Q/A USING FOR DPS

Question Answer

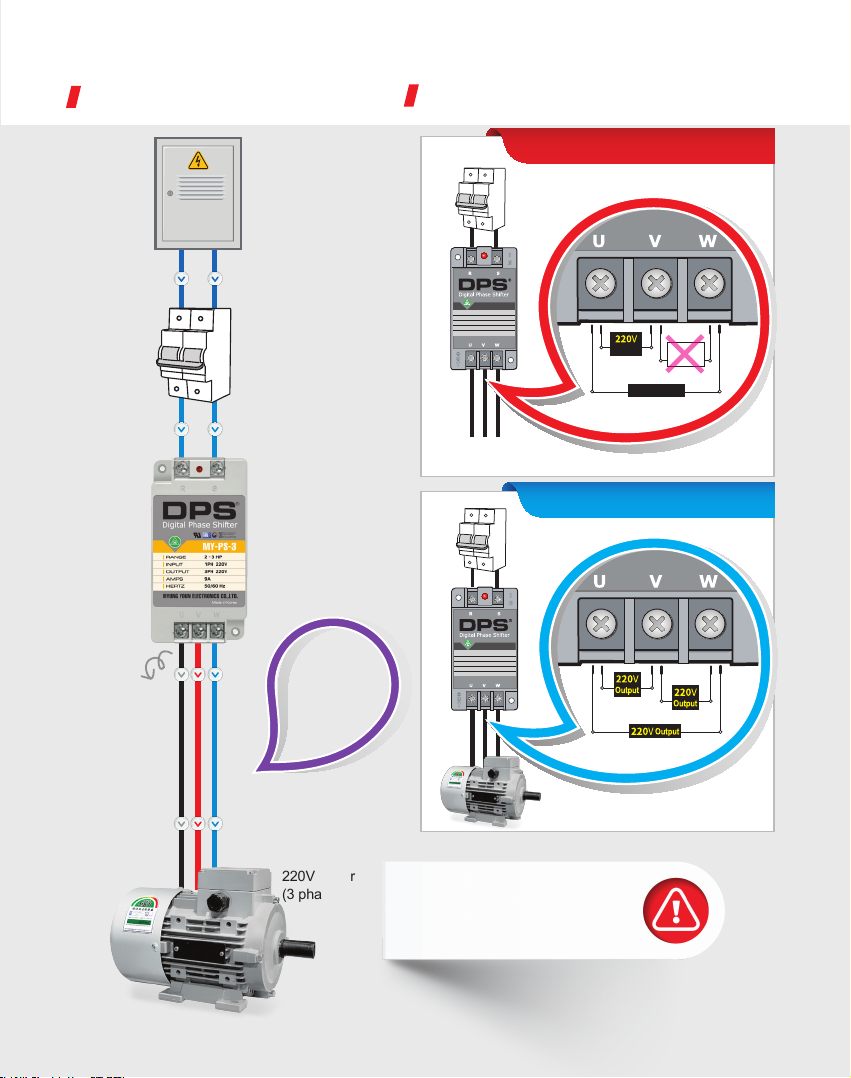

Only 2 phases come out from

the DPS's output voltage.

3 phase voltages are output only when the motor is running.When

the motor is not running, it is normal for only single phase output to

come out.

DPS output voltage and

current are irregular.

Initially, there may be voltage and current imbalances,

but when the load take more than 50%, the voltage and current will

soon balance.This phenomenon occurs in the process of making

three phases from single phase.

The motor runs well at rst,

then suddenly the breaker

was tripped.

Check the capacity of the breaker. You need to select twice the

capacity of the motor rated current.

e.g. Motor 15A : Breaker 30A

The power of the DPS is

checked, but the motor

is not running.

Check the DPS and motor connections

(check whether the magnetic control lines are connected to U and W

of DPS's output).

Connected the DPS to the motor

and running the motor, but the

voltages and current value are

too high.

Check the capacity of the DPS and motor.

If the DPS capacity is too large for the motor capacity, that happens.

Or, please check whether two motors are installed in the machine.

It should be used only for one DPS per one motor.

Is DPS available when the

machine has 2~3 motors?

Originally, you should use one DPS for only one motor.

However, if the start and stop times of the motor are the same,

you could use one DPS for multiple motors.

The DPS LED power does not

come on in spite of entering

power.

Please contact the head ofce after checking the input power.

The motor runs well by

connecting the DPS, but

suddenly it doesn't work well.

Check the magnet switch connection,

overload capacity, and breaker capacity (twice the motor rated

current). And check for the overload.

The motor is operated

too weak.

Check if the input voltage and power volume are normal and check

the motor load.Also, make sure that the magnetic conrol line is

connected to the U and W positions of the DPS output.

How should the magnet switch,

overload, and breaker capacities

be selected?

When using the above products, it should be selected as twice the

capacity of the rated current of the motor.

The motor slows down and does

not run smoothly.

Please check the load volume of the motor and use the load less

than 85% (overcurrent phenomenon caused by overloading).

There's a lot of noise when

the motor is running.

Check the DPS and motor capacity

(The motor is noisy and generates heat when using a DPS with a

specication higher than the appropriate capacity).

The current of Motor output is

too high and overheating occurs.

Please check if the motor capacity and DPS capacity are properly

selected.

e.g. MY-PS-3 model: Used for 2HP motor,

MY-PS-5 model: Used for 3HP motor

Is DPS available for sunbeds,

welders, ovens, and tenning

machines?

You can use it after contacting our head ofce.

However, it is slightly less efcient than when used in motors.

(approximately 70%)

4 5