3

K 100 (W) Cl2, SCl2, ClO2, O2, O3, H2O2

Contents

1. Your K 100 .....................................................................................................4

1.1General and Safetyinstructions ...............................................................5

1.2Application ...............................................................................................6

1.3Intendeduse ............................................................................................6

1.4Features...................................................................................................7

1.5Technicaldata ..........................................................................................8

2. Instructions for installation and connections .............................................9

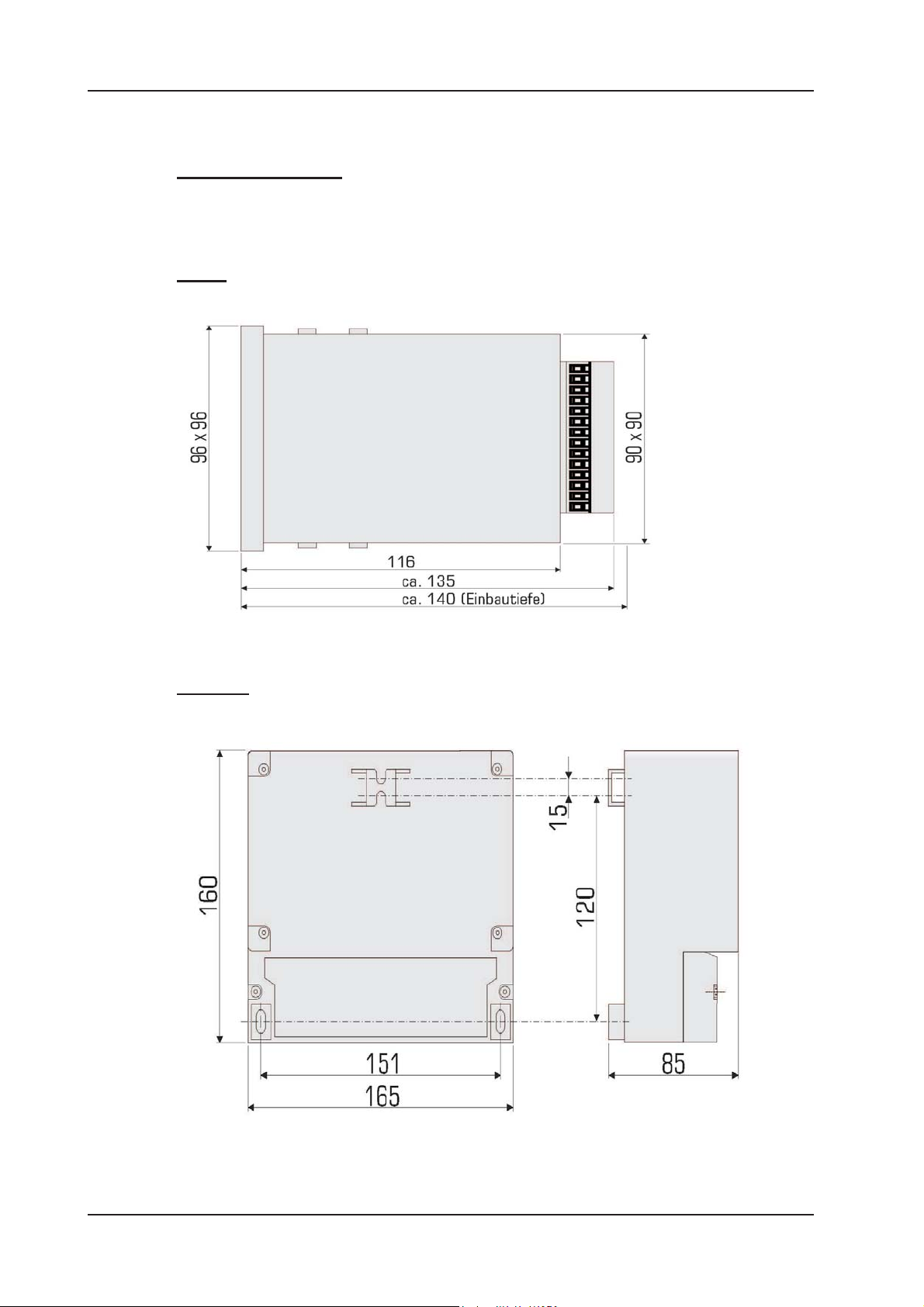

2.1Dimensions ............................................................................................ 10

2.2 Installation K 100 ................................................................................... 11

2.3 Installation K 100 W ............................................................................... 12

2.4Connection diagram K100 ..................................................................... 13

2.5 Connection diagram K 100 W................................................................. 14

3. Operation of the instrument....................................................................... 15

3.1How to adjustparameters....................................................................... 16

3.2Where to lookforinformation.................................................................. 17

3.3Menuoverview ........................................................................................ 18

4. Code and laguage...................................................................................... 19

5. Adjustment of the meter ............................................................................ 20

5.1 Calibration .............................................................................................. 21

5.2Temperaturecompensation .................................................................... 22

5.3Automatic sensorcleaningASR(option)................................................. 23

5.4Averaging ............................................................................................... 23

6. Adjustment of the controller ...................................................................... 24

6.1ON/OFFcontroller .................................................................................. 25

6.2P /PIcontroller asimpulse-frequencycontroller..................................... 26

6.3 P / PI controller as pulse-pause controller .............................................. 27

6.4Activation and deactivationofthecontroller............................................. 28

6.5Turn-ondelay ......................................................................................... 28

6.6External controllerstop(digital input) ..................................................... 28

6.7Manual operation oftherelays................................................................ 29

6.8 Dosage check ........................................................................................ 30

7. Data output.................................................................................................. 31

7.1Currentoutput ........................................................................................ 31

7.2Current output ascontrolleroutput ......................................................... 31

7.3Serialinterface RS485 (option) ............................................................... 31

8. Limit values and Alarm.............................................................................. 32

8.1Alarm ..................................................................................................... 33

8.2Configurationof the alarmrelay .............................................................. 34

8.3Error messages...................................................................................... 35

9. Operation and maintenace........................................................................ 36

10. Service ...................................................................................................... 38

Index ............................................................................................................... 39

Customer settings - for reference! ................................................................. 41