Draper GPAUG52-B User manual

68294

EN

Original Instructions

Version 2

For your safety, it is essential that these instructions are read and understood in full by

the operator before attempting to assemble, operate, adjust or maintain this product.

PETROL

EARTH

AUGER KIT

1.1 Product Reference

User Manual for: Petrol Earth Auger Kit

Stock No: 68294

Part No: GPAUG52-B

1.2 Revisions

Version 1: January 2021

First release

Version 2: February 2023

General content and formatting updates

Addition of safety lanyard instructions

As our manuals are continually updated, always ensure

that the latest version is used.

Please visit drapertools.com/manuals for the latest

version of this manual and the associated parts list,

if applicable.

1.3 Understanding the Safety Content of

This Manual

WARNING!

– Situations or actions that may result

in personal injury or death.

CAUTION! – Situations or actions that may result

in damage to the product or surroundings.

Important: – Information or instructions of particular

importance.

1.4 Copyright © Notice

Copyright © Draper Tools Limited.

Permission is granted to reproduce this manual for

personal and educational use ONLY. Commercial

copying, redistribution, hiring or lending is strictly

prohibited.

No part of this manual may be stored in a retrieval system

or transmitted in any other form or means without written

permission from Draper Tools Limited.

In all cases, this copyright notice must remain intact.

1. Preface

– 2 –

These are the original product instructions. This

document is part of the product; retain it for the life

of the product, passing it on to subsequent holders.

Read this manual in full before attempting to

assemble, operate or maintain this product.

This Draper Tools manual describes the purpose

of the product and contains all the necessary

information to ensure its correct and safe use.

Following all the instructions and guidance in

this manual will ensure the safety of both the

product and the operator and increase the

lifespan of the product.

All photographs and drawings within this manual are

supplied by Draper Tools to help illustrate correct

operation of the product.

Every eort has been made to ensure the

information contained in this manual is accurate.

However, Draper Tools reserves the right to amend

this document without prior warning. Always use the

latest version of the product manual.

EN

2. Contents

– 3 –

EN

1. Preface 2

1.1 Product Reference 2

1.2 Revisions 2

1.3 Understanding the Safety Content of

This Manual 2

1.4 Copyright © Notice 2

2. Contents 3

3. Product Introduction 4

3.1 Intended Use 4

3.2 Specication 4

4. Health and Safety Information 6

4.1 General Health and Safety Precautions

for Agricultural Equipment 6

4.2 Additional Safety Information for this Tool 7

4.3 Health and Safety Information for Machines

With a Petrol Engine 8

4.4 Residual Risk 8

5. Identication and Unpacking 9

5.1 Product Overview 9

5.2 What’s in the Box? 10

5.3 Packaging 10

6. Preparation Instructions 11

6.1 Fuelling the Auger 11

6.2 Attaching the Auger Bit 13

7. Operating Instructions 14

7.1 The Safety Wrist Lanyard 14

7.2 Starting the Engine 14

7.3 Notes on Use 16

8. Maintenance and Troubleshooting 17

8.1 General Maintenance 17

8.2 Draining the Fuel 17

8.3 Air Filter Care 17

8.4 Spark Plug Care 18

8.5 Replacing the Fuel Filter 19

8.6 Storing the Product 19

8.7 Troubleshooting 21

9. Spares, Returns and Disposal 23

10. Warranty 24

11. Explanation of Symbols 25

3. Product Introduction

– 4 –

EN

3.2 Specication

Stock No. 68294

Part No. GPAUG52-B

Engine:

Type: Two-stroke

Max. performance: 1.45kW

Displacement: 52cm3

Speed at idle: 3,000min-1 (rpm)

Clutch engagement speed: 4,500min-1 (rpm)

Max. speed: 9,000min-1 (rpm)

Fuel:

Capacity: 1,200cm3(ml)

Type: E10* (RON 95) or other unleaded petrol

Oil type: Synthetic two-stroke

Fuel to oil ratio: 25:1

Bit sizes:

Diameters: 100, 150, 200mm

Length: 800mm

Noise emissions:

Sound pressure level (LpA): 91.3dB(A)

Uncertainty: 3dB(A)

Sound power level (LWA): 108dB(A)

Uncertainty: 3dB(A)

Guaranteed sound power level: 110 (dB(A)

Vibrations:

Main handle: 12.201m/s2

Auxiliary handle: 13.332m/s2

Uncertainty: 1.5m/s2

3.1 Intended Use

This product is designed to bore cylindrical holes into

soil for the purposes of fencing, bore holes and planting

hedges and saplings. This kit includes auger bits of

100mm, 150mm and 200mm in diameter. Any other

application beyond the conditions established for use

will be considered misuse. Draper Tools accepts no

responsibility for improper use of this product.

WARNING! This product is not a toy and

must be respected.

Read this manual in full before attempting to assemble,

operate or maintain the product and retain it for later use.

3. Product Introduction

– 5 –

EN

Weight:

Motor unit (no fuel): 8.9kg

100mm bit (bit only): 1.76kg

150mm bit (bit only): 2.30kg

200mm bit (bit only): 2.82kg

Important: The declared vibration total values and noise

emissions values have been measured in accordance

with a standard test method and may be used for

comparing one tool with another. These values may also

be used in a preliminary assessment of exposure.

WARNING! The vibration and noise emissions

during actual use of the product can dier from

the declared values depending on the type of

work and the material upon which it is used.

Before each use, estimate the likely exposure

resulting from the actual conditions of use.

Take into account all parts of the operation

cycle in order to identify any safety measures

required to protect the operator.

*Draper Tools recommends using an additive or stabiliser

with E10 petrol so the fuel can be safely stored in the fuel

tank for longer.

4. Health and Safety Information

– 6 –

EN

Important: Read all the Health and Safety instructions

before attempting to operate, maintain or repair this

product. Non-compliance with these instructions may

result in injury or damage to the user or the product.

4.1 General Health and Safety

Precautions for Agricultural Equipment

• Only personnel who have read and understood this

manual in full and are familiar with the operation,

safe working techniques and safety features of this

machine may operate, adjust or maintain this product.

− DO NOT allow anyone who is unfamiliar with

this product or unqualied in its use to operate

this machine.

− This machine is not intended for use by persons

with reduced physical, sensory or mental

capabilities or lack of experience and knowledge

unless they have been given supervision or

instruction in its use by a person responsible for

their safety.

− Keep this product out of reach of children at

all times.

• Observe all standard safety precautions and good

practices when working with machines and

mechanical drilling tools in an outdoor environment.

• DO NOT modify this product in any way and ONLY use

spare parts supplied by Draper Tools.

• Use this product only in the manner described in

this manual.

• ONLY use this product with the attachment tools and

accessories supplied.

− NEVER use this machine with any other tools or

accessories attached.

• Use this product only in exterior and well-ventilated

environments.

• Keep your work environment clear and well-lit,

with bystanders at a safe distance.

− Work ONLY in daylight or good articial light.

− NEVER work while children or pets are nearby.

• Before every use, inspect the product and all

accessories for broken, cracked, loose or corroded

parts and leakages.

Important: DO NOT use this product if it is damaged

or leaking in any way. Contact Draper Tools to discuss

repair and replacement options. DO NOT use

damaged or worn blades.

• DO NOT use this product if you suspect that it

has been subjected to sharp knocks or it has

been dropped.

• Ensure that all safety features are in good working

order before EVERY use.

− DO NOT use this product if any of the safety

features, including the safety lanyard, are missing

or faulty, or the machine cannot be switched on

and o using the ignition switch.

− DO NOT tamper with or disable any of the safety

systems employed by the machine.

− DO NOT operate this tool if the safety lanyard is

not connected to your person.

− ALWAYS ensure that all safety labels are visible

before use.

• Keep in mind that the operator is responsible for

accidents or hazards occurring to other people or

their property while using this machine.

• DO NOT operate this machine if you are tired or under

the inuence of alcohol, drugs or other medication.

• Be aware of your surroundings and stay alert to any

hazards that may arise that are concealed by the noise

of the machine.

• ALWAYS ensure that the machine is positioned safely

and is unobstructed when starting the engine.

• Keep a rm and secure grip on both handles

during use.

− Grip the machine by the designated insulated

areas ONLY as the bit blades may come into

contact with live wires, which may cause an

electric shock.

− Keep all handles dry and free from grease or other

substances that may cause you to lose control of

the machine.

• Keep hands, feet and other body parts away from

moving parts at all times.

• DO NOT overreach and maintain good balance while

using the tool.

• DO NOT touch the engine or exhaust during or

immediately after use.

• DO NOT leave the machine running unattended under

any circumstances.

• DO NOT refuel the machine while it is running.

• Unless an emergency occurs, reduce the throttle

during engine shut down before turning o the

ignition switch.

4. Health and Safety Information

– 7 –

EN

• Maintain the machine appropriately and correctly to

prevent damage to moving parts and mechanisms.

− Keep all attachments and xings tight to ensure

the machine is in a safe working condition.

− Replace worn or damaged parts immediately.

− Replace faulty silencers.

− Keep air vents free from dust and debris.

− ONLY have the machine serviced by authorised

and suitably qualied personnel.

• Remove all adjustment tools before use.

• DO NOT immerse this product in water or subject it to

wet conditions.

• DO NOT expose this product to frost.

• ALWAYS switch o the product, disconnect the spark

plug cover and allow the machine to completely stop

and cool before performing any adjustment,

maintenance or other inspection or transporting

the tool.

• Allow the engine to cool before storing it.

4.2 Additional Safety Information for

this Tool

• This product is suitable for drilling into soil ONLY.

NEVER attempt to drill into any other materials using

this machine.

• Wear appropriate personal protective equipment:

− Wear a protective safety helmet to protect from

projectile debris and falling materials.

− Wear safety goggles or a face shield to protect

against projectile debris.

− Wear noise-reductive ear defenders.

− Wear protective gloves.

− Wear protective knee shields.

− Wear slip-resistant protective footwear.

• In addition to personal protective equipment, dress

appropriately for the work:

− Wear durable, close-tting clothing that will not

get tangled or caught in moving parts.

− Wear substantial full-length trousers and long

sleeves.

− Keep long hair tied back and remove any long or

loose items of jewellery before use.

− DO NOT operate this machine while barefoot or

wearing sandals.

• DO NOT wield the machine in any way other than that

described in this manual.

• Operating this tool is physically demanding; maintain

good posture and balance while operating the tool

and take regular breaks to prevent injury from strain

or fatigue.

• NEVER work alone; always work in earshot of

someone who can come to your aid in the event of

an emergency.

• Thoroughly inspect the area where the tool is to be

used before operation.

− Identify any hidden objects such as wires or power

cables that may cause injury or damage if severed

by the tool.

− Identify and remove any obstructions or objects in

the intended path of the machine that might be

thrown into the air during operation.

• Operate this tool ONLY on at, level ground.

− NEVER operate this tool on sloped ground.

• NEVER operate this tool above shoulder height or on

a platform or ladder.

• Start the engine carefully, only when the required bit

has been installed and the tool is in the correct

operating position.

• Before EVERY use, test that the bit does NOT rotate

while the engine is idling.

− If the bit operates while the engine is idling,

contact Draper Tools for support.

• If the tool vibrates abnormally during use,

immediately stop the engine, allow it to cool and

investigate the cause.

− DO NOT use the tool until the issue has been

resolved.

• DO NOT allow soil to accumulate on the auger bit

blade as this will obstruct the ejection of soil from the

hole and may cause the tool to operate heavily.

• To reduce the risks associated with prolonged

exposure to vibrations through the handles, avoid

operating the machine for longer than necessary and

do not use excessive engine speeds.

• DO NOT operate the engine in conned spaces where

dangerous carbon monoxide fumes can collect.

• NEVER transport the tool between positions with the

auger bit in motion.

• NEVER drain the fuel tank inside.

4. Health and Safety Information

– 8 –

EN

• Ensure all appropriate safety precautions are

observed when transporting the machine:

− Remove the bit from the tool before

transporting it.

− When transporting the product by hand,

maintain a rm grip on both handles and keep

the machine steady.

− When transporting the product in a vehicle,

lay the tool and accessories at and strap them

securely in place.

Important: Drain all fuel and oil from the product

before transporting it in a vehicle and ensure that

all reservoir caps are tightly sealed. Keep the

transportation unit well-ventilated.

Important: ALWAYS ensure that the machine is

switched o and the spark plug cover is disconnected

during transportation.

Important: To prevent injury, ALWAYS mark and secure

holes after operation so that they are easily visible.

4.3 Health and Safety Information for

Machines With a Petrol Engine

WARNING!

Petrol is highly ammable.

• Store fuel in containers specically designed for this

purpose.

• Refuel outdoors and DO NOT smoke while refuelling.

• Replace all fuel caps securely after use.

• Add fuel before starting the engine; never remove the

cap of the fuel tank or add petrol to the machine while

the engine is running or hot.

− Take care when opening the fuel cap after use as

hot vapour may be released from the opening.

• NEVER smoke in the vicinity of the machine.

• NEVER use this product in environments where there

is a risk of explosion.

• If petrol is spilled, DO NOT attempt to start the

engine; move the machine away from the spillage area

and avoid creating any source of ignition until the

petrol vapours have dissipated.

• The engine, exhaust and fuel get hot during use.

− DO NOT touch the engine during or immediately

after use and allow it to cool before refuelling.

− ALWAYS operate the tool with the exhaust

directed away from your body.

• NEVER place objects on the engine while it is in

use and keep all air vents clear of dust, dirt and

other obstructions.

• NEVER store the machine with fuel in the tank inside

any structure where petrol fumes could reach an open

ame or spark.

• To reduce the risk of re, keep the engine, silencer

and petrol storage area free from vegetation and

excessive grease.

WARNING! The machine exhaust emits toxic

carbon monoxide: a colourless, odourless gas.

Breathing exhaust fumes can cause loss of

consciousness, permanent respiratory damage

and eventually death. ONLY operate this machine

in a well-ventilated outdoor environment.

Important: E10 petrol is hygroscopic and attracts

moisture. Read all the preparation and maintenance

information relating to E10 fuel before using it in this

machine. Draper Tools recommends using an additive or

stabiliser with E10 petrol to extend the period that it can

be safely stored in the fuel tank. ALWAYS read the label

of any additive or stabiliser applied.

4.4 Residual Risk

The safety instructions in this manual cannot account for

all possible conditions and situations that may occur.

Exercise common sense and caution when using this

product and protect against any additional conceivable

risks.

5. Identication and Unpacking

5.1 Product Overview

– 9 –

EN

(1) Air lter cover

(2) Auger bit

(3) Carburettor

(4) Choke lever

(5) Connection pin

(6) Drive shaft

(7) Exhaust

(8) Fuel tank

(9) Fuel tank cap

(10) Handlebars

(11) Ignition switch

(12) Lanyard activation point

(13) Pilot drill

(14) Priming bulb

(15) Recoil starter

(16) Safety wrist lanyard

(17) Spark plug cover

(18) Throttle lever

(1)

(3)

(2)

(7)

(4)

(17)

(18)

(5)

(9)

(14)

(18)

(10)

(16)

(11)

(12)

(15)

(13)

(8)

(6)

5. Identication and Unpacking

Please visit drapertools.com for our full range of accessories and consumables.

– 10 –

EN

5.3 Packaging

Keep the product packaging for the duration of the

warranty period for reference should the product need to

be returned for repair.

WARNING! Keep packaging materials out of

reach of children. Dispose of packaging

correctly and responsibly and in accordance

with local regulations.

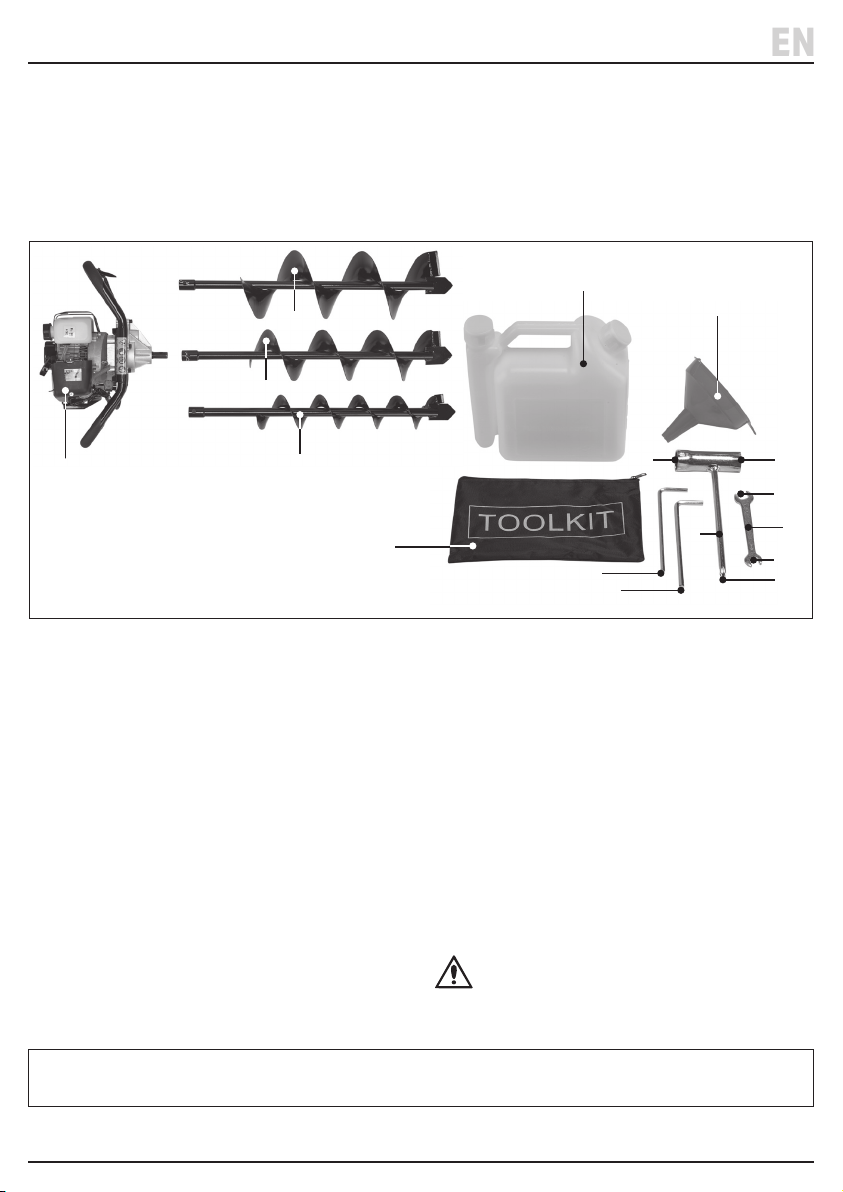

(A) 1 x Engine unit

(B) 1 x Ø 200mm bit

(C) 1 x Ø 150mm bit

(D) 1 x Ø 100mm bit

(E) 1 x Two-stroke mixing bottle

(F) 1 x Funnel

(G) 1 x Spanner driver

(G1) 19mm (M12) box spanner

(G2) 17mm (M10) box spanner

(G3) PH-type screwdriver

(H) 1 x Combination spanner

(H1) 10mm (M6) spanner

(H2) 8mm (M5) spanner

(I) 1 x 5mm hex key

(J) 1 x 4mm hex key

(K) 1 x Tool bag

5.2 What’s in the Box?

Carefully remove the product from the packaging and

examine it for any signs of damage that may have

occurred during shipment.

Before assembling the product, lay the contents out and

check them against the parts shown below. If any part is

damaged or missing, do not attempt to use the product.

Please contact the Draper Helpline; contact details can

be found at the back of this manual.

(A)

(B)

(C)

(D)

(E)

(F)

(H)

(H2)

(G3)

(H1)

(G2)(G1)

(J) (I)

(G)

(K)

– 11 –

EN

6. Preparation Instructions

Important: Read all the Health and Safety guidance for

use of petrol as a fuel before lling or otherwise

preparing this product.

6.1 Fuelling the Auger

CAUTION! This machine is shipped WITHOUT

fuel. Check the fuel level before EVERY use and

top up as appropriate. NEVER attempt to run the

engine on an empty fuel tank.

Important: ALWAYS ensure that the correct type and

mixture of fuel and oil is used. Damage caused by failure

to add fuel or by the use of incorrect or poor-quality fuel

is not covered by your warranty.

The engine on this machine requires a mixture of petrol

and oil to run. The mixture must contain the following

components and quantities:

Component Quantity Notes

Petrol 25 parts Only use fresh, clean and

good-quality unleaded

automotive petrol.

Oil 1 part Only use high-quality

two-stroke synthetic oil.

DO NOT use any other type

of oil, including engine oil,

as this will permanently

damage the engine.

ALWAYS use automotive petrol. Draper Tools

recommends E10 (95 RON) automotive fuel,

with an appropriate additive or stabiliser, for use

with this product.

CAUTION! E10 petrol is hygroscopic and

attracts moisture, which may damage the

fuel system if stored in the product for more

than four weeks. See Using E10 Petrol below

for guidance.

WARNING! ALWAYS mix fuel in a well-ventilated

area away from sources of ignition. Store fuel

only for short periods, away from direct

sunlight and heat sources, and only in

containers specically designed for that

purpose. Avoid prolonged contact with the

skin and inhalation of petrol vapour.

Important: The engine unit MUST be in an upright

position when fuel is added.

To fuel the machine:

1. Disconnect the spark plug cover (17).

1 Fig.

2. Mix the fuel and oil:

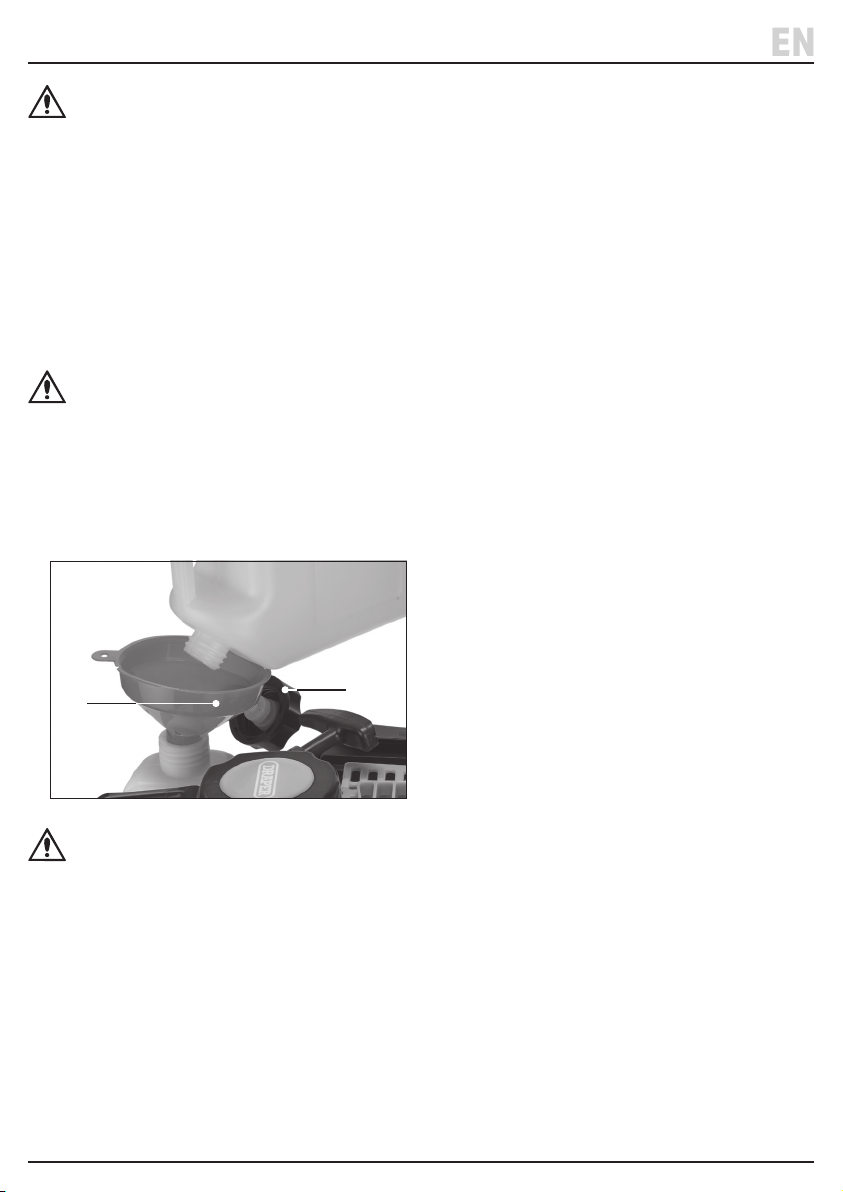

2 Fig.

a. Holding the two-stroke mixing bottle with the

25:1 marking (19) visible, remove the bottle fuel

cap (20).

b. Pour unleaded petrol through the fuel cap opening

until the 10 level mark on the main reservoir (21)

is reached.

c. Remove the bottle oil cap (22) and pour two-stroke

oil through the opening until the 10 level mark on

the ancillary reservoir (23) is reached.

d. Ensure that both caps are tightly tted and tip the

mixing bottle to allow all of the oil to run into the

main reservoir through the openings at the top of

the bottle (24).

e. Shake the bottle gently to thoroughly mix the fuel

and oil.

(17)

25.1

10

(19)

(23)

(22) (20)

(21)

55

10

(24)

Fill fuel

to here

Fill oil

to here

– 12 –

EN

6. Preparation Instructions

CAUTION! ALWAYS use the 25:1 scale on the

ancillary reservoir to measure the oil. Using the

incorrect mixture may cause permanent damage

to the engine. Damage caused in this manner is

not covered by your warranty.

Important: Only mix as much fuel as is necessary

for the operation as fuel quality degrades rapidly.

When measuring dierent amounts of fuel, ll the

ancillary reservoir with oil to the corresponding

level mark.

3. Twist the fuel tank cap (9) anticlockwise to remove it

and allow it to hang clear of the opening.

WARNING! If the tool has been recently used,

hot steam may vent from the fuel tank outlet.

Take care when opening the fuel tank.

4. Using the funnel (F), carefully pour the fuel mixture

into the fuel tank so that the level is just below the

ller neck.

The fuel tank should accommodate a little more than

one full mixture from the two-stroke mixing bottle.

3 Fig.

CAUTION! DO NOT overll the fuel tank as this

may damage the engine. NEVER allow dust,

dirt, water or dirty fuel to enter the fuel tank.

Clean up any spillages IMMEDIATELY.

5. Reattach the fuel cap, ensuring it is properly tted

and securely tightened.

6. Reconnect the spark plug cover when the machine is

ready for use.

A 25:1 ratio can alternatively be considered as adding

40ml of oil to 1L of fuel.

Using E10 Petrol

All Draper petrol products are compatible with E10

petrol. However, due to the increased ethanol level,

E10 petrol is hygroscopic: this means that it attracts and

mixes with water from the air, which accumulates in the

engine and the petrol deteriorates more quickly. If E10

petrol is stored in a machine’s fuel tank for extended

periods, this build-up of water can form a corrosive gum

that rusts the fuel system from the inside.

Draper Tools recommends the use of petrol additives or

stabilisers when using E10 petrol. Additives and

stabilisers are widely available and can extend the length

of time that E10 petrol can be safely stored in a product

fuel tank.

The impact of additives or stabilisers on the lifespan of

the fuel varies with each product and will deteriorate over

time – always read the label. E10 petrol should not

remain in the fuel tank for more than four weeks without

an additive or stabiliser.

Even where additives or stabilisers are used, Draper Tools

recommends that E10 fuel is drained from the fuel tank

every three to four weeks to reduce the risk of damage to

the product. The fuel must be drained from the fuel tank

within the time limit specied by any additives or

stabilisers added to the fuel. If the machine will not be

used for longer than this time, drain it before putting it

into storage.

After draining the fuel tank, always run the engine until

the last of the fuel in the system is spent and drain the

oat bowl when the engine is cool.

E10 petrol should be used within 30 days of purchase.

Some petrol brands contain other quantities of ethanol.

DO NOT use fuels with more than 10% ethanol in

Draper products.

Always store and dispose of fuels responsibly and in

accordance with local regulations.

(9)

(F)

– 13 –

EN

6. Preparation Instructions

6.2 Attaching the Auger Bit

Important: DO NOT connect any auger bit to this tool

that has not been supplied with this product. Other auger

bits may be unsuitable for the engine or t incorrectly

and result in injury or cause damage to the tool.

WARNING! Never use an auger bit if the

R-pin or locking bar is missing, damaged or

signicantly corroded.

1. Remove the R-pin (25) from the locking bar (26) and

slide the locking bar away from the auger bit.

4 Fig.

2. Install the auger bit onto the engine unit drive shaft

(6) and align the holes.

5 Fig.

3. Insert the locking pin and secure it in place with

the R-pin.

4. Pull outwards on the auger bit to ensure that it is

securely held in place.

(25)(26)

(6)

– 14 –

EN

7. Operating Instructions

Important: Before operating this product, read and

understand all the safety instructions listed in

this manual.

WARNING! DO NOT start the machine until the

auger bit and safety lanyard have been installed.

This machine must be operated with both hands

(one on each handle) at all times.

WARNING! Using this tool can pose a danger to

wildlife. Before attempting to use the auger,

check the area – particularly in long grass and

under bushes – for signs of life and responsibly

relocate any creatures found there if necessary.

Not all wildlife will be deterred by the noise of

this machine alone.

7.1 The Safety Wrist Lanyard

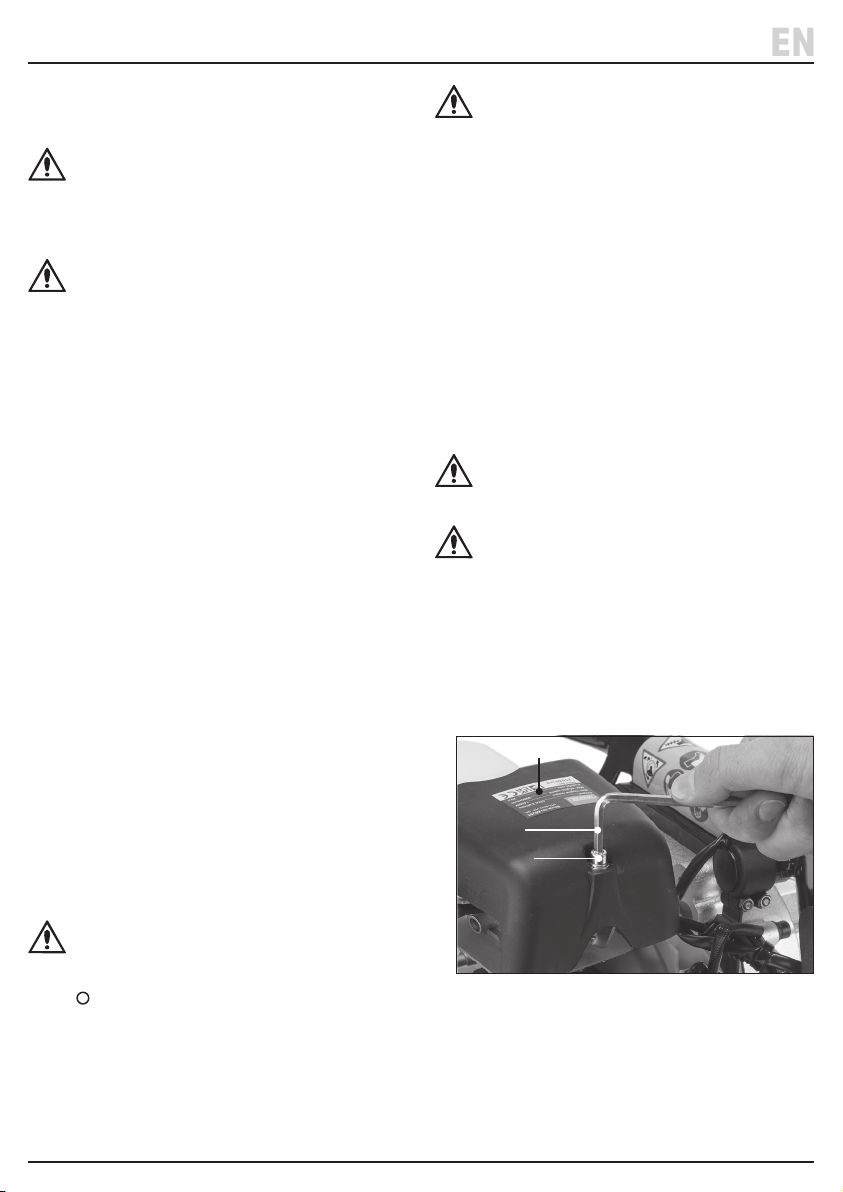

The safety wrist lanyard (16) must be installed in order to

use this product and acts as a safety cut-o should you

lose control of the tool.

WARNING! DO NOT use this tool if the safety

wrist lanyard is damaged or weakened. If the

lanyard cord breaks, it will not cut power to

the engine.

6 Fig.

The lanyard is pre-installed onto the engine unit before

shipment. If it has been removed, push the cup end of the

lanyard rmly onto the lanyard activation point (12).

Wrap the other end of the lanyard around your wrist and

use the clip to secure it. If you lose your grip on the tool

during operation, the lanyard cup will be pulled from the

engine unit and stop the tool, allowing you to regain

control safely.

Important: If the safety wrist lanyard is not installed,

the auger will NOT operate.

7.2 Starting the Engine

CAUTION! This machine is NOT shipped with

fuel or oil. DO NOT attempt to start the engine

until an appropriate mix of fuel and oil has been

added to the tool.

WARNING! DO NOT start this tool until the

appropriate auger bit has been securely

installed. Read all the safety and operation

instructions in this manual before use.

Important: DO NOT start the machine until it is in

its operating position at the location to be drilled.

NEVER travel with the machine switched on.

WARNING! DO NOT start this tool unless the

safety wrist lanyard is correctly installed onto

the engine unit and is secured around your

wrist. Failure to connect the lanyard to your

person disables one of the safety features of

this tool and is prohibited.

Performing a Cold Start

1. Ensure that the spark plug cover (17) is

connected and move the ignition switch (11) into

the on ( I ) position.

7 Fig.

(11)

(16)

(12)

– 15 –

EN

7. Operating Instructions

2. Slide the choke lever (4) to the closed ( ) position.

8 Fig.

3. Press the priming bulb around six times until fuel can

be see owing through the clear hose from the fuel

tank (8) to the carburettor (3).

9 Fig.

CAUTION! Over-priming the engine will cause it

to be ooded with too much fuel, which may

immerse the spark plug and prevent the engine

from starting. The engine will smell strongly of

fuel if this occurs.

4. Slowly pull on the recoil starter (15) until resistance is

felt, then pull it out rapidly.

10 Fig.

CAUTION! DO NOT attempt to start the engine

when the recoil starter is fully retracted.

DO NOT allow the recoil starter to snap back

against the engine. Return it gently to prevent

damage to the starter.

5. Do this several times until the engine starts.

6. Allow the engine to run for a few seconds, then open

the choke slightly.

7. After a further few seconds, move the choke lever

fully to the open ( ) position.

8. Gently press the throttle lever (18) to engage the drive

shaft, then increase pressure on the throttle lever to

start the operation.

Performing a Warm Start

1. Ensure that the spark plug cover (17) is

connected and move the ignition switch (11) into

the on ( I ) position.

11 Fig.

(8)

(3)

(11)

(15)

(4)

– 16 –

EN

7. Operating Instructions

2. Slide the choke lever (4) to the open ( ) position.

12 Fig.

3. Slowly pull on the recoil starter (15) until resistance is

felt, then pull it out rapidly.

13 Fig.

CAUTION! DO NOT attempt to start the engine

when the recoil starter is fully retracted.

DO NOT allow the recoil starter to snap back

against the engine. Return it gently to prevent

damage to the starter.

4. Do this several times until the engine starts.

If the engine does not start after the fth attempt

during a warm start, attempt a cold start.

5. Allow a few seconds for the engine to reach its

working temperature, then gently press the throttle

lever (18) to engage the drive shaft.

6. Increase pressure on the throttle lever to begin the

operation.

Important: If the auger bit rotates while the engine is

idling, switch o the engine immediately and contact

Draper Tools for support.

CAUTION! The internal components of the

engine will undergo a bedding-in period during

the rst few uses.

For the rst six tanks of fuel, avoid running the

engine at high revolutions as the stress during this

bedding-in period may cause damage to the

engine. The clutch may also slip more frequently

during this period.

7.3 Notes on Use

During operation, hold the earth auger in a vertical

position and grip it rmly with both hands at all times.

Stand comfortably with your legs slightly apart and the

auger centrally in front of you to maintain a stable and

well-balanced position. Ensure that your legs and body

stay clear of the drilling area.

Position the auger engine unit so that the exhaust (7) is

directed away from you. This also ensures that, should

the auger bit catch in the soil, the engine recoil will pull

the throttle lever out of your grip and the bit will stop

turning. Brace yourself against sudden recoil caused by

contact with hidden rocks, roots and other debris

beneath the surface.

Apply rm downward pressure onto the handlebars

throughout the operation, but DO NOT force the tool;

let the tool do the work.

Draper Tools recommends beginning the operation

using half-throttle speed and gradually increasing

pressure on the throttle lever (18), particularly when

boring deeper holes.

Important: ALWAYS mark and secure holes after

operation so that they are easily visible to prevent injury

to others.

(15)

(4)

– 17 –

EN

Important: Maintenance and repairs should be carried

out ONLY by authorised and suitably qualied personnel.

WARNING! ALWAYS switch o the engine,

disconnect the spark plug cover and allow the

machine to cool before maintaining this

product. Remove any auger bit from the engine

unit before performing any maintenance.

WARNING! If the engine must be run for testing,

ensure that this is carried out in a well-ventilated

environment that allows carbon monoxide from

the exhaust to dissipate quickly.

Regular and thorough maintenance will contribute to an

extended life of the product. Poor maintenance can lead

to reduced performance and rapid deterioration of the

engine and blades.

8.1 General Maintenance

• Keep all air vents clean and free from obstructions at

all times.

• Clean the machine with a damp cloth ONLY.

Important: DO NOT use solvents as this may damage

the plastic parts of the machine.

• Use ONLY spare parts supplied by Draper Tools.

• Keep all auger bits free from debris and clean them

after every use.

− Wear protective gloves while maintaining the

auger bits.

− Use a brush or other tool to remove debris from

cutting parts; NEVER use your bare hands.

• Replace auger bits when they became damaged or

excessively worn.

8.2 Draining the Fuel

Important: Read all the Health and Safety guidance

for the use of petrol as a fuel before lling or draining

this product.

WARNING!

NEVER drain the fuel tank indoors.

1. Ensure that the ignition switch (11) is in the

o ( ) position and the spark plug cover (17)

is disconnected.

2. Remove the fuel tank cap (9) slowly and tip the

engine unit backwards to allow the fuel to drain

into a suitable container.

WARNING! If the tool has been recently used,

hot steam may vent from the fuel tank outlet.

Take care when opening the fuel tank.

3. Reattach the fuel tank cap securely and wipe up

any spillages.

4. Reconnect the spark plug cover and start the engine;

see 7.2 Starting the Engine.

5. Allow the engine to run until it cuts out; this exhausts

any fuel remaining in the carburettor.

8.3 Air Filter Care

Clean the air lter chamber and element regularly

to ensure consistent airow into the carburettor.

Increase the frequency of cleaning when working in

dusty environments.

WARNING! NEVER use petrol or solvents to

clean the air lter elements as this may result in

a re when the machine is next used.

CAUTION! NEVER run the machine without the

air lter elements in place as this may cause the

engine to degrade rapidly.

1. Ensure that the choke lever (4) is in the closed

position to prevent any debris from entering

the carburettor.

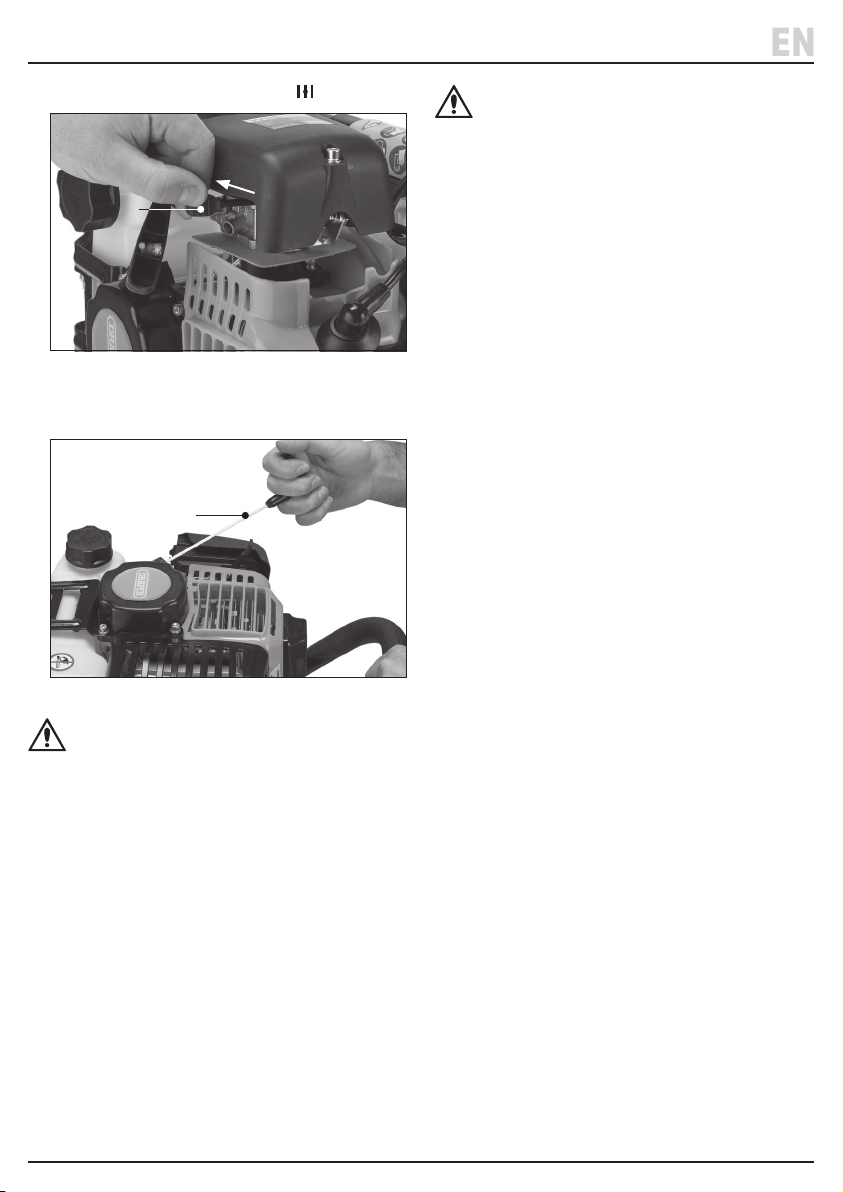

2. Use the 4mm hex key (J) to loosen and remove the

socket bolt (27) and washers that secure the air lter

cover (1) in place.

14 Fig.

Important: Ensure that the washer and spring washer

remain in the correct positions on the bolt.

8. Maintenance and Troubleshooting

(J)

(27)

(1)

– 18 –

EN

3. Open the air lter housing and remove the foam

element; check it for holes, tears and obstructions.

15 Fig.

Important: If the foam element is damaged, replace it

with a new one. DO NOT use the machine if the air

lter is damaged.

4. Wash the element in warm soapy water and

allow it to dry thoroughly.

Important: DO NOT use solvents to clean

the element.

5. Clean the compartment and covers of any dust,

dirt or other obstructions.

6. Reassemble the air lter and screw in the socket bolt

and washers to secure the housing back in place.

8.4 Spark Plug Care

Ensure that the spark plug is clean and correctly gapped.

The spark plug may become contaminated over time if

the machine is run with part-throttle for prolonged

periods or the fuel mixture contains too much oil.

Important: Replace the spark plug after every 60 hours

of use or at least once a year. ONLY use L7TC or similar

compatible spark plugs with the same heat range.

1. Remove the spark plug cover (17).

16 Fig.

Important: DO NOT use tools to remove the cover as

it may damage the HT lead.

2. Use the M12 box spanner (G1) to loosen and remove

the spark plug from the socket.

17 Fig.

3. Visually inspect the spark plug and replace it if the

ceramic insulator is cracked or chipped.

4. Measure the spark plug gap using a feeler gauge

(not supplied) and correct as appropriate by gently

bending the electrode into position.

Important: The gap should be 0.6–0.7mm.

8. Maintenance and Troubleshooting

(G1)

(17)

– 19 –

EN

8. Maintenance and Troubleshooting

5. Attach the spark plug washer and thread the plug into

place by hand.

Important: If mounting a new spark plug, use the

spark plug wrench to screw the spark plug an

additional half rotation after hand-tightening to the

point that the washer is compressed. If mounting an

old spark plug, screw no more than up to an

additional quarter rotation as appropriate.

6. Replace the spark plug cover securely.

CAUTION! The spark plug MUST be securely

tightened. Loose spark plugs can become very

hot and cause damage to the engine. NEVER use

a spark plug with a heat range that is not

appropriate for the machine in which it is used.

8.5 Replacing the Fuel Filter

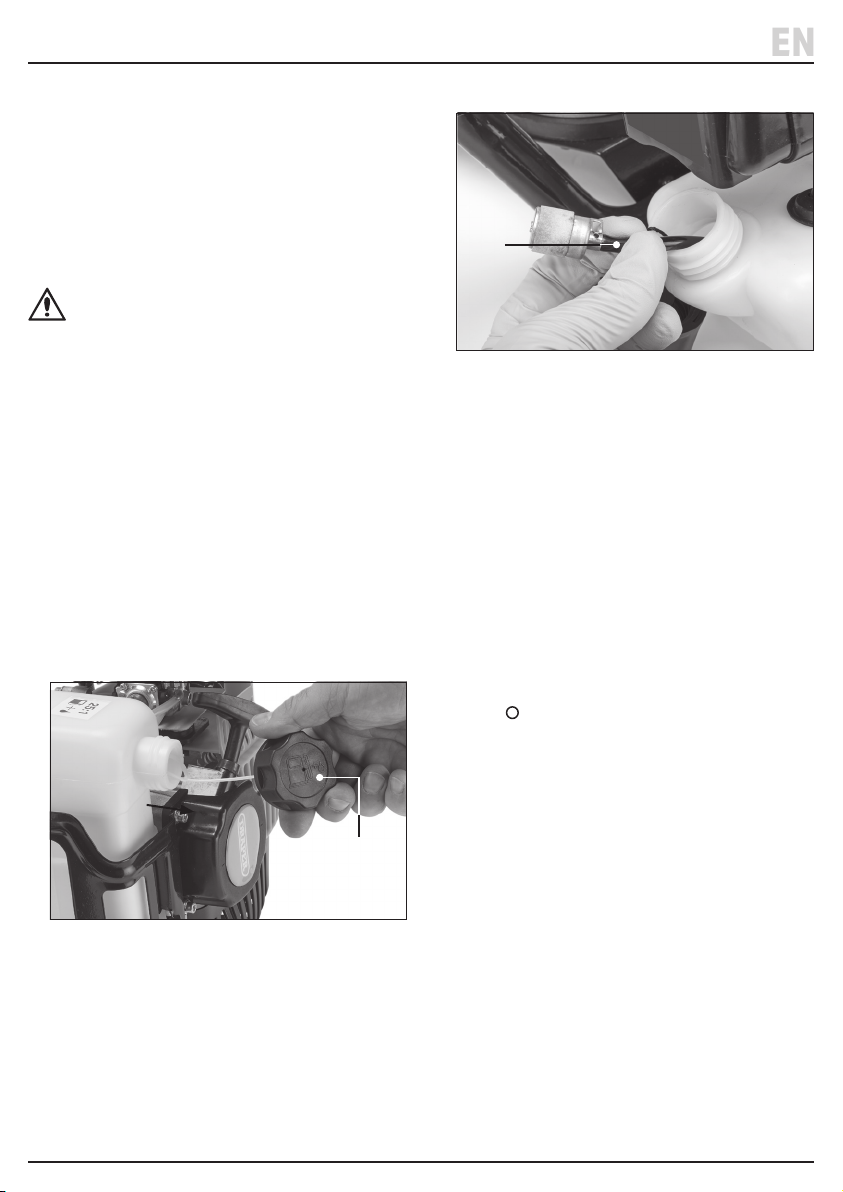

A small fuel lter is installed inside the fuel tank (8) to

ensure that the feed of fuel into the carburettor remains

clean. This lter must be checked regularly and replaced

when it becomes clogged.

Important: Wear protective gloves to protect your hands

from the fuel.

1. Completely drain the fuel from the fuel tank;

see 8.2 Draining the Fuel.

2. Gently pull on the fuel tank cap (9) to draw the spring

clip out of the tank.

18 Fig.

3. Tilt the engine so that the fuel tank opening is at the

lowest point and rmly shake the unit to allow the

lter to fall within reach.

If the lter does not fall towards the opening, the fuel

pickup line can be manoeuvred by reaching inside

the fuel tank.

Important: Be wary of dripping fuel when reaching

inside the fuel tank to remove the lter.

4. Gently pull the lter out of the fuel tank opening.

19 Fig.

5. Without letting go of the fuel pickup line (28),

detach the lter from the end of the tube.

6. While still holding the fuel pickup line, insert a

new lter onto the tube and insert it back into the

fuel tank.

7. Push the cap spring clip back into the fuel tank and

tighten the cap in place.

8.6 Storing the Product

Important: ALWAYS ensure that the engine has

completely cooled before storing the machine.

• Prepare the machine correctly for storage:

− Ensure that the ignition switch is in the

o ( ) position.

− Disconnect the spark plug cover (17).

− Drain the fuel (see 8.2).

− Remove, clean and dry the auger bits.

− Tighten all reservoir caps and leakage points.

− Cover the machine with a plastic sheet to protect

it against dust and moisture.

• Store the machine and attachments in a dry and

dust-free environment, out of reach of children.

• Store the machine at a temperature of 0–30°.

• Start the engine at periodic intervals to prevent

seizure within the engine and driveshaft.

(28)

(9)

– 20 –

EN

8. Maintenance and Troubleshooting

If the machine is to be stored for a prolonged period,

ensure that the engine cylinder is suciently lubricated

to prevent it from seizing:

1. Remove the spark plug; see 8.4 Spark Plug Care.

2. Pour a few drops of SAE 5W-30 oil into the socket.

3. Pull the recoil starter (15) slowly to distribute the oil.

4. Return the spark plug securely to the socket.

5. When restarting after storage:

a. Remove the spark plug.

b. Hold a cloth around the spark plug socket opening.

Important: DO NOT smother or completely cover

the opening.

c. Pull on the recoil starter several times and

catch any ejected oil using the cloth.

Do this until no more oil is ejected from

the opening.

d. Return the spark plug securely to the socket

e. Start the engine in the usual way;

see 7.2 Starting the Engine.

Other manuals for GPAUG52-B

1

This manual suits for next models

1

Table of contents

Other Draper Tools manuals

Draper

Draper 28357 User manual

Draper

Draper TK58/BL Operation manual

Draper

Draper GPAUG52-B User manual

Draper

Draper Storm Force SFAH4 User manual

Draper

Draper PTF User manual

Draper

Draper 98421 User manual

Draper

Draper 18745 User guide

Draper

Draper 27118 User guide

Draper

Draper A10/EXP/F User manual

Draper

Draper 23313 User manual

Draper

Draper BC1000 User manual

Draper

Draper PT2000D User manual

Draper

Draper STORMFORCE MT400 User manual

Draper

Draper ALG33 User manual

Draper

Draper 17819 User guide

Draper

Draper DTK-FORD 52576 User manual

Draper

Draper 19141 User guide

Draper

Draper 19525 User manual

Draper

Draper PJSK User manual

Draper

Draper 4314K User manual