Installation Instructions •Rexnord®Omega®Metric Couplings

(Page 1 of 4) Type E and ES • Sizes 2M-140M

Rexnord 80152M

5555 S. Moorland Rd., New Berlin, WI 53151-7953 June 2016

Telephone: 262-796-4060 Fax: 262-796-4064 www.rexnord.com Supersedes 428-313M

1. General Information

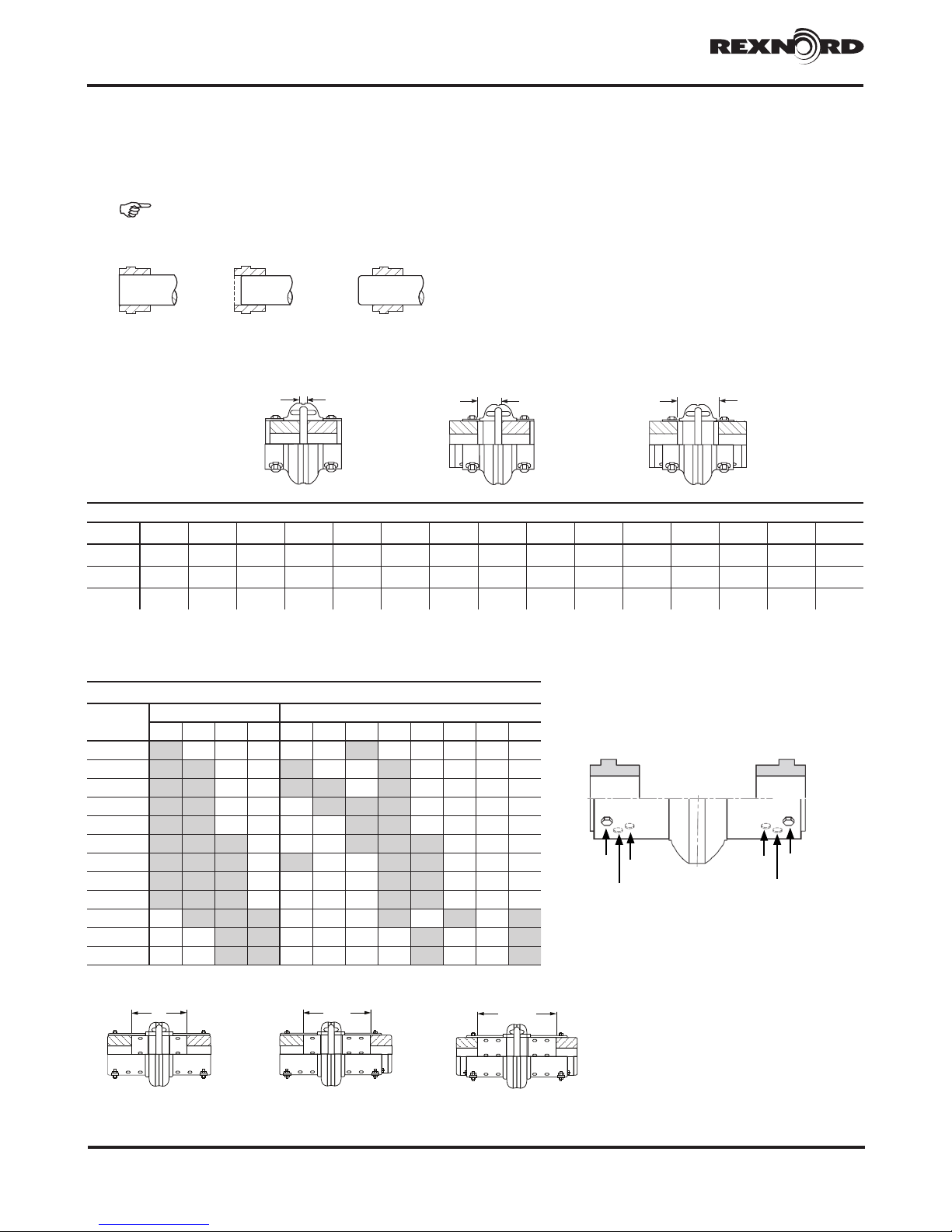

1.1. Omega Couplings are designed to provide a mechanical connection between the rotating shafts of mechanical equipment, using

a torsionally soft flexible element to accommodate inherent misalignment while transmitting the power and torque between the

shafts.

1.2. These instructions are intended to help you install and maintain your Omega coupling. Please read these instructions prior to

installing the coupling, and prior to maintenance of the coupling and connected equipment. Keep these instructions near the

coupling installation and available for review by maintenance personnel.

1.3. Rexnord Industries, LLC owns the copyright of this material. These Installation and Maintenance instructions may not be

reproduced in whole or in part for competitive purposes.

1.4. Symbol descriptions:

Danger of injury to persons.

Damages on the machine possible.

Pointing to important items.

2. Safety and Advice Hints

DANGER!

2.1. Safety should be a primary concern in all aspects of coupling installation, operation and maintenance.

2.2. All rotating power transmission products are potentially dangerous and can cause serious injury. They must be guarded in

compliance with OSHA, ANSI, ATEX and any other local standard for the applications they are used. It is the responsibility of the

user to provide proper guarding.

2.3. Failure to secure cap screws properly could cause coupling component(s) to dislodge during operation and result in personal

injury. See Table 3 for proper tightening torques.

2.4. Do not use on turbine drives if the coupling cannot be protected from steam leakage or overspeed situations beyond the

coupling’s published speed rating.

2.5. Before installing this coupling on systems involving sleeve bearings, herringbone gearsets or other axially sensitive devices,

consult Rexnord.

2.6. Elastomeric couplings can hold a static electric charge that may discharge and ignite in an explosive environment. Both shafts of

the connected equipment must have a path to ground.

3. Preventative Maintenance

DANGER!

Do not make contact with the coupling when it is rotating and/or in operation.

3.1. Periodic visual inspection is necessary to evaluate the condition of the flex element. Inspection can be done during the operation

using a strobe light.

3.2. When inspecting the element look for:

• Fatigue cracks at element splits, discoloration and surface cracking in body of element.

ATTENTION! Replace element if necessary.

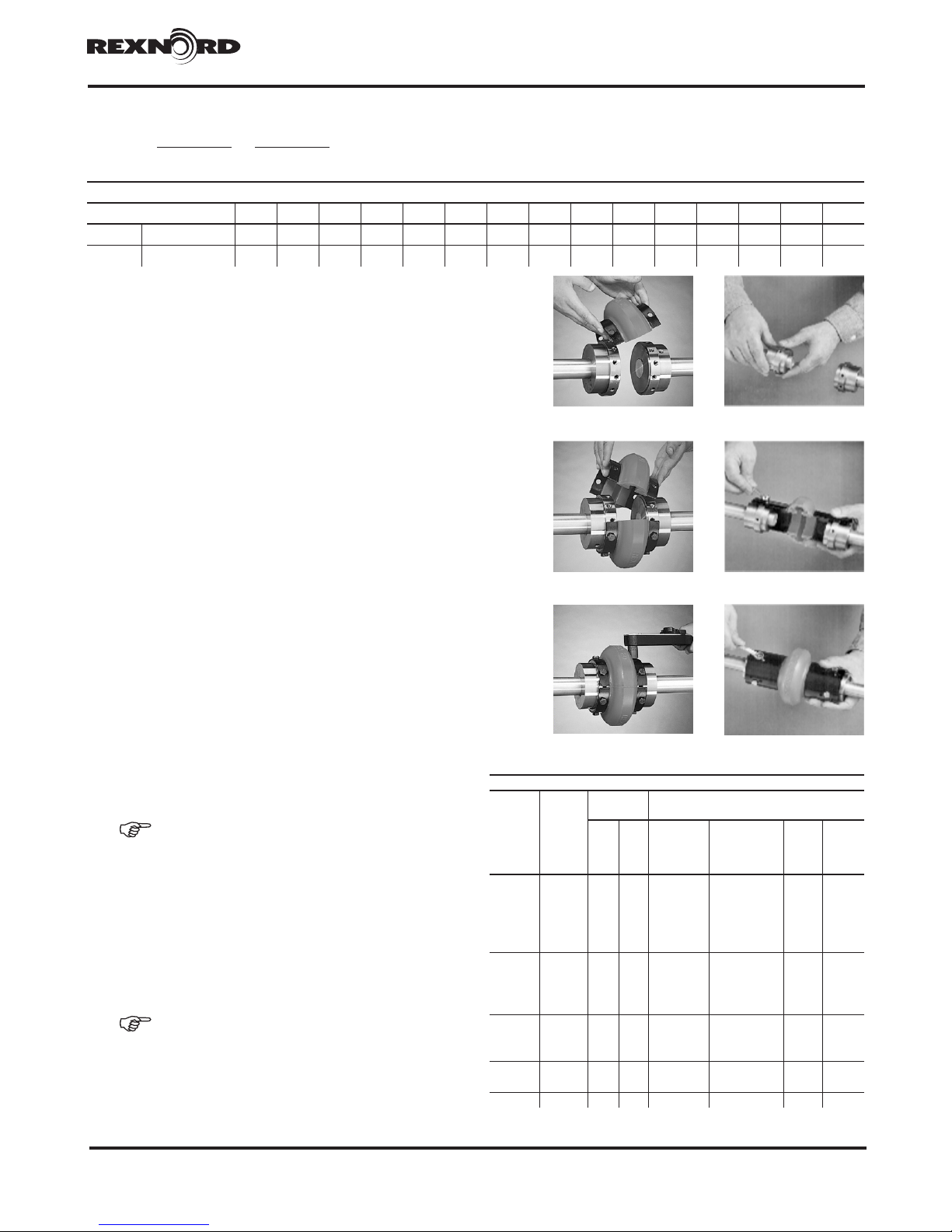

4. Element Replacement

DANGER!

Stop the motor and lock it out to prevent start-up during installation of coupling.

4.1. Always replace both half elements.

4.2. Install both half elements from the same box.

4.3. Follow installation instructions (see Section 7, Rexnord Omega Coupling Installation).

4.4. Tighten element cap screws to proper torque (see Table 3).

The designation ATEX (Atmosphere Explosibles) has established itself for the new guidelines. ATEX 100a controls all

regulations for the condition of explosion-proof equipment.

Model No. ___________________ Category____________________ Reference ___________________

Mfg Year ____________________ Max Temperature _____________