4

Warning

It is compulsory to observe the safety instructions included in this manual!

Special designs and versions may differ from the standard models in terms of their technical

details. If any points are unclear, we urgently recommend that you contact DR.BENDER GmbH,

indicating the machine type and machine number.

1.0 General notes

1.1 Symbol- and Pictograph description

This sign tells you rules, if you not pay attention for this your health and the function of

the machine is in danger. You have no warranty if the machine breaks down because

you not looking about this.

1.2 Technical description

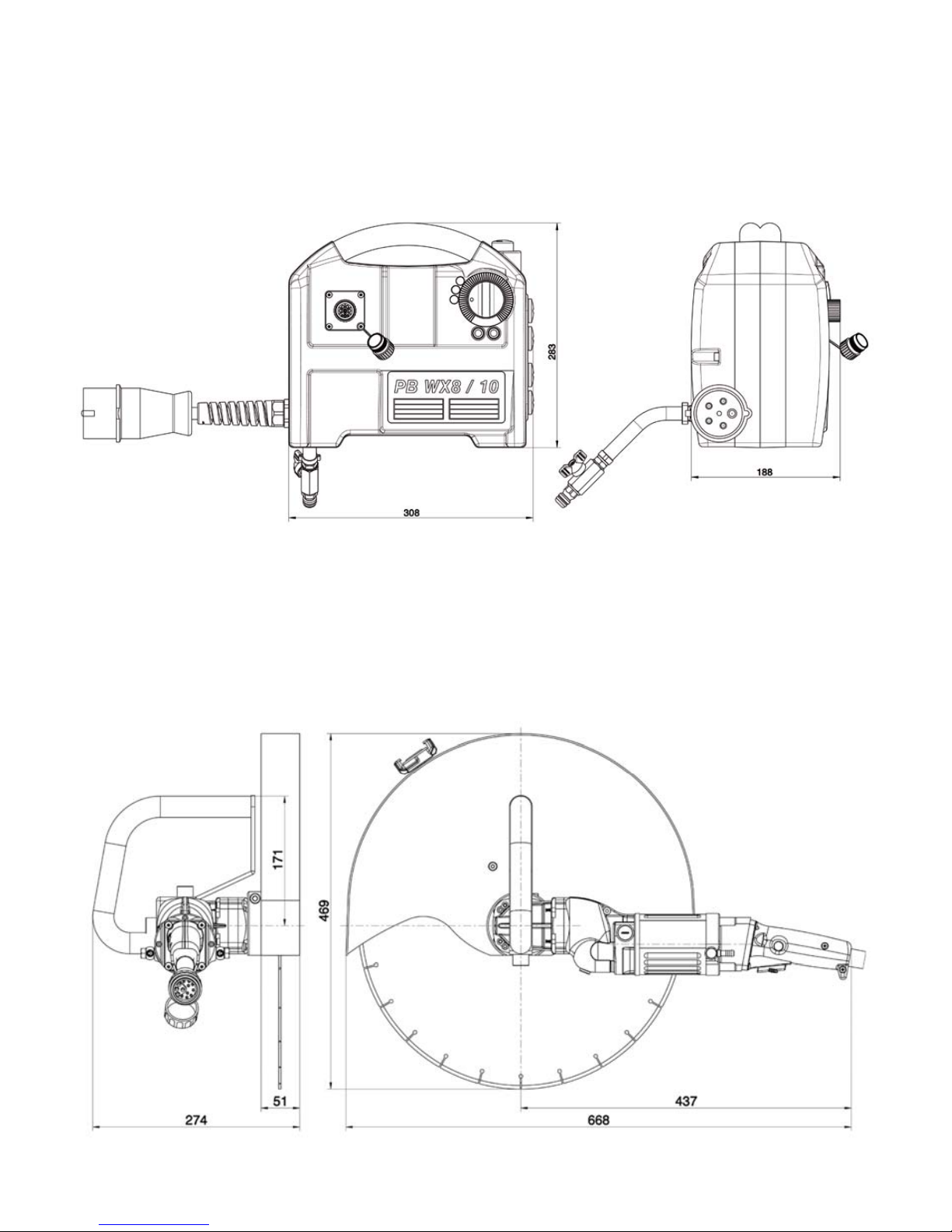

BELUGA, ORCA and SQUATINA represent a completely new generation of driving machines used for

stone processing. The highly extensive modular design principle provides the nowadays so important

flexibility in performing cutting operations in concrete and stone. In the process, quite newly developed high

frequency elements are employed in the motor. The frequency range is adjusted within 0 – 1000 Hz by

means of the frequency changer integrated in the Powerbox. At 100 Hz, the rotor reaches a speed of

30,000 min-1. A main advantage results from a weight / performance ratio (motor output = 11 kW / weight =

21.5 kg -> 0.51) so far unequalled with the conventional technology, such as the BBM33extra type (motor

output = 2.4 kW / weight = 13.5 kg -> 0.17). This means that the weight of the machine could be reduced

three times by means of the high frequency technology. Further advantages result from the infinitely

variable speed regulation. Thus, each tool diameter may be assigned its optimum speed, in order to

achieve the best cutting speed possible at the tool. Furthermore, the speed may be continuously reduced in

the process when steel reinforcements appear, thus providing its optimum adaptation to the working

progress. In this case, it is possible to run at much higher cutting speeds (Caution! They depend on the

tool), achieving an up to 150% faster working progress. In the case of conventional machines, the torque

dramatically decreases at high speeds, rendering this advantage impossible.

1.3 Application

The handsaw and the appropriate Powerboxes can be used for the purposes outlined by the data on the

model plate. If you are using special machines, the details in the quotation and order confirmation also

apply.

The driving machines and the Powerboxes are supplied as standard in protection class I, only this can

guarantee the full high quality protection of the FI switch.

If you use suitable saw blades, you will be able to cut in the most diverse material types:

- concrete (even if it contains thick reinforcement steel)

- sandstone and limestone

- all building materials for solid walls

- asphalt carpets

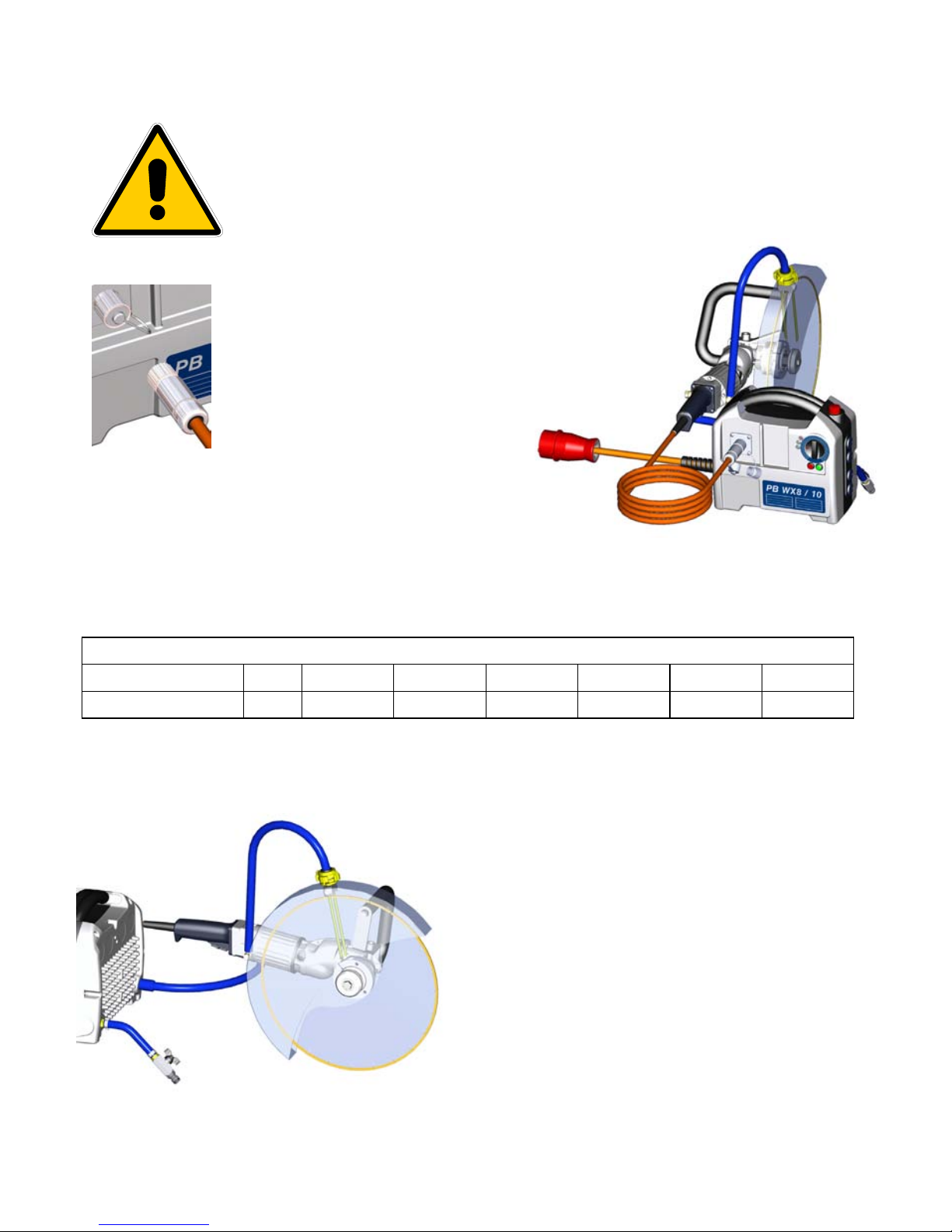

The machine must be

- connected to a duly grounded EEC socket (EEC 5poles, 3P+PE 32A 6h – 400V). No zero

conductor is required.

- operated with a pre-connected all-current failure FI protection or protection insulating transformer

in order to ensure the protection of the operator.