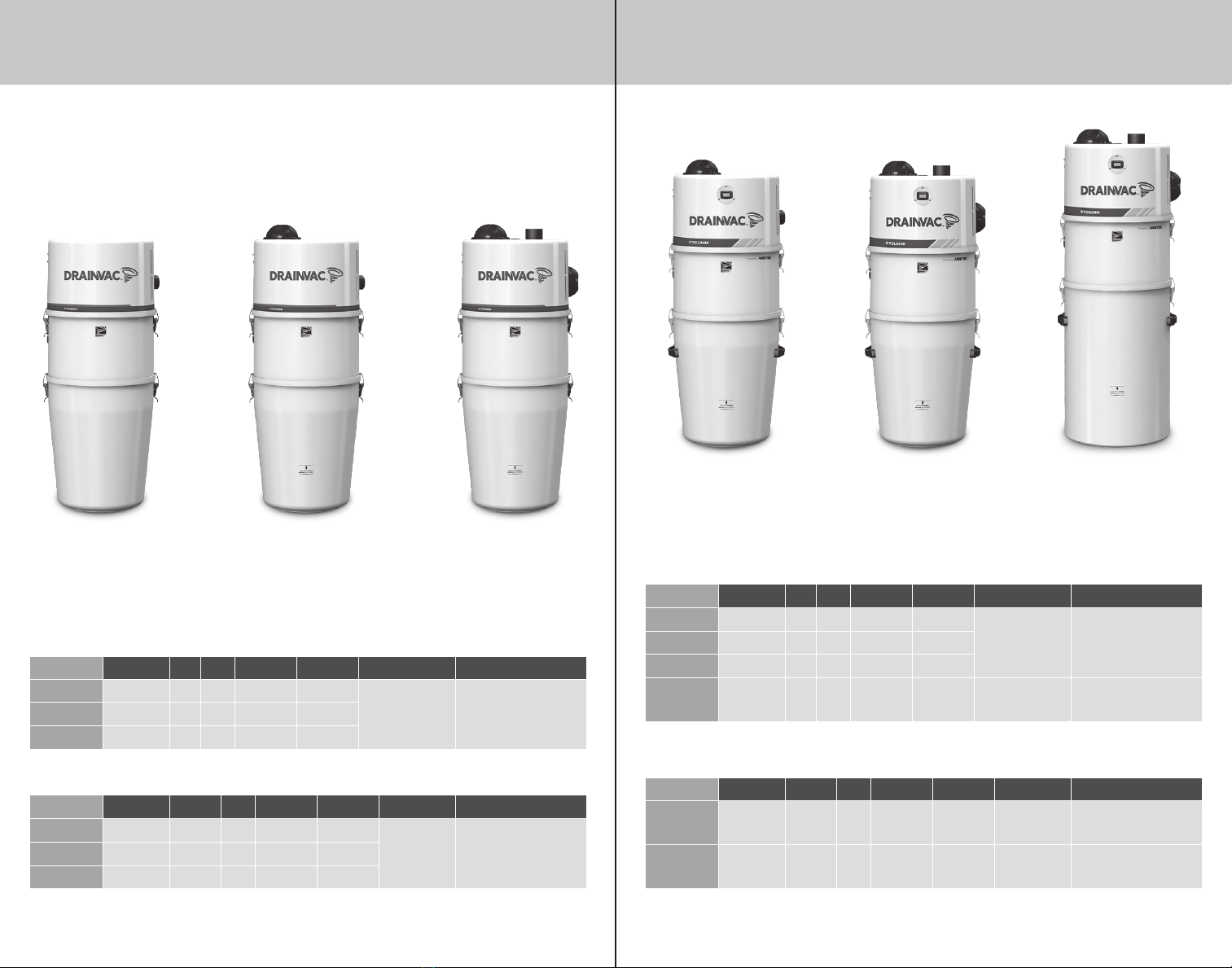

The compact series’ models

do not comply with NFPA standards.

IMPORTANT SAFETY INSTRUCTIONS

When using an electronic appliance, basic safety precautions should always be

followed. Read all guidelines before operating the unit.

To reduce risk of fire, electric discharges or injuries :

• Use this vacuum only for its intended use as described in this manual. (Use of

attachments not recommended by the manufacturer may cause fire, electric shock,

injury or damage to system components.)

• Do not allow vacuum to be used as a toy. Close supervision is necessary when this

vacuum is used by or near children.

• Do not leave the unit running without any supervising. Disconnect the unit if it is not

used and before maintenance.

• The Cyclonik series is designed to pick up small quantities of liquids only, up to 16 L

(3.5 imp. gal.). However, models DV1R800 and DF1R630 cannot pick up any liquid.

• Do not pick up anything that is burning or smoking, such as cigarettes, matches, or

hot ashes.

• Do not pick up any flammable liquids or combustible materials (gasoline, fuel, diesel)

hot debris, waste solvents (paint or other), explosive materials that would cause

harm to the vacuum cleaner.

• Do not vacuum drywall dust or baking flour as it may cause damage to your vacuum.

• Avoid picking up hard or sharp objects to prevent damaging or block the hose and

the plastic pipes.

• Do not put any object into openings. Do not use if an opening is blocked. Keep free

of dust, lint, hair and anything that may reduce airflow/suction. Lack of air flow will

cause the motor to overheat.

• This vacuum cleaner creates suction. Keep hair, face, fingers, all body parts and

loose clothing away from any openings.

• Never operate without dust bag and/or filter in place.

• Never plug in a unit designed to operate with a current of 120V in a 230V outlet and

vice versa.

• If the power cord is damaged, it must be replaced by a special cord available from

the authorized local dealer/distributor.

• Do not use extension cords or outlets with inadequate current carry capacity.

• Never operate this vacuum if it has a damaged cord or plug, if it is not working

properly, or if it has been dropped or damaged. Return to authorized dealers/

distributor for repairs.

• Never handle plug, cord or power units with wet hands.

• Never disconnect plug by pulling cord. To disconnect from the outlet, grasp the plug,

not the cord.

• Connect to a properly grounded outlet only. See grounding instructions.

• Keep cord away from heated surfaces.

• Turn off all controls before unplugging.

• Hoses with electrical connections must not be used if damaged.

By overlooking safety rules, you might risk putting your health in danger and to those

who surround you!

Drainvac disclaims any responsibility should you infringe upon these guidelines.

SAVE THESE INSTRUCTIONS