CONTENTS

0 Safety Instruction

0.1 Mechanical Injury----------------------------------------------------------------------------------------------- 2

0.2 Electrical Hazard------------------------------------------------------------------------------------------------ 2

0.3 Heat Injury--------------------------------------------------------------------------------------------------------2

0.4 The Injury from Materials------------------------------------------------------------------------------------- 3

0.5 Explosion Hazard----------------------------------------------------------------------------------------------- 3

0.6 Noise Hazard----------------------------------------------------------------------------------------------------- 3

0.7 Risk of Pump Damage------------------------------------------------------------------------------------------3

1 Overview

1.1 Summarize ------------------------------------------------------------------------------------------------------ 4

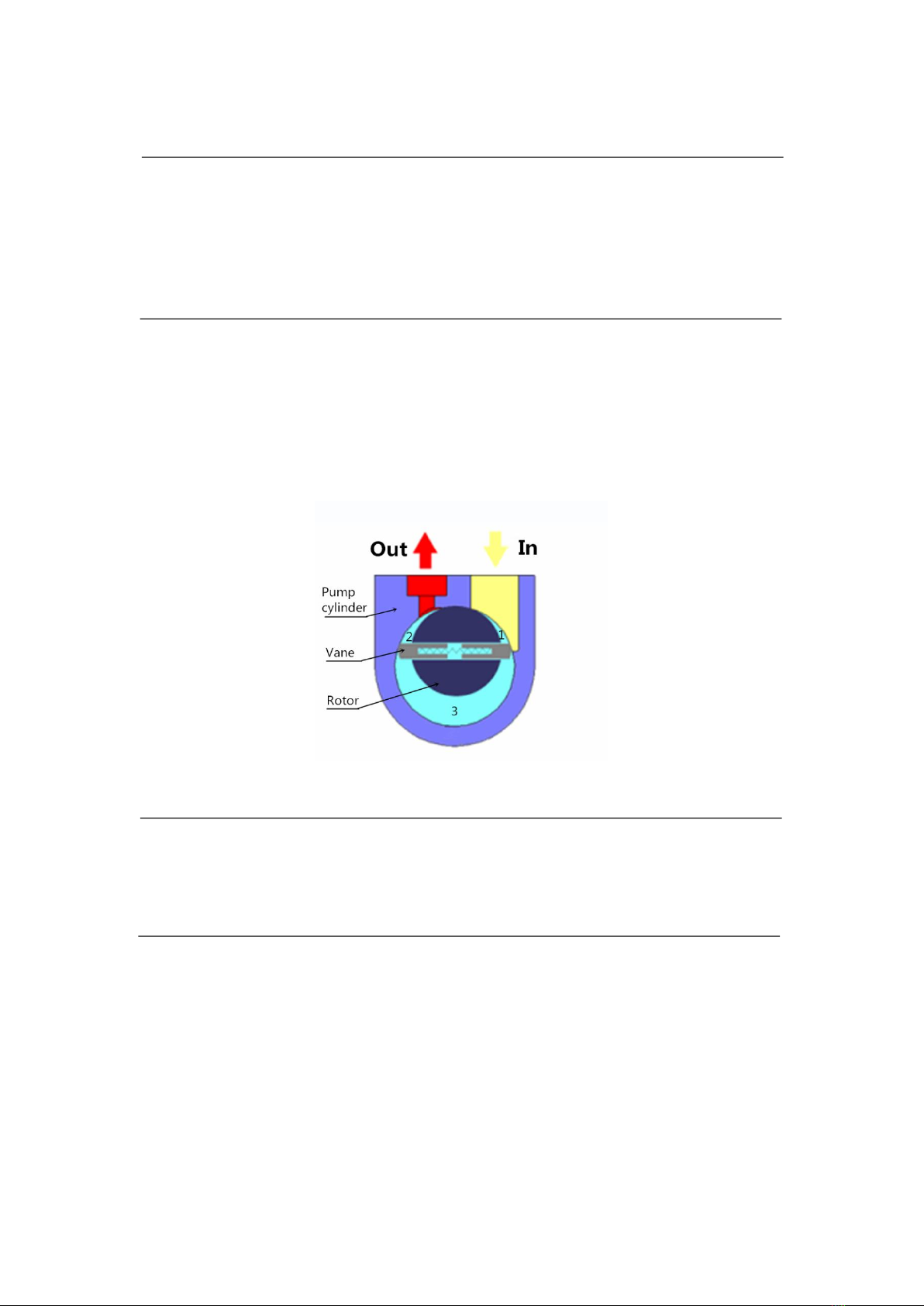

1.2 Working Theory ------------------------------------------------------------------------------------------------4

1.3 Lubrication ------------------------------------------------------------------------------------------------------4

1.4 Configuration ---------------------------------------------------------------------------------------------------4

1.5 Optional Accessories ------------------------------------------------------------------------------------------ 5

1.6 Technical Data --------------------------------------------------------------------------------------------------5

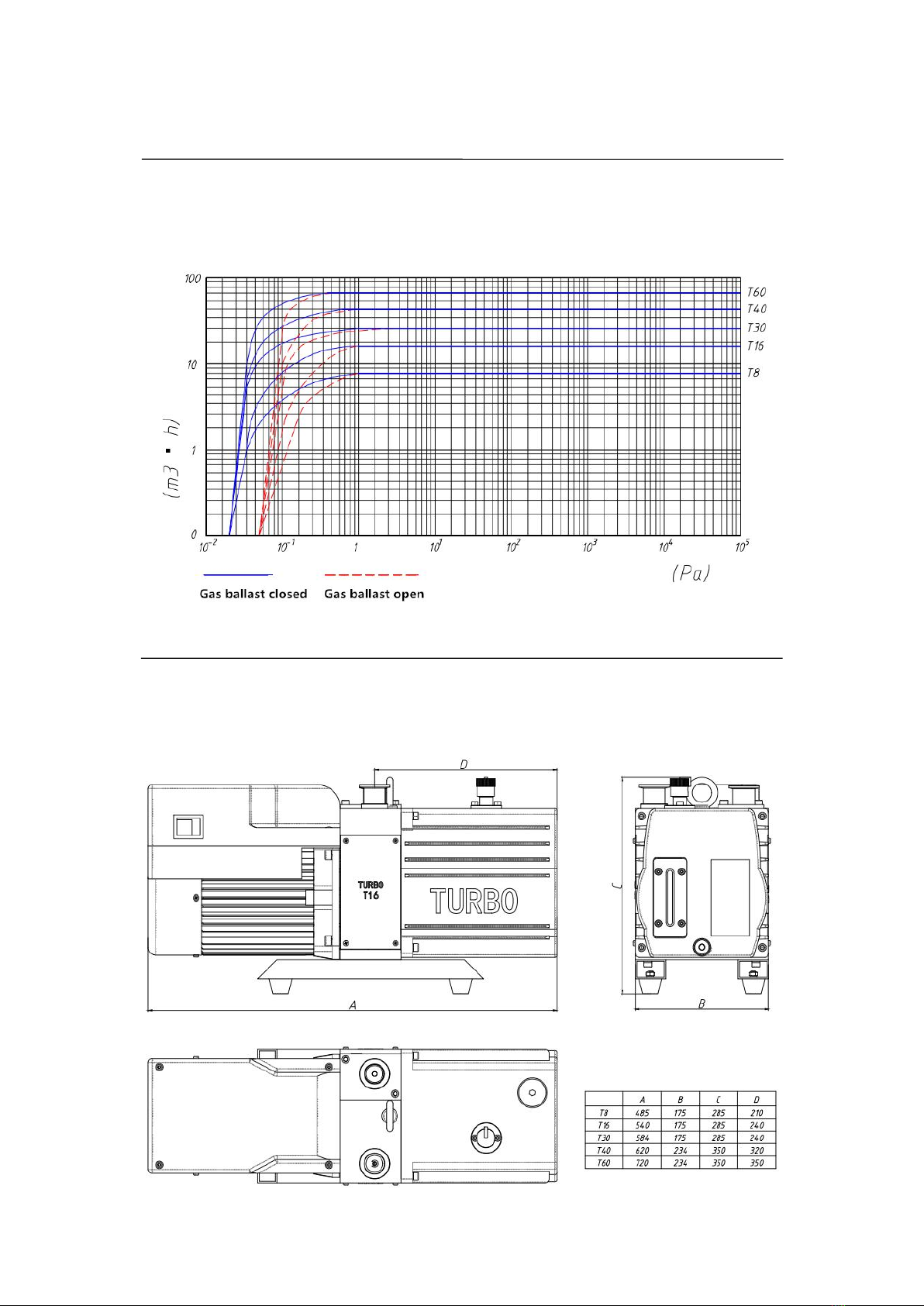

1.7 Pumping Speed -------------------------------------------------------------------------------------------------6

1.8 Size Details ----------------------------------------------------------------------------------------------------- 6

2 Installation

2.1 Placement ------------------------------------------------------------------------------------------------------- 7

2.2 Application ------------------------------------------------------------------------------------------------------7

2.3 Vacuum System Connection --------------------------------------------------------------------------------- 8

2.4 Electrical Connection ----------------------------------------------------------------------------------------- 8

3 Operation

3.1 Start-up ---------------------------------------------------------------------------------------------------------- 9

3.2 Noise ------------------------------------------------------------------------------------------------------------- 9

3.3 Stop Pumping ---------------------------------------------------------------------------------------------------9

3.4 Control System -------------------------------------------------------------------------------------------------9

4 Maintenance

4.1 Maintenance Plan -------------------------------------------------------------------------------------------- 10

4.2 Important Note ------------------------------------------------------------------------------------------------10

4.3 Warranty ------------------------------------------------------------------------------------------------------- 10

5 Trouble Shooting -------------------------------------------------------------------------------------------- 11

6 Spare Parts --------------------------------------------------------------------------------------------------- 12