Manual

V 1.7 Page 1of 47

Contents

Introduction ............................................................................................................................................4

Limitations...........................................................................................................................................4

Delivery................................................................................................................................................4

Important Health and Safety Information ............................................................................................4

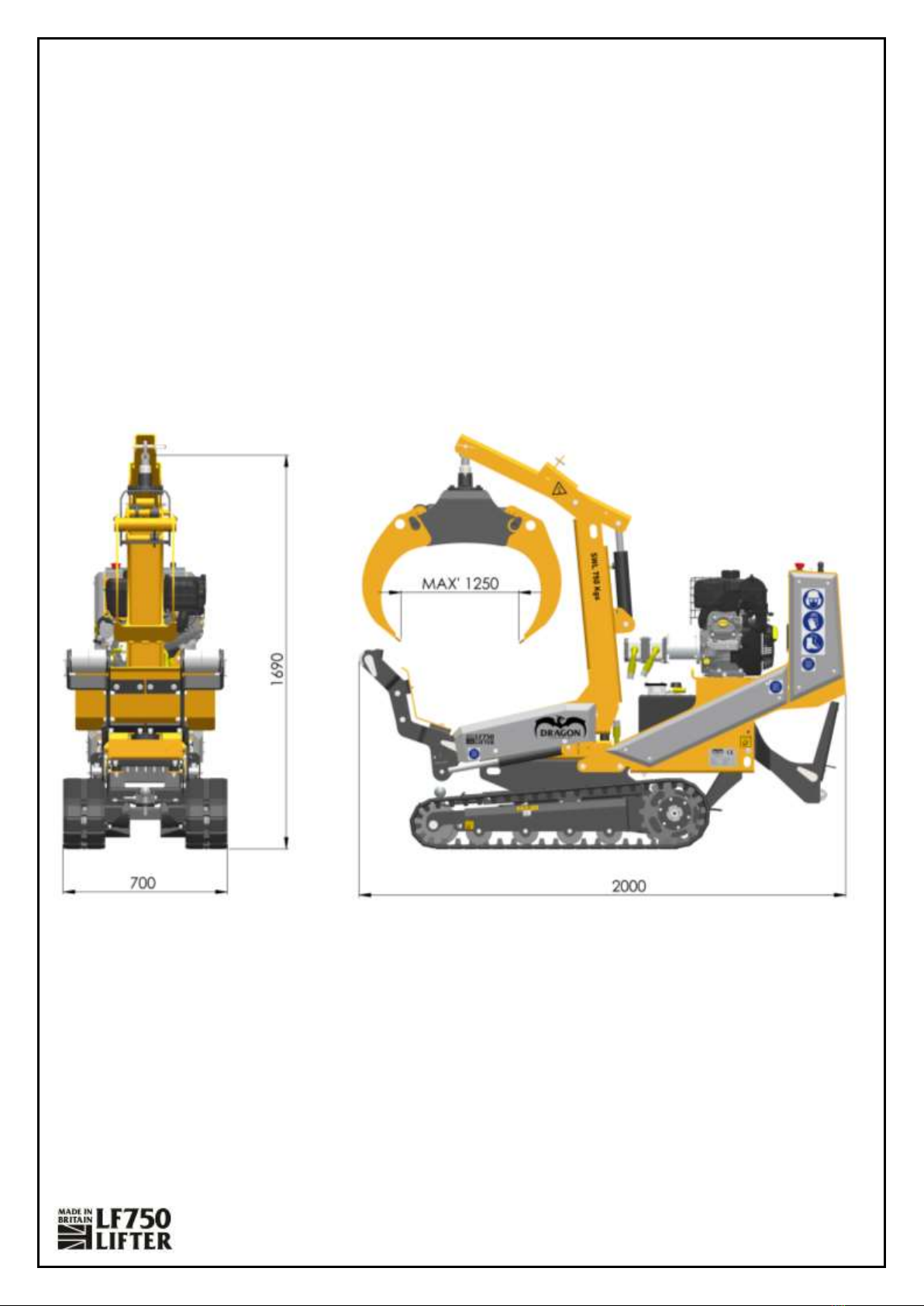

Specifications ..........................................................................................................................................5

Safe Working...........................................................................................................................................7

Operator’s Personal Protective Equipment (PPE).................................................................................7

Basic Operation Safety.........................................................................................................................7

General Safety Matters........................................................................................................................7

Engine Noise........................................................................................................................................8

Refuelling.............................................................................................................................................8

Operating Instructions............................................................................................................................9

Storage and Parking.............................................................................................................................9

Starting the Machine .........................................................................................................................10

Checks Before Starting..................................................................................................................10

Starting Procedure........................................................................................................................10

Stopping the Machine........................................................................................................................11

Emergency Stopping ..........................................................................................................................11

Tracking the Machine.........................................................................................................................12

Tracking Controls ..........................................................................................................................12

Checks Before Tracking.................................................................................................................12

Tracking Procedure .......................................................................................................................12

Lifting and Auxiliary Accessory ...........................................................................................................14

Lifting and Auxiliary Controls........................................................................................................14

General Lifting Operation .............................................................................................................14

Connecting and Disconnecting the Auxiliary Accessory ...............................................................15

Log Grab Accessory & Operation..................................................................................................16

Troubleshooting....................................................................................................................................17

Service Instructions...............................................................................................................................18

Safe Maintenance..............................................................................................................................18

Safe Lifting and Securing of the LF750 Lifter ................................................................................18

Lubrication and Servicing..............................................................................................................18

Recommended Lubricants ............................................................................................................18