Stock Nos. .......................................................... 30586, 30587

Part Nos. ........................................................... ALG33, ALG34

Air supply pressure min ................................ 6.9 bar (100lbf-in2)

Air supply pressure max ............................. 13.8 bar (200lbf-in2)

Pressure range ....................................... 0-9.6 bar (0-138lbf-in2)

Air inlet ....................................................

1/4

" BSP taper (female)

Hose length....................................................... 0.5M (approx.)

Accuracy......................... EC directive (only bar scale approved)

FOR USE IN VEHICLE WORKSHOPS AND TYRE FITTING

BAYS. NOT RECOMMENDED FOR USE ON AIRCRAFT TYRES

ALWAYS WEAR EAR & EYE PROTECTION

Draper air tools have been carefully tested and inspected before shipment and are

guaranteed to be free from defective materials and workmanship for 6 months

from the date of purchase except where tools are hired out when the guarantee

period is ninety days from the date of purchase.

Should the machine develop any fault, please return the complete tool to your

nearest authorized warranty repair agent or contact Draper Tools Limited,

Chandler’s Ford, Eastleigh, Hampshire, SO53 1YF. England.

Telephone (023) 8049 4344.

If, upon inspection it is found that the fault occurring is due to defective materials

or workmanship, repairs will be carried out free of charge. This guarantee does not

apply to normal wear and tear, nor does it cover any damage caused by misuse,

careless or unsafe handling, alterations, accident, or repairs attempted or made by

any persons other than the authorized Draper warranty repair agent.

This guarantee applies in lieu of any other guarantee expressed or implied and

variation of its terms are not authorized.

Your Draper guarantee is not effective unless you can produce upon request a

dated receipt or invoice to verify your proof of purchase within the guarantee

period.

Please note that this guarantee is an additional benefit and does not affect your

statutory rights.

- IMPORTANT: Prior to installation of the air line gauge ensure

the air supply line is clear and drain off the compressor tank

and pipework. Connect the air line gauge to a pressure

vessel (tyre) and actuate the calibrated indicator assembly

approximately 10 operations up/down scale.

- ACCURACY: (EC DIRECTIVE 86/217)

This air line gauge has been calibrated in its normal working

position on test equipment with an accuracy that is traceable

to the UK National Standard through the National Physical

Laboratory Reference 08010/C4/1/P383 via a system of

calibration which includes Dead Weight Tester, Serial

No.4361, Piston Unit No.:A890. Dead Weight Tester

calibrated at Theta Systems Ltd. - Namas Laboratory No.409.

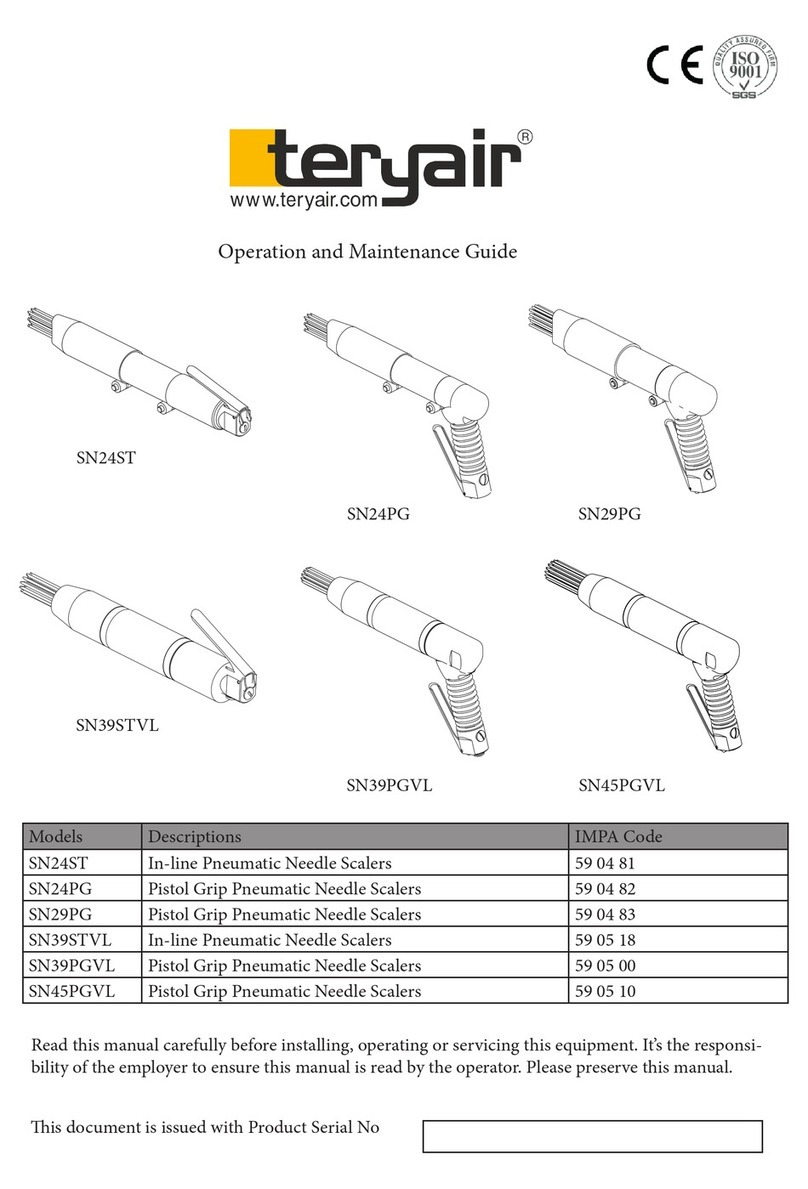

MODEL No. DESCRIPTION PART No. STOCK No.

ALG33 Hose & connector ass'y YRHA2121 30769

ALG34 Hose & connector ass'y YRHA2122 30770

ALG33 Twin hold connector YC01A03 30771

ALG34 Single clip-on connector YC02E03 30773

ALG33/34 Valve ass'y YSAS4115 30764

1. Always wear safety goggles or glasses.

2. Always ensure machine is switched off before connecting to air

supply.

3. Disconnect any machine from the air supply before changing

blades or discs, and before servicing any type of machine.

4. Always keep your air tool clean and lubricated. Daily lubrication is

essential to avoid internal corrosion and possible failure.

5. Do not wear watches, rings, bracelets or loose clothing when using

air tools.

6. Using only light weight coil hoses from a tool to the wall or

compressor coupling. Do not fit quick change couplings onto the

machine as vibration can cause the coupling to fail.

7. Do not overload the machine. Allow the tool to operate at its

optimum speed for maximum efficiency.

8. Do not increase the air pressure above the manufacturer's

recommended level, as excessive overload can cause the machine

casing to split. Also this creates excessive wear on moving parts

and possible failure.

9. In the interests of safety and possible damage to the

machine/operator, always ensure that the machine has stopped

before putting it down after use.

10. Always ensure that the workpiece is firmly secured leaving both

hands free to control the machine.

11. Always ensure that the accessories such as blades, discs, sockets,

etc. are rated/designed for use with the machine. Also correctly

and securely fastened before connecting the machine to the air

supply.

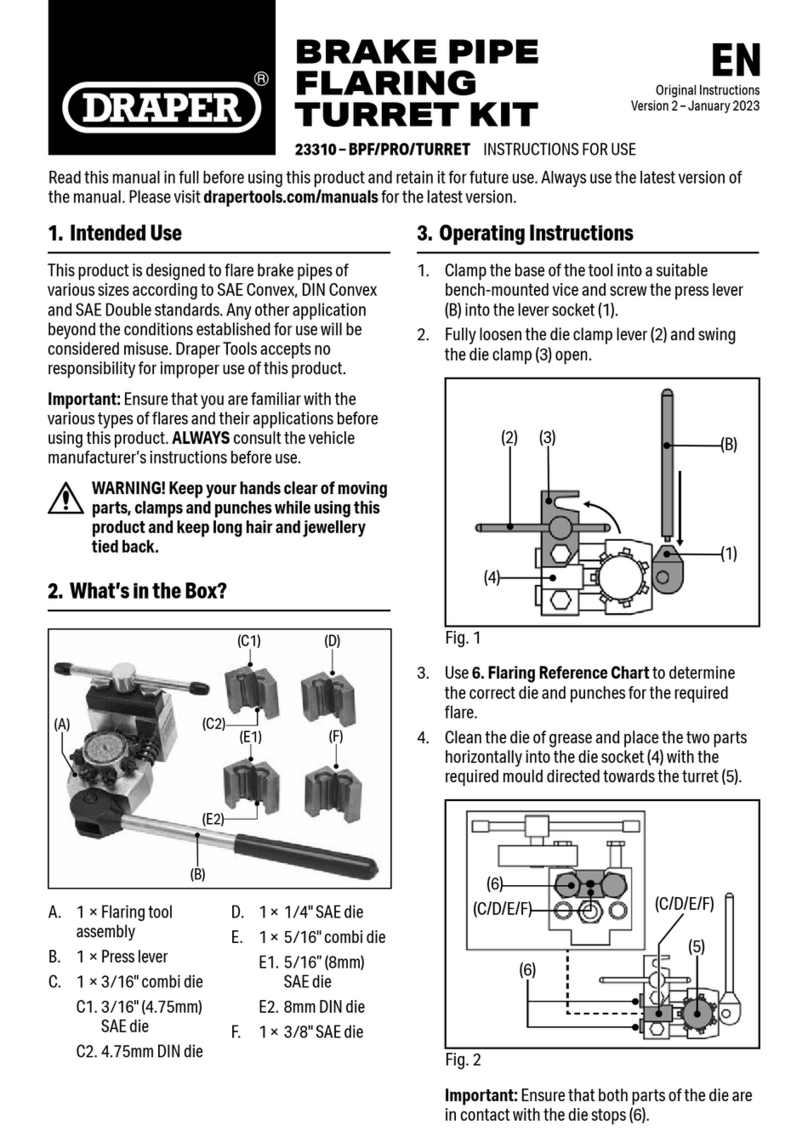

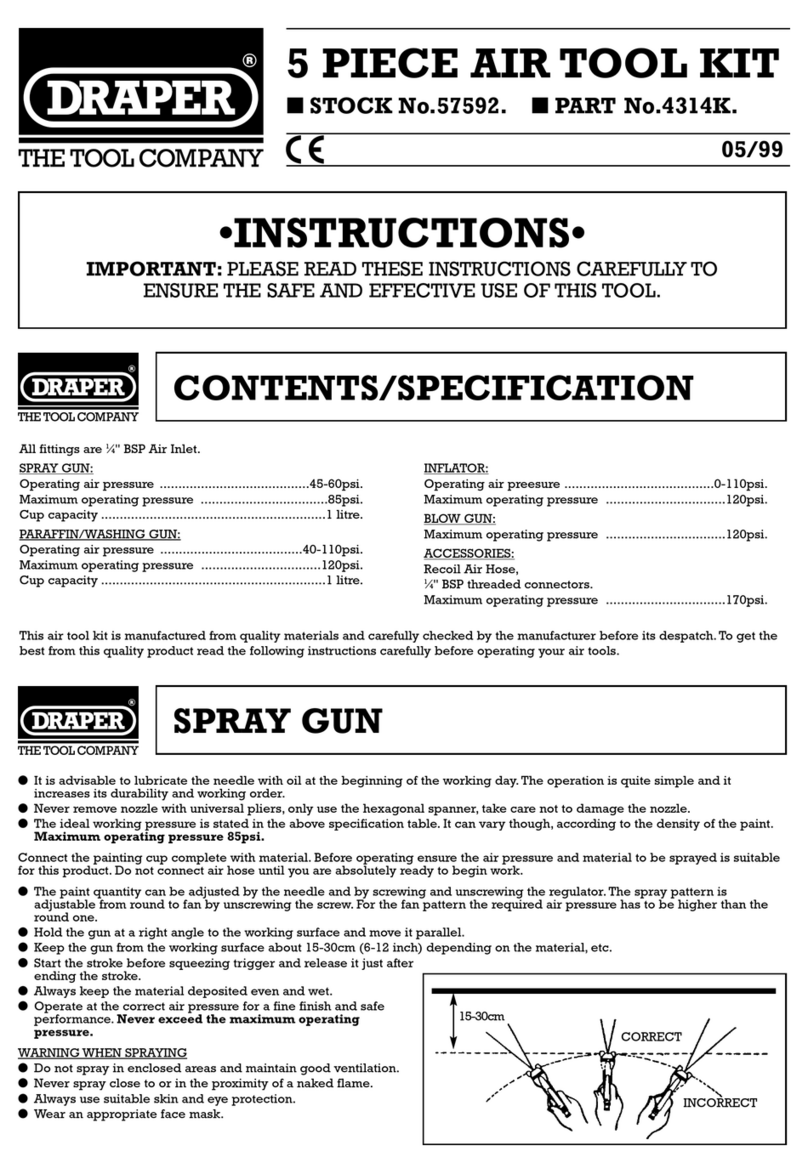

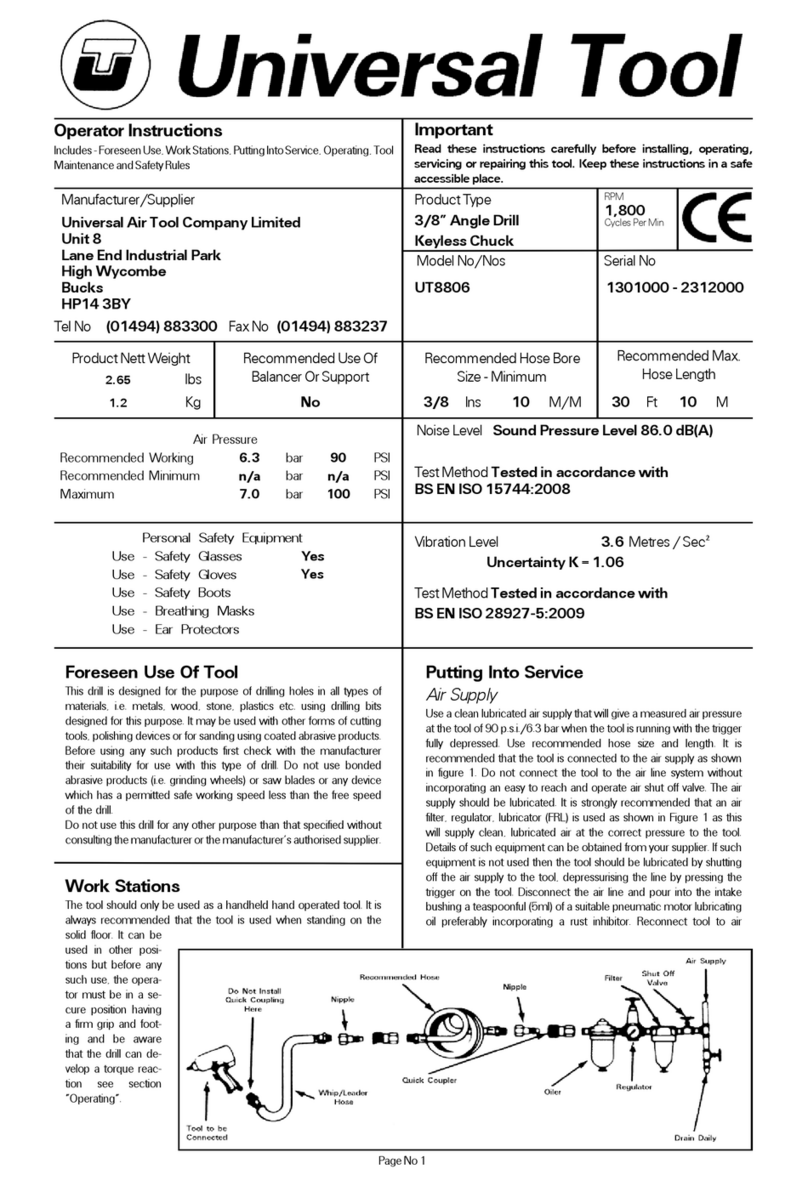

- AIR SUPPLY:

Tools in the range generally operate at a maximum

pressure of 13.8 bar (see specifications) and this should be

controlled via a combined regulator/water separator such

as the Draper 4222/4 unit which with proper

maintenance will ensure a constant supply of dry air at all

times. See Fig.1. Always check tool operating pressure

before use.

Water in the compressor tank will cause serious corrosion

to your air tools and should be drained daily to avoid

excessive water in your air supply. Dirty wet air rapidly

shortens the life of your air tool.

If you are using an air tool on a hose over 25ft. long it is

advisable to increase the bore of the hose to the next larger size available ie.1⁄4" increases 3⁄8". This will ensure adequate pressure and

volume of air to power the tool.

- OPERATION (Fig.1):

Air tools without inbuilt regulators vary the pressure on your air supply regulator.Push or clip the connector accordingly over the valve

to take the pressure reading. To inflate, fully depress the trigger and release to take the new pressure reading. To deflate, slightly

depress the trigger. Air will be heard to be escaping while this position is maintained. Remove connector from valve and replace valve

cover if applicable.

- NOTE: Observe manufacturer's inflation levels. Do not use on toy inflatables as damage will occur.

FIG.1 Leader Hose.

Quick Coupling.

Recoil Hose.

Nipple. Nipple.

Regualtor.

Water Separation.

Drain Daily.

Air Supply.

To your

Air Tool.

Do not install Quick

Coupling here.

SPECIFICATION GUARANTEE

ASSEMBLY

OPERATING INSTRUCTIONS

GENERAL SAFETY RULES

FOR AIR TOOLS PRODUCTS