DRI-STEEM Ultra-sorb Steam Dispersion Panel Installation, Operation, and Maintenance Manual • Page 3

Unpacking High-efficiency tubes

CAUTION!

The High-efficiency tubes are sleeved in clear poly

film for protection during processing, shipping,

and installation.

To prevent dirty insulating material, leave the clear

poly film on until installation is complete.

Equally important, remove and discard the clear

poly film before start-up by tearing it along the

perforations.

NOTE: If you have an Ultra-sorb without High-efficiency

dispersion tubes (non-insulated tubes), please skip to the next

page.

Unpacking

• Remove the dispersion assembly from the shipping container; be

careful not to bump or scrape the PVDF insulating material on

the dispersion tubes.

• Some dispersion panels are shipped unassembled by customer

request or by shipping necessity. Do not lay High-efficiency tubes

across or under anything that could compress or damage the

insulating material. Compressed insulating material has a reduced

R-value.

• Avoid bumping or snagging the PVDF insulating material.

Although PVDF is robust, rough handling can cause tears, which

could negatively impact performance.

• Before start-up, remove the clear poly film by tearing it along the

perforation. Do not use a knife or sharp object to remove the poly

film.

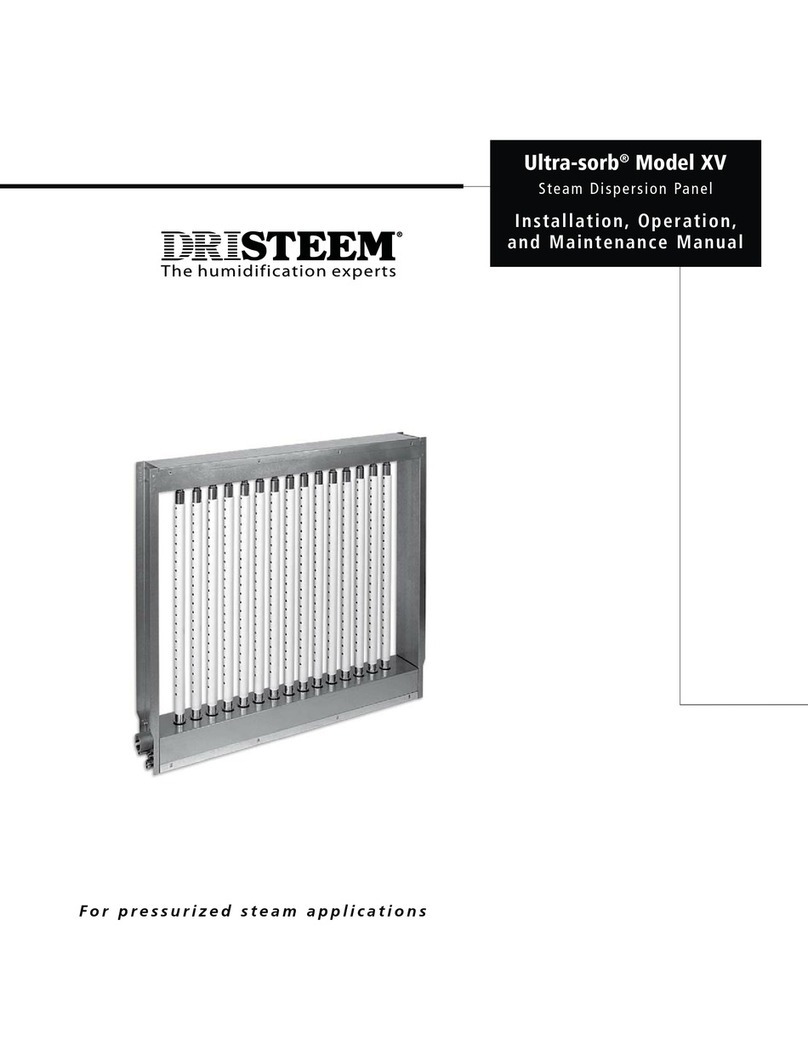

High-efficiency Tube option

Ultra-sorb dispersion assemblies with the

High-efficiency Tube option are designed to

produce significantly less dispersion-generated

condensate and airstream heat gain, which

reduces wasted energy by up to 85%. These

improvements are accomplished by reducing

the thermal conductivity of the tubes with

1/8" of polyvinylidene fluoride (PVDF)

insulating material on the outside of the tubes.

These assemblies require careful unpacking,

installation, and handling. If your dispersion

assembly has the High-efficiency Tube option,

be sure to read this section carefully.

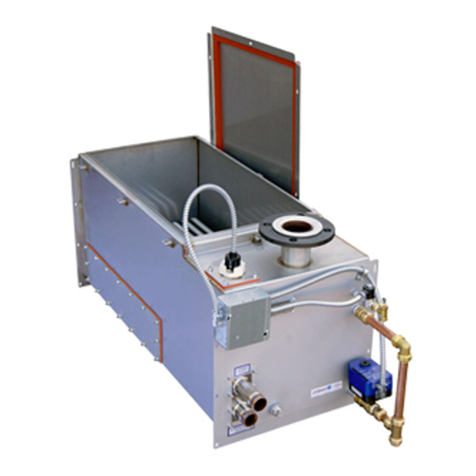

Figure 3-1:

Ultra-sorb with the High-efficiency

Tube option

US-IOM-0108.pdf 3 4/21/2010 11:34:56 AM