4

TiTre

INTRODUCTION

REGISTRATION

We wish to thank you for your trust and congratulate you for having chosen a Drainvac product. It is a sound

investment that will satisfy your vacuuming needs for years to come. The concept of Drainvac’s Automatik

central vacuum cleaners is unique and patented. They are manufactured and checked at our plant by our

qualified staff who have been specifically trained to this end. A number of installation and operating methods

must be followed to ensure your system’s maximum performance and to avoid unnecessary service calls.

Please read this manual carefully.

To fill in the Drainvac product registration form, go to www.drainvac.com/register-your-drainvac

TAbLE Of CONTENTS

HOW THE SYSTEM WORKS

OPERATION SEQUENCE ..................................................................6-7

TYPE OF UNITS (TECHNICAL SPECIFICATIONS) ......................................... 8

BOOSTER HEAD OPTION (TECHNICAL SPECIFICATIONS) ............................. 9

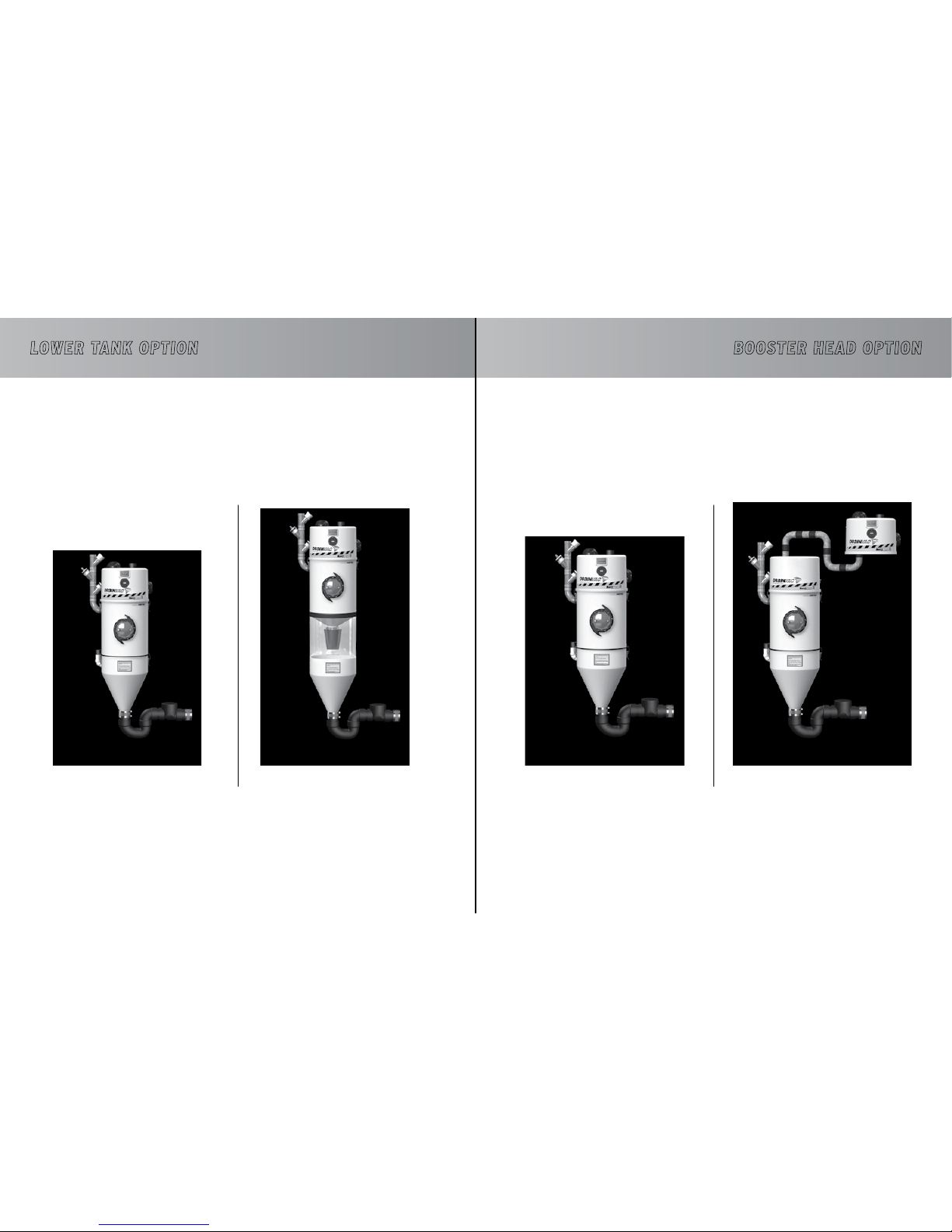

LOWER TANK OPTION ............................................................10

BOOSTER HEAD OPTION ........................................................ 11

UNIT DESCRIPTION

DV1A150, DF1A150 ........................................................................12

DV2A310, DF2A310 .......................................................................13

DV2A31, DF2A31 ..........................................................................14

DV2A32, DF2A32 ........................................................................15

DVDC40, DFDC40 (SERIES CONFIGURATION) ................................................16

DVDC40, DFDC40 (PARALLEL CONFIGURATION) .............................................17

HOW THE MEMBRANE WORKS

WHY CHANGE THIS PARAMETER? / SETTING THE EVACUATION TIMEFRAME ...................18

INSTALLING THE UNIT

FIRST THINGS FIRST ...................................................................19-20

STEP SEQUENCE ......................................................................21-27

INSTALLING THE PIPING SYSTEM

GENERAL INFORMATION.................................................................. 28

FROM DRY TO WET....................................................................... 29

DIFFERENT INSTALLATION POSSIBILITIES

(RESIDENTIAL AND COMMERCIAL INSTALLATION)

......30-31

EXAMPLES OF PROPER AND IMPROPER INSTALLATIONS.................................. 32-34

ELECTRICAL POWER SUPPLY

PROCEDURE / EXAMPLES OF PROPER AND IMPROPER INSTALLATIONS ....................... 35

DIAGRAMS OF THE APPROPRIATE CONNECTIONS FOR YOUR MODEL .......................... 36

GROUNDING INSTRUCTIONS .............................................................. 37

MAINTENANCE PROCEDURES

VISUAL INSPECTION / REGULAR MAINTENANCE ............................................ 38

MOTOR BRUSHES / WEEE GUIDELINES ..................................................... 39

TECHNICAL PROBLEMS ......................................................... 35

ANNEX

ANNEX I (CIRC-14)

ANNEX II (CIRC-14)

First off, we recommend you to fill out this form before you start

the installation process. If you have any concerns or problems

you may encounter, please contact the nearest retailer. The unit’s

profile will be required.

Model* :

Serial number* :

Retailer’s name :

Date of purchase:

Date of the last maintenance :

*These informations are found on a metal

tag located on the left side of the unit.

Metal tag