3

K 100 PR & K 100 W PR

Contents

1. Your K 100 ..................................................................................................... 4

1.1GeneralandSafetyinstructions ...............................................................5

1.2Features...................................................................................................6

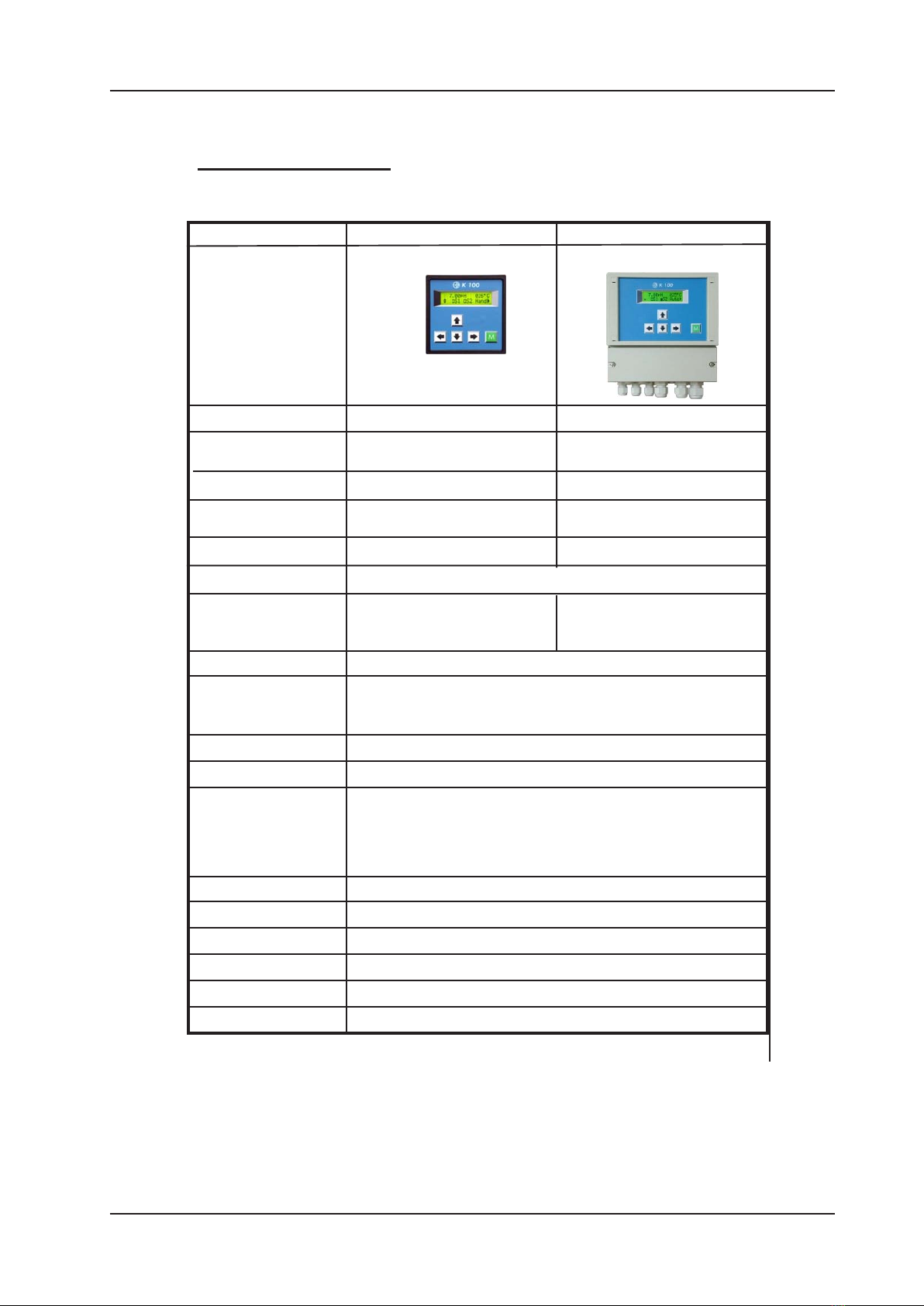

1.3Technicaldata ..........................................................................................7

1.4DeclarationofEGconformity....................................................................8

2. Instructions for installation and connections .............................................9

2.1Dimensions ............................................................................................ 10

2.2 Installation K 100 ................................................................................... 11

2.3 Installation K 100 W ............................................................................... 12

2.4ConnectiondiagramK100 PR ............................................................... 13

2.5 Connection diagram K 100 W PR........................................................... 14

3. Operation of the instrument....................................................................... 15

3.1Howtoadjustparameters....................................................................... 16

3.2Menuoverview ........................................................................................ 17

4. Password and language ............................................................................ 18

5. Adjustments for measurement .................................................................. 19

5.1 Calibration .............................................................................................. 20

5.2Temperaturecompensation .................................................................... 21

5.3ORPmeasurements............................................................................... 22

6. Adjustments of the controller .................................................................... 23

6.1ON/OFFcontroller.................................................................................. 24

6.2P / PI controller as impulse-frequency controller..................................... 25

6.3 P / PI controller as pulse-pause controller .............................................. 26

6.4Activationanddeactivationofthecontroller............................................. 27

6.5Turn-ondelay ......................................................................................... 27

6.6 External controller stop .......................................................................... 27

6.7Manualoperationoftherelays................................................................ 28

6.8LimitvaluesandAlarm ........................................................................... 29

7. Data output.................................................................................................. 30

7.1Currentoutput ........................................................................................ 30

7.2SerialinterfaceRS485(option) ............................................................... 30

8. Operation and maintenace........................................................................ 31

9. Service ........................................................................................................ 32

9.1Productinfo............................................................................................ 32

9.2Analoginputs ......................................................................................... 32

9.3 Erase settings (reset)............................................................................. 32

10.Errormessages ......................................................................................... 33

Index ............................................................................................................... 34