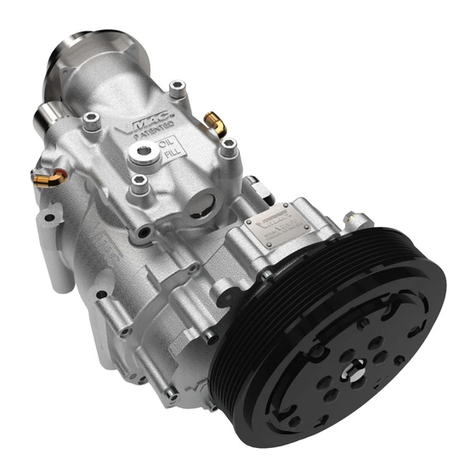

Connecting Wiring System

oThe Twin Compressor comes ready to plug into the supplied Solenoid/Pressure Switch (F-30368) harness

which in turn can be plugged into the supplied Switching Harness (F-14002).

oThe wiring diagram for the compressor, Solenoid/Pressure Switch Harness and Switching Harness can be

seen in Figure 1.

oThe recommended power supply harness configuration can be seen in Figure 2. The diagram also illustrates

the MINIMUM wire gauges and any terminals required for the power harness. The routes and lengths of the

wiring harness should be carefully measure before fabricating the harness.

oThe Power Supply harness, which is not included, will need to be fabricated by suitably qualified personnel.

oUsing the wiring diagram depicted in Figures 1 & 2, plug the correct coloured female terminals to the

appropriate switch terminals.

oIt may be convenient to bundle the Red/Yellow and Blue/White 12V & Dash Light cables respectively along

with Power Supply harness loom.

oLocate an accessory outlet or power outlet that supplies 12V DC and is powered when the vehicle ignition

key in the “ACC” or “ON” position.

oTJM recommends wiring the Red/Yellow +12 V wire to the Ignition circuit to reduce likelihood of compressor

draining the battery.

oUsing an automotive quality connectors or soldering iron, splice the Red/Yellow wire to the positive (+)

wire on the chosen source, insulate the connection to prevent possible short circuit.

oLocate an active dash light 12 V supply wire.

oUsing an automotive quality connectors or soldering iron, splice the Blue/White wire to the active dash

light supply wire, insulate the connection prevent possible short circuit.

oRoute the remainder of the loom to the battery.

oPlug the dual solenoid connectors into the loom; the yellow and black connector to the Rear Locker

Solenoid, and the green and black connector to the Front Locker Solenoid.

oConnect the red wire to the battery positive terminal, and the black wire to the battery negative terminal,

use suitable terminals which are capable of carrying at least 80A

oSecure the loom to the vehicle at regular intervals to prevent wear.

Note: If additional wire is required to reach the battery, use 6 AWG wire or larger.