SHR 521 20

© Drayton 06334 SHR 521 20.monen.indd

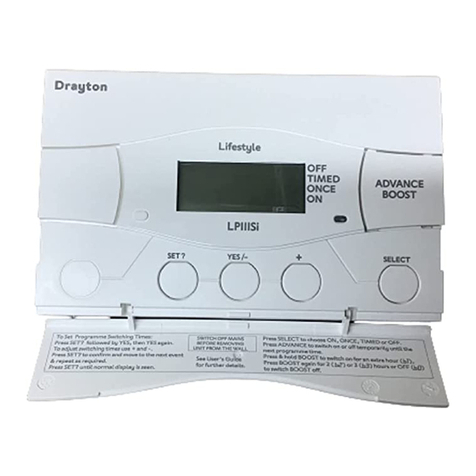

| 2

Contents

Disclaimer ............................................................................2

Safety Regulations ...............................................................2

Technical data and function ...............................................3

1. Installation .............................................................5

1.1 Mounting .................................................................................. 5

1.2 Electrical wiring ...................................................................... 5

1.2.1 Standard solar system ........................................................... 6

1.2.2 Solar system and back-up heating ...................................... 6

2. Operation and function ........................................7

2.1 Adjustment buttons .............................................................. 7

2.2 System-screen display ........................................................... 7

2.2.1 Channel indication ................................................................. 7

2.2.2 Tool bar .................................................................................... 7

2.2.3 System screen ......................................................................... 8

2.3 Flashing symbols ..................................................................... 8

2.3.1 System-Screen flashing symbols ......................................... 8

2.3.2 Flashing symbols ..................................................................... 8

3. Commissioning ......................................................9

4. Control parameter and indication channels ... 10

4.1 Channel overview ................................................................ 10

4.1.1-6 Indication channels ..............................................................11

4.1.7-17 Adjustment channels ........................................................... 12

5. Tips for fault finding ........................................... 17

5.1 Miscellaneous ........................................................................18

6. Accessories ......................................................... 20

Security advice

Please pay attention to the following security advice in order

to avoid danger and damage to people and property.

Instructions

Attention should be paid

- to the statutory provisions for prevention of industrial

accidents,

- to the statutory provisions for environmental protection,

- to the Health and Safety at Work Act 1974

- to Part P of the Building Regulations 2005

- to BS7671 Requirements for electrical installations and

relevant safety regulations of DIN, EN, DVGW, TRGI, TRF

and VDE.

This instruction is exclusively addressed to authorised

skilled personnel.

- Only qualified electricians should carry out electrical

works.

- Initial installation should be effected by named qualified

personnel

Declaration of conformity

We, Invensys Controls Europe, declare under our sole re-

sponsibility that our product SHR 52120 complies with the

following standards:

EN 55 014-1

EN 60 730-1

According to the regulations of the above directives, the

product is labelled with :

89/336/EWG

73/ 23/EWG