8

STS Humidifier

Obstruction

¾" Tubing

Funnel or Floor

Drain*

Air Gap

4" Minimum H

PIPING

Steam Supply

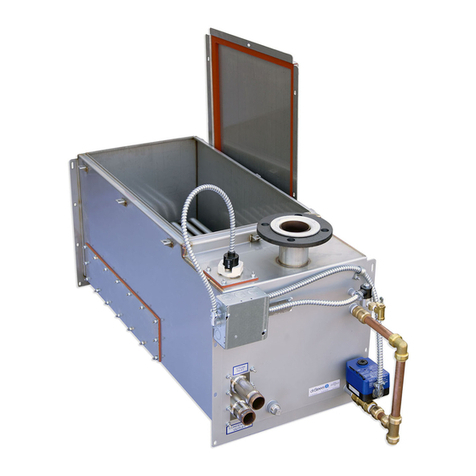

The heat exchanger in the STS®standard humidifier is

designed for a maximum steam pressure of 15 psi. The

steam valve, trap and strainer are shipped loose for field

installation.

Make-upWaterPiping

Either cold or hot water can be used for make-up. The

water pressure must be between 25 to 100 psi. If the

waterpressureis above 60 psiand/orwaterhammer

wouldbeobjectionable, apressurereducingvalveor

shock arrester should be installed. Even though the STS

has an inner 1" air gap, some local codes may require a

vacuum breaker in the water supply pipe.

Make-upWaterConsiderations

When non-metallic water piping is used, it must be rated

to withstand 212°F or greater temperature. If not, the final

3 feet connected to the humidifier should be metallic and

shouldnotbeinsulated.

As part of the fill valve assembly, a needle valve is

provided. It restricts the rush of cold water entering the

evaporatingchamberduring each fill cycle.The needle

valve adjusted to minimize output disruption and potential

"waterhammer"(waterpressuremustbebetween25and

100psi).

The STS Humidifier works with all water types - potable,

softenedordemineralizedmake-upwater.

Preferably this humidifier should be supplied with

softenedwater. Theprobetypelevelcontrolsystem

requireswaterconductivityof100micromhos/cm

(2 gr/gal) minimum to function and will not operate

with water treated by reverse osmosis or deionizing

process. Specially designed STS DI humidifiers are

availableforusewiththese water types.

SoftenedWater

Therearetwo majoradvantagesderivedfromusing

softenedwaterinsteadofpotable water (assuming the

untreatedsupplywater hardness isover 10 grains per

gallon):maintenance and accuracy of control.

Maintenance

The skimmer, in conjunction with softened water, is an

unbeatablecombinationforeliminatingscaleformation in

theevaporatingchamber. Severalseasonsofoperation

with no need for cleaning is normal, even with water

having up to 30 grains of dissolved minerals per gallon

priortobeingsoftened.

AccuracyofControl

Reducingthe higher skimmer quantity andeliminating the

drain/flush cycle (both of which are accomplished by the

use of softened water) improves controllability.

SoftenedWaterReducesWaterUsage

The fewer number of make-ups per unit of time and the

lesser the amount of water per make-up, the more "on

time" or actual humidifying time will occur thus improving

control accuracy. This is especially true when modulating

control of the steam input to the humidifier is used.

Figure8-1:

This piping method is recommended when obstruction

prevents dispersion tube from being continuously pitched

back to the humidifier.

OM-702 * Note: Refer to governing codes

for drain pipe size requirements.