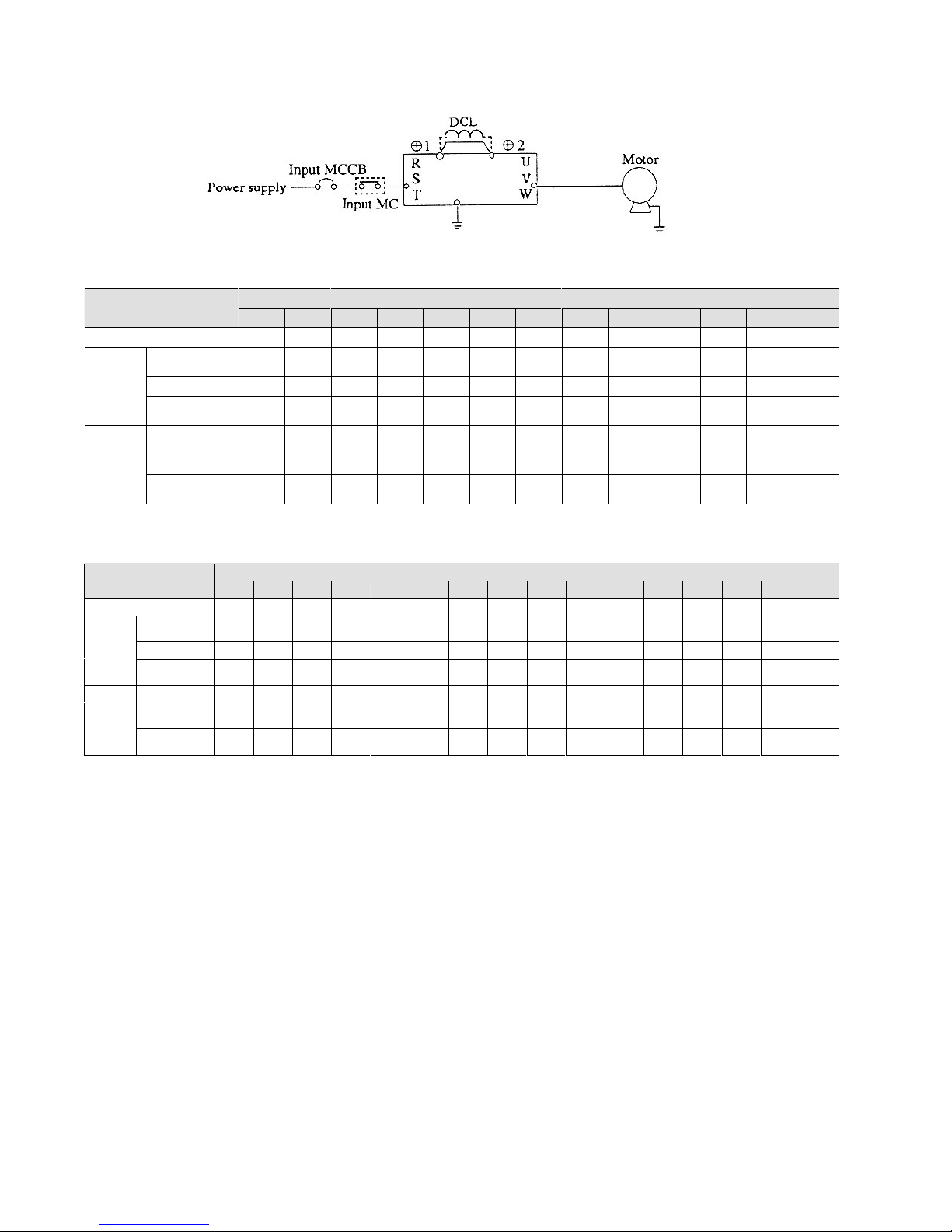

1.5 Peripheral devices and ire sizes

1.5.1 Selection of I/O devices and precautions for main circuit iring.

The follo ing sho s the I/O devices of the VF61 unit and their ire sizes.

-5-

Type VF61-__ __ __ 22

2R222 3R722 5R522 7R522 1122 1522 2222 3022 3722 4522 5522 7522 9022

Applicable motor (HP) 3 5 7.5 10 15 20 30 40 50 60 75 100 130

Peripheral

device

Input MCCB

(Note 1) 15A 20A 30A 40A 60A 60A 100A 125A 150A 225A 300A 400A 400A

Input MC (Note 2) K20 K20 K35 K50 K65 K65 K95 K125 K150 K220 K300 K400 K400

Output MC K20 K20 K25 K35 K50 K65 K95 K125 K150 K220 K300 K300 K400

Wire size

(mm²)

Input side (Note 3) 2.0 2.0 3.5 5.5 8.0 8.0 22 38 38 60 80 150 150

Output side (Note

4) 3.5 5.5 8.0 14 14 22 22 38 38 60 80 100 150

DCL terminals

(1 & 2) 2.0 2.0 3.5 5.5 8.0 14 38 38 50 80 100 150 200

200V type

Type VF61-__ __ __ 44

2R244 3R744 5R544 7R544 1144 1544 2244 3044 3744 4544 5544 7544 11044 16044 20044 25044

Applicable motor (HP) 3 5 7.5 10 15 20 30 40 50 60 75 100 150 200 250 300

Peripheral

device

Input MCCB

(Note 1) 15A 10A 15A 30A 50A 50A 75A 75A 100A 100A 125A 200A 300A 400A 500A 600A

Input MC (Note 2) K20 K20 K20 K25 K35 K50 K50 K80 K95 K100 K125 K180 K300 K400 K600 K600

Output MC K20 K20 K20 K20 K25 K50 K50 K80 K95 K95 K125 K150 K220 K300 K400 K600

Wire size

(mm²)

Input side (Note 3) 2.0 2.0 2.0 2.0 3.5 5.5 8.0 14 14 22 38 60 80 150 200 250

Output side

(Note 4) 2.0 2.0 2.0 3.5 5.5 8.0 8.0 14 22 38 38 80 150 150 150 250

DCL terminals

(1 & 2) 2.0 2.0 2.0 3.5 5.5 8.0 14 22 38 38 60 100 200 250 250 150 (x2)

400V type

Notes:

1. The values of the input MCB sho the rated currents.

(Determine the breaking capacity from the source capacity, etc.)

2. The sho n values are those of the electromagnetic contactors MS-K series made by

Mitsubishi Electric Corp.

3. The ire sizes bet een the MCB and inverter input terminals are the sizes of the KIV or RD

ires.

4. The cable length bet een the inverter and motor should be less than 30 meters. The sho n

values are those of the CV cables.

5. If the input MC is used, the interval bet een turning on and off should be more than 10

minutes.

Safety Precautions

1. If the motor has a phase advancing capacitor, be sure to disconnect it. (If the inverter runs

ith the phase advancing capacitor connected, the inverter may be broken.)

2. Be sure to connect a circuit breaker (input MCB) on the inverter input side.

3. Be sure to connect the inverter and motor to ground.

(Use the exclusive grounding terminal.)