired and in

good electrical condition, and large enough for the Ampere rating of the DC To

DC Converter Product as specified in the following TABLE:

RECOMMENDED MINIMUM AWG SIZE FOR WIRE AND CABLE

For 16A Input and for cable up to 25ft: Use 14Ga minimum

For 16A Output and for cable up to 25ft: Use 14Ga minimum

For 30A Output and for cable up to 25ft: Use 10Ga minimum

3.5. If Branch Circuit Wiring supplies multiple loads, such as that used from a Fuse

Block or Fuse Box, refer to the National Electrical Code (NEC) for wire gauges

appropriately sized to carry the load currents.

4. PERSONAL PRECAUTIONS While Working With Batteries

4.1. Have someone within range of your voice to come to your aid if needed.

4.2. Have plenty of fresh water and soap nearby in case battery acid contacts your

skin, clothing or eyes. Wear eye & clothing protection & avoid touching eyes.

4.3. If battery acid contacts skin or clothing, wash immediately with soap and water.

4.4. If acid enters eye, immediately flush eye with running cold water for at least 10

minutes. Get medical attention immediately.